无机材料学报 ›› 2023, Vol. 38 ›› Issue (2): 163-169.DOI: 10.15541/jim20220106

华思恒( ), 杨东旺, 唐昊, 袁雄, 展若雨, 徐卓明, 吕嘉南, 肖娅妮, 鄢永高(

), 杨东旺, 唐昊, 袁雄, 展若雨, 徐卓明, 吕嘉南, 肖娅妮, 鄢永高( ), 唐新峰(

), 唐新峰( )

)

收稿日期:2022-03-02

修回日期:2022-05-09

出版日期:2023-02-20

网络出版日期:2022-05-27

通讯作者:

鄢永高, 研究员. E-mail: yanyonggao@whut.edu.cn;作者简介:华思恒(1997-), 男, 硕士研究生. E-mail: si.heng_0-1@whut.edu.cn

基金资助:

HUA Siheng( ), YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao(

), YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao( ), TANG Xinfeng(

), TANG Xinfeng( )

)

Received:2022-03-02

Revised:2022-05-09

Published:2023-02-20

Online:2022-05-27

Contact:

YAN Yonggao, professor. E-mail: yanyonggao@whut.edu.cn;About author:HUA Siheng (1997-), male, Master candidate. E-mail: si.heng_0-1@whut.edu.cn

Supported by:摘要:

Bi2Te3基微型热电器件的尺寸越小, 界面结合强度及接触电阻对于器件力学性能、开路电压以及输出功率等的影响就越显著。因此开发成本低、工艺简单的热电单元制备技术, 并使n型Bi2Te3基块体材料与阻挡层间的界面兼具低接触电阻、高结合强度具有重要意义。本工作将n型Bi2Te3基热电材料薄片在混合酸溶液(pH~3)中进行表面处理, 随后进行化学镀Ni(5 μm), 再与Cu电极焊接制备得到热电单元。腐蚀后, n型Bi2Te3基热电材料表面大的沟壑与Ni阻挡层间形成锚固效应, 腐蚀6 min的材料结合强度高达15.88 MPa。大沟壑表面进一步腐蚀后出现的精细分支与Ni阻挡层间形成纳米孔洞, 显著增大了界面接触电阻, 腐蚀2 min的材料达到2.23 Ω·cm2。最终, 腐蚀4 min后镀Ni的n型Bi2Te3基热电片材与p型Bi2Te3基热电片材制备的微型热电器件在20 K温差(高温端306 K, 低温端286 K)下的输出功率高达3.43 mW, 相较于商用电镀镀层制备的同尺寸器件提升了31.92%。本工作将为微型热电器件的性能优化提供支撑。

中图分类号:

华思恒, 杨东旺, 唐昊, 袁雄, 展若雨, 徐卓明, 吕嘉南, 肖娅妮, 鄢永高, 唐新峰. n型Bi2Te3基材料表面处理对热电单元性能的影响[J]. 无机材料学报, 2023, 38(2): 163-169.

HUA Siheng, YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao, TANG Xinfeng. Effect of Surface Treatment of n-type Bi2Te3-based Materials on the Properties of Thermoelectric Units[J]. Journal of Inorganic Materials, 2023, 38(2): 163-169.

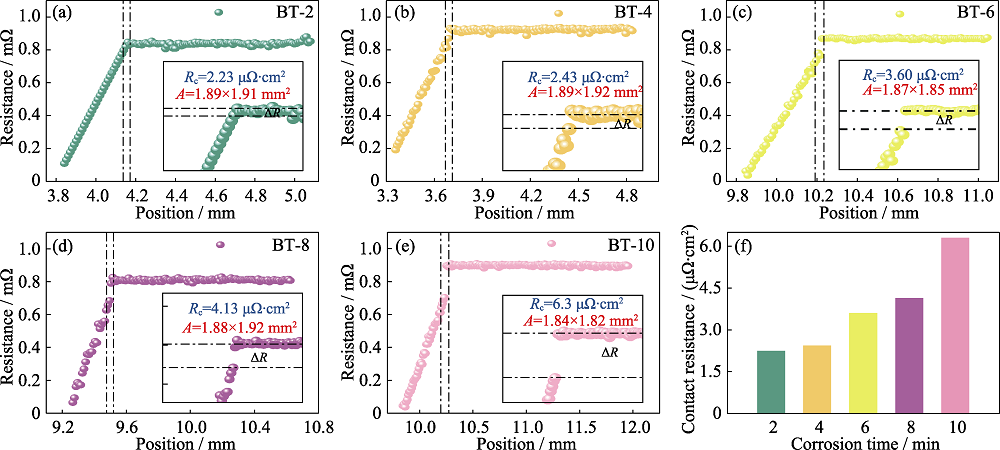

图1 BT-x (x=2 (a), 4 (b), 6 (c), 8(d), 10 (e))材料与Ni阻挡层之间的接触电阻测试曲线和 (f) 不同腐蚀时间材料接触电阻的柱状分布图

Fig. 1 Test curves of contact resistances between BT-x(x=2 (a), 4 (b), 6 (c), 8(d), 10 (e)) materials and Ni barrier layers, and (f) histogram of contact resistance for BT-x A: Test sample cross-sectional area; Rc: Contact resistance; ΔR: Resistance mutation value

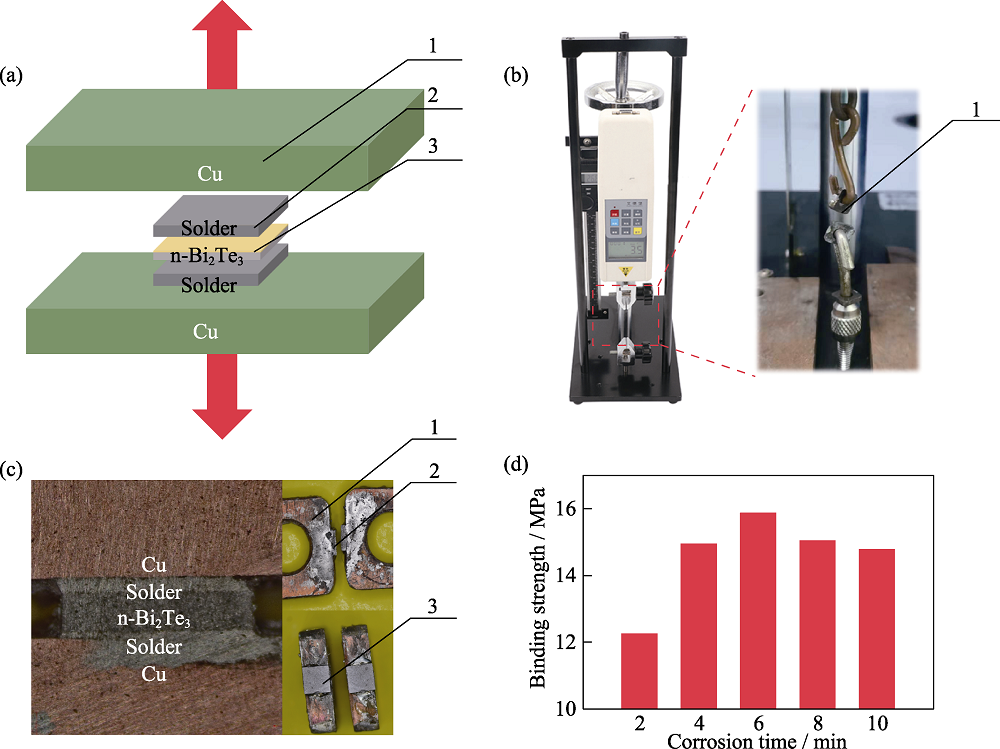

图2 界面结合强度测试

Fig. 2 Interface bonding strength test (a) Schematic diagram of tensile strength test model; (b) Picture of tensile test equipment; (c) Pictures of tensile test object; (d) Histogram of bonding strength for BT-x; 1: copper ring, 2: SAC305 solder, 3: BT-x

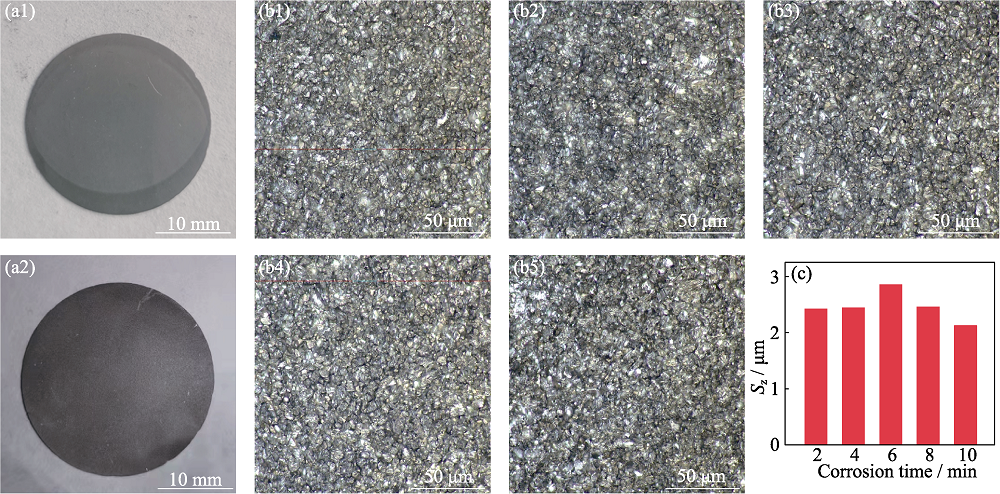

图3 BT-4样品腐蚀(a1)前(a2)后的数码照片; 样品BT-x(x=2 (b1), 4 (b2), 6 (b3), 8 (b4), 10 (b5)) 表面的光学显微结构; (c)不同腐蚀时间材料表面粗糙度的柱状分布图

Fig. 3 Digital photos of BT-4 sample before (a1) and after (a2) corrosion, optical microstructures of BT-x(x=2 (b1), 4 (b2), 6 (b3), 8 (b4), 10 (b5)) surfaces, and (c) histogram of roughness for BT-x

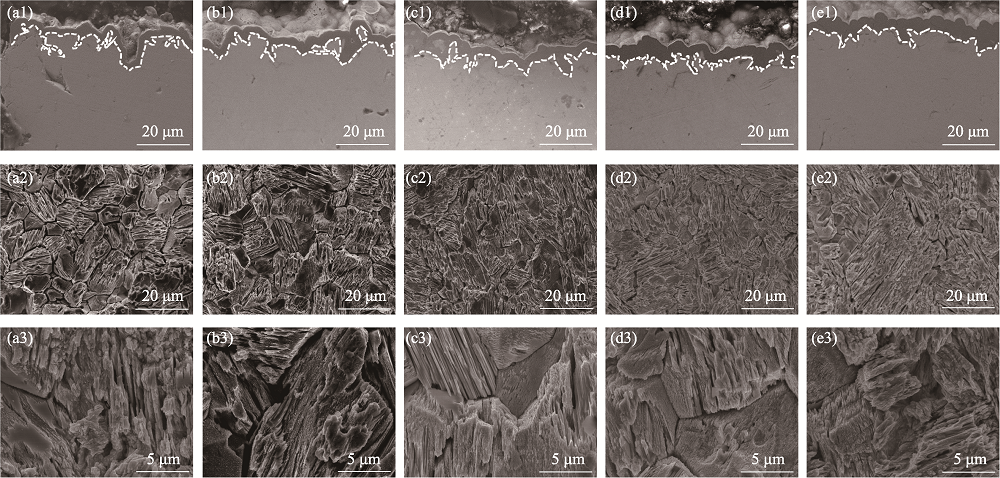

图4 BT-x(x= 2 (a1~a3), 4 (b1~b3)6, (c1~c3), 8 (d1~d3), 10 (e1~e3))与Ni阻挡层材料界面的显微结构

Fig. 4 Microstructures of material interfaces between BT-x(x=2 (a1-a3), 4 (b1-b3), 6 (c1-c3), 8 (d1-d3), 10 (e1-e3)) and Ni barrier layers (a1-e1) Interfacial backscattered image; (a2-e2, a3-e3) Secondary electron images of corrosion surfaces

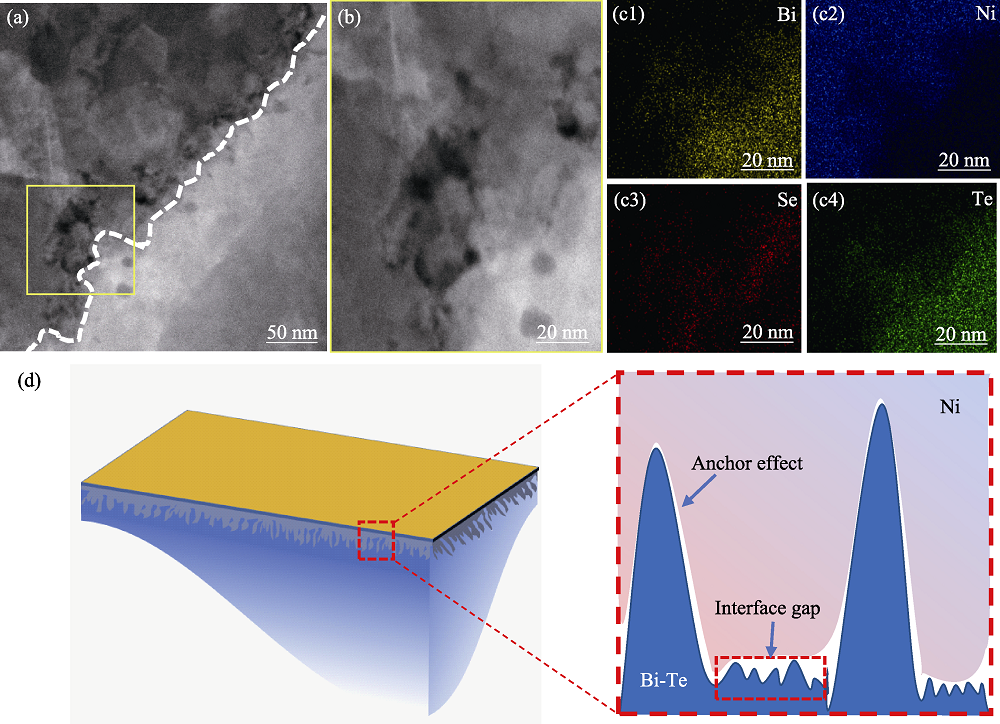

图5 (a)BT-4与Ni材料界面的精细显微结构,(b)局部放大图及对应的(c1)Bi, (c2)Ni, (c3)Se, (c4)Te元素面分布图; (d)BT-4与Ni阻挡层材料界面结构示意图

Fig. 5 (a) Fine microstructure of the interface between BT-4 material and Ni layer, (b) partially enlarged image and corresponding (c1) Bi, (c2) Ni, (c3) Se, (c4) Te surficial elemental distribution mappings, and (d) schematic diagram of interface structure between BT-4 material and Ni barrier layer

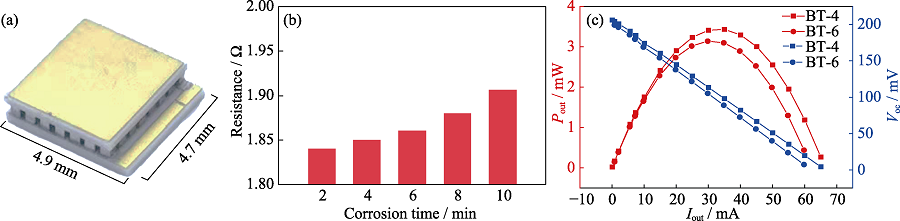

图6 微型热电器件性能

Fig. 6 Performance of micro thermoelectric device (a) Photo of micro thermoelectric device, (b) histogram of internal resistance of micro thermoelectric device prepared with BT-x, and (c) Volt-ampere curves and output power curves of micro thermoelectric devices prepared with BT-4 and BT-6

| Ref. | Contact resistance/ (μΩ·cm2) | Bonding strength/MPa | Device size/mm3 |

|---|---|---|---|

| LIU[ | <1 | 16 | 1.8×1.8×2.4 |

| TANG[ | 5.31 | 17.62 | 2×2×0.45 |

| This work (BT-4) | 2.43 | 14.95 | 2×2×0.45 |

表1 n型Bi2Te3阻挡层的接触电阻与拉伸测试结合强度参数

Table 1 Contact resistance and tensile bonding strength parameters of n-type Bi2Te3 barrier layers

| Ref. | Contact resistance/ (μΩ·cm2) | Bonding strength/MPa | Device size/mm3 |

|---|---|---|---|

| LIU[ | <1 | 16 | 1.8×1.8×2.4 |

| TANG[ | 5.31 | 17.62 | 2×2×0.45 |

| This work (BT-4) | 2.43 | 14.95 | 2×2×0.45 |

| [1] |

CHEN W Y, SHI X L, ZOU J, et al. Thermoelectric coolers: progress, challenges, and opportunities. Small Methods, 2022, 6(2): 2101235.

DOI URL |

| [2] |

ROSENBERG Z B, WEINER N C, SHAHARIAR H, et al. Design of a scalable, flexible, and durable thermoelectric cooling device for soft electronics using Kirigami cut patterns. Flexible and Printed Electronics, 2022, 7(1): 015002.

DOI URL |

| [3] |

CUI Y J, WANG B L, WANG K F, et al. An analytical model to evaluate the fatigue crack effects on the hybrid photovoltaic- thermoelectric device. Renewable Energy, 2022, 182: 923.

DOI URL |

| [4] |

WU Z H, ZHANG S, LIU Z K, et al. Thermoelectric converter: strategies from materials to device application. Nano Energy, 2022, 91: 106692.

DOI URL |

| [5] |

LIU Y J, HOU S H, WANG X D, et al. Passive radiative cooling enables improved performance in wearable thermoelectric generators. Small, 2022, 18(10): 2106875.

DOI URL |

| [6] |

YUSUF A, BALLIKAYA S. Electrical, thermomechanical and cost analyses of a low-cost thermoelectric generator. Energy, 2022, 241: 122934.

DOI URL |

| [7] |

TOHIDI F, HOLAGH S G, CHITSAZ A. Thermoelectric generators: a comprehensive review of characteristics and applications. Applied Thermal Engineering, 2022, 201(A): 117793.

DOI URL |

| [8] |

MASOUMI S, O'SHAUGHNESSY S, PAKDEL A. Organic-based flexible thermoelectric generators: from materials to devices. Nano Energy, 2022, 92: 106774.

DOI URL |

| [9] | HASAN M N, NAFEA M, NAYAN N, et al. Thermoelectric generator: materials and applications in wearable health monitoring sensors and internet of things devices. Advanced Materials Technologies, 2021: 2101203. |

| [10] |

ZAIA E W, GORDON M P, YUAN P Y, et al. Progress and perspective: soft thermoelectric materials for wearable and internet-of-things applications. Advanced Electronic Materials, 2019, 5(11): 1800823.

DOI URL |

| [11] |

ZHANG Q H, BAI S Q, CHEN L D. Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials, 2019, 34(3): 279.

DOI URL |

| [12] |

CHENG J, HU X, LI Q. Influences of different barrier films on microstructures and electrical properties of Bi2Te3-based joints. Journal of Materials Science: Materials in Electronics, 2020, 31(17): 14714.

DOI URL |

| [13] |

HU X K, ZHANG S M, ZHAO F, et al. Thermoelectric device: contact interface and interface materials. Journal of Inorganic Materials, 2019, 34(3): 269.

DOI URL |

| [14] |

LIU W S, WANG H Z, WANG L J, et al. Understanding of the contact of nanostructured thermoelectric n-type Bi2Te2.7Se0.3 legs for power generation applications. Journal of Materials Chemistry A, 2013, 1(42): 13093.

DOI URL |

| [15] | WEITZMAN L H. Etching bismuth telluride. USA US30736863A. 1967. |

| [16] | 陈良杰. 用于半导体N/P型致冷晶片表面电镀前处理的粗化液及相关的电镀前处理工艺. 中国 CN101701348A. 2010. |

| [17] | 蔡新志, 朱刘, 李德全. 碲铋基晶片的表面处理方法. 中国 CN107723767B. 2019. |

| [18] |

TANG H, BAI H, YANG X, et al. Thermal stability and interfacial structure evolution of Bi2Te3-based micro thermoelectric devices. Journal of Alloys and Compounds, 2022, 896: 163090.

DOI URL |

| [19] |

GUPTA R P, MCCARTY R, SHARP J. Practical contact resistance measurement method for bulk Bi2Te3-based thermoelectric devices. Journal of Electronic Materials, 2014, 43(6): 1608.

DOI URL |

| [20] |

GUPTA R P, XIONG K, WHITE J B, et al. Low resistance Ohmic contacts to Bi2Te3 using Ni and Co metallization. Journal of the Electrochemical Society, 2010, 157(6): H666.

DOI URL |

| [21] |

BEN KHEDIM M, CAGNON L, ANDRE E, et al. Contact resistance optimization for development of thermoelectric modules based on bismuth telluride nanowires. AIP Advances, 2021, 11(5): 055109.

DOI URL |

| [22] | KONG X, WEI Z, CAO L, et al. Controllable electrical contact resistance between Cu and oriented-Bi2Te3 film via interface tuning. 2017, 9(30): 25606. |

| [23] |

ZHU X, CAO L, ZHU W, et al. Enhanced interfacial adhesion and thermal stability in bismuth telluride/nickel/copper multilayer films with low electrical contact resistance. Advanced Materials Interfaces, 2018, 5(23): 1801279.

DOI URL |

| [24] |

ZOU X, SARIYEV B, CHEN K, et al. Enhanced interfacial bonding strength between metal and polymer via synergistic effects of particle anchoring and chemical bonding. Journal of Manufacturing Processes, 2021, 68: 558.

DOI URL |

| [25] |

TAYLOR P J, MADDUX J R, MEISSNER G, et al. Controlled improvement in specific contact resistivity for thermoelectric materials by ion implantation. Applied Physics Letters, 2013, 103(4): 043902.

DOI URL |

| [26] | HILL L R. Method of bonding bismuth-containing bodies. USA US3110100A, 1963. |

| [27] | KAZEMI D, YAFTIAN M R, KOLEV S D. Selective extraction of Bi(III) from sulfate solutions by a poly(vinyl chloride) based polymer inclusion membrane incorporating bis(2-ethylhexyl) phosphoric acid as the extractant. Reactive & Functional Polymers, 2021, 164: 104935. |

| [28] | TERAMOTO I, TAKAYANAGI S. Dislocation etch pits on bismuth telluride crystals. Journal of Applied Physics, 1961, 32(1): 119. |

| [29] | CHEN K K, ZHENG Y J. Selective extracting Te from tellurium richen residue containing precious metals by H2SO4-H2O2 solutions. Chinese Journal of Rare Metals, 2013, 37(6): 946. |

| [30] | FU S J, LI Z X, WANG S L, et al. Extracting tellurium from alkaline residue. Chinese Journal of Rare Metals, 2011, 35(1): 124. |

| [31] | LIU B G, HUANG X J. Patents technical reviews of metallurgical extraction of bismuth. Guangdong Chemical Industry, 2018, 45(4): 111. |

| [32] |

BOGREKCI I, DURAKBASA M N, DEMIRCIOGLU P. Comparison between 3D digital and optical microscopes for the surface measurement by computer vision. At-Automatisierungstechnik, 2013, 61(3): 195.

DOI URL |

| [33] |

LEI G F, LIU Q S, PENG X X, et al. Experimental study on mechanical properties of fractured rock mass under different anchoring modes. European Journal of Environmental and Civil Engineering, 2020, 24(7): 931.

DOI URL |

| [34] |

YUAN C, CHEN W S, PHAM T M, et al. New epoxy anchor for better bonding between FRP sheets and concrete. Construction and Building Materials, 2020, 248: 118628.

DOI URL |

| [1] | 杨枭, 苏贤礼, 鄢永高, 唐新峰. (GeTe)nBi2Te3的结构与热电性能研究[J]. 无机材料学报, 2021, 36(1): 75-80. |

| [2] | 邓 元, 李 娜, 王 瑶, 杨 萌. Te纳米线模板法加工Bi2Te3-Te片式棒热电材料[J]. 无机材料学报, 2010, 25(6): 664-668. |

| [3] | 刘松秀,刘红梅,黄开勋. 低温湿化学还原法制备Bi2Te3单晶纳米棒[J]. 无机材料学报, 2008, 23(2): 305-308. |

| [4] | 王为,贾法龙,黄庆华,张伟玲,郭鹤桐,申玉田. 电化学组装一维纳米线阵列p型Bi2Te3温差电材料[J]. 无机材料学报, 2004, 19(3): 517-522. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||