无机材料学报 ›› 2022, Vol. 37 ›› Issue (8): 821-840.DOI: 10.15541/jim20220145

所属专题: 【结构材料】陶瓷基复合材料; 【结构材料】核用陶瓷

欧阳琴1,2( ), 王艳菲1,2, 徐剑1,2, 李寅生1, 裴学良1,2, 莫高明1,2, 李勉1,2, 李朋1, 周小兵1,2, 葛芳芳1,2, 张崇宏2,3, 何流1,2, 杨磊2,3, 黄政仁1,2, 柴之芳1, 詹文龙2,3, 黄庆1,2(

), 王艳菲1,2, 徐剑1,2, 李寅生1, 裴学良1,2, 莫高明1,2, 李勉1,2, 李朋1, 周小兵1,2, 葛芳芳1,2, 张崇宏2,3, 何流1,2, 杨磊2,3, 黄政仁1,2, 柴之芳1, 詹文龙2,3, 黄庆1,2( )

)

收稿日期:2022-03-16

修回日期:2022-05-11

出版日期:2022-08-20

网络出版日期:2022-05-15

通讯作者:

黄 庆, 研究员. E-mail: huangqing@nimte.ac.cn作者简介:欧阳琴(1981-), 男, 副研究员. E-mail: ouyangqin@nimte.ac.cn

基金资助:

OUYANG Qin1,2( ), WANG Yanfei1,2, XU Jian1,2, LI Yinsheng1, PEI Xueliang1,2, MO Gaoming1,2, LI Mian1,2, LI Peng1, ZHOU Xiaobing1,2, GE Fangfang1,2, ZHANG Chonghong2,3, HE Liu1,2, YANG Lei2,3, HUANG Zhengren1,2, CHAI Zhifang1, ZHAN Wenlong2,3, HUANG Qing1,2(

), WANG Yanfei1,2, XU Jian1,2, LI Yinsheng1, PEI Xueliang1,2, MO Gaoming1,2, LI Mian1,2, LI Peng1, ZHOU Xiaobing1,2, GE Fangfang1,2, ZHANG Chonghong2,3, HE Liu1,2, YANG Lei2,3, HUANG Zhengren1,2, CHAI Zhifang1, ZHAN Wenlong2,3, HUANG Qing1,2( )

)

Received:2022-03-16

Revised:2022-05-11

Published:2022-08-20

Online:2022-05-15

Contact:

HUANG Qing, professor. E-mail: huangqing@nimte.ac.cnAbout author:OUYANG Qin (1981-), male, associate professor. E-mail: ouyangqin@nimte.ac.cn

Supported by:摘要:

碳化硅纤维增强碳化硅(SiCf/SiC)复合材料具有低中子毒性、耐中子辐照和耐高温氧化等特性, 成为先进核能系统重要的候选结构材料。近年来, 国内外学术界和工业界针对核用SiCf/SiC复合材料开展了大量研究工作, 取得了一系列重要的研究进展。针对SiCf/SiC复合材料面向核用所关注的重点方向, 如核用SiC纤维、纤维/基体界面相、复合材料制备工艺、数值仿真、腐蚀行为和表面防护、连接技术以及辐照损伤等方面, 本文进行了综述和讨论, 并针对核用要求指出了SiCf/SiC复合材料存在的主要问题和可能的解决思路, 希望对该材料的进一步研发和最终应用有所裨益。

中图分类号:

欧阳琴, 王艳菲, 徐剑, 李寅生, 裴学良, 莫高明, 李勉, 李朋, 周小兵, 葛芳芳, 张崇宏, 何流, 杨磊, 黄政仁, 柴之芳, 詹文龙, 黄庆. 核用碳化硅纤维增强碳化硅复合材料研究进展[J]. 无机材料学报, 2022, 37(8): 821-840.

OUYANG Qin, WANG Yanfei, XU Jian, LI Yinsheng, PEI Xueliang, MO Gaoming, LI Mian, LI Peng, ZHOU Xiaobing, GE Fangfang, ZHANG Chonghong, HE Liu, YANG Lei, HUANG Zhengren, CHAI Zhifang, ZHAN Wenlong, HUANG Qing. Research Progress of SiC Fiber Reinforced SiC Composites for Nuclear Application[J]. Journal of Inorganic Materials, 2022, 37(8): 821-840.

| Hi-Nicalon Type S | Tyranno SA | |

|---|---|---|

| Fiber diameter/μm | 12 | 10 |

| Tow number | 800 | 800 |

| Linear density/(g·km-1) | 195 | 170 |

| Bulk density/(g·cm-3) | 2.85 | 3.10 |

| Tensile strength/GPa | 3.1 | 2.4 |

| Tensile modulus/GPa | 380 | 380 |

| Si content/(%, in mass) | 69 | 67 |

| C content/(%, in mass) | 31 | 31 |

| O content/(%, in mass) | 0.8 | <1 |

| C/Si | 1.05 | 1.08 |

| Thermal conductivity/(W·m-1·K-1) | 24 | 65 |

表1 核用第三代SiC纤维的主要性能[21-23]

Table 1 Key properties of the third-generation SiC fibers for nuclear application[21-23]

| Hi-Nicalon Type S | Tyranno SA | |

|---|---|---|

| Fiber diameter/μm | 12 | 10 |

| Tow number | 800 | 800 |

| Linear density/(g·km-1) | 195 | 170 |

| Bulk density/(g·cm-3) | 2.85 | 3.10 |

| Tensile strength/GPa | 3.1 | 2.4 |

| Tensile modulus/GPa | 380 | 380 |

| Si content/(%, in mass) | 69 | 67 |

| C content/(%, in mass) | 31 | 31 |

| O content/(%, in mass) | 0.8 | <1 |

| C/Si | 1.05 | 1.08 |

| Thermal conductivity/(W·m-1·K-1) | 24 | 65 |

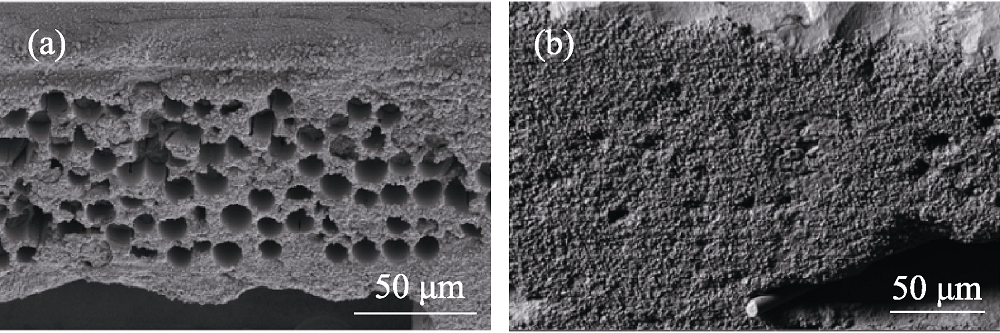

图1 采用不同SiC纤维增强CVI SiC复合材料经中子辐照后的SEM照片[9]

Fig. 1 SEM images of CVI SiC composites reinforced with different SiC fibers after neutron irradiation[9] (a) Hi-Nicalon Type S fiber; (b) Tyranno SA3 fiber

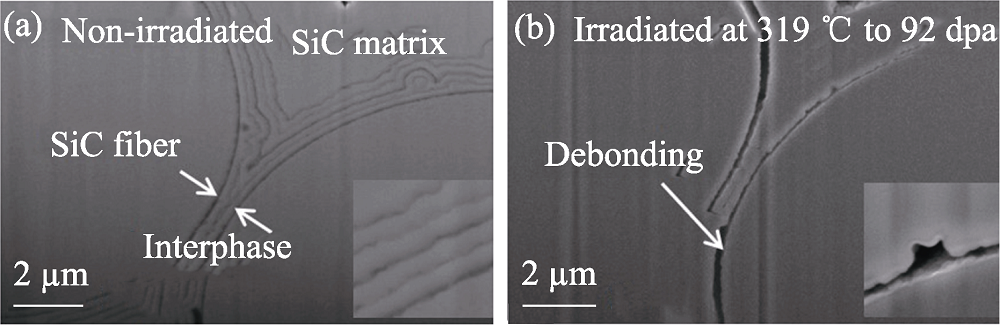

图2 以PyC为界面相的SiCf/SiC复合材料中子辐照前(a)和辐照后(b)的界面微观结构[35]

Fig. 2 Interfacial microstructures of SiCf/SiC composites with PyC as a interphase before (a) and after (b) neutron irradiation[35]

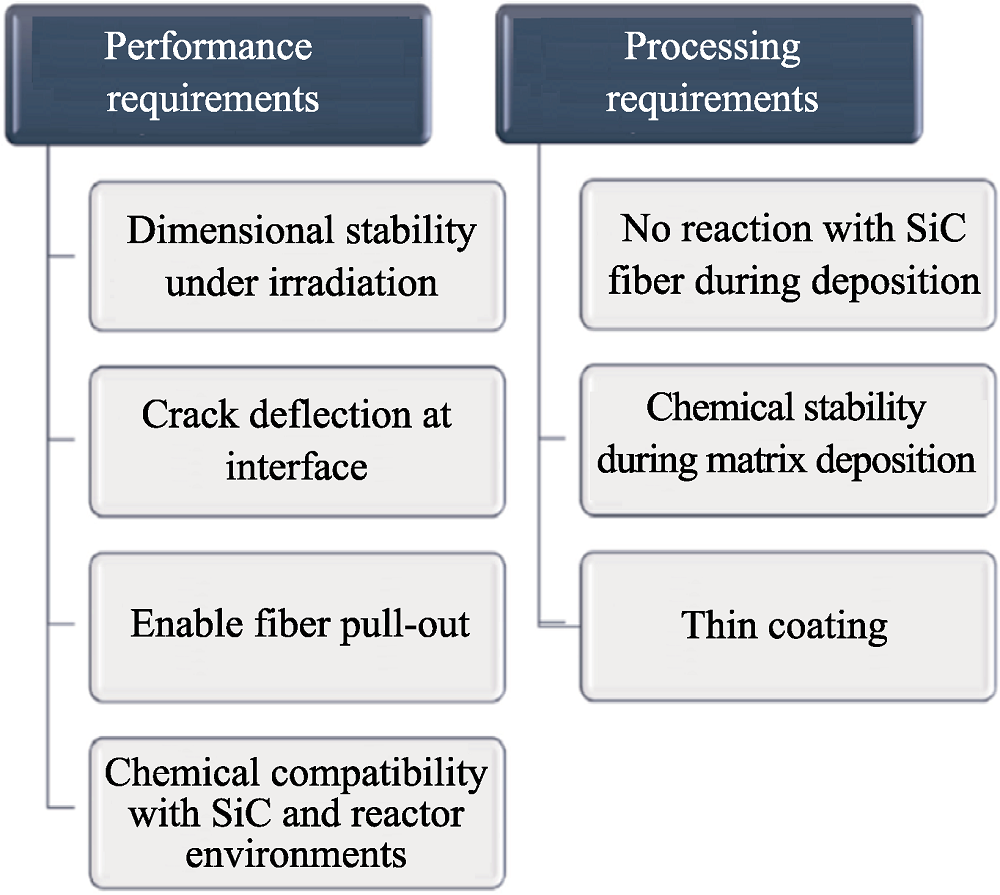

图3 开发用于高剂量辐照环境的SiCf/SiC复合材料对于界面相的性能和工艺要求[9]

Fig. 3 Performance and processing requirements for development of the interphase between fiber and matrix in SiCf/SiC composites for use in high-dose radiation environments[9]

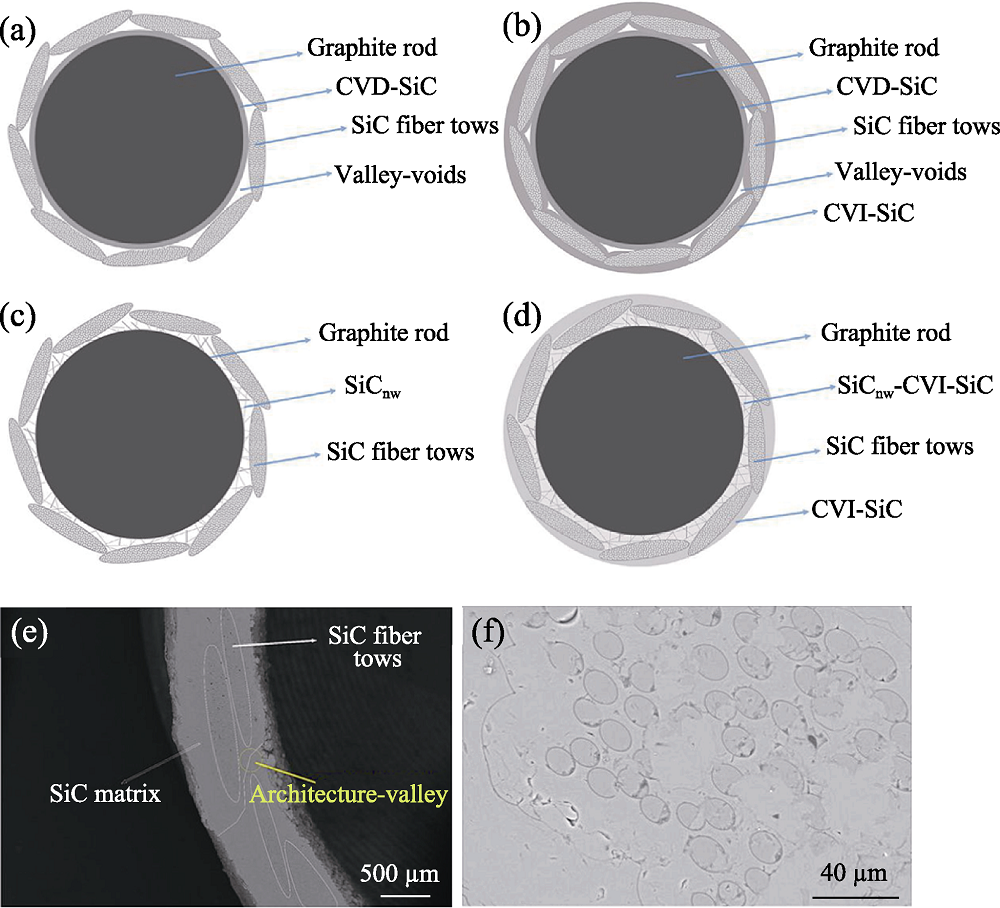

图4 两种类型的包壳管致密化过程示意图(a~d), 纳米线增强SiC包壳管的微观结构((e)低倍率SEM照片, (f)纤维束间的SEM照片)[66]

Fig. 4 Schematic illustration of densification process of two types of cladding tubes (a-d) and microstructures of as- obtained three-layer-NWs SiC cladding tube (at low magnification (e) and intrabundle area (f) of the SiCf/SiC composite layer)[66] (a) Preform structure of the three-layer SiC cladding tube before CVI process; (b) Structure of the three-layer SiC cladding tube after CVI process; (c) Preform structure of the three-layer-NWs SiC cladding tube before CVI process; (d) Structure of the three-layer SiCNWs cladding tube after CVI process

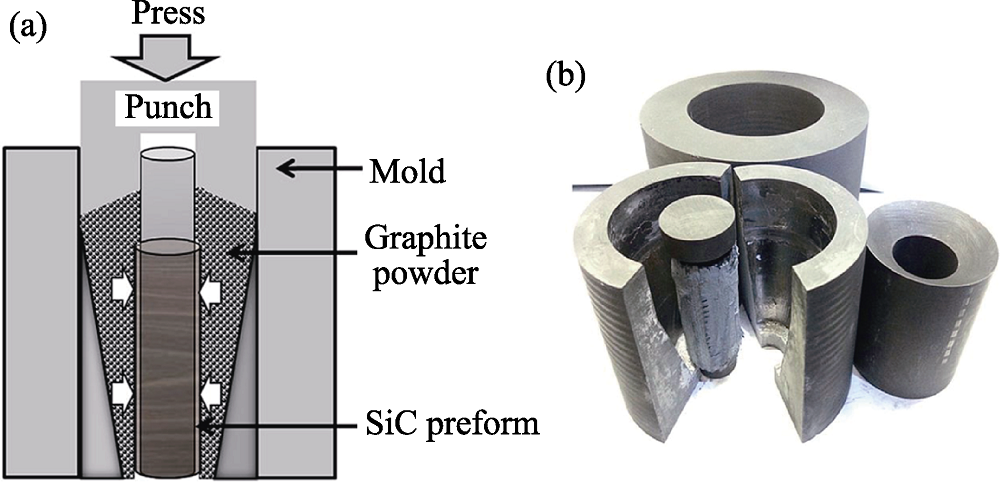

图5 NITE工艺制备管状SiCf/SiC复合材料的新模具结构示意图(a)和模具及管状样品实物图片(b)[72]

Fig. 5 Schematic diagram of new graphite mold for preparing tubular SiCf/SiC composites via NITE process (a), and photograph of new graphite mold and tubular specimen (b)[72]

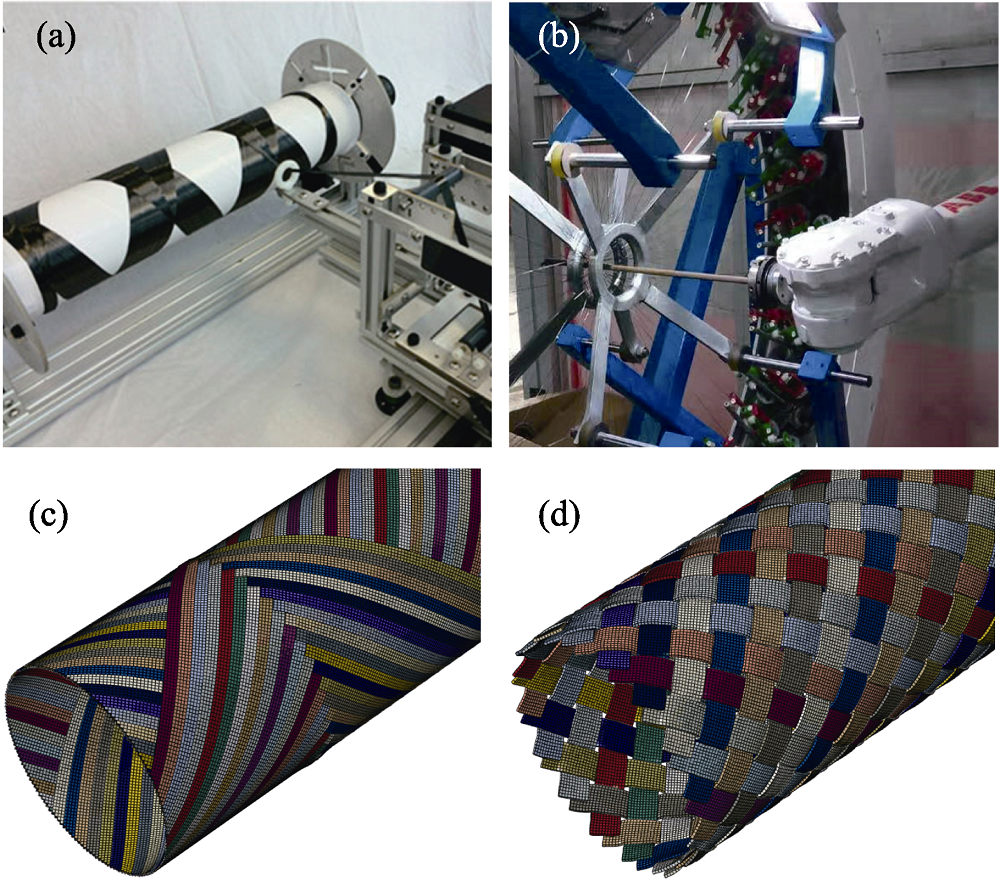

图6 包壳管成型工艺

Fig. 6 Cladding tube forming technology (a) Winding technology[88]; (b) Braiding technique[89]; (c) Winding mesostructure[88]; (d) Braided mesostructure[89]

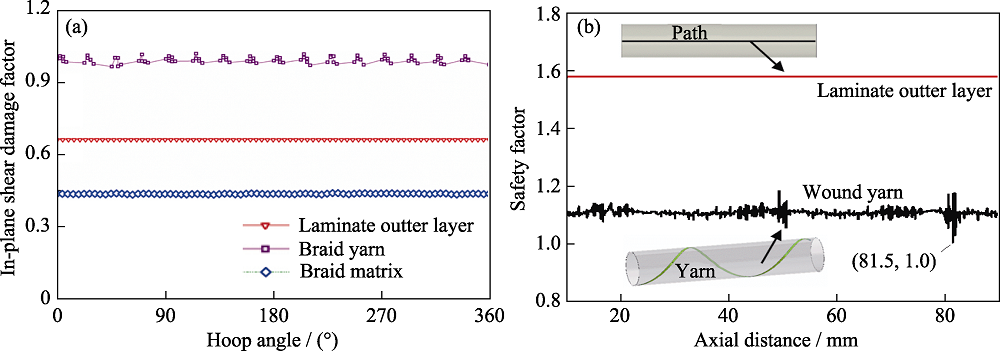

图7 编织管与层合管在轴向的面内损伤系数(a)[88]和缠绕管与层合管在轴向的剪切安全系数(b)[89]

Fig. 7 In-plane damage factors of the braided tube yarn, braided tube matrix, and laminated tube on the hoop direction (a)[88] and safety factor of shear stress of the winding tube and laminated tube (b)[89]

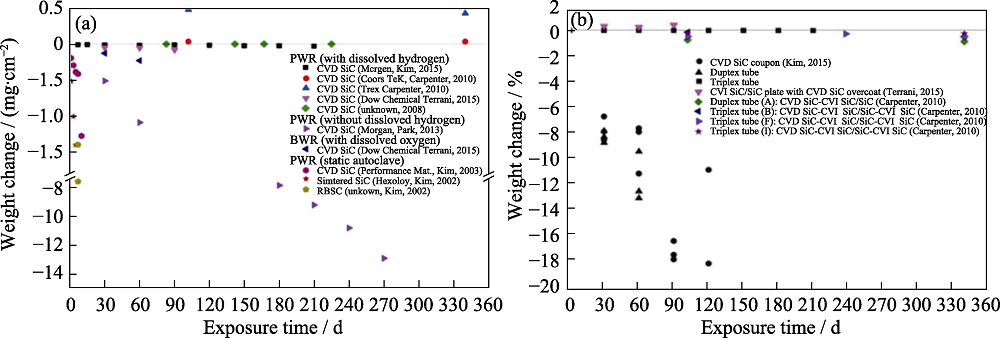

图9 不同类型SiC在热水腐蚀环境中的重量变化(a)和模拟PWR冷却环境的重量变化(b)[97]

Fig. 9 Weight changes of monolithic SiC ceramics in the hydrothermal corrosion environments (a) and corrosion rate of SiC ceramics in simulated PWR coolant environment without irradiation (b)[97]

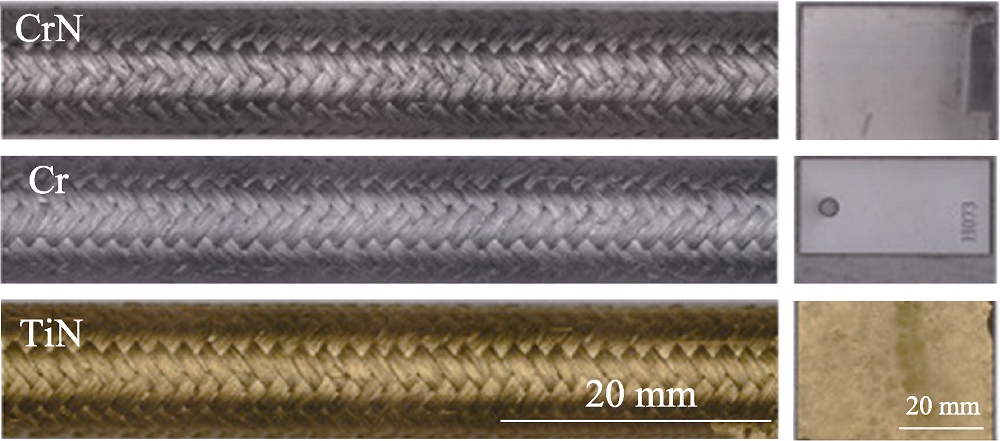

图12 SiCf/SiC复合棒上(左)和CVD试样(右)沉积的CrN、Cr和TiN涂层的光学照片[116]

Fig. 12 Optical images of the as-deposited CrN, Cr and TiN coatings on SiC/SiC composite rods (left) and CVD samples (right)[116]

| Material | Vickers hardness/ GPa | Flexural strength/ MPa | Fracture toughness/ (MPa·m1/2) | Thermal conductivity/ (W·m-1·K-1) | Electrical conductivity/ (×106 , S·m-1) |

|---|---|---|---|---|---|

| Ti3SiC2 | 10.4 | 881(//c-axis) | 14.1(//c-axis) | 32.4 | 0.49(//c-axis) |

| Ti3AlC2 | 9.1 | 1261(//c-axis) | 13.1(//c-axis) | 14.6(//c-axis) | 1.01(//c-axis) |

| Ti2AlC | 7.9 | 735(//c-axis) | 8.5(//c-axis) | 27 | 2.5 |

| Nb4AlC3 | 7.0 | 789(⊥c-axis) | 9.3(⊥c-axis) | 21.1 | 0.81 |

表2 几种典型的MAX相及其性能对比[158-162]

Table 2 Comparison of related properties of several typical MAX phases[158-162]

| Material | Vickers hardness/ GPa | Flexural strength/ MPa | Fracture toughness/ (MPa·m1/2) | Thermal conductivity/ (W·m-1·K-1) | Electrical conductivity/ (×106 , S·m-1) |

|---|---|---|---|---|---|

| Ti3SiC2 | 10.4 | 881(//c-axis) | 14.1(//c-axis) | 32.4 | 0.49(//c-axis) |

| Ti3AlC2 | 9.1 | 1261(//c-axis) | 13.1(//c-axis) | 14.6(//c-axis) | 1.01(//c-axis) |

| Ti2AlC | 7.9 | 735(//c-axis) | 8.5(//c-axis) | 27 | 2.5 |

| Nb4AlC3 | 7.0 | 789(⊥c-axis) | 9.3(⊥c-axis) | 21.1 | 0.81 |

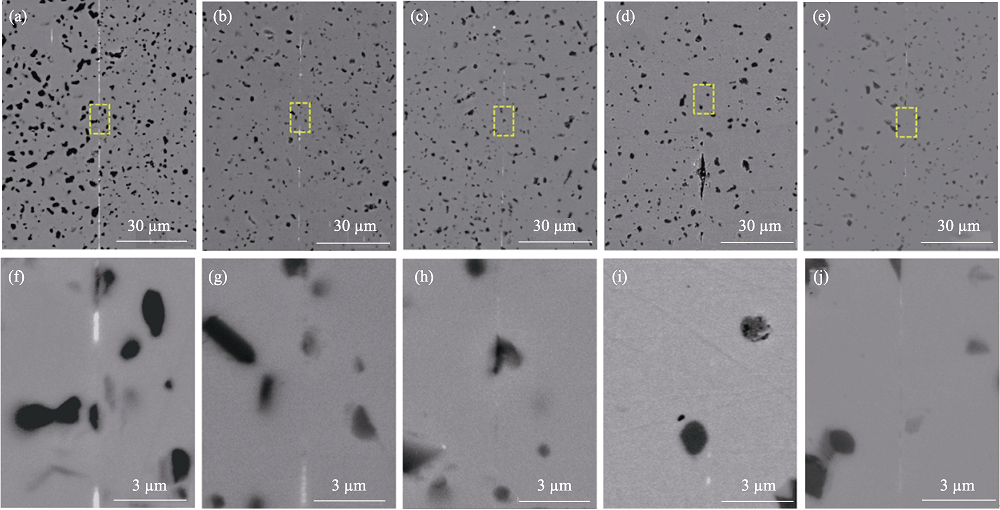

图13 不同温度下连接的SiC/Yb/SiC的低倍和高倍背散射(BSE)图[157]

Fig. 13 Low and high magnification back-scattered electron (BSE) images of the SiC/Yb/SiC joints joined at different temperatures[157] (a, f) 1200 ℃; (b, g) 1400 ℃; (c, h) 1500 ℃, (d, i) 1700 ℃; (e, j) 1500 ℃ (dwell time of 15 min)

| [1] | 荆春宁, 高力, 马佳鹏, 等. “碳达峰、碳中和”背景下能源发展趋势与核能定位研判. 核科学与工程, 2022, 42: 1-9. |

| [2] | YANG Z, LI F, CHAI G. Status and perspective of China’s nuclear safety philosophy and requirements in the post-fukushima era. Frontiers in Energy Research, 2022, 9: 819634. |

| [3] | 詹文龙, 杨磊, 闫雪松, 等. 加速器驱动先进核能系统及其研究进展. 原子能科学技术, 2019, 53(10): 1809-1815. |

| [4] | 荣健, 刘展. 先进核能技术发展与展望. 原子能科学技术, 2020, 54(9): 1638-1643. |

| [5] | 王建强, 戴志敏, 徐洪杰. 核能综合利用研究现状与展望. 中国科学院院刊, 2019, 34(4): 460-468. |

| [6] |

PHAM H V, KURATA M, STEINBRUECK M. Steam oxidation of silicon carbide at high temperatures for the application as accident tolerant fuel cladding, an overview. Thermo, 2021, 1(2): 151-167.

DOI URL |

| [7] |

DECK C P, JACOBSEN G M, SHEEDER J, et al. Characterization of SiC-SiC composites for accident tolerant fuel cladding. Journal of Nuclear Materials, 2015, 466: 667-681.

DOI URL |

| [8] | KATOH Y, SNEAD L L. Silicon carbide and its composites for nuclear applications-historical overview. Journal of Nuclear Materials, 2019, 526: 151849. |

| [9] | TAKAAKI K, YUTAI K, TAKASHI N. Design and strategy for next- generation silicon carbide composites for nuclear energy. Journal of Nuclear Materials, 2020, 540: 152375. |

| [10] | STEIBEL J. Ceramic matrix composites taking flight at GE Aviation. Am. Ceram. Soc. Bull., 2019, 98(3): 32-36. |

| [11] | 陈代荣, 韩伟健, 李思维, 等. 连续陶瓷纤维的制备、结构、性能和应用: 研究现状及发展方向. 现代技术陶瓷, 2018, 39(3): 151-222. |

| [12] | IDRIS M I, KONISHI H, IMAI M, et al. Neutron irradiation swelling of SiC and SiCf/SiC for advanced nuclear applications. 4th International Symposium on Innovative Nuclear Energy Systems (INES-4), 2015, 71: 328-336. |

| [13] |

TERRANI K A. Accident tolerant fuel cladding development: promise, status, and challenges. Journal of Nuclear Materials, 2018, 501: 13-30.

DOI URL |

| [14] |

HASEGAWA A, YOUNGBLOOD G E, JONES R H. Effect of irradiation on the microstructure of Nicalon fibers. Journal of Nuclear Materials, 1996, 231(3): 245-248.

DOI URL |

| [15] |

OSBORNE M C, HUBBARD C R, SNEAD L L, et al. Neutron irradiation effects on the density, tensile properties and microstructural changes in Hi-Nicalon (TM) and Sylramic (TM) SiC fibers. Journal of Nuclear Materials, 1998, 253: 67-77.

DOI URL |

| [16] |

HENAGER C H, YOUNGBLOOD G E, SENOR D J, et al. Dimensional stability and tensile strength of irradiated Nicalon-CG and Hi-Nicalon fibers. Journal of Nuclear Materials, 1998, 253: 60-66.

DOI URL |

| [17] |

HINOKI T, KATOH Y, KOHYAMA A. Effect of fiber properties on neutron irradiated SiC/SiC composites. Materials Transactions, 2002, 43(4): 617-621.

DOI URL |

| [18] | YOUNGBLOOD G E, JONES R H, KOHYAMA A, et al. Radiation response of SiC-based fibers. Journal of Nuclear Materials, 1998, 258: 1551-1556. |

| [19] |

KOYANAGI T, KATOH Y. Mechanical properties of SiC composites neutron irradiated under light water reactor relevant temperature and dose conditions. Journal of Nuclear Materials, 2017, 494: 46-54.

DOI URL |

| [20] |

NEWSOME G, SNEAD L L, HINOKI T, et al. Evaluation of neutron irradiated silicon carbide and silicon carbide composites. Journal of Nuclear Materials, 2007, 371(1/2/3): 76-89.

DOI URL |

| [21] | Introducing NicalonTM silicon carbide to benefit evolving industries (2020-04-24) http://ngs-advanced-fibers.com/eng/item/index.html. |

| [22] | Tyranno Fiber® Chemicals: Continuous Inorganic Fiber (2022-04-24) https://www.ube.com/contents/en/chemical/continuous_inorganic_fiber/tyranno_fiber.html. |

| [23] |

ICHIKAWA H. Polymer-derived ceramic fibers. Annual Review of Materials Research, 2016, 46: 335-356.

DOI URL |

| [24] |

KATOH Y, SNEAD L L, NOZAWA T, et al. Thermophysical and mechanical properties of near-stoichiometric fiber CVI SiC/SiC composites after neutron irradiation at elevated temperatures. Journal of Nuclear Materials, 2010, 403(1/2/3): 48-61.

DOI URL |

| [25] | BRAUN J, SAUDER C. Mechanical behavior of SiC/SiC composites reinforced with new Tyranno SA4 fibers: effect of interphase thickness and comparison with Tyranno SA3 and Hi- Nicalon S reinforced composites. Journal of Nuclear Materials, 2022, 558: 153367. |

| [26] |

WANG P R, GOU Y Z, WANG H. Third generation SiC fibers for nuclear applications. Journal of Inorganic Materials, 2020, 35(5): 525-531.

DOI URL |

| [27] |

KATOH Y, OZAWA K, SHIH C, et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. Journal of Nuclear Materials, 2014, 448(1/2/3): 448-476.

DOI URL |

| [28] |

NGUYEN B N, HENAGER C H. Fiber/matrix interfacial thermal conductance effect on the thermal conductivity of SiC/SiC composites. Journal of Nuclear Materials, 2013, 440(1/2/3): 11-20.

DOI URL |

| [29] |

JACQUES S, LOPEZ-MARURE A, VINCENT C, et al. SiC/SiC minicomposites with structure-graded BN interphases. Journal of the European Ceramic Society, 2000, 20(12): 1929-1938.

DOI URL |

| [30] |

CAO X Y, YIN X W, FAN X M, et al. Effect of PyC interphase thickness on mechanical behaviors of SiBC matrix modified C/SiC composites fabricated by reactive melt infiltration. Carbon, 2014, 77: 886-895.

DOI URL |

| [31] |

NASLAIN R R, PAILLER R J F, LAMON J L. Single and multilayered interphases in SiC/SiC composites exposed to severe environmental conditions: an overview. International Journal of Applied Ceramic Technology, 2010, 7(3): 263-275.

DOI URL |

| [32] |

SNEAD L L, BURCHELL T D, KATOH Y. Swelling of nuclear graphite and high quality carbon fiber composite under very high irradiation temperature. Journal of Nuclear Materials, 2008, 381 (1/2): 55-61.

DOI URL |

| [33] |

KATOH Y, NOZAWA T, SHIH C H. High-dose neutron irradiation of Hi-Nicalon Type S silicon carbide composites. Part 2: Mechanical and physical properties. Journal of Nuclear Materials, 2015, 462: 450-457.

DOI URL |

| [34] | NOZAWA T, KATOH Y, SNEAD L L. The effects of neutron irradiation on shear properties of monolayered PyC and multilayered PyC/SiC interfaces of SiC/SiC composites. Journal of Nuclear Materials, 2007, 367-370(Part A): 685-691. |

| [35] |

KOYANAGI T, NOZAWA T, KATOH Y, et al. Mechanical property degradation of high crystalline SiC fiber-reinforced SiC matrix composite neutron irradiated to -100 displacements per atom. Journal of the European Ceramic Society, 2018, 38(4): 1087-1094.

DOI URL |

| [36] | 程唯珈. 从1%到95%,“吃干榨净”核废料! 中国科学报社, 2020-01-20: 4. |

| [37] | SNEAD L L, LARA-CURZIO E. Interphase integrity of neutron irradiated SiC composites. MRS Online Proceedings Library, 1998, 540(1): 273-278. |

| [38] |

KOYANAGI T, KATOH Y, NOZAWA T, ET AL. Recent progress in the development of SiC composites for nuclear fusion applications. Journal of Nuclear Materials, 2018, 511: 544-555.

DOI URL |

| [39] |

POMPIDOU S LAMON J. Analysis of crack deviation in ceramic matrix composites and multilayers based on the cook and gordon mechanism. Composites Science and Technology, 2007, 67(10): 2052-2060.

DOI URL |

| [40] |

LI H, MORSCHER G N, LEE J, et al. Tensile and stress-rupture behavior of SiC/SiC minicomposite containing chemically vapor deposited zirconia interphase. Journal of the American Ceramic Society, 2004, 87(9): 1726-1733.

DOI URL |

| [41] | UTKIN A V, MATVIENKO A A, TITOV A T, et al. Multiple zirconia interphase for SiC/SiCf composites. Surface and Coatings Technology, 2011, 205(8/9): 2724-2729. |

| [42] | PROKIP V, LOZANOV V, MOROZOVA N, et al. The zirconia- based interfacial coatings on SiC fibers obtained by different chemical methods. Materials Today: Proceedings, 2019, 19(Part 5): 1861-1864. |

| [43] |

CALLENDER R L, BARRON A R. Novel route to alumina and aluminate interlayer coatings for SiC, carbon, and Kevlart® fiber- reinforced ceramic matrix composites using carboxylate-alumoxane nanoparticles. Journal of Materials Research, 2011, 15(10): 2228-2237.

DOI URL |

| [44] | IGAWA N, TAGUCHI T, YAMADA R, et al. Preparation of silicon-based oxide layer on high-crystalline SiC fiber as an interphase in SiC/SiC composites. Journal of Nuclear Materials, 2004, 329-333(Part A): 554-557. |

| [45] |

SHI Y, LUO F, DING D, et al. Effects of ZrO2 interphase on mechanical and microwave absorbing properties of SiCf/SiC composites. Physica Status Solidi (A), 2013, 210(12): 2668-2673.

DOI URL |

| [46] |

RUGGLES-WRENN M, BOUCHER N, PRZYBYLA C. Fatigue of three advanced SiC/SiC ceramic matrix composites at 1200 ℃ in air and in steam. International Journal of Applied Ceramic Technology, 2018, 15(1): 3-15.

DOI URL |

| [47] |

JACQUES S, JOUANNY I, LEDAIN O, et al. Nanoscale multilayered and porous carbide interphases prepared by pressure- pulsed reactive chemical vapor deposition for ceramic matrix composites. Applied Surface Science, 2013, 275: 102-109.

DOI URL |

| [48] |

ANG C, ZINKLE S, SHIH C, et al. Phase stability, swelling, microstructure and strength of Ti3SiC2-TiC ceramics after low dose neutron irradiation. Journal of Nuclear Materials, 2017, 483: 44-53.

DOI URL |

| [49] |

ANG C, SILVA C, SHIH C, et al. Anisotropic swelling and microcracking of neutron irradiated Ti3AlC2-Ti5Al2C3 materials. Scripta Materialia, 2016, 114: 74-78.

DOI URL |

| [50] |

TALLMAN D J, HOFFMAN E N, CASPI E N, et al. Effect of neutron irradiation on select MAX phases. Acta Materialia, 2015, 85: 132-143.

DOI URL |

| [51] |

FILBERT-DEMUT I, BEI G P, HOSCHEN T, et al. Influence of Ti3SiC2 fiber coating on interface and matrix cracking in an SiC fiber-reinforced polymer-derived ceramic. Advanced Engineering Materials, 2015, 17(8): 1142-1148.

DOI URL |

| [52] |

LI M, ZHOU X B, YANG H, et al. The critical issues of SiC materials for future nuclear systems. Scripta Materialia, 2018, 143: 149-153.

DOI URL |

| [53] |

LI M, WANG K, WANG J, et al. Preparation of TiC/Ti2AlC coating on carbon fiber and investigation of the oxidation resistance properties. Journal of the American Ceramic Society, 2018, 101(11): 5269-5280.

DOI URL |

| [54] |

WANG K, LI M, LIANG Y Q, et al. Interface modification of carbon fibers with TiC/Ti2AlC coating and its effect on the tensile strength. Ceramics International, 2019, 45(4): 4661-4666.

DOI URL |

| [55] |

WANG J, WANG K, PEI X L, et al. Irradiation behavior of Cf/SiC composite with titanium carbide (TiC)-based interphase. Journal of Nuclear Materials, 2019, 523: 10-15.

DOI URL |

| [56] |

ZHONG H, WANG Z, ZHOU H, et al. Properties and microstructure evolution of Cf/SiC composites fabricated by polymer impregnation and pyrolysis (PIP) with liquid polycarbosilane. Ceramics International, 2017, 43(10): 7387-7392.

DOI URL |

| [57] |

LI X, PEI X, ZHONG X, et al. Highly effective free-radical-catalyzed curing of hyperbranched polycarbosilane for near stoichiometric SiC ceramics. Journal of the American Ceramic Society, 2019, 102(3): 1041-1048.

DOI URL |

| [58] |

RAHMAN A, ZUNJARRAO S C, SINGH R P. Effect of degree of crystallinity on elastic properties of silicon carbide fabricated using polymer pyrolysis. Journal of the European Ceramic Society, 2016, 36(14): 3285-3292.

DOI URL |

| [59] | KATOH Y, KOTANI M, KISHIMOTO H, et al. Properties and radiation effects in high-temperature pyrolyzed PIP-SiC/SiC. Journal of Nuclear Materials, 2001, 289(1/2): 42-47. |

| [60] |

LUO Z, ZHOU X, YU J, et al. High-performance 3D SiC/PyC/SiC composites fabricated by an optimized PIP process with a new precursor and a thermal molding method. Ceramics International, 2014, 40(5): 6525-6532.

DOI URL |

| [61] |

YIN J, LEE S H, FENG L, et al. Fabrication of SiCf/SiC composites by hybrid techniques of electrophoretic deposition and polymer impregnation and pyrolysis. Ceramics International, 2016, 42(14): 16431-16435.

DOI URL |

| [62] |

LI M, YANG D, WANG H, et al. Fabrication of a 3D4d braided SiCf/SiC composite via PIP process assisted with an EPD method. Ceramics International, 2019, 45(9): 11668-11676.

DOI URL |

| [63] |

IVEKOVIĆ A, DRAŽIĆ G, NOVAK S. Densification of a SiC- matrix by electrophoretic deposition and polymer infiltration and pyrolysis process. Journal of the European Ceramic Society, 2011, 31(5): 833-840.

DOI URL |

| [64] |

KIM W J, KANG S M, PARK J Y, et al. Effect of a SiC whisker formation on the densification of Tyranno SA/SiC composites fabricated by the CVI process. Fusion Engineering and Design, 2006, 81(8-14): 931-936.

DOI URL |

| [65] |

KANG S M, PARK J Y, KIM W J, et al. Densification of SiCf/SiC composite by the multi-step of whisker growing and matrix filling. Journal of Nuclear Materials, 2004, 329-333: 530-533.

DOI URL |

| [66] |

TAO P, WANG Y. Fabrication of highly dense three-layer SiC cladding tube by chemical vapor infiltration method. Journal of the American Ceramic Society, 2019, 102(11): 6939-6945.

DOI URL |

| [67] | KOHYAMA A, KATOH Y. Advanced SiC/SiC ceramic composites: developments and applications in energy systems. Ceramic Transactions, 2002, 144: 3-18. |

| [68] | 高晔, 焦健. NITE工艺制备SiCf/SiC复合材料的研究进展. 材料工程, 2019, 47(8): 33-39. |

| [69] | KOHYAMA A, DONG S, KATOH Y. Development of SiC/SiC composites by Nano-Infiltration and Transient Eutectoid (NITE) process. Ceramic Engineering and Science Proceedings, 2002, 23(3): 8. |

| [70] |

KONISHI H, IDRIS M I, IMAI M, et al. Neutron irradiation effects of oxide sintering additives for SiCf/SiC composites. Energy Procedia, 2015, 71: 306-312.

DOI URL |

| [71] |

PARISH C M, TERRANI K A, KIM Y J, et al. Microstructure and hydrothermal corrosion behavior of NITE-SiC with various sintering additives in LWR coolant environments. Journal of the European Ceramic Society, 2017, 37(4): 1261-1279.

DOI URL |

| [72] |

YU H W, FITRIANI P, LEE S, et al. Fabrication of the tube- shaped SiCf/SiC by hot pressing. Ceramics International, 2015, 41(6): 7890-7896.

DOI URL |

| [73] |

MARGIOTTA J C, ZHANG D, NAGLE D C. Microstructural evolution during silicon carbide (SiC) formation by liquid silicon infiltration using optical microscopy. International Journal of Refractory Metals and Hard Materials, 2010, 28(2): 191-197.

DOI URL |

| [74] | 焦健, 杨金华, 李宝伟. 熔渗法制备陶瓷基复合材料的研究进展. 航空制造技术, 2015(S2): 1-6, 11. |

| [75] | 胡建宝, 杨金山, 张翔宇, 等. 高致密反应烧结SiCf/SiC复合材料的微观结构与性能. 航空制造技术, 2018, 61(14): 16-21. |

| [76] | DICARLO J A, YUN H M, MORSCHER, G N, et al. SiC/SiC composites for 1200 ℃ and above. In: Bansal N P. (eds) Handbook of Ceramic Composites. Springer, Boston, MA. https://doi.org/10.1007/0-387-23986-3_4. |

| [77] | JE G. CMC Research at NASA Glenn in 2019: Recent Progress and Plans. NASA: Ceramic & Polymer Composites Branch, 2019. |

| [78] |

LIU R, WANG F, ZHANG J, et al. Effects of CVI SiC amount and deposition rates on properties of SiCf/SiC composites fabricated by hybrid chemical vapor infiltration (CVI) and precursor infiltration and pyrolysis (PIP) routes. Ceramics International, 2021, 47(19): 26971-26977.

DOI URL |

| [79] | 李鸣, 张瑞谦, 何宗倍, 等. 耐事故SiCf/SiC复合材料包壳管CVI+无模具NITE制备技术研究. 核动力工程, 2020, 41(S1): 169-173. |

| [80] | 刘海韬, 程海峰, 王军, 等. SiCf/SiC复合材料界面相研究进展. 材料导报, 2010, 24(1): 10-14+30. |

| [81] |

WANG L, WANG Z, DONG S, et al. Finite element simulation of stress distribution and development of Cf/SiC ceramic-matrix composite coated with single layer SiC coating during thermal shock. Composites Part B: Engineering, 2013, 51: 204-214.

DOI URL |

| [82] |

LI L, SONG Y, SUN Y C. Modeling the tensile behavior of unidirectional C/SiC ceramic-matrix composites. Mechanics of Composite Materials, 2014, 49(6): 659-672.

DOI URL |

| [83] |

MEYER P, WAAS A. FEM predictions of damage in continous fiber ceramic matrix composites under transverse tension using the crack band method. Acta Materialia, 2016, 102: 292-303.

DOI URL |

| [84] |

WANG J, CHEN Y, FENG Y, et al. Influence of porosity on anisotropic thermal conductivity of SiC fiber reinforced SiC matrix composite: a microscopic modeling study. Ceramics International, 2020, 46(18): 28693-28700.

DOI URL |

| [85] | MITAL S K, BEDNARCYK B A, ARNOLD S M, et al. Modeling of melt-infiltrated SiC/SiC composite properties. 2009: NASA/ TM-2009-215806. |

| [86] |

VAJARI D A, GONZALEZ C, LLORCA J, et al. A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites. Composites Science and Technology, 2014, 97(16): 46-54.

DOI URL |

| [87] |

VAJARI D A. A micromechanical study of porous composites under longitudinal shear and transverse normal loading. Composite Structures, 2015, 125: 266-276.

DOI URL |

| [88] | FENG Y, WANG J, SHANG N, et al. Multiscale modeling of SiCf/SiC nuclear fuel cladding based on FE-simulation of braiding process. Frontiers in Materials, 2021, 7: 634112. |

| [89] | TANG J, ZHAO G, WANG J, et al. Computational geometry- based 3D yarn path modeling of wound SiCf/SiC-cladding tubes and its application to meso-scale finite element model. Frontiers in Materials, 2021, 8: 701205. |

| [90] |

BICKMORE B R, WHEELER J C, BATES B, et al. Reaction pathways for quartz dissolution determined by statistical and graphical analysis of macroscopic experimental data. Geochimica Et Cosmochimica Acta, 2008, 72(18): 4521-4536.

DOI URL |

| [91] | DOVE P M, HAN N Z, DE YOREO J J. Mechanisms of classical crystal growth theory explain quartz and silicate dissolution behavior. Proceedings of the National Academy of Sciences of the United States of America, 2005, 102 (43): 15357-15362. |

| [92] |

GERYA T V, MARESCH W V, BURCHARD M, et al. Thermodynamic modeling of solubility and speciation of silica in H2O-SiO2 fluid up to 1300 ℃ and 20 kbar based on the chain reaction formalism. European Journal of Mineralogy, 2005, 17(2): 269-283.

DOI URL |

| [93] |

HACKLEY V A, PAIK U, KIM B H, et al. Aqueous processing of sintered reaction-bonded silicon nitride.1. Dispersion properties of silicon powder. Journal of the American Ceramic Society, 1997, 80(7): 1781-1788.

DOI URL |

| [94] |

HIRAYAMA H, KAWAKUBO T, GOTO A, et al. Corrosion behavior of silicon carbide in 290 ℃ water. Journal of the American Ceramic Society, 1989, 72(11): 2049-2053.

DOI URL |

| [95] |

JACOBSON N S, GOTOTSI Y G, YOSHIMURA M. Thermodynamic and experimental study of carbon formation on carbides under hydrothermal conditions. Journal of Materials Chemistry, 1995, 5(4): 595-601.

DOI URL |

| [96] |

TERRANI K A, YANG Y, KIM Y J, et al. Hydrothermal corrosion of SiC in LWR coolant environments in the absence of irradiation. Journal of Nuclear Materials, 2015, 465: 488-498.

DOI URL |

| [97] |

KIM D, LEE H J, JANG C, et al. Influence of microstructure on hydrothermal corrosion of chemically vapor processed SiC composite tubes. Journal of Nuclear Materials, 2017, 492: 6-13.

DOI URL |

| [98] |

KIM W J, HWANG H S, PARK J Y. Corrosion behavior of reaction-bonded silicon carbide ceramics in high-temperature water. Journal of Materials Science Letters, 2002, 21(9): 733-735.

DOI URL |

| [99] |

KIM W J, HWANG H S, PARK J Y, et al. Corrosion behaviors of sintered and chemically vapor deposited silicon carbide ceramics in water at 360 ℃. Journal of Materials Science Letters, 2003, 22(8): 581-584.

DOI URL |

| [100] |

KIM D, LEE H G, PARK Y, et al. Effect of dissolved hydrogen on the corrosion behavior of chemically vapor deposited SiC in a simulated pressurized water reactor environment. Corrosion Science, 2015, 98: 304-309.

DOI URL |

| [101] |

TAN L, ALLEN T R, BARRINGER E. Effect of microstructure on the corrosion of CVD-SiC exposed to supercritical water. Journal of Nuclear Materials, 2009, 394 (1): 95-101.

DOI URL |

| [102] |

SHIN J H, KIM D, LEE H G, et al. Factors affecting the hydrothermal corrosion behavior of chemically vapor deposited silicon carbides. Journal of Nuclear Materials, 2019, 518: 350-356.

DOI URL |

| [103] | HALLSTADIUS L, JOHNSON S, LAHODA E. Cladding for high performance fuel. Progress in Nuclear Energy, 2012, 57: 71-76. |

| [104] |

KIM D, LEE H G, PARK J Y, et al. Fabrication and measurement of hoop strength of SiC triplex tube for nuclear fuel cladding applications. Journal of Nuclear Materials, 2015, 458: 29-36.

DOI URL |

| [105] | QIN Y M, LI X Q, LIU C X, et al. Effect of deposition temperature on the corrosion behavior of CVD SiC coatings on SiCf/SiC composites under simulated PWR conditions. Corrosion Science, 2021, 181: 13. |

| [106] |

YANG H, LI X Q, LIU C X, et al. Hydrothermal corrosion behavior of SiCf/SiC composites candidate for PWR accident tolerant fuel cladding. Ceramics International, 2018, 44(18): 22865-22873.

DOI URL |

| [107] |

PARK J Y, KIM I H, JUNG Y I, et al. Long-term corrosion behavior of CVD SiC in 360 ℃ water and 400 ℃ steam. Journal of Nuclear Materials, 2013, 443(1/2/3): 603-607.

DOI URL |

| [108] | DOYLE P J, KOYANAGI T, ANG C, et al. Evaluation of the effects of neutron irradiation on first-generation corrosion mitigation coatings on SiC for accident-tolerant fuel cladding. Journal of Nuclear Materials, 2020, 536: 152203. |

| [109] | XI J Q, LIU C, MORGAN D, et al. An unexpected role of H during SiC corrosion in water. Journal of Physical Chemistry C, 2020, 124(17): 9394-9400. |

| [110] |

KONDO S, LEE M, HINOKI T, et al. Effect of irradiation damage on hydrothermal corrosion of SiC. Journal of Nuclear Materials, 2015, 464: 36-42.

DOI URL |

| [111] |

KONDO S, MOURI S, HYODO Y, et al. Role of irradiation- induced defects on SiC dissolution in hot water. Corrosion Science, 2016, 112: 402-407.

DOI URL |

| [112] |

LIU G L, LI Y P, HE Z B, et al. Investigation of microstructure and nanoindentation hardness of C+ & He+ irradiated nanocrystal sic coatings during annealing and corrosion. Materials (Basel), 2020, 13(23): 5567.

DOI URL |

| [113] | SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling. Journal of Nuclear Materials, 2007, 371(1/2/3): 329-377. |

| [114] | LIN Y R, CHEN L G, HSIEH C Y, et al. Atomic configuration of point defect clusters in ion-irradiated silicon carbide. Scientific Reports, 2017, 7: 14635. |

| [115] |

MAEDA Y, FUKAMI K, KONDO S, et al. Irradiation-induced point defects enhance the electrochemical activity of 3C-SiC: an origin of SiC corrosion. Electrochemistry Communications, 2018, 91: 15-18.

DOI URL |

| [116] | MOUCHE P A, ANG C, KOYANAGI T, et al. Characterization of PVD Cr, CrN, and TiN coatings on SiC. Journal of Nuclear Materials, 2019, 527: 151781. |

| [117] | RAIMAN S S, ANG C, DOYLE P, et al. Hydrothermal corrosion of SiC materials for accident tolerant fuel cladding with and without mitigation coatings. 18th International Conference on Environmental Degradation of Materials in Nuclear Power Systems - Water Reactors, 2017: 259-267. |

| [118] |

WAGIH M, SPENCER B, HALES J, et al. Fuel performance of chromium-coated zirconium alloy and silicon carbide accident tolerant fuel claddings. Annals of Nuclear Energy, 2018, 120: 304-318.

DOI URL |

| [119] | ISHIBASHI R, ISHIDA K, KONDO T, et al. Corrosion-resistant metallic coating on silicon carbide for use in high-temperature water. Journal of Nuclear Materials, 2021, 557: 153214. |

| [120] | DOYLE P J, ANG C, SNEAD L, et al. Hydrothermal corrosion of first-generation dual-purpose coatings on silicon carbide for accident- tolerant fuel cladding. Journal of Nuclear Materials, 2021, 544: 152695. |

| [121] |

HE Z, LI C, SI X, et al. Wetting of Si-14Ti alloy on SiCf/SiC and C/C composites and their brazed joint at high temperatures. Ceramics International, 2021, 47(10): 13845-13852.

DOI URL |

| [122] |

HE Z, SUN L, LI C, et al. Wetting and brazing of Cf/C composites with Si-Zr eutectic alloys: the formation of nano- and coarse-SiC reaction layers. Carbon, 2020, 167: 92-103.

DOI URL |

| [123] |

LUO Z, JIANG D, ZHANG J, et al. Development of SiC-SiC joint by reaction bonding method using SiC/C tapes as the interlayer. Journal of the European Ceramic Society, 2012, 32(14): 3819-3824.

DOI URL |

| [124] |

DENG J, LU B, HU K, et al. Thermodynamics equilibrium analysis on the chemical vapor deposition of HfC as coatings for ceramic matrix composites with HfClx(x=2-4)-CyHz(CH4, C2H4 and C3H6)-H2-Ar system. Advanced Composites and Hybrid Materials, 2018, 2 (1): 102-114.

DOI URL |

| [125] |

LI J, LIU L, WU Y, et al. A high temperature Ti-Si eutectic braze for joining SiC. Materials Letters, 2008, 62(17/18): 3135-3138.

DOI URL |

| [126] |

DONG H, LI S, TENG Y, et al. Joining of SiC ceramic-based materials with ternary carbide Ti3SiC2. Materials Science and Engineering: B, 2011, 176(1): 60-64.

DOI URL |

| [127] |

DONG H, YU Y, JIN X, et al. Microstructure and mechanical properties of SiC-SiC joints joined by spark plasma sintering. Ceramics International, 2016, 42(13): 14463-14468.

DOI URL |

| [128] |

SINGH M, MATSUNAGA T, LIN H T, et al. Microstructure and mechanical properties of joints in sintered SiC fiber-bonded ceramics brazed with Ag-Cu-Ti alloy. Materials Science and Engineering: A, 2012, 557: 69-76.

DOI URL |

| [129] |

GRASSO S, TATARKO P, RIZZO S, et al. Joining of β-SiC by spark plasma sintering. Journal of the European Ceramic Society, 2014, 34(7): 1681-1686.

DOI URL |

| [130] |

RIZZO S, GRASSO S, SALVO M, et al. Joining of C/SiC composites by spark plasma sintering technique. Journal of the European Ceramic Society, 2014, 34(4): 903-913.

DOI URL |

| [131] |

FERRARIS M, SALVO M, CASALEGNO V, et al. Joining of SiC-based materials for nuclear energy applications. Journal of Nuclear Materials, 2011, 417(1/2/3): 379-382.

DOI URL |

| [132] |

FERRARIS M, CASALEGNO V, RIZZO S, et al. Effects of neutron irradiation on glass ceramics as pressure-less joining materials for SiC based components for nuclear applications. Journal of Nuclear Materials, 2012, 429(1/2/3): 166-172.

DOI URL |

| [133] | SINGH M. Joining of sintered silicon carbide ceramics for high- temperature applications. Journal of Materials Science Letters, 1998, 17(6): 459-461. |

| [134] |

SINGH M. A reaction forming method for joining of silicon carbide-based ceramics. Scripta Materialia, 1997, 37(8): 1151-1154.

DOI URL |

| [135] |

LEWINSOHN C A, JONES R H, COLOMBO P, et al. Silicon carbide-based materials for joining silicon carbide composites for fusion energy applications. Journal of Nuclear Materials, 2002, 307-311: 1232-1236.

DOI URL |

| [136] |

JEONG D H, SEPTIADI A, FITRIANI P, et al. Joining of SiCf/ SiC using polycarbosilane and polysilazane preceramic mixtures. Ceramics International, 2018, 44(9): 10443-10450.

DOI URL |

| [137] |

KATOH Y, SNEAD L L, CHENG T, et al. Radiation-tolerant joining technologies for silicon carbide ceramics and composites. Journal of Nuclear Materials, 2014, 448(1/2/3): 497-511.

DOI URL |

| [138] |

JUNG H C, PARK Y H, PARK J S, et al. R&D of joining technology for SiC components with channel. Journal of Nuclear Materials, 2009, 386-388: 847-851.

DOI URL |

| [139] |

COLOMBO P, RICCARDI B, DONATO A, et al. Joining of SiC/SiCf ceramic matrix composites for fusion reactor blanket applications. Journal of Nuclear Materials, 2000, 278(2/3): 127-135.

DOI URL |

| [140] |

FERRARIS M, SALVO M, CASALEGNO V, et al. Joining of machined SiC/SiC composites for thermonuclear fusion reactors. Journal of Nuclear Materials, 2008, 375(3): 410-415.

DOI URL |

| [141] |

FAN S, LIU J, MA X, et al. Microstructure and properties of SiCf/SiC joint brazed by Y-Al-Si-O glass. Ceramics International, 2018, 44(7): 8656-8663.

DOI URL |

| [142] |

WANG L, FAN S, SUN H, et al. Pressure-less joining of SiCf/SiC composites by Y2O3-Al2O3-SiO2 glass: microstructure and properties. Ceramics International, 2020, 46(17): 27046-27056.

DOI URL |

| [143] |

WANG L, FAN S, YANG S, et al. Microstructure and properties of SiCf/SiC composite joints with CaO-Y2O3-Al2O3-SiO2 interlayer. Ceramics International, 2021, 47(12): 16603-16613.

DOI URL |

| [144] |

TATARKO P, CASALEGNO V, HU C, et al. Joining of CVD-SiC coated and uncoated fibre reinforced ceramic matrix composites with pre-sintered Ti3SiC2 MAX phase using spark plasma sintering. Journal of the European Ceramic Society, 2016, 36(16): 3957-3967.

DOI URL |

| [145] |

TATARKO P, CHLUP Z, MAHAJAN A, et al. High temperature properties of the monolithic CVD β-SiC materials joined with a pre-sintered MAX phase Ti3SiC2 interlayer via solid-state diffusion bonding. Journal of the European Ceramic Society, 2017, 37(4): 1205-1216.

DOI URL |

| [146] |

FITRIANI P, SEPTIADI A, HYUK J D, et al. Joining of SiC monoliths using a thin MAX phase tape and the elimination of joining layer by solid-state diffusion. Journal of the European Ceramic Society, 2018, 38(10): 3433-3440.

DOI URL |

| [147] |

ZHOU X, YANG H, CHEN F, et al. Joining of carbon fiber reinforced carbon composites with Ti3SiC2 tape film by electric field assisted sintering technique. Carbon, 2016, 102: 106-115.

DOI URL |

| [148] |

ZHOU X, HAN Y H, SHEN X, et al. Fast joining SiC ceramics with Ti3SiC2 tape film by electric field-assisted sintering technology. Journal of Nuclear Materials, 2015, 466: 322-327.

DOI URL |

| [149] |

ZHOU X, LI Y, LI Y, et al. Residual thermal stress of SiC/Ti3SiC2/ SiC joints calculation and relaxed by post-annealing. International Journal of Applied Ceramic Technology, 2018, 15(5): 1157-1165.

DOI URL |

| [150] |

ZHOU X, LIU Z, LI Y, et al. SiC ceramics joined with an in-situ reaction gradient layer of TiC/Ti3SiC2 and interface stress distribution simulations. Ceramics International, 2018, 44(13): 15785-15794.

DOI URL |

| [151] |

SEPTIADI A, FITRIANI P, SHARMA A S, et al. Low pressure joining of SiCf/SiC composites using Ti3AlC2 or Ti3SiC2 MAX phase tape. Journal of the Korean Ceramic Society, 2017, 54(4): 340-348.

DOI URL |

| [152] |

FITRIANI P, KWON H, ZHOU X, et al. Joining of SiCf/SiC using a layered Ti3SiC2-SiCw and TiC gradient filler. Journal of the European Ceramic Society, 2020, 40(4): 1043-1051.

DOI URL |

| [153] |

FITRIANI P, YOON D H. Joining of SiCf/SiC using a Ti3AlC2 filler and subsequent elimination of the joining layer. Ceramics International, 2018, 44(18): 22943-22949.

DOI URL |

| [154] |

YANG H, ZHOU X, SHI W, et al. Thickness-dependent phase evolution and bonding strength of SiC ceramics joints with active Ti interlayer. Journal of the European Ceramic Society, 2017, 37(4): 1233-1241.

DOI URL |

| [155] |

ZHOU X, LIU J, ZOU S, et al. Almost seamless joining of SiC using an in-situ reaction transition phase of Y3Si2C2. Journal of the European Ceramic Society, 2020, 40(2): 259-266.

DOI URL |

| [156] |

WAN P, LI M, XU K, et al. Seamless joining of silicon carbide ceramics through an sacrificial interlayer of Dy3Si2C2. Journal of the European Ceramic Society, 2019, 39(16): 5457-5462.

DOI URL |

| [157] |

SHI L K, ZHOU X, XU K, et al. Low temperature seamless joining of SiC using a ytterbium film. Journal of the European Ceramic Society, 2021, 41(15): 7507-7515.

DOI URL |

| [158] |

ZHANG Z, DUAN X, JIA D, et al. On the formation mechanisms and properties of MAX phases: a review. Journal of the European Ceramic Society, 2021, 41(7): 3851-3878.

DOI URL |

| [159] |

ZHOU X, JING L, KWON Y D, et al. Fabrication of SiCw/Ti3SiC2 composites with improved thermal conductivity and mechanical properties using spark plasma sintering. Journal of Advanced Ceramics, 2020, 9(4): 462-470.

DOI URL |

| [160] |

ZHANG H B, HU C F, SATO K, et al. Tailoring Ti3AlC2 ceramic with high anisotropic physical and mechanical properties. Journal of the European Ceramic Society, 2015, 35(1): 393-397.

DOI URL |

| [161] |

BAI Y, HE X, ZHU C, et al. Microstructures, electrical, thermal, and mechanical properties of bulk Ti2AlC synthesized by self- propagating high-temperature combustion synthesis with Pseudo Hot Isostatic Pressing. Journal of the American Ceramic Society, 2012, 95(1): 358-364.

DOI URL |

| [162] |

HU C, SAKKA Y, NISHIMURA T, et al. Physical and mechanical properties of highly textured polycrystalline Nb4AlC3 ceramic. Sci. Technol. Adv. Mater., 2011, 12(4): 044603.

DOI URL |

| [163] |

BARSOUM M W. The MN+1AXN phases: a new class of solids: thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000, 28(1-4): 201-281.

DOI URL |

| [164] |

SUN Z M. Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2011, 56(3): 143-166.

DOI URL |

| [165] |

EL-RAGHY T, ZAVALIANGOS A, BARSOUM M W, et al. Damage mechanisms around hardness indentations in Ti3SiC2. Journal of the American Ceramic Society, 1997, 80(2): 513-516.

DOI URL |

| [166] |

TALLMAN D J, HE L, GARCIA-DIAZ B L, et al. Effect of neutron irradiation on defect evolution in Ti3SiC2 and Ti2AlC. Journal of Nuclear Materials, 2016, 468: 194-206.

DOI URL |

| [167] |

YANG T, WANG C, TAYLOR C A, et al. The structural transitions of Ti3AlC2 induced by ion irradiation. Acta Materialia, 2014, 65: 351-359.

DOI URL |

| [168] |

WANG C, YANG T, KONG S, et al. Effects of He irradiation on Ti3AlC2: damage evolution and behavior of He bubbles. Journal of Nuclear Materials, 2013, 440(1/2/3): 606-611.

DOI URL |

| [169] |

SNEAD L L, SCHOLZ R, HASEGAWA A, et al. Experimental simulation of the effect of transmuted helium on the mechanical properties of silicon carbide. Journal of Nuclear Materials, 2002, 307-311: 1141-1145.

DOI URL |

| [170] |

CHEN J, JUNG P, TRINKAUS H. Evolution of Helium platelets and associated dislocation loops in α-SiC. Physical Review Letters, 1999, 82(13): 2709-2712.

DOI URL |

| [171] |

GREGORY R B, WETTEROTH T A, WILSON S R, et al. Effects of irradiation temperature and dose on exfoliation of H+-implanted silicon carbide. Applied Physics Letters, 1999, 75(17): 2623-2625.

DOI URL |

| [172] | HOJOU K, FURUNO S, KUSHITA K N, et al. EELS analysis of SiC crystals under hydrogen and helium dual-ion beam irradiation. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 1998, 141(1-4): 148-153. |

| [173] |

MIWA S, HASEGAWA A, TAGUCHI T, et al. Cavity formation in a SiC/SiC composite under simultaneous irradiation of hydrogen, helium and silicon ions. Materials Transactions, 2005, 46(3): 536-542.

DOI URL |

| [174] |

UDAYAKUMAR A, SRI GANESH A, RAJA S, et al. Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI. Journal of the European Ceramic Society, 2011, 31(6): 1145-1153.

DOI URL |

| [175] |

BUET E, SAUDER C, SORNIN D, et al. Influence of surface fibre properties and textural organization of a pyrocarbon interphase on the interfacial shear stress of SiC/SiC minicomposites reinforced with Hi-Nicalon S and Tyranno SA3 fibres. Journal of the European Ceramic Society, 2014, 34(2): 179-188.

DOI URL |

| [176] |

REBILLAT F, LAMON J, NASLAIN R, et al. Interfacial bond strength in SiC/C/SiC composite materials, as studied by single- fiber push-out tests. Journal of the American Ceramic Society, 1998, 81(4): 965-978.

DOI URL |

| [177] |

YU H, ZHOU X, ZHANG W, et al. Mechanical behavior of SiCf/ SiC composites with alternating PyC/SiC multilayer interphases. Materials & Design, 2013, 44: 320-324.

DOI URL |

| [178] |

YANG L W, LIU H T, CHENG H F. Processing-temperature dependent micro- and macro-mechanical properties of SiC fiber reinforced SiC matrix composites. Composites Part B: Engineering, 2017, 129: 152-161.

DOI URL |

| [179] |

LIU H T, YANG L W, SUN X, et al. Enhancing the fracture resistance of carbon fiber reinforced SiC matrix composites by interface modification through a simple fiber heat-treatment process. Carbon, 2016, 109: 435-443.

DOI URL |

| [180] |

YANG L W, LIU H T, JIANG R, et al. Weak interface dominated high temperature fracture strength of carbon fiber reinforced mullite matrix composites. Journal of the European Ceramic Society, 2017, 37(8): 2991-2996.

DOI URL |

| [181] |

LIU H T, YANG L W, HAN S, et al. Interface controlled micro- and macro-mechanical properties of aluminosilicate fiber reinforced SiC matrix composites. Journal of the European Ceramic Society, 2017, 37(3): 883-890.

DOI URL |

| [182] |

YANG L W, WANG J Y, LIU H T, et al. Sol-Gel temperature dependent ductile-to-brittle transition of aluminosilicate fiber reinforced silica matrix composite. Composites Part B: Engineering, 2017, 119: 79-89.

DOI URL |

| [183] |

JIANG R, YANG L, LIU H, et al. A multiscale methodology quantifying the sintering temperature-dependent mechanical properties of oxide matrix composites. Journal of the American Ceramic Society, 2018, 101(7): 3168-3180.

DOI URL |

| [1] | 丁玲, 蒋瑞, 唐子龙, 杨运琼. MXene材料的纳米工程及其作为超级电容器电极材料的研究进展[J]. 无机材料学报, 2023, 38(6): 619-633. |

| [2] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [3] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [4] | 林俊良, 王占杰. 铁电超晶格的研究进展[J]. 无机材料学报, 2023, 38(6): 606-618. |

| [5] | 牛嘉雪, 孙思, 柳鹏飞, 张晓东, 穆晓宇. 铜基纳米酶的特性及其生物医学应用[J]. 无机材料学报, 2023, 38(5): 489-502. |

| [6] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [7] | 马晓森, 张丽晨, 刘砚超, 汪全华, 郑家军, 李瑞丰. 13X@SiO2合成及其甲苯吸附性能[J]. 无机材料学报, 2023, 38(5): 537-543. |

| [8] | 张硕, 付前刚, 张佩, 费杰, 李伟. C/C多孔体的高温热处理对C/C-SiC复合材料摩擦磨损行为的影响[J]. 无机材料学报, 2023, 38(5): 561-568. |

| [9] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [10] | 杨洋, 崔航源, 祝影, 万昌锦, 万青. 柔性神经形态晶体管研究进展[J]. 无机材料学报, 2023, 38(4): 367-377. |

| [11] | 游钧淇, 李策, 杨栋梁, 孙林锋. 氧化物双介质层忆阻器的设计及应用[J]. 无机材料学报, 2023, 38(4): 387-398. |

| [12] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [13] | 陈昆峰, 胡乾宇, 刘锋, 薛冬峰. 多尺度晶体材料的原位表征技术与计算模拟研究进展[J]. 无机材料学报, 2023, 38(3): 256-269. |

| [14] | 张超逸, 唐慧丽, 李宪珂, 王庆国, 罗平, 吴锋, 张晨波, 薛艳艳, 徐军, 韩建峰, 逯占文. 新型GaN与ZnO衬底ScAlMgO4晶体的研究进展[J]. 无机材料学报, 2023, 38(3): 228-242. |

| [15] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||