无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 353-360.DOI: 10.15541/jim20210636

所属专题: 增材制造专题(2022)

• 研究快报 • 上一篇

刘国仟1( ), 闫长海1, 张可强2, 金华3, 何汝杰2(

), 闫长海1, 张可强2, 金华3, 何汝杰2( )

)

收稿日期:2021-10-17

修回日期:2021-11-09

出版日期:2022-03-20

网络出版日期:2021-12-24

通讯作者:

何汝杰, 副教授. E-mail: herujie@bit.edu.cn

作者简介:刘国仟(1980-), 男, 高级工程师. E-mail: 15201631565@163.com

LIU Guoqian1( ), YAN Changhai1, ZHANG Keqiang2, JIN Hua3, HE Rujie2(

), YAN Changhai1, ZHANG Keqiang2, JIN Hua3, HE Rujie2( )

)

Received:2021-10-17

Revised:2021-11-09

Published:2022-03-20

Online:2021-12-24

Contact:

HE Rujie, associate professor. E-mail: herujie@bit.edu.cn

About author:LIU Guoqian (1980-), male, senior engineer. E-mail: 15201631565@163.com

Supported by:摘要:

对于陶瓷立体光刻增材制造技术, 光敏树脂浆料的固含量发挥着重要的作用。本工作首先制备了不同固含量的Al2O3陶瓷浆料, 并采用立体光刻增材制造技术, 制备了Al2O3陶瓷, 并研究了Al2O3浆料的固含量与陶瓷性能的关联关系。其次, 探索了固含量对Al2O3浆料的流变行为、固化性能, 以及对Al2O3陶瓷的微观结构、力学性能的影响规律。结果表明, 随着固含量增加, 浆料的粘度和剪切应力均增大。在光固化增材制造过程中, 高固含量导致浆料的粘度高于其自流平的临界值, 且Al2O3浆料的固化性能与固含量高度相关。此外, 固含量明显影响光固化增材制造的Al2O3陶瓷的缺陷。这些制造缺陷对于Al2O3陶瓷的力学性能有重要影响。最后, 本工作总结了光敏Al2O3浆料的流变行为、固化性能与Al2O3陶瓷的微观结构和力学性能之间的关联关系。浆料的高粘度造成陶瓷的微观结构不均匀, 最终导致其力学强度较差。本研究结果可为陶瓷的光固化增材制造提供一定的参考。

中图分类号:

刘国仟, 闫长海, 张可强, 金华, 何汝杰. 立体光刻增材制造中固含量对Al2O3陶瓷性能的影响[J]. 无机材料学报, 2022, 37(3): 353-360.

LIU Guoqian, YAN Changhai, ZHANG Keqiang, JIN Hua, HE Rujie. Effect of Solid Loading on the Property of Al2O3 Ceramics in Stereolithographic Additive Manufacturing[J]. Journal of Inorganic Materials, 2022, 37(3): 353-360.

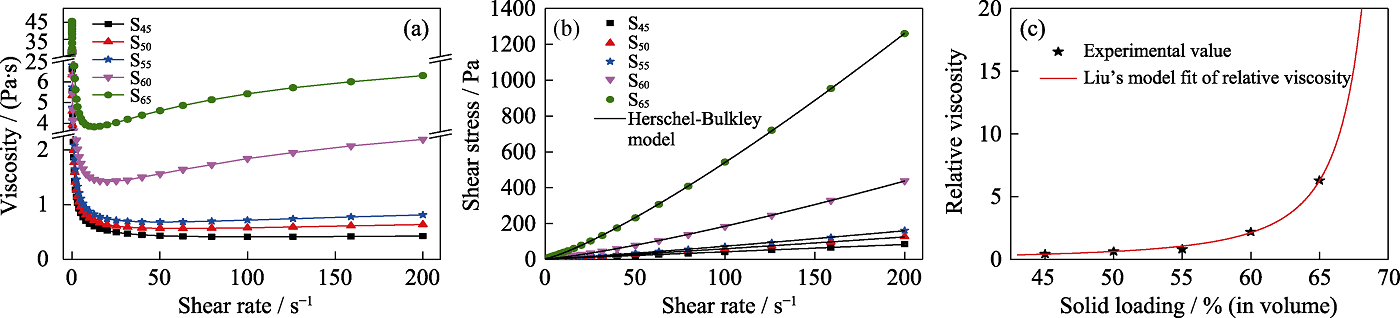

Fig. 2 (a) Apparent viscosity and (b) shear stress vs shear rate curves of photosensitive Al2O3 slurries with different solid loadings (c) relative viscosity dependence on solid loading at the shear rate of 200 s-1

| Solid loading /% (in volume) | τ0/Pa | K | n | R2 |

|---|---|---|---|---|

| 45 | 1.24243 | 0.41855 | 0.99596 | 0.99825 |

| 50 | 1.43614 | 0.37397 | 1.09476 | 0.99871 |

| 55 | 1.77148 | 0.37481 | 1.14081 | 0.99883 |

| 60 | 2.26134 | 0.57750 | 1.25022 | 0.99975 |

| 65 | 3.97074 | 1.87845 | 1.22798 | 0.99992 |

Table 1 Herschel-Bulkley model parameters of Al2O3 slurries

| Solid loading /% (in volume) | τ0/Pa | K | n | R2 |

|---|---|---|---|---|

| 45 | 1.24243 | 0.41855 | 0.99596 | 0.99825 |

| 50 | 1.43614 | 0.37397 | 1.09476 | 0.99871 |

| 55 | 1.77148 | 0.37481 | 1.14081 | 0.99883 |

| 60 | 2.26134 | 0.57750 | 1.25022 | 0.99975 |

| 65 | 3.97074 | 1.87845 | 1.22798 | 0.99992 |

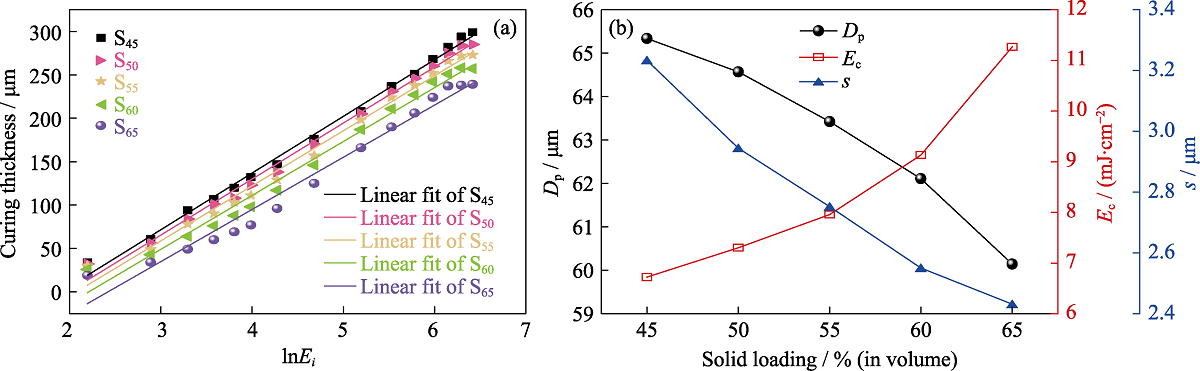

Fig. 6 (a) Curing thickness vs logarithm of input density of energy, (b) depth of penetration, critical density of energy and interparticle spacing vs solid loading for Al2O3 slurries

| [1] |

LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 2021, 116: 100736.

DOI URL |

| [2] | LI X B, ZHONG H, ZHANG J X, et al. Powder characteristics on the rheological performance of resin-based zirconia suspension for stereolithography. Journal of Inorganic Materials, 2020, 35(2): 231-235. |

| [3] |

HE C, MA C, LI X L, et al. Continuous fast 3D printing of SiOC ceramic components. Additive Manufacturing, 2021, 46: 102111.

DOI URL |

| [4] |

YANG L L, ZENG X J, DITTA A, et al. Preliminary 3D printing of large inclined-shaped alumina ceramic parts by direct ink writing. Journal of Advanced Ceramics, 2020, 9: 312-319.

DOI URL |

| [5] |

HU X A, ZHAO G L, LIU F C, et al. Microstructure and mechanical behavior of Inconel 625 alloy processed by selective laser melting at high temperature up to 1000 ℃. Rare Metal, 2020, 39: 1181-1189.

DOI URL |

| [6] |

CHEN F, ZHU H, WU J M, et al. Preparation and biological evaluation of ZrO2 all-ceramic teeth by DLP technology. Ceramics International, 2020, 46(8): 11268-11274.

DOI URL |

| [7] |

ZHANG K Q, XIE C, WANG G, et al. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceramics International, 2019, 45(1): 203-208.

DOI URL |

| [8] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [9] |

HE R J, ZHOU, N P, ZHANG K Q, et al. Progress and challenges towards additive manufacturing of SiC ceramic. Journal of Advanced Ceramics, 2021, 10(4): 637-674.

DOI URL |

| [10] |

SU B, DHARA S, WANG L. Green ceramic machining: a top- down approach for the rapid fabrication of complex-shaped ceramics. Journal of the European Ceramic Society, 2008, 28(11): 2109-2115.

DOI URL |

| [11] |

LI H, LIU Y S, LIU Y S, et al. Microstructure and mechanical properties of 3D printed ceramics with different vinyl acetate contents. Rare Metals, 2021, 40: 3241-3250.

DOI URL |

| [12] |

DING G J, HE R J, ZHANG K Q, et al. Dispersion and stability of SiC ceramic slurry for stereolithography. Ceramics International, 2020, 46(4): 4720-4729.

DOI URL |

| [13] |

LI K H, ZHAO Z. The effect of the surfactants on the formulation of UV-curable SLA alumina suspension. Ceramics International, 2017, 43(6): 4761-4767.

DOI URL |

| [14] |

NIE J B, LI M S, LIU W W, et al. The role of plasticizer in optimizing the rheological behavior of ceramic pastes intended for stereolithography-based additive manufacturing. Journal of the European Ceramic Society, 2021, 41(1): 646-654.

DOI URL |

| [15] |

AZARMI F, ALI A. Microstructural evolution during fabrication of alumina via laser stereolithography technique. Ceramics International, 2019, 45(1): 271-278.

DOI URL |

| [16] |

NDINISA S S, WHITEFIELD D J, SIGALAS I. Fabrication of complex shaped alumina parts by gelcasting on 3D printed moulds. Ceramics International, 2020, 46(3): 3177-3182.

DOI URL |

| [17] |

WEI J J, LI J L, SONG X X, et al. Effects of solid loading on the rheological behaviors and mechanical properties of injection- molded alumina ceramics. Journal of Alloys and Compounds, 2018, 768: 503-509.

DOI URL |

| [18] |

ZHANG K Q, HE R J, DING G J, et al. Digital light processing of 3Y-TZP strengthened ZrO2 ceramics. Material Science Engineering A, 2020, 774: 138768.

DOI URL |

| [19] | ISO 14704-2000. Fine Ceramics-Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature. |

| [20] |

HERSCHEL W H, BULKLEY R. Konsistenzmessungen von gummi-benzollosungen. Kolloid Zeitschrift, 1926, 39: 291-300.

DOI URL |

| [21] |

LEWIS J A. Colloidal processing of ceramics. Journal of the American Ceramic Society, 2000, 83: 2341-2359.

DOI URL |

| [22] |

LIU D M. Particle packing and rheological property of highly- concentrated ceramic suspensions: φm determination and viscosity prediction. Journal of Materials Science, 2000, 35(21): 5503-5507.

DOI URL |

| [23] |

CHARITIER T, CHAPUT C, DOREAU F, et al. Stereolithography of structural complex ceramic parts. Journal of Materials Science, 2002, 37: 3141-3147.

DOI URL |

| [24] |

ABOULIATIM Y, CHARTIER T, ABELARD P, et al. Optical characterization of stereolithography alumina suspensions using the Kubelka-Munk model. Journal of the European Ceramic Society, 2009, 29(5): 919-924.

DOI URL |

| [25] |

GRIFFITH M L, HALLORAN J W. Freeform fabrication of ceramics via stereolithography. Journal of the American Ceramic Society, 1996, 79: 2601-2608.

DOI URL |

| [26] | DIENER S, FRANCHIN G, ACHILLES N, et al. X-ray microtomography investigations on the residual pore structure in silicon nitride bars manufactured by Direct Ink Writing using different printing patterns. Open Ceramic, 2021, 5: 100042. |

| [27] |

ZHANG K Q, MENG Q Y, CAI N J, et al. Effects of solid loading on stereolithographic additive manufactured ZrO2 ceramic: a quantitative defect study by X-ray computed tomography. Ceramics International, 2021, 47(17): 24353-24359.

DOI URL |

| [28] |

ZHANG K Q, HE R J, DING G J, et al. Effects of fine grains and sintering additives on stereolithography additive manufactured Al2O3 ceramic. Ceramics International, 2021, 47(1): 2303-2310.

DOI URL |

| [1] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [2] | 南博, 臧佳栋, 陆文龙, 杨廷旺, 张升伟, 张海波. 增材制造压电陶瓷研究进展[J]. 无机材料学报, 2022, 37(6): 585-595. |

| [3] | 曹继伟, 王沛, 刘志远, 刘长勇, 吴甲民, 陈张伟. 基于粉末成形的激光增材制造陶瓷技术研究进展[J]. 无机材料学报, 2022, 37(3): 241-254. |

| [4] | 刘海方, 苏海军, 申仲琳, 姜浩, 赵迪, 刘园, 张军, 刘林, 傅恒志. 激光增材制造超高温氧化物共晶陶瓷研究进展[J]. 无机材料学报, 2022, 37(3): 255-266. |

| [5] | 杨勇, 郭啸天, 唐杰, 常浩天, 黄政仁, 胡秀兰. 非氧化物陶瓷光固化增材制造研究进展及展望[J]. 无机材料学报, 2022, 37(3): 267-277. |

| [6] | 刘凯, 孙策, 史玉升, 胡佳明, 张庆庆, 孙云飞, 章嵩, 涂溶, 闫春泽, 陈张伟, 黄尚宇, 孙华君. 增材制造压电陶瓷的现状与展望[J]. 无机材料学报, 2022, 37(3): 278-288. |

| [7] | 周港怀, 刘耀, 石原, 刘绍军. 活性氧化铝催化剂载体的光固化浆料制备与成型[J]. 无机材料学报, 2022, 37(3): 297-302. |

| [8] | 王亚宁, 张玉琪, 宋索成, 陈若梦, 刘亚雄, 段玉岗. 氧化锆陶瓷扫描光固化成形与脱脂烧结工艺研究[J]. 无机材料学报, 2022, 37(3): 303-309. |

| [9] | 朱俊逸, 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟. 脱脂工艺对光固化3D打印堇青石陶瓷性能的影响[J]. 无机材料学报, 2022, 37(3): 317-324. |

| [10] | 李乔磊, 顾玥, 于雪华, 张朝威, 邹明科, 梁静静, 李金国. 烧结温度对3D打印硅基陶瓷型芯表面形貌及粗糙度的影响[J]. 无机材料学报, 2022, 37(3): 325-332. |

| [11] | 祝泉, 胡建宝, 杨金山, 周海军, 董绍明. 采用定向SiC纳米线烧结制备高强多孔SiC陶瓷[J]. 无机材料学报, 2021, 36(5): 547-551. |

| [12] | 李兴邦,仲鹤,张景贤,段于森,江东亮. 粉体性质对树脂基氧化锆光固化浆料流变行为的影响[J]. 无机材料学报, 2020, 35(2): 231-235. |

| [13] | 吴 霜, 刘 波, 陈士伟, 张娟楠, 刘小林, 顾 牡, 黄世明, 倪 晨, 薛超凡. Lu2SiO5: Ce3+透明薄膜制备及其发光性能研究[J]. 无机材料学报, 2016, 31(9): 948-954. |

| [14] | 吴 霜, 刘 波, 邱志澈, 陈士伟, 张娟楠, 刘小林, 顾 牡, 黄世明, 倪 晨. LuTaO4:Ln3+(Ln=Eu,Tb)透明薄膜制备改进与其发光性能研究[J]. 无机材料学报, 2016, 31(4): 372-376. |

| [15] | 孙竞博,李 勃,黄学光,蔡坤鹏,周 济,李龙土. 基于光敏浆料的直写精细无模三维成型[J]. 无机材料学报, 2009, 24(6): 1147-1150. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||