无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 317-324.DOI: 10.15541/jim20210624

所属专题: 增材制造专题(2022); 【虚拟专辑】增材制造及3D打印(2021-2022)

朱俊逸( ), 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟(

), 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟( )

)

收稿日期:2021-10-08

修回日期:2021-10-21

出版日期:2022-03-20

网络出版日期:2021-11-01

通讯作者:

陈张伟, 教授. E-mail: chen@szu.edu.cn

作者简介:朱俊逸(1996-), 男, 硕士研究生. E-mail: 386398374@qq.com

基金资助:

ZHU Junyi( ), ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei(

), ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei( )

)

Received:2021-10-08

Revised:2021-10-21

Published:2022-03-20

Online:2021-11-01

Contact:

CHEN Zhangwei, professor. E-mail: chen@szu.edu.cn

About author:ZHU Junyi (1996-), male, Master candidate. E-mail: 386398374@qq.com

Supported by:摘要:

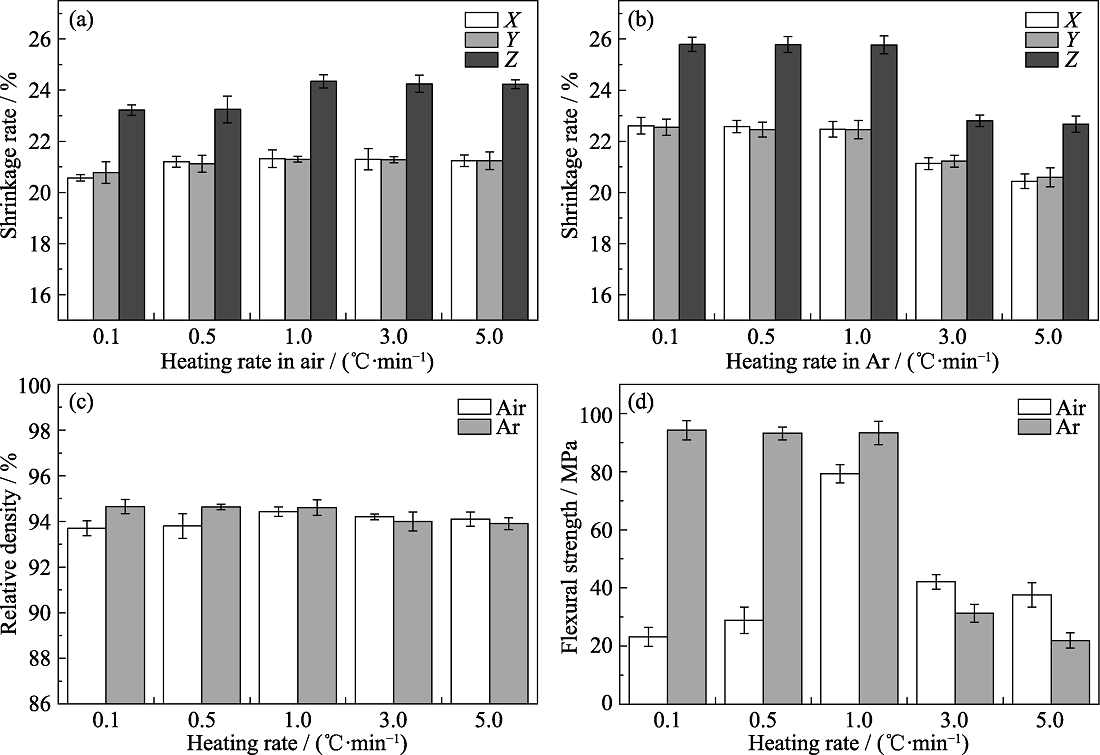

光固化3D打印是制造高度复杂结构陶瓷的一种有效方法。打印的样件需要经历脱脂和烧结等热处理才能成为可用的陶瓷件, 脱脂工艺对打印件性能影响巨大。本工作通过研究脱脂工艺对DLP光固化3D打印制备的堇青石陶瓷性能的影响规律, 建立缺陷抑制策略。比较并分析了脱脂气氛和升温速率对陶瓷样件的表面裂纹和元素分布状态的影响, 还对比进一步烧结后样件显微组织、尺寸收缩率、相对密度和弯曲强度等性能。研究发现脱脂气氛对样件各性能影响最大, 使用氩气脱脂可显著降低表面裂纹, 提高相对密度与弯曲强度; 并确定最佳升温速率为1 ℃/min。最终获得表面完整无裂纹且相对密度为(94.6±0.3)%, 弯曲强度为(94.3±3.2) MPa的堇青石陶瓷样件。本研究为光固化3D打印堇青石陶瓷的无缺陷制造与应用提供了科学依据与技术参考。

中图分类号:

朱俊逸, 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟. 脱脂工艺对光固化3D打印堇青石陶瓷性能的影响[J]. 无机材料学报, 2022, 37(3): 317-324.

ZHU Junyi, ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei. Influence of Debinding Process on the Properties of Photopolymerization 3D Printed Cordierite Ceramics[J]. Journal of Inorganic Materials, 2022, 37(3): 317-324.

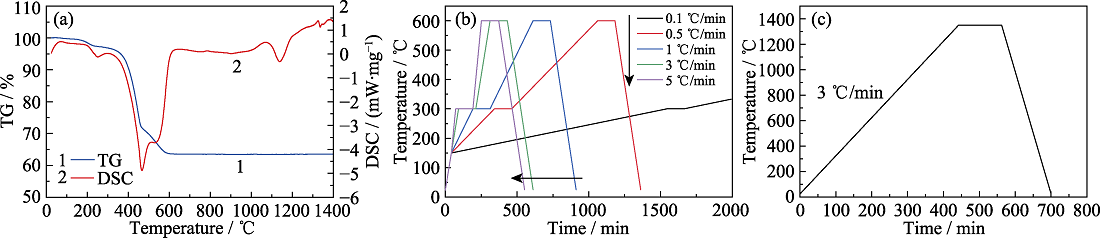

图2 堇青石陶瓷生坯的热重分析结果与脱脂和烧结曲线

Fig. 2 TG/DSC curves, debinding and sintering curves of printed cordierite green body (a) TG/DSC curves; (b) Debinding curve; (c) Sintering curve

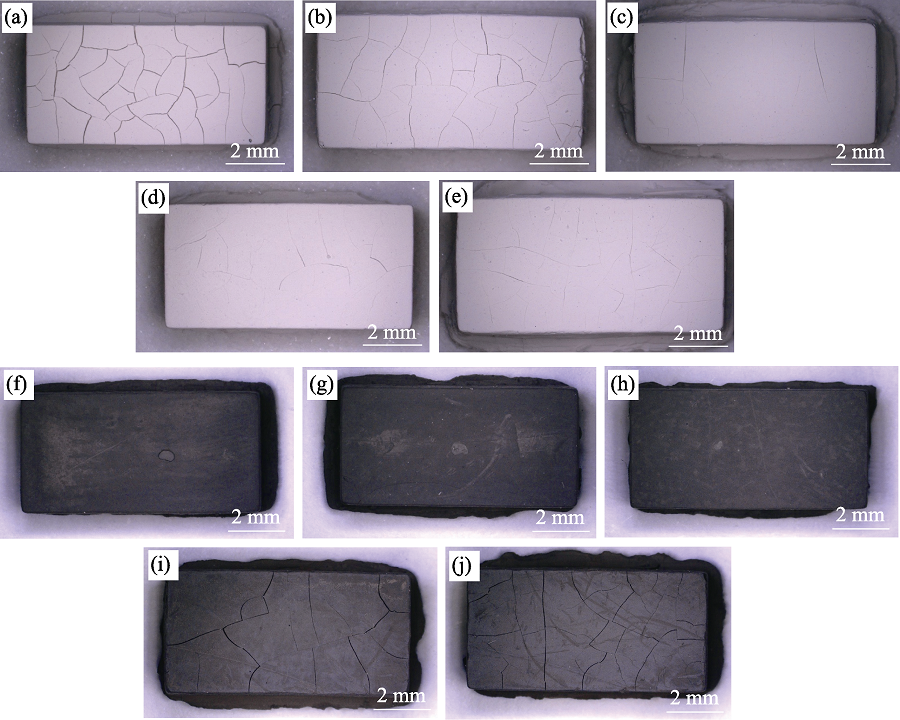

图3 不同升温速率脱脂后的样件表面宏观形貌

Fig. 3 Surface macro-graphs of sample after debinding at different heating rates In air: (a) 0.1 ℃/min; (b) 0.5 ℃/min; (c) 1 ℃/min; (d) 3 ℃/min; (e) 5 ℃/min; In argon: (f) 0.1 ℃/min; (g) 0.5 ℃/min; (h) 1 ℃/min; (i) 3 ℃/min; (j) 5 ℃/min

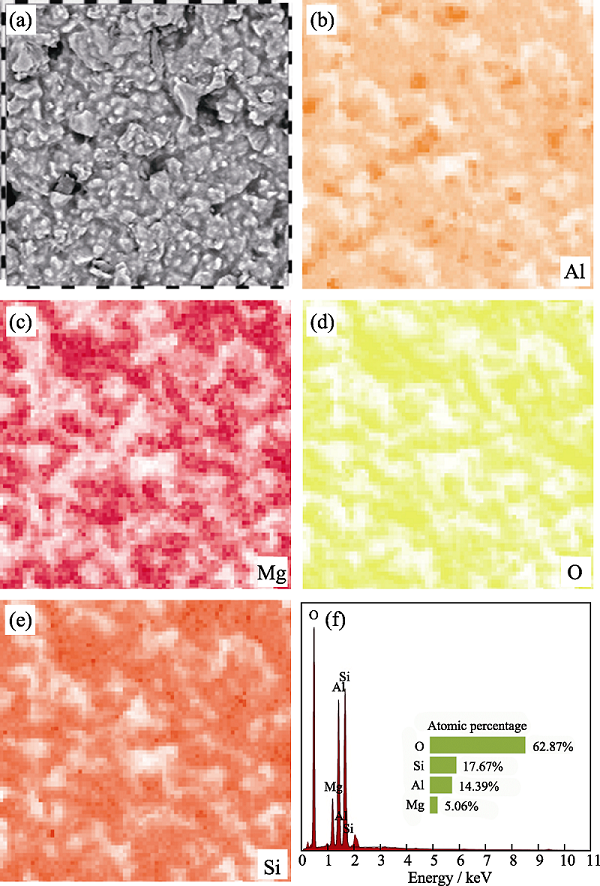

图4 空气气氛下脱脂后样件的EDS元素分析

Fig. 4 Element analysis of sample after debinding in air (a) SEM image; EDS mappings of (b) Al, (c) Mg, (d) O and (e) Si; (f) EDS spectrum

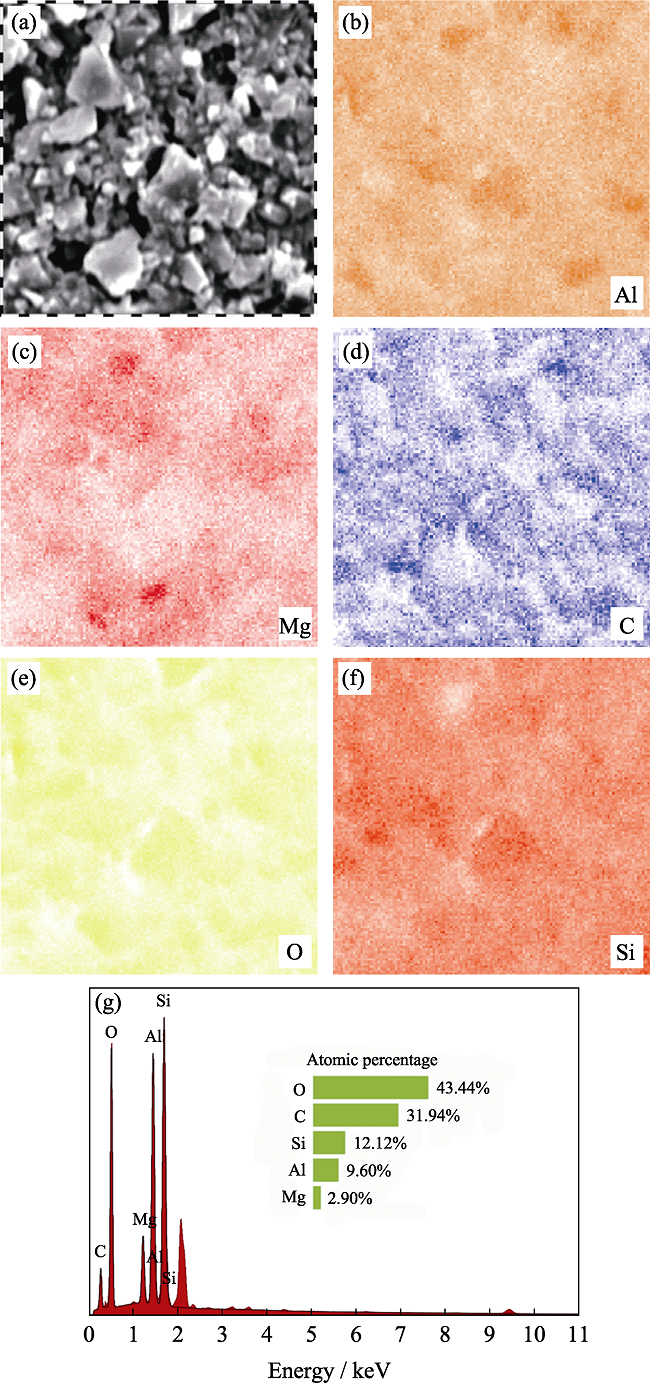

图5 氩气气氛下脱脂后样件EDS元素分析

Fig. 5 Element analysis after debinding in argon (a) SEM image; EDS mappings of (b) Al, (c) Mg, (d) C and (e) O; (f) Si; (g) EDS spectrum

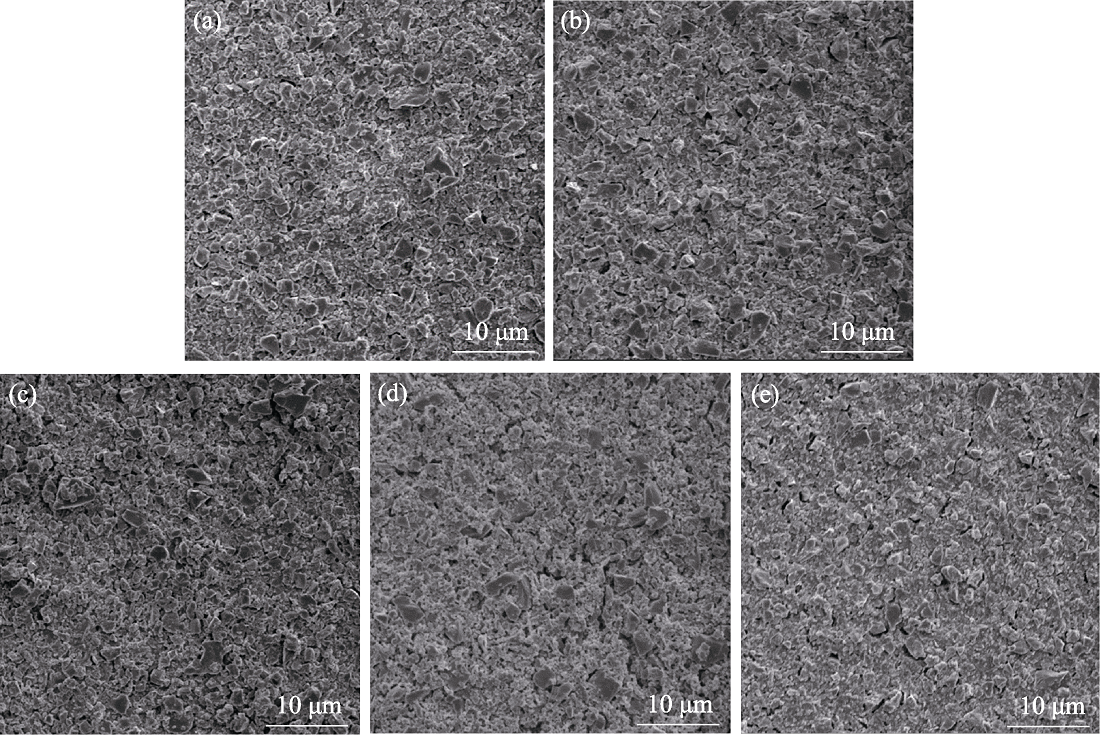

图6 在氩气气氛下脱脂后的样件表面微观形貌

Fig. 6 Micrographs of sample surfaces after debinding in argon(a) 0.1 ℃/min; (b) 0.5 ℃/min; (c) 1 ℃/min; (d) 3 ℃/min; (e) 5 ℃/min

图7 在不同气氛、不同脱脂升温速率下脱脂并经烧结后样件的性能

Fig. 7 Properties of samples after debinding in different atmospheres followed by sintering (a) Shrinkage rate-debinding in air; (b) Shrinkage rate-debinding in argon; (c) Relative density; (d) Bending strength

图8 优化脱脂策略后烧结的样件

Fig. 8 Final cordierite ceramics prepared with optimized debinding scheme followed by sintering (a, b) Dense rectangular sample; (c) Honeycomb structures with complex inter-crossing channels

| [1] |

CAMERUCCI M A, URRETAVIZCAYA G, CASTRO M S, et al. Electrical properties and thermal expansion of cordierite and cordierite- mullite materials. Journal of the European Ceramic Society, 2001, 21(16): 2917-2923.

DOI URL |

| [2] |

LAMARA S, REDAOUI D, SAHNOUNE F, et al. Microstructure, thermal expansion, hardness and thermodynamic parameters of cordierite materials synthesized from Algerian natural clay minerals and magnesia. Boletín de la Sociedad Española de Cerámica y Vidrio, 2020, 60(5): 291-306.

DOI URL |

| [3] | SITTIAKKARANON S. Thermal shock resistance of mullite- cordierite ceramics from kaolin, talc and alumina raw materials. Materials Today: Proceedings, 2019, 17(4): 1864-1871. |

| [4] |

CHEN Z, LIU C, LI J, et al. Mechanical properties and microstructures of 3D printed bulk cordierite parts. Ceramics International, 2019, 45(15): 19257-19267.

DOI URL |

| [5] |

GÖKÇE H, AĞAOĞULLARI D, ÖVEÇOĞLU M L, et al. Characterization of microstructural and thermal properties of steatite/ cordierite ceramics prepared by using natural raw materials. Journal of the European Ceramic Society, 2011, 31(14): 2741-2747.

DOI URL |

| [6] |

AVILA P, MONTES M, MIRÓ E E. Monolithic reactors for environmental applications: a review on preparation technologies. Chemical Engineering Journal, 2005, 109(1/2/3): 11-36.

DOI URL |

| [7] |

DAS R N, MADHUSOODANA C D, OKADA K, Rheological studies on cordierite honeycomb extrusion. Journal of the European Ceramic Society, 2002, 22(16): 2893-2900.

DOI URL |

| [8] |

LIANG Q, LI D, YANG G. Rapid fabrication of diamond-structured ceramic photonic crystals with graded dielectric constant and its controllable stop band properties. Ceramics International, 2013, 39(1): 153-157.

DOI URL |

| [9] |

MELCHELS F P W, FEIJEN J, GRIJPMA D W. A review on stereolithography and its applications in biomedical engineering. Biomaterials, 2010, 31(24): 6121-6130.

DOI URL |

| [10] |

ZHOU W, LI D, CHEN Z. Direct fabrication of an integral ceramic mould by stereolithography. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2010, 224(2): 237-243.

DOI URL |

| [11] |

ZOCCA A, COLOMBO P, GOMES C M, et al. Additive manufacturing of ceramics: issues, potentialities, and opportunities. Journal of the American Ceramic Society, 2015, 98(7): 1983-2001.

DOI URL |

| [12] |

CHEN Z, LI Z, LI J, et al. 3D printing of ceramics: a review. Journal of the European Ceramics Society, 2019, 39(4): 661-687.

DOI URL |

| [13] |

CHEN Z, LI D, ZHOU W. Process parameters appraisal of fabricating ceramic parts based on stereolithography using the Taguchi method. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(7): 1249-1258.

DOI URL |

| [14] |

LIU Y, CHEN Z, LI J, et al. 3D printing of ceramic cellular structures for potential nuclear fusion application. Additive Manufacturing, 2020, 35: 101348.

DOI URL |

| [15] |

RASAKI S A, XIONG D, XIONG S, et al. Photopolymerization- based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442-471.

DOI URL |

| [16] |

LIU C, XU F, LIU Y, et al. High mass loading ultrathick porous Li4Ti5O12 electrodes with improved areal capacity fabricated via low temperature direct writing. Electrochimica Acta, 2019, 314: 81-88.

DOI URL |

| [17] |

WU Z, HUAN Z, ZHU Y, et al. 3D printing and characterization of microsphere hydroxyapatite scaffolds. Journal of Inorganic Materials, 2021, 36(6): 601-607.

DOI URL |

| [18] |

CHEN Z, BRANDON N. Inkjet printing and nanoindentation of porous alumina multilayers. Ceramics International, 2016, 42(7): 8316-8324.

DOI URL |

| [19] |

CHEN Z, OUYANG J, LIANG W, et al. Development and characterizations of novel aqueous-based LSCF suspensions for inkjet printing. Ceramics International, 2018, 44(11): 13381-13388.

DOI URL |

| [20] |

ZHANG L, YANG X, XU X, et al. 3D printed zirconia ceramics via fused deposit modeling and its mechanical properties. Journal of Inorganic Materials, 2021, 36(4): 436-442.

DOI |

| [21] |

LIU S, LI M, WU J, et al. Preparation of high-porosity Al2O3 ceramic foams via selective laser sintering of Al2O3 poly-hollow microspheres. Ceramics International, 2020, 46(4): 4240-4247.

DOI URL |

| [22] |

FERRAGE L, BERTRAND G, LENORMAND P. Dense yttria- stabilized zirconia obtained by direct selective laser sintering. Additive Manufacturing, 2018, 21: 472-478.

DOI URL |

| [23] |

MINASYAN T, LIU L, AGHAYAN M, et al. A novel approach to fabricate Si3N4 by selective laser melting. Ceramics International, 2018, 44(12): 13689-13694.

DOI URL |

| [24] |

CHEN Z, LI J, LIU C, et al. Preparation of high solid loading and low viscosity ceramic slurries for photopolymerization-based 3D printing. Ceramics International, 2019, 45(9): 11549-11557.

DOI URL |

| [25] |

SHUAI X, ZENG Y, LI P, et al. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Journal of Materials Science, 2020, 55: 6771-6782.

DOI URL |

| [26] | LI H, SONG L, SUN J, et al. Stereolithography-fabricated zirconia dental prostheses: concerns based on clinical requirements. Journal of Advances in Applied Ceramics, 2020, 119(5/6): 236-243. |

| [27] |

FENG C, ZHANG C, HE R, et al. Additive manufacturing of hydroxyapatite bioceramic scaffolds: dispersion, digital light processing, sintering, mechanical properties, and biocompatibility. Journal of Advanced Ceramics, 2020, 9: 360-373.

DOI URL |

| [28] |

HE R, DING G, ZHANG K, et al. Fabrication of SiC ceramic architectures using stereolithography combined with precursor infiltration and pyrolysis. Ceramics International, 2019, 45(11): 14006-14014.

DOI URL |

| [29] |

ZHANG C, LUO Z, LIU C, et al. Dimensional retention of photocured ceramic units during 3D printing and sintering processes. Ceramics International, 2021, 47(8): 11097-11108.

DOI URL |

| [30] |

CHEN Z, LIU C, LI J, et al. Mechanical properties and microstructures of 3D printed bulk cordierite parts. Ceramics International, 2019, 45(15): 19257-19267.

DOI URL |

| [1] | 汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670. |

| [2] | 吴锐, 张敏慧, 金成韵, 林健, 王德平. 光热核壳TiN@硼硅酸盐生物玻璃纳米颗粒的降解和矿化性能[J]. 无机材料学报, 2023, 38(6): 708-716. |

| [3] | 林俊良, 王占杰. 铁电超晶格的研究进展[J]. 无机材料学报, 2023, 38(6): 606-618. |

| [4] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [5] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [6] | 钱新宇, 王无敌, 宋青松, 董永军, 薛艳艳, 张晨波, 王庆国, 徐晓东, 唐慧丽, 曹桂新, 徐军. 0.6%Pr, x%La:CaF2的发光性能研究和Judd-Ofelt分析[J]. 无机材料学报, 2023, 38(3): 357-362. |

| [7] | 王志强, 吴济安, 陈昆峰, 薛冬峰. 大尺寸Er,Yb:YAG单晶的生长及其性能[J]. 无机材料学报, 2023, 38(3): 329-334. |

| [8] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [9] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [10] | 陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162. |

| [11] | 冯静静, 章游然, 马名生, 陆毅青, 刘志甫. 冷烧结技术的研究现状及发展趋势[J]. 无机材料学报, 2023, 38(2): 125-136. |

| [12] | 潘洋洋, 梁波, 洪督, 祁志祥, 牛亚然, 郑学斌. TiAl合金表面TiAlCrY/YSZ涂层高温长时间服役性能[J]. 无机材料学报, 2023, 38(1): 105-112. |

| [13] | 付师, 杨增朝, 李宏华, 王良, 李江涛. 复合烧结助剂对Si3N4陶瓷力学性能和热导率的影响[J]. 无机材料学报, 2022, 37(9): 947-953. |

| [14] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [15] | 盛丽丽, 常江. 光/磁热Fe2SiO4/Fe3O4双相生物陶瓷及其复合电纺丝膜制备及抗菌性能研究[J]. 无机材料学报, 2022, 37(9): 983-990. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||