无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 933-940.DOI: 10.15541/jim20210721

收稿日期:2021-11-24

修回日期:2022-03-07

出版日期:2022-09-20

网络出版日期:2022-06-16

通讯作者:

夏鸿雁, 副教授. E-mail: hyxia0707@xjtu.edu.cn作者简介:胡佳军(1993-), 男, 博士研究生. E-mail: hujiajun1123@stu.xjtu.edu.cn

基金资助:

HU Jiajun( ), WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan(

), WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan( )

)

Received:2021-11-24

Revised:2022-03-07

Published:2022-09-20

Online:2022-06-16

Contact:

XIA Hongyan, associate professor. E-mail: hyxia0707@xjtu.edu.cnAbout author:HU Jiajun (1993-), male, PhD candidate. E-mail: hujiajun1123@stu.xjtu.edu.cn

Supported by:摘要:

随着电力电子器件封装密度提高, 开发导热性能优异的热界面材料受到了广泛关注。绝大多数传统导热填料的热导率较低, 因此合成新型高导热填料是提高热界面材料导热性能的重要途径。本研究通过简单的熔盐法合成了高导热的磷化硼(BP)颗粒, 与氮化硼(h-BN)混合并通过搅拌和浇注的方法填充到环氧树脂(EP)基体中制备得到树脂基复合材料(BP-BN/EP)。实验结果表明:采用三盐法(NaCl : KCl : LiCl)合成的BP产率最高达到74%, 相对于单盐法(41%)和双盐法(39%)分别提高了33%和35%。对于BP-BN/EP复合材料, 复合材料的微结构显示BP和BN颗粒均匀分布在环氧树脂基体。当混合填料体积分数为30%时, 该复合材料的热导率达到1.81 W•m-1•K-1, 是纯树脂热导率(0.21 W•m-1•K-1)的8.6倍, 这与BP颗粒作为桥梁连接相邻BN颗粒形成导热网络有关。除此以外, 相较于不含BP的复合材料(SBN-BN/EP), BP-BN/EP复合材料展现出更加优异的热导率、热稳定性和较好的热力学性能。因此, 熔盐法合成的BP在热管理领域具有较大的应用前景。

中图分类号:

胡佳军, 王凯, 侯鑫广, 杨婷, 夏鸿雁. 熔盐法合成高导热磷化硼及其热管理性能研究[J]. 无机材料学报, 2022, 37(9): 933-940.

HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance[J]. Journal of Inorganic Materials, 2022, 37(9): 933-940.

| Sample | Salt types | Holding time/h | Yield/% |

|---|---|---|---|

| 1 | NaCl | 1 | 41 |

| 2 | NaCl-KCl | 1 | 39 |

| 3 | NaCl-KCl-LiCl | 1 | 67 |

| 4 | NaCl-KCl-LiCl | 5 | 74 |

| 5 | NaCl-KCl-LiCl | 10 | 64 |

表1 不同条件下合成BP的产率

Table 1 Yields of BP under different synthetic conditions

| Sample | Salt types | Holding time/h | Yield/% |

|---|---|---|---|

| 1 | NaCl | 1 | 41 |

| 2 | NaCl-KCl | 1 | 39 |

| 3 | NaCl-KCl-LiCl | 1 | 67 |

| 4 | NaCl-KCl-LiCl | 5 | 74 |

| 5 | NaCl-KCl-LiCl | 10 | 64 |

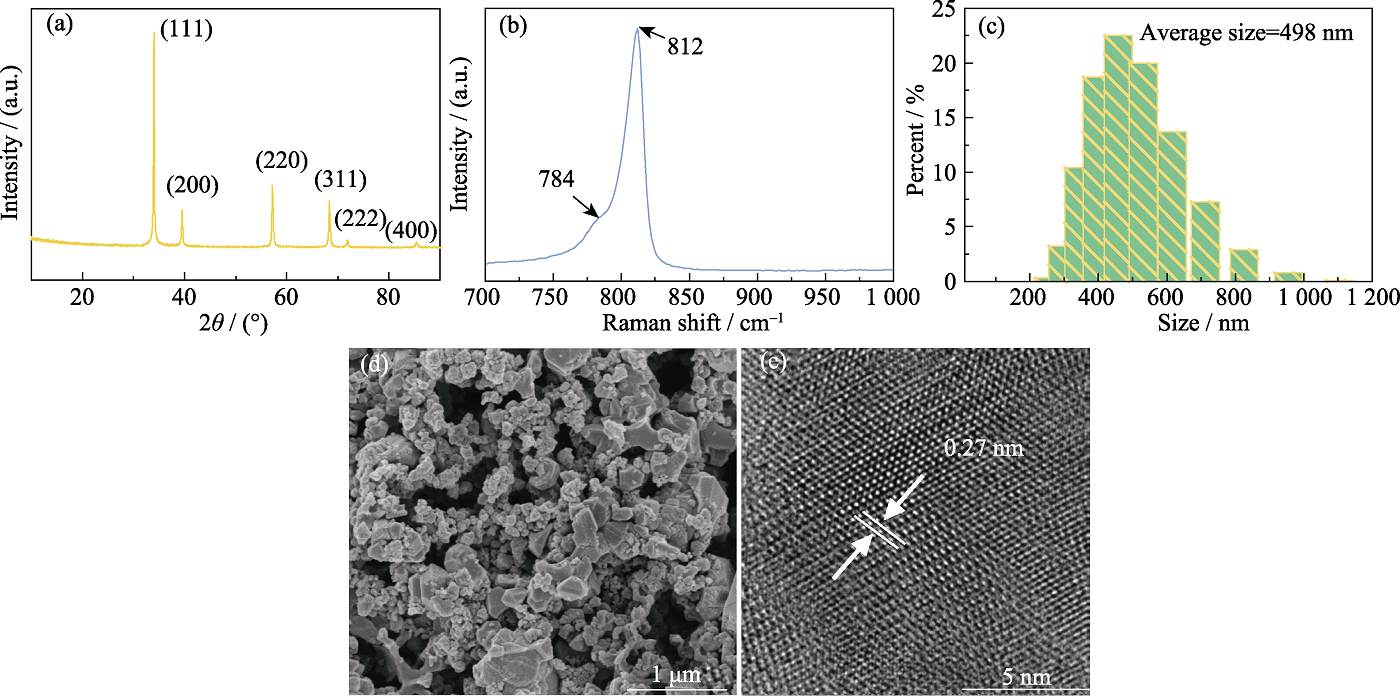

图2 BP粉末的形貌和结构表征

Fig. 2 Morphological and structural characterizations of BP (a) XRD pattern; (b) Raman spectrum; (c) Size distribution; (d) SEM image; (e) TEM image

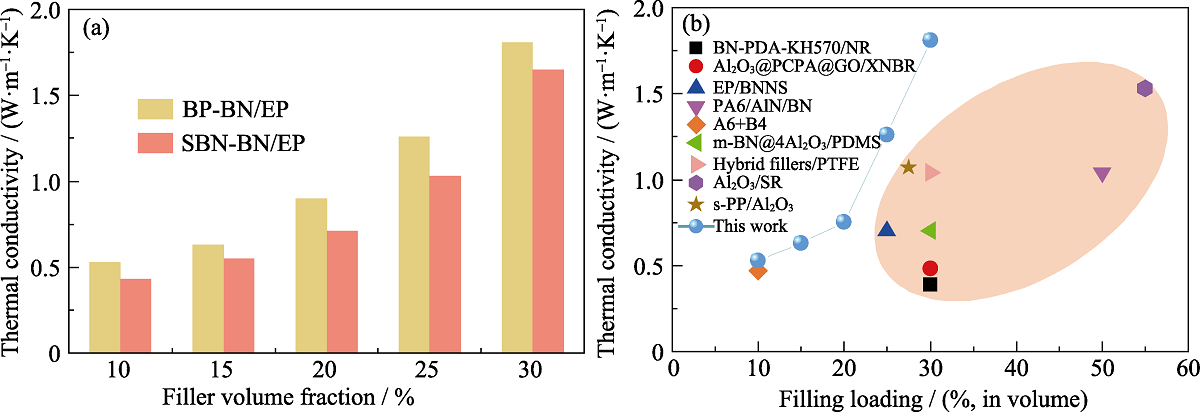

图4 复合材料的导热性能

Fig. 4 Thermal conductivity of the composites (a) Thermal conductivity of the composites; (b) Comparison of BP-BN/EP composites with relevant literatures[16,28⇓⇓⇓⇓⇓⇓ -35]

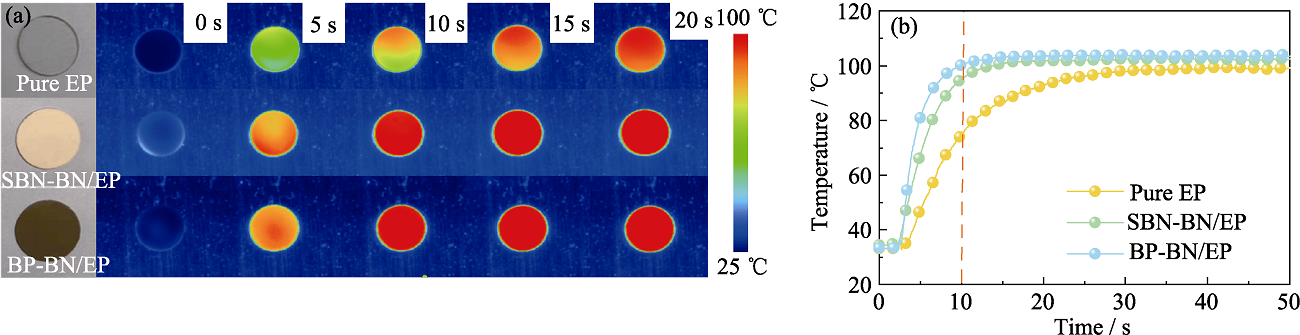

图5 纯EP、BP-BN/EP和SBN-BN/EP复合材料的热传输性能

Fig. 5 Thermal transport properties of pure EP, BP-BN/EP and SBN-BN/EP composites (a) IR thermal images at different time; (b) Temperature changes of sample surface at different time Colorful figures are available on website

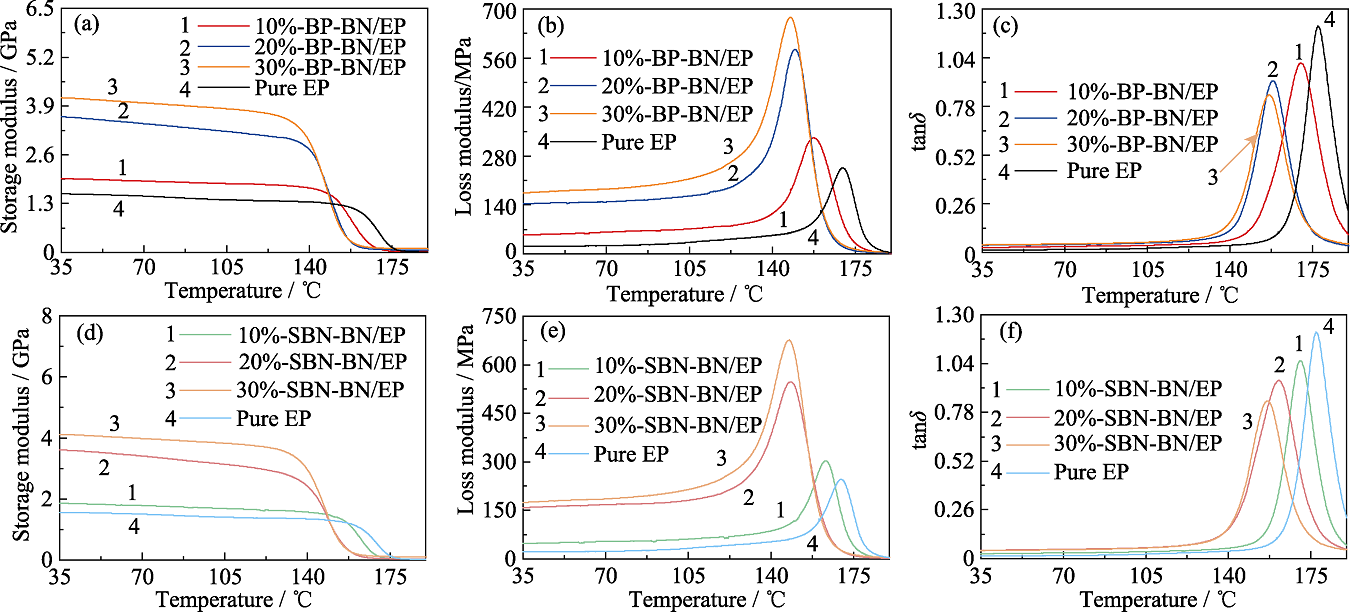

图7 BP-BN/EP和SBN-BN/EP复合材料的热力学性能

Fig. 7 Thermodynamic property of BP-BN/EP and SBN-BN/EP composites (a,d) Curves of storage modulus with temperature change; (b,e) Curves of loss modulus with temperature change; (c,f) Curves of loss factor (tanδ) with temperature change

| [1] |

SONG H F, LIU J M, LIU B L, et al. Two dimensional materials for thermal management applications. Joule, 2018, 2(3): 442-463.

DOI URL |

| [2] |

MOORE A L, SHI L. Emerging challenges and materials for thermal management of electronics. Mater. Today, 2014, 17(4): 163-174.

DOI URL |

| [3] | ZHANG R C, HUANG Z H, SUN D, et al. New insights into thermal conductivity of uniaxially stretched high density polyethylene films. Polymer, 2018, 154: 42-47. |

| [4] | CHEN H Y, GINZBURG V V, YANG J, et al. Thermal conductivity of polymerbased composites: fundamentals and applications. Prog. Polym. Sci., 2016, 59: 41-85. |

| [5] | BO Z, YING C Y, ZHU H R, et al. Bifunctional sandwich structure of vertically-oriented graphenes and boron nitride nanosheets for thermal management of LEDs and Li-ion battery. Appl. Therm. Eng., 2019, 150: 1016-1027. |

| [6] |

WANG X, WU P. Preparation of highly thermally conductive polymer composite at low filler content via a self-assembly process between polystyrene microspheres and boron nitride nanosheets. ACS Appl. Mater. Interfaces, 2017, 9(23): 19934-19944.

DOI URL |

| [7] |

SHEN H, GUO J, WANG H, ZHAO N, et al. Bioinspired modification of h-BN for high thermal conductive composite films with aligned structure. ACS Appl. Mater. Interfaces, 2015, 7(10): 5701-5708.

DOI URL |

| [8] |

HUANG X, ZHI C, JIANG P, et al. Polyhedral oligosilsesquioxane- modified boron nitride nanotube based epoxy nanocomposites: an ideal dielectric material with high thermal conductivity. Adv. Funct. Mater., 2013, 23(14): 1824-1831.

DOI URL |

| [9] |

HU J, HUANG Y, YAO Y, et al. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN. ACS Appl. Mater. Interfaces, 2017, 9(15): 13544-13553.

DOI URL |

| [10] |

PAN G, YAO Y, ZENG X, et al. Learning from natural nacre: constructing layered polymer composites with high thermal conductivity. ACS Appl. Mater. Interfaces, 2017, 9(38): 33001-33010.

DOI URL |

| [11] | SUN R, YAO H, ZHANG H B, et al. Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy composites. Compos. Sci. Technol., 2016, 137: 16-23. |

| [12] |

YAO Y M, ZHU X D, ZENG X L, et al. Vertically aligned and interconnected SiC nanowire networks leading to significantly enhanced thermal conductivity of polymer composites. ACS Appl. Mater. Interfaces, 2018, 10(11): 9669-9678.

DOI URL |

| [13] |

HUANG Y, HU J T, YAO Y M, et al. Manipulating orientation of silicon carbide nanowire in polymer composites to achieve high thermal conductivity. Adv. Mater. Interfaces, 2017, 4(17): 1700446.

DOI URL |

| [14] |

YU S Z, HING P, HU X. Thermal conductivity of polystyrene- aluminum nitride composite. Compos. Part A-Appl. S., 2002, 33(2): 289-292.

DOI URL |

| [15] | ZHOU Y, YAO Y, CHEN C Y, et al. The use of polyimidemodified aluminum nitride fillers in AlN@PI/epoxy composites with enhanced thermal conductivity for electronic encapsulation. Sci. Rep., 2014, 4: 4779. |

| [16] | WANG X W, WU P Y. Melamine foam-supported 3D interconnected boron nitride nanosheets network encapsulated in epoxy to achieve significant thermal conductivity enhancement at an ultralow filler loading. Chem. Eng. J., 2018, 348: 723-731. |

| [17] |

HOU X, CHEN Y P, LV L, et al. High-thermal-transport-channel construction within flexible composites via the welding of boron nitride nanosheets. ACS Appl. Nano Mater., 2019, 2(1): 360-368.

DOI URL |

| [18] | YANG J, TANG L S, BAO R Y, et al. Largely enhanced thermal conductivity of poly (ethylene glycol)/boron nitride composite phase change materials for solar-thermal-electric energy conversion and storage with very low content of graphene nanoplatelets. Chem. Eng. J., 2017, 315: 481-490. |

| [19] | ZHI T, TAO T, LIU B, et al. High quality CVD single crystal diamonds grown on nanorods patterned diamond seed. Diam. Relat. Mater., 2021, 119: 108605. |

| [20] | SOLOZHENKO V L, BUSHLYA V, ZHOU J M. Mechanical properties of ultra-hard nanocrystalline cubic boron nitride. J. Appl. Phys., 2019, 126: 075107. |

| [21] |

ZHENG Q Y, LI S, LI C H, et al. High thermal conductivity in isotopically enriched cubic boron phosphide. Adv. Funct. Mater., 2018, 28(43): 1805116.

DOI URL |

| [22] | SOLOZHENKO V L, BUSHLYA V. Mechanical properties of boron phosphides. J. Suprerhard Mater., 2019, 41: 84-89. |

| [23] |

DING N, XU J Q, ZHANG Q, et al. Controllable carrier type in boron phosphide nanowires toward homostructural optoelectronic devices. ACS Appl. Mater. Interfaces, 2018, 10(12): 10296-10303.

DOI URL |

| [24] |

MUKHANOV V A, VREL D, SOKOLOV P S, et al. Ultra-fast mechanochemical synthesis of boron phosphides, BP and B12P2. Dalton Trans., 2016, 45(25): 10122-10126.

DOI URL |

| [25] |

FENG X, SHI L Y, HANG J Z, et al. Low temperature synthesis of boron phosphide nanocrystals. Mater. Lett., 2005, 59(8/9): 865-867.

DOI URL |

| [26] |

KANG J S, WU H, HU Y J. Thermal properties and phonon spectral characterization of synthetic boron phosphide for high thermal conductivity applications. Nano Lett., 2017, 17(12): 7507-7514.

DOI URL |

| [27] |

SUGIMOTO H, FUJII M, IMAKITA K. Size-controlled growth of cubic boron phosphide nanocrystals. RSC Adv., 2015, 5(11): 8427-8431.

DOI URL |

| [28] | ZHANG X, XIA X C, YOU H, et al. Design of continuous segregated polypropylene/Al2O3 nanocomposites and impact of controlled Al2O3 distribution on thermal conductivity. Compos. Part A-Appl. S., 2020, 131: 105825. |

| [29] | OUYANG Y, LI X F, DING F, et al. Simultaneously enhance thermal conductive property and mechanical properties of silicon rubber composites by introducing ultrafine Al2O3 nanospheres prepared via thermal plasma. Compos. Sci. Technol., 2020, 190: 108019. |

| [30] | PAN C, KOU K C, ZHANG Y, et al. Enhanced through-plane thermal conductivity of PTFE composites with hybrid fillers of hexagonal boron nitride platelets and aluminum nitride particles. Compos. Part B-Eng., 2018, 153: 1-8. |

| [31] |

GUAN S W, SU Z R, CHEN F, et al. Spherical hybrid filler BN@Al2O3 via chemical adhesive for enhancing thermal conductivity and processability of silicon rubber. J. Appl. Polym. Sci., 2021, 138(41): 51211.

DOI URL |

| [32] | WANG Z D, MENG G D, WANG L L, et al. Simultaneously enhanced dielectric properties and through-plane thermal conductivity of epoxy composites with alumina and boron nitride nanosheets. Sci. Rep., 2021, 11: 2495. |

| [33] | YıIDıZ G, AKKOYUN M. Thermal and electrical properties of aluminum nitride/boron nitride filled polyamide 6 hybrid polymer composites. J. Appl. Polym. Sci., 2021, 138(22): e50516. |

| [34] | WEI Q G, YANG D, YU L Y, et al. Fabrication of carboxyl nitrile butadiene rubber composites with high dielectric constant and thermal conductivity using Al2O3@PCPA@GO hybrids. Compos. Sci. Technol., 2020, 199: 108344. |

| [35] | YANG D, NI Y F, KONG X X, et al. Mussel-inspired modification of boron nitride for natural rubber composites with high thermal conductivity and low dielectric constant. Compos. Sci. Technol., 2019, 177: 18-25. |

| [36] | REN J W, LI Q H, YAN L, et al. Enhanced thermal conductivity of epoxy composites by introducing graphene@boron nitride nanosheets hybrid nanoparticles. Mater. Design, 2020, 191: 108663. |

| [37] | WANG H T, DING D L, LIU Q, et al. Highly anisotropic thermally conductive polyimide composites via the alignment of boron nitride platelets. Compos. Part B-Eng., 2019, 158: 311-318. |

| [1] | 付师, 杨增朝, 李宏华, 王良, 李江涛. 复合烧结助剂对Si3N4陶瓷力学性能和热导率的影响[J]. 无机材料学报, 2022, 37(9): 947-953. |

| [2] | 王鹏将, 康慧君, 杨雄, 刘颖, 程成, 王同敏. 熵调控抑制ZrNiSn基half-Heusler热电材料的晶格热导率[J]. 无机材料学报, 2022, 37(7): 717-723. |

| [3] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 碳化硅纳米线增强多孔碳化硅陶瓷基复合材料的制备[J]. 无机材料学报, 2022, 37(4): 459-466. |

| [4] | 娄许诺, 邓后权, 李爽, 张青堂, 熊文杰, 唐国栋. Ge掺杂MnTe材料的热电输运性能[J]. 无机材料学报, 2022, 37(2): 209-214. |

| [5] | 舒朝琴, 朱敏, 朱钰方. 熔盐法制备含钴氯磷灰石及其抗氧化性能和细胞相容性研究[J]. 无机材料学报, 2022, 37(11): 1225-1235. |

| [6] | 吴爱军, 朱敏, 朱钰方. 含铜硅酸钙纳米棒复合水凝胶用于肿瘤治疗和皮肤伤口愈合性能研究[J]. 无机材料学报, 2022, 37(11): 1203-1216. |

| [7] | 王为得, 陈寰贝, 李世帅, 姚冬旭, 左开慧, 曾宇平. 以YbH2-MgO体系为烧结助剂制备高热导率高强度氮化硅陶瓷[J]. 无机材料学报, 2021, 36(9): 959-966. |

| [8] | 桑玮玮, 张红松, 陈华辉, 温斌, 李新春. (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7高熵陶瓷的制备及热物理性能[J]. 无机材料学报, 2021, 36(4): 405-410. |

| [9] | 牟庭海, 许文涛, 凌军荣, 董天文, 秦梓轩, 周有福. 微波烧结制备ZrO2-AlN复合陶瓷的微观结构与性能研究[J]. 无机材料学报, 2021, 36(11): 1231-1236. |

| [10] | 邱小小,周细应,傅赟天,孙晓萌,王连军,江莞. Ge1-xInxTe微观结构对热电性能的影响[J]. 无机材料学报, 2020, 35(8): 916-922. |

| [11] | 周星圆, 柳伟, 张程, 华富强, 张敏, 苏贤礼, 唐新峰. Nb掺杂Mo1-xWxSeTe固溶体的热-电输运性能优化[J]. 无机材料学报, 2020, 35(12): 1373-1379. |

| [12] | 何端鹏,高鸿,张静静,吴杰,刘泊天,王向轲. 氮化铝覆铜板在空间热场下热学性能的模拟仿真及实验验证[J]. 无机材料学报, 2019, 34(9): 947-952. |

| [13] | 马伯乐, 马文, 黄威, 白玉, 贾瑞灵, 董红英. 单相双稀土改性SrZrO3热障涂层的热物理性能[J]. 无机材料学报, 2019, 34(4): 394-400. |

| [14] | 骆军, 何世洋, 李志立, 李永博, 王风, 张继业. 热电材料高通量实验制备与表征方法[J]. 无机材料学报, 2019, 34(3): 247-259. |

| [15] | 沈家骏, 方腾, 傅铁铮, 忻佳展, 赵新兵, 朱铁军. 热电材料中的晶格热导率[J]. 无机材料学报, 2019, 34(3): 260-268. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||