无机材料学报 ›› 2022, Vol. 37 ›› Issue (8): 903-910.DOI: 10.15541/jim20220115

韦婷婷( ), 徐华蕊(

), 徐华蕊( ), 朱归胜, 龙神峰, 张秀云, 赵昀云, 江旭鹏, 宋金杰, 郭宁杰, 龚祎鹏

), 朱归胜, 龙神峰, 张秀云, 赵昀云, 江旭鹏, 宋金杰, 郭宁杰, 龚祎鹏

收稿日期:2022-03-04

修回日期:2022-04-12

出版日期:2022-08-20

网络出版日期:2022-04-26

通讯作者:

徐华蕊, 教授. E-mail: huaruixu@guet.edu.cn作者简介:韦婷婷(1995-), 女, 硕士研究生. E-mail: 631359334@QQ.com

基金资助:

WEI Tingting( ), XU Huarui(

), XU Huarui( ), ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng

), ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng

Received:2022-03-04

Revised:2022-04-12

Published:2022-08-20

Online:2022-04-26

Contact:

XU Huarui, professor. E-mail: huaruixu@guet.edu.cnAbout author:WEI Tingting(1995-), female, Master candidate. E-mail: 631359334@QQ.com

Supported by:摘要:

近年来, 冷烧结低温制备陶瓷引起了很大关注, 并在BaTiO3陶瓷的制备上取得了一定进展。为了提高冷烧结BaTiO3陶瓷性能, 本研究采用水热法制备了分散性好、粒径为100 nm的四方相(晶格参数c/a为1.0085) BaTiO3粉末。采用0.1 mol/L的乙酸在100 ℃/1 h的条件下对粉末进行水热活化处理。以质量分数10% Ba(OH)2·8H2O为熔剂, 在350 MPa、400 ℃/1 h的条件下对粉体进行冷烧结, 最后经600 ℃/0.5 h退火获得了相对密度为96.62%、晶粒尺寸为180 nm, 常温介电(εr)为2836, 介电损耗(tanδ)低至0.03的BaTiO3陶瓷。乙酸处理后高活性粉末表面形成的非晶钛层有效促进了陶瓷的致密化, 抑制了杂相的生成和晶粒长大, 提高了介电性能, 大幅改善了冷烧结BaTiO3陶瓷出现的介电弥散现象, 从而实现了BaTiO3陶瓷的低温冷烧结制备。

中图分类号:

韦婷婷, 徐华蕊, 朱归胜, 龙神峰, 张秀云, 赵昀云, 江旭鹏, 宋金杰, 郭宁杰, 龚祎鹏. BaTiO3陶瓷的低温冷烧结制备及性能研究[J]. 无机材料学报, 2022, 37(8): 903-910.

WEI Tingting, XU Huarui, ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng. Preparation and Properties of BaTiO3 Ceramics by Low Temperature Cold Sintering[J]. Journal of Inorganic Materials, 2022, 37(8): 903-910.

| Powder | D10/nm | D50/nm | D90/nm |

|---|---|---|---|

| A1 | 74 | 103 | 124 |

| A2 | 76 | 107 | 129 |

表1 粉体粒径分布数据

Table 1 Size distribution of powders

| Powder | D10/nm | D50/nm | D90/nm |

|---|---|---|---|

| A1 | 74 | 103 | 124 |

| A2 | 76 | 107 | 129 |

| Powder | Ba | Ti | O | C | Ba/Ti |

|---|---|---|---|---|---|

| A1 | 10.88 | 10.81 | 39.81 | 38.45 | 1.0075 |

| A2 | 7.52 | 13.47 | 39.14 | 39.87 | 0.5583 |

表2 粉末A1、A2表面各元素的相对原子比

Table 2 Relative atomic ratio of A1 and A2 powder surfaces

| Powder | Ba | Ti | O | C | Ba/Ti |

|---|---|---|---|---|---|

| A1 | 10.88 | 10.81 | 39.81 | 38.45 | 1.0075 |

| A2 | 7.52 | 13.47 | 39.14 | 39.87 | 0.5583 |

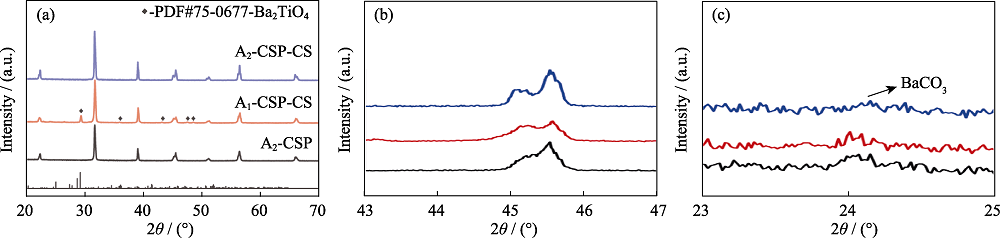

图5 BaTiO3陶瓷的XRD图谱

Fig. 5 XRD patterns of BaTiO3 ceramics (b, c) Local magnification XRD patterns in the range of 2θ=43°-47° and 21.5°-25°, respectively

| Process | Relative density | εr (1 kHz) | εr@Tc (1 kHz) | Tc (1 kHz) | tanδ |

|---|---|---|---|---|---|

| A2-CPS | 92.73% | 930 | 1413 | 128 ℃ | 0.08 |

| A1-CPS-CS | 95.78% | 2768 | 5813 | 124 ℃ | 0.06 |

| A2-CPS-CS | 96.62% | 2836 | 7274 | 123 ℃ | 0.03 |

表3 陶瓷的相对密度与介电性能

Table 3 Relative density and dielectric properties of ceramics

| Process | Relative density | εr (1 kHz) | εr@Tc (1 kHz) | Tc (1 kHz) | tanδ |

|---|---|---|---|---|---|

| A2-CPS | 92.73% | 930 | 1413 | 128 ℃ | 0.08 |

| A1-CPS-CS | 95.78% | 2768 | 5813 | 124 ℃ | 0.06 |

| A2-CPS-CS | 96.62% | 2836 | 7274 | 123 ℃ | 0.03 |

| Process | Flux (in mass) | Temperature/Pressure | Time/h | Density/% | εr(1 kHz) | tanδ (1 kHz) | Heat treatment | Ref. |

|---|---|---|---|---|---|---|---|---|

| CSP-CS | Ba(OH)2/TiO2 soultion | 180 ℃/430 MPa | 1-3 h | 95 | 1760 | 0.04 | 700-900 ℃/3 h | [ |

| CSP | NaOH-KOH | 300 ℃/520 MPa | 12 h | 98 | 1800 | 0.04 | - | [ |

| Surface coating/CSP-CS | H2O, Ba(OH)2 solution | 220 ℃/500 MPa | 1 h | 97 | 1550 | 0.02 | 700-900 ℃/3 h | [ |

| 1 mol/L acetic acid/powder-CSP | 20% Ba(OH)2∙8H2O | 225 ℃/350 MPa | 1 h | 95 | 1440 | 0.09 | - | [ |

| 1 mol/L acetic acid/powder-CSP | 11% Sr(OH)2∙8H2O | 275 ℃/350 MPa | 1 h | 92 | 1500 | 0.08 | - | [ |

| 0.1 mol/L acetic acid/powder-CSP | 10% Ba(OH)2∙8H2O | 400 ℃/350 MPa | 1 h | 96 | 2830 | 0.03 | 600 ℃/0.5 h | Thiswork |

表4 文献报道的BaTiO3陶瓷冷烧结性能对比

Table 4 Summary of cold sintering of BaTiO3 ceramics

| Process | Flux (in mass) | Temperature/Pressure | Time/h | Density/% | εr(1 kHz) | tanδ (1 kHz) | Heat treatment | Ref. |

|---|---|---|---|---|---|---|---|---|

| CSP-CS | Ba(OH)2/TiO2 soultion | 180 ℃/430 MPa | 1-3 h | 95 | 1760 | 0.04 | 700-900 ℃/3 h | [ |

| CSP | NaOH-KOH | 300 ℃/520 MPa | 12 h | 98 | 1800 | 0.04 | - | [ |

| Surface coating/CSP-CS | H2O, Ba(OH)2 solution | 220 ℃/500 MPa | 1 h | 97 | 1550 | 0.02 | 700-900 ℃/3 h | [ |

| 1 mol/L acetic acid/powder-CSP | 20% Ba(OH)2∙8H2O | 225 ℃/350 MPa | 1 h | 95 | 1440 | 0.09 | - | [ |

| 1 mol/L acetic acid/powder-CSP | 11% Sr(OH)2∙8H2O | 275 ℃/350 MPa | 1 h | 92 | 1500 | 0.08 | - | [ |

| 0.1 mol/L acetic acid/powder-CSP | 10% Ba(OH)2∙8H2O | 400 ℃/350 MPa | 1 h | 96 | 2830 | 0.03 | 600 ℃/0.5 h | Thiswork |

| [1] |

YANG H J, BAO W C, LU Z L, et al. High-energy storage performance in BaTiO3-based lead-free multilayer ceramic capacitors. Journal of Materials Research, 2021, 36(6): 1285-1294.

DOI URL |

| [2] |

ZHAO P Y, CAI Z M, WU L W, et al. Perspectives and challenges for lead-free energy-storage multilayer ceramic capacitors. Journal of Advanced Ceramics, 2021, 10(6): 1153-1193.

DOI URL |

| [3] |

IM T, PYO J, LEE J, et al. Fabrication of homogeneous nanosized nickel powders using a planetary ball mill: applications to multilayer ceramic capacitors (MLCCs). Powder Technology, 2021, 382(2021): 118-125.

DOI URL |

| [4] |

WANG M J, YANG H, ZHANG Q L, et al. Low temperature sintering properties of LiF-doped BaTiO3-based dielectric ceramics for AC MLCCs. Journal of Materials Science: Materials in Electronics, 2015, 26(1): 162-167.

DOI URL |

| [5] | WANG D W, ZHOU D, SONG K X, et al. Cold-sintered C0G multilayer ceramic capacitors. ACS Sustainable Chemistry, 2019, 5(7): 1900025. |

| [6] |

WANG D W, SIAME B, ZHANG S Y, et al. Direct integration of cold sintered, temperature-stable Bi2Mo2O9-K2MoO4 ceramics on printed circuit boards for satellite navigation antennas. Journal of the European Ceramic Society, 2020, 40(12): 4029-4034.

DOI URL |

| [7] | WANG D W, ZHOU D, ZHANG S Y, et al. Cold-sintered temperature stable Na0.5Bi0.5MoO4-Li2MoO4 microwave composite ceramics. ACS Sustainable Chemistry, 2018, 6(2): 2438-2444. |

| [8] |

HAO J Y, GUO J, ZHAO E, et al. Grain size effect on microwave dielectric properties of Na2WO4 ceramics prepared by cold sintering process. Ceramics International, 2020, 46(17): 27193-27198.

DOI URL |

| [9] |

YANG C, LI J P, SHI H F, et al. Effects of the liquid phase content on the microstructure and properties of the ZrW2O8 ceramics with negative thermal expansion fabricated by the cold sintering process. Journal of the European Ceramic Society, 2020, 40(15): 6079-6086.

DOI URL |

| [10] |

JIANG X P, ZHU G S, XU H R, et al. Preparation of high density ZnO ceramics by the Cold Sintering Process. Ceramics International, 2019, 45(14): 17382-17386.

DOI URL |

| [11] |

ZHAO E, HAO J Y, XUE X, et al. Rutile TiO2 microwave dielectric ceramics prepared via cold sintering assisted two step sintering. Journal of the European Ceramic Society, 2021, 41(6): 3459-3465.

DOI URL |

| [12] |

GUO H Z, BAKER A, GUO J, et al. Protocol for ultralow- temperature ceramic sintering: an integration of nanotechnology and the cold sintering process. ACS Nano, 2016, 10(11): 10606-10614.

DOI URL |

| [13] |

GUO H Z, BAKER A, GUO J, et al. Cold sintering process: a novel technique for low-temperature ceramic processing of ferroelectrics. Journal of the American Ceramic Society, 2016, 99(11): 3489-3507.

DOI URL |

| [14] |

TSUJI K, NDAYISHIMIYE A, LOWUM S, et al. Single step densification of high permittivity BaTiO3 ceramics at 300 ℃. Journal of the European Ceramic Society, 2020, 40(4): 1280-1284.

DOI URL |

| [15] |

SADA T, NDAYISHIMIYE A, FAN Z M, et al. Surface modification of BaTiO3 with catechol surfactant and effects on cold sintering. Journal of Applied Physics, 2021, 129(18): 184102.

DOI URL |

| [16] |

SADA T, TSUJI K, NDAYISHIMIYE A, et al. High permittivity BaTiO3 and BaTiO3-polymer nanocomposites enabled by cold sintering with a new transient chemistry: Ba(OH)2∙8H2O. Journal of the European Ceramic Society, 2021, 41(1): 409-417.

DOI URL |

| [17] |

SADA T, FAN Z M, NDAYISHIMIYE A, et al. In situ doping of BaTiO3 and visualization of pressure solution in flux-assisted cold sintering. Journal of the American Ceramic Society, 2021, 104(1): 96-104.

DOI URL |

| [18] |

WANG D X, GUO H Z, MORANDI C S, et al. Cold sintering and electrical characterization of lead zirconate titanate piezoelectric ceramics. APL Materials, 2018, 6(1): 016101.

DOI URL |

| [19] |

BOSTON R, GUO J, FUNAHASHI S, et al. Reactive intermediate phase cold sintering in strontium titanate. RSC Advances, 2018, 8(36): 20372-20378.

DOI URL |

| [20] |

USHER T M, KAVEY B, CARUNTU G, et al. Effect of BaCO3 impurities on the structure of BaTiO3 nanocrystals: implications for multilayer ceramic capacitors. ACS Applied Nano Materials, 2020, 3(10): 9715-9723.

DOI URL |

| [21] |

REDA G M, FAN H Q, TIAN H L. Room-temperature solid state synthesis of Co3O4/ZnO p-n heterostructure and its photocatalytic activity. Advanced Powder Technology, 2017, 28(3): 953-963.

DOI URL |

| [22] |

SIEMEK K, OLEJNICZAK A, KOROTKOV L N, et al. Investigation of surface defects in BaTiO3 nanopowders studied by XPS and positron annihilation lifetime spectroscopy. Applied Surface Science, 2022, 578(2022): 151807.

DOI URL |

| [23] |

HUNG C C, RIMAN R E. An XPS investigation of hydrothermal and commercial barium titanate powders. KONA Powder Particle Journal, 1990, 8(1990): 99-104.

DOI URL |

| [24] |

LIU G C, FAN H Q, XU J, et al. Colossal permittivity and impedance analysis of niobium and aluminum co-doped TiO2 ceramics. RSC Advances, 2016, 6(54): 48708-48714.

DOI URL |

| [25] |

KOTA R, LEE B. Effect of lattice hydroxyl on the phase transition and dielectric properties of barium titanate particles. Journal of Materials Science: Materials in Electronics, 2007, 18(12): 1221-1227.

DOI URL |

| [26] |

ZHENG Q, FAN H Q, LONG C B. Microstructures and electrical responses of pure and chromium-doped CaCu3Ti4O12 ceramics. Journal of Alloys and Compounds, 2012, 511(1): 90-94.

DOI URL |

| [27] |

BEAUGER A, MUTIN J C, NIEPCE J C. Role and behaviour of orthotitanate Ba2TiO4 during the processing of BaTiO3 based ferroelectric ceramics. Journal of Materials Science, 1984, 19(1): 195-201.

DOI URL |

| [28] |

LEE J K, HONG K S, JANG J W. Roles of Ba/Ti ratios in the dielectric properties of BaTiO3 ceramics. Journal of the American Ceramic Society, 2001, 84(9): 2001-2006.

DOI URL |

| [29] |

PINCELOUP P, COURTOIS C, LERICHE A, et al. Hydrothermal synthesis of nanometer-sized barium titanate powders: control of barium/titanium ratio, sintering, and dielectric properties. Journal of the American Ceramic Society, 1999, 82(11): 3049-3056.

DOI URL |

| [30] |

MARIA J P, KANG X Y, FLOYD R, et al. Cold sintering: current status and prospects. Journal of Materials Research, 2017, 32(17): 3205-3218.

DOI URL |

| [1] | 陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162. |

| [2] | 冯静静, 章游然, 马名生, 陆毅青, 刘志甫. 冷烧结技术的研究现状及发展趋势[J]. 无机材料学报, 2023, 38(2): 125-136. |

| [3] | 姚晓刚, 彭海益, 顾忠元, 何飞, 赵相毓, 林慧兴. 聚苯醚/钙镧钛微波复合基板[J]. 无机材料学报, 2022, 37(5): 493-498. |

| [4] | 叶芬, 江向平, 陈云婧, 黄枭坤, 曾仁芬, 陈超, 聂鑫, 成昊. (0.96NaNbO3-0.04CaZrO3)-xFe2O3反铁电陶瓷的介电及储能性能研究[J]. 无机材料学报, 2022, 37(5): 499-506. |

| [5] | 孙扬善, 杨治华, 蔡德龙, 张正义, 柳琪, 房树清, 冯良, 石丽芬, 王友乐, 贾德昌. 粉末烧结法制备α-堇青石基玻璃陶瓷的析晶动力学和性能[J]. 无机材料学报, 2022, 37(12): 1351-1357. |

| [6] | 张晓燕, 刘馨玥, 闫金华, 谷耀行, 齐西伟. 钙钛矿型(La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3高熵氧化物陶瓷的制备及性能研究[J]. 无机材料学报, 2021, 36(4): 379-385. |

| [7] | 王通,王渊浩,杨海波,高淑雅,王芬,鲁雅文. BaTiO3-ZnNb2O6陶瓷介电及储能性能研究[J]. 无机材料学报, 2020, 35(4): 431-438. |

| [8] | 简刚, 刘美瑞, 张晨, 邵辉. 用于高介电复合材料的全包裹Ag@TiO2填充颗粒的制备[J]. 无机材料学报, 2019, 34(6): 641-645. |

| [9] | 甘慧, 王传彬, 沈强, 张联盟. La2NiMnO6双钙钛矿陶瓷的等离子活化烧结[J]. 无机材料学报, 2019, 34(5): 541-545. |

| [10] | 黄龙, 丁士华, 张晓云, 严欣堪, 李超, 朱惠. Li2O-B2O3-SiO2玻璃相对BaAl2Si2O8结构及微波介电性能的影响[J]. 无机材料学报, 2019, 34(10): 1091-1096. |

| [11] | 韩林材, 丁士华, 宋天秀, 黄龙, 张晓云, 熊中. ZBAS对BaAl2Si2O8结构与微波介电性能的影响[J]. 无机材料学报, 2018, 33(8): 883-888. |

| [12] | 穆阳, 邓佳欣, 李皓, 周万城. 两种连续SiC纤维的高温介电及吸波性能对比[J]. 无机材料学报, 2018, 33(4): 427-433. |

| [13] | 屈婧婧, 魏星, 刘飞, 袁昌来, 陈国华, 黄先培. 热处理对Mg-Al-Si-Ti-B系微晶玻璃析晶及介电性能的影响[J]. 无机材料学报, 2018, 33(12): 1309-1315. |

| [14] | 刘 飞, 黄先培, 袁昌来, 陈国华. 烧结温度和CaTiO3添加对不稳定层状Can+1TinO3n+1 (n = 1)陶瓷体系结构与介电性能的影响[J]. 无机材料学报, 2017, 32(5): 489-494. |

| [15] | 屈婧婧, 魏 星, 宋小辉, 袁昌来, 刘 飞. B位(Mg1/3Ta2/3)4+置换对新型Sr基(Sr, Nd, Ca)TiO3微波陶瓷结构及介电性能的影响[J]. 无机材料学报, 2017, 32(3): 293-298. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||