无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 297-302.DOI: 10.15541/jim20210604

收稿日期:2021-09-30

修回日期:2021-10-26

出版日期:2022-03-20

网络出版日期:2021-11-12

通讯作者:

刘 耀, 讲师. E-mail: liuyao1985@csu.edu.com; 刘绍军, 教授. E-mail: liumatthew@csu.edu.cn

作者简介:周港怀(1997-), 男, 硕士研究生. E-mail: 193312100@csu.edu.cn

基金资助:

ZHOU Ganghuai1, LIU Yao2( ), SHI Yuan1, LIU Shaojun1(

), SHI Yuan1, LIU Shaojun1( )

)

Received:2021-09-30

Revised:2021-10-26

Published:2022-03-20

Online:2021-11-12

Contact:

LIU Yao, lecturer. E-mail: liuyao1985@csu.edu.com; LIU Shaojun, professor. E-mail: liumatthew@csu.edu.cn

About author:ZHOU Ganghuai (1997-), male, Master candidate. E-mail: 193312100@csu.edu.cn

Supported by:摘要:

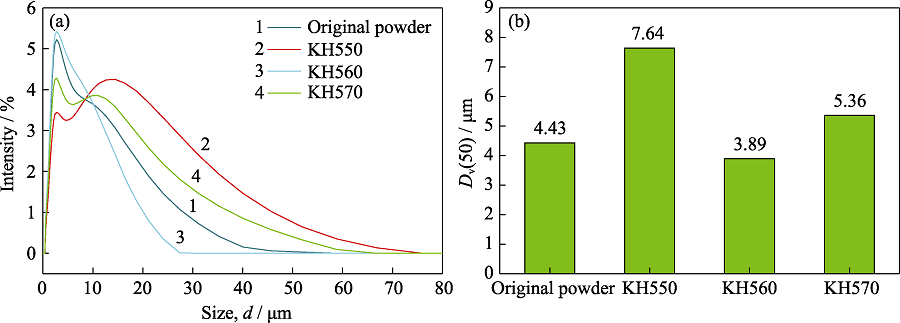

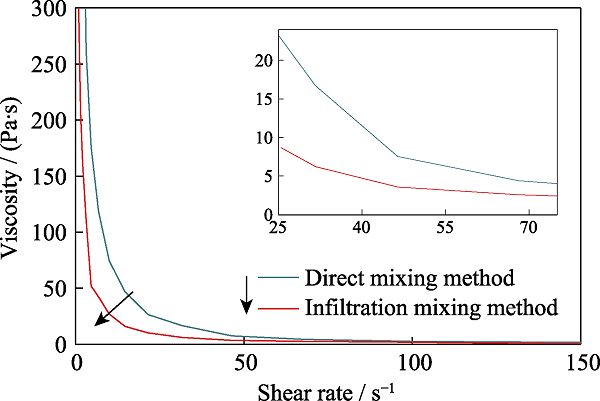

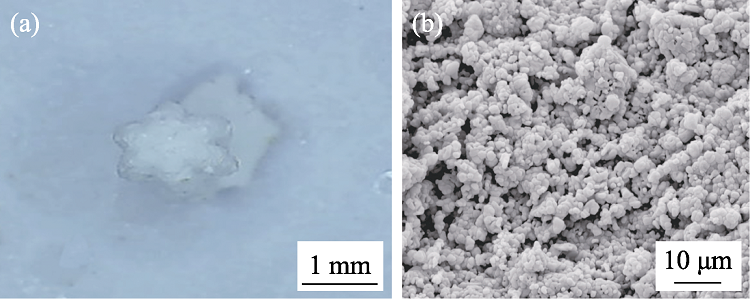

为制备具有高效化学催化反应和复杂精细结构的活性氧化铝催化剂载体, 制备出低粘度、高均匀性和高固相含量的光固化浆料, 通过粒度分析和流变测试等手段, 研究树脂配比和偶联剂改性剂改性活性氧化铝表面对粉末粒度分布和浆料的稳定性、均匀性和流变性的影响。当w(HEA) : w(HDDA) : w(TMPTA) : w(modified-EA)=1.5 : 1.0 : 2.5 : 5.0时, 预混液在剪切速率为1 s-1时的粘度仅为0.35 Pa·s; 粉末改性后KH560高分子链附着在活性氧化铝表面, 使得活性氧化铝由亲水性改性为疏水性, 提高浆料的均匀性和稳定性, 并使粉末之间产生空间位阻, 降低粉末团聚, 其平均直径从4.43 μm降低至3.89 μm; 采用浸润混合法制备固相含量为52%(质量分数)的浆料并成功打印。脱脂烧结后的活性氧化铝样品保持了复杂异形薄壁结构, 其开孔率和密度分别为51.3%和1.93 g/cm3。

中图分类号:

周港怀, 刘耀, 石原, 刘绍军. 活性氧化铝催化剂载体的光固化浆料制备与成型[J]. 无机材料学报, 2022, 37(3): 297-302.

ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier[J]. Journal of Inorganic Materials, 2022, 37(3): 297-302.

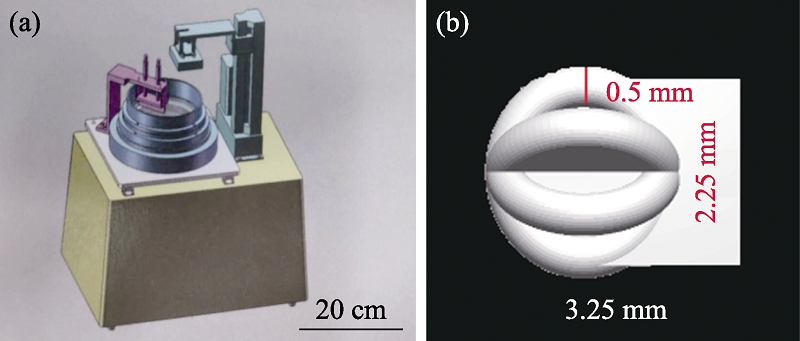

图1 光固化成型机器的三维结构示意图(a)和活性氧化铝打印模型图(b)

Fig. 1 Three-dimensional structure diagram of stereolithographic machine (a) and print model diagram of activated alumina (b)

图4 质量分数为2%的KH550、KH560和KH570偶联剂改性后活性氧化铝的粒度分布图(a)和平均颗粒直径图(b)

Fig. 4 Particle size distribution (a) and average particle diameter (b) of activated alumina diagram after 2% (mass percentage) KH550, KH560 and KH570 coupling agent modification

图6 改性活性氧化铝和树脂不同混合方式的浆料黏度图

Fig. 6 Viscosity diagram of slurry with different mixing methods of modified activated alumina and resin. Inset shows the enlarged curues under shear rate less than 70 s-1

图7 光固化活性氧化铝样品脱脂烧结后样品照片(a)和光固化活性氧化铝脱样品脂烧结后的SEM照片(b)

Fig. 7 Stereolithographic activated alumina sample diagram (a) after debounding and sintering and SEM image (b) of stereolithographic activated alumina sample after debounding and sintering

| [1] |

SHI L, YIN Y, WANG S, et al. Rational catalyst design for N2 reduction under ambient conditions: strategies towards enhanced conversion efficiency. ACS Catalysis, 2020, 10(12): 6870-6899.

DOI URL |

| [2] |

LIU L. Multiscale structural characterization of shaped catalysts. Trends in Chemistry, 2021, 3(11): 898-901.

DOI URL |

| [3] |

DENG Z Y, FUKASAWA T, ANDO M, et al. High-surface-area alumina ceramics fabricated by the decomposition of Al(OH)3. Journal of the American Ceramic Society, 2010, 84(3): 485-491.

DOI URL |

| [4] |

NIJMEIJER A, KRUIDHOF H, BREDESEN R, et al. Preparation and properties of hydrothermally stable-alumina membranes. Journal of the American Ceramic Society, 2010, 84(1): 136-140.

DOI URL |

| [5] |

RODIANSONO, MD ASTUTI, MUJIYANTI D R, et al. Novel preparation method of bimetallic Ni-In alloy catalysts supported on amorphous alumina for the highly selective hydrogenation of furfural. Molecular Catalysis, 2018, 445: 52-60.

DOI URL |

| [6] |

HE Y, LIU S, PRIEST C, et al. Atomically dispersed metal-nitrogen- carbon catalysts for fuel cells: advances in catalyst design, electrode performance, and durability improvement. Chemical Society Reviews, 2020, 49(11): 3484-3524.

DOI URL |

| [7] | CHEN R, LIAN Q, WANG J, et al. A stereolithographic diamond- mixed resin slurry for complex SiC ceramic structure. Journal of the European Ceramic, 2021, 41(7): 3991-3999. |

| [8] |

LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 2021, 116(2/3): 100736.

DOI URL |

| [9] |

BIKAS H, STAVROPOULOS P, CHRYSSOLOURIS G. Additive manufacturing methods and modelling approaches: a critical review. The International Journal of Advanced Manufacturing Technology, 2016, 83(1-4): 389-405.

DOI URL |

| [10] |

SALMI M. Additive manufacturing processes in medical applications. Materials, 2021, 14(1): 191.

DOI URL |

| [11] |

ZHAO S, SIQUEIRA G, D RDOVA S, et al. Additive manufacturing of silica aerogels. Nature, 2020, 584(7821): 387-392.

DOI URL |

| [12] |

XING H Y, ZOU B, LIU X Y, et al. Original Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. Journal of the European Ceramic Society, 2020, 40(15): 5797-5809.

DOI URL |

| [13] |

ZHOU T, ZHANG L, YAO Q, et al. SLA 3D printing of high quality spine shaped β-TCP bioceramics for the hard tissue repair applications. Ceramics International, 2019, 46(6): 7609-7614.

DOI URL |

| [14] | STRAATHOF M H, DRIEL C, LINGEN J, et al. Development of propellant compositions for vat photopolymerization additive manufacturing. Propellants, Explosives, Pyrotechnics, 2020, 45(1): 36-52. |

| [15] |

XU X, AWAD A, MARTINEZ P R, et al. Vat photopolymerization 3D printing for advanced drug delivery and medical device applications. Journal of Controlled Release, 2020, 329(10): 743-757.

DOI URL |

| [16] |

WEI L N, JIA M L, ZHOU M, et al. Vat polymerization-based bioprinting-process, materials, applications and regulatory challenges. Biofabrication, 2020, 12(2): 022001.

DOI URL |

| [17] |

QUAN H, ZHANG T, XU H, et al. Photo-curing 3D printing technique and its challenges. Bioactive Materials, 2020, 5(1): 110-115.

DOI URL |

| [18] |

BAE C J, RAMACHANDRAN A, HALLORAN J W. Quantifying particle segregation in sequential layers fabricated by additive manufacturing. Journal of the European Ceramic Society, 2018, 38(11): 4082-4088.

DOI URL |

| [19] |

LIU Y, CHENG L J, LI H, et al. Formation mechanism of stereolithography of Si3N4 slurry using silane coupling agent as modifier and dispersant. Ceramics International, 2020, 46(10): 14583-14590.

DOI URL |

| [20] |

SUN J, BINNER J, BAI J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography. Journal of the European Ceramic Society, 2019, 39(4): 1660-1667.

DOI URL |

| [21] |

ZHANG J, WEI L, MENG X, et al. Digital light processing- stereolithography three-dimensional printing of yttria-stabilized zirconia. Ceramics International, 2020, 46(7): 8745-8753.

DOI URL |

| [22] |

SHUAI Z, NA S, ZHE Z. Surface modification of α-Al2O3 with dicarboxylic acids for the preparation of UV-curable ceramic suspensions. Journal of the European Ceramic Society, 2017, 37(4): 1607-1616.

DOI URL |

| [23] |

ZHANG K Q, XIE C, WANG G, et al. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceramics International, 2019, 45(1): 203-208.

DOI URL |

| [24] |

DUFAUD O, MARCHAL P, CORBEL S. Rheological properties of PZT suspensions for stereolithography. Journal of the European Ceramic Society, 2002, 22(13): 2081-2092.

DOI URL |

| [25] |

WU X, LIAN Q, LI D, et al. Effects of soft-start exposure on the curing characteristics and flexural strength in ceramic projection stereolithography process. Journal of the European Ceramic Society, 2019, 39(13): 3788-3796.

DOI URL |

| [26] |

LI X, ZHANG J, DUAN Y, et al. Rheology and curability characterization of photosensitive slurries for 3D printing of Si3N4 ceramics. Applied Sciences, 2020, 10(18): 6438.

DOI URL |

| [27] |

GENTRY S, HALLORAN J W. Light scattering in absorbing ceramic suspensions: effect on the width and depth of photopolymerized features. Journal of the European Ceramic Society, 2015, 35(6): 1895-1904.

DOI URL |

| [28] |

BADEV A, ABOULIATIM Y, CHARTIER T, et al. Photopolymerization kinetics of a polyether acrylate in the presence of ceramic fillers used in stereolithography. Journal of Photochemistry and Photobiology A-Chemistry, 2011, 222(1): 117-122.

DOI URL |

| [29] |

ZHANG Y, XU Y, SIMON-MASSERON A, et al. Radical photoinitiation with LEDs and applications in the 3D printing of composites. Chemical Society Reviews, 2021, 50(6): 3824-3841.

DOI URL |

| [1] | 周红莉, 蔡志勇, 王小锋, 曾婧, 冯艳, 彭超群, 王日初. 石膏的直写成型:可打印石膏浆料的研制[J]. 无机材料学报, 2022, 37(3): 338-346. |

| [2] | 李兴邦,仲鹤,张景贤,段于森,江东亮. 粉体性质对树脂基氧化锆光固化浆料流变行为的影响[J]. 无机材料学报, 2020, 35(2): 231-235. |

| [3] | 付云飞, 朱伯铨, 李享成, 陈平安. 含镁铝尖晶石的铝酸钙水泥的合成与流变特性[J]. 无机材料学报, 2017, 32(8): 884-890. |

| [4] | 谢雨洲, 彭超群, 王小锋, 王日初, 罗 丰. HEMA-TBA凝胶体系制备多孔氧化铝陶瓷[J]. 无机材料学报, 2017, 32(7): 731-738. |

| [5] | 舒 夏, 李 军, 张海龙, 董满江, 岛井骏臧, 王士维. 水溶性共聚物为交联剂的凝胶注成型AlN陶瓷的研究[J]. 无机材料学报, 2014, 29(3): 327-330. |

| [6] | 高 兰,马会茹,刘秧生,官建国. 硫酸改性TiO2粒子的表征与电流变性能研究[J]. 无机材料学报, 2009, 24(6): 1121-1124. |

| [7] | 吴 昊,桑绍柏,李 炜,蒲 健,李 箭. 流延法制备SOFC阳极支撑体基片[J]. 无机材料学报, 2008, 23(1): 82-86. |

| [8] | 汤枫秋,黄校先,张玉峰,郭景坤. 盐离子对纳米氧化锆浆料流变性能的影响[J]. 无机材料学报, 1999, 14(2): 239-244. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||