无机材料学报 ›› 2022, Vol. 37 ›› Issue (1): 51-57.DOI: 10.15541/jim20210179

所属专题: 【虚拟专辑】计算材料

收稿日期:2021-03-20

修回日期:2021-04-30

出版日期:2022-01-20

网络出版日期:2021-12-30

通讯作者:

TIKHONOV Evgenii, 助理教授. E-mail: tikhonov.e@nwpu.edu.cn

作者简介:彭军辉(1989-), 男, 博士研究生. E-mail: pjh1989@yeah.net

基金资助:

PENG Junhui1,2( ), TIKHONOV Evgenii1(

), TIKHONOV Evgenii1( )

)

Received:2021-03-20

Revised:2021-04-30

Published:2022-01-20

Online:2021-12-30

Contact:

TIKHONOV Evgenii, assistant professor. E-mail: tikhonov.e@nwpu.edu.cn

About author:PENG Junhui(1989-), male, PhD candidate. E-mail: pjh1989@yeah.net

Supported by:摘要:

本研究理论预测了三元Hf-Ta-C空位有序结构以及空位对力学性质的影响。采用第一性原理进化晶体结构预测软件USPEX, 预测得到了5种热力学稳定和3种亚稳的(Hf, Ta)C1-x空位有序结构, 这些结构都属于岩盐结构。采用第一性原理方法, 计算了(Hf, Ta)C1-x空位有序结构的力学性质, 并分析了力学性质随空位浓度的变化。(Hf, Ta)C1-x都具有较高的体模量、剪切模量、杨氏模量和维氏硬度;各(Hf, Ta)C1-x的Hf/Ta比相同时, 其模量、硬度等随空位浓度增大而减小。最后, 计算了(Hf, Ta)C1-x的电子态密度, 发现其均具有强共价性和弱金属性。本研究结果对于了解Hf-Ta-C体系的空位结构及其力学性质和应用, 具有重要参考价值。

中图分类号:

彭军辉, TIKHONOV Evgenii. 空位对Hf-Ta-C体系的结构、力学性质及电子性质影响的第一性原理研究[J]. 无机材料学报, 2022, 37(1): 51-57.

PENG Junhui, TIKHONOV Evgenii. Vacancy on Structures, Mechanical and Electronic Properties of Ternary Hf-Ta-C System: a First-principles Study[J]. Journal of Inorganic Materials, 2022, 37(1): 51-57.

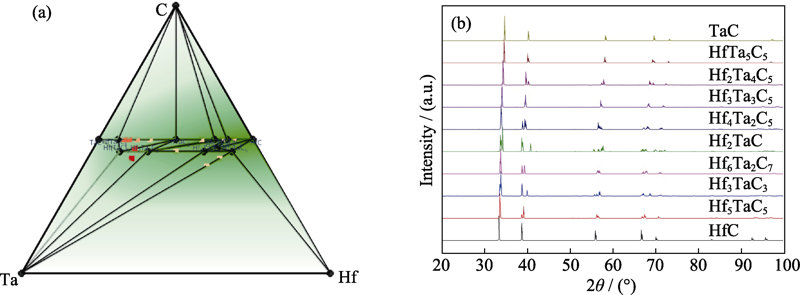

图1 晶体结构预测及(Hf,Ta)C1-x空位有序结构

Fig. 1 Crystal structure prediction and (Hf, Ta)C1-x vacancy ordered structure (a) Enthalpy convex-hull of ternary Hf-Ta-C system (black sphere indicating stable structure, while others indicating metastable structure, and red square representing the structure with high enthalpy above the convex-hull, but not considered here); (b) Simulated X-ray diffractions of (Hf, Ta)C1-x vacancy ordered structures with a copper Kα X-ray source

| Compound | Space group | Lattice constants/nm | Above convex-hull /(eV·atom-1) | ΔHf /(eV·atom-1) | CN | x |

|---|---|---|---|---|---|---|

| Hf5TaC5 | Cm | a=0.567, b=0.976, c=0.929, β=145.1° | 0 | -0.8925 | 5, 5 | 1/6 |

| Hf3TaC3 | P-1 | a=0.567, b=0.648, c=0.565 α=89.4°, β=69.6°, γ=91.3° | 0.0007 | -0.8408 | 5/4, 4 | 1/4 |

| Hf6Ta2C7 | P-1 | a=0.565, b=0.562, c=0.653 α=90.4°, β=72.4°, γ=99.8° | 0 | -0.8868 | 6/5, 5 | 1/8 |

| Hf2TaC2 | P-1 | a=0.566, b=0.554, c=0.560 α=119.4°, β=98.4°, γ=102.4° | 0.0012 | -0.7842 | 4, 4 | 1/3 |

| Hf4Ta2C5 | P-1 | a=0.559, b=0.561, c=0.559 α=109.1°, β=100.1°, γ=60.3° | 0 | -0.8604 | 5, 5 | 1/6 |

| Hf3Ta3C5 | Cm | a=0.558, b=0.963, c=0.644, β=125.2° | 0.0009 | -0.8161 | 5, 5 | 1/6 |

| Hf2Ta4C5 | C2/m | a=0.551, b=0.963, c=0.551, β=71.3° | 0 | -0.7735 | 5, 5 | 1/6 |

| HfTa5C5 | Cm | a=0.548, b=0.954, c=0.548, β=109.2° | 0 | -0.7033 | 5, 5 | 1/6 |

表1 (Hf, Ta)C1-x空位有序结构的空间群、晶格常数、高于凸包线的焓值、形成焓(ΔHf)、原子配位数(CN)、空位浓度(x)

Table 1 Space groups, lattice constants, enthalpy above the convex-hull, formation enthalpy (ΔHf), concentration of vacancy (x) and coordination number (CN) of Hf or Ta for ternary (Hf, Ta)C1-x vacancy ordered structures

| Compound | Space group | Lattice constants/nm | Above convex-hull /(eV·atom-1) | ΔHf /(eV·atom-1) | CN | x |

|---|---|---|---|---|---|---|

| Hf5TaC5 | Cm | a=0.567, b=0.976, c=0.929, β=145.1° | 0 | -0.8925 | 5, 5 | 1/6 |

| Hf3TaC3 | P-1 | a=0.567, b=0.648, c=0.565 α=89.4°, β=69.6°, γ=91.3° | 0.0007 | -0.8408 | 5/4, 4 | 1/4 |

| Hf6Ta2C7 | P-1 | a=0.565, b=0.562, c=0.653 α=90.4°, β=72.4°, γ=99.8° | 0 | -0.8868 | 6/5, 5 | 1/8 |

| Hf2TaC2 | P-1 | a=0.566, b=0.554, c=0.560 α=119.4°, β=98.4°, γ=102.4° | 0.0012 | -0.7842 | 4, 4 | 1/3 |

| Hf4Ta2C5 | P-1 | a=0.559, b=0.561, c=0.559 α=109.1°, β=100.1°, γ=60.3° | 0 | -0.8604 | 5, 5 | 1/6 |

| Hf3Ta3C5 | Cm | a=0.558, b=0.963, c=0.644, β=125.2° | 0.0009 | -0.8161 | 5, 5 | 1/6 |

| Hf2Ta4C5 | C2/m | a=0.551, b=0.963, c=0.551, β=71.3° | 0 | -0.7735 | 5, 5 | 1/6 |

| HfTa5C5 | Cm | a=0.548, b=0.954, c=0.548, β=109.2° | 0 | -0.7033 | 5, 5 | 1/6 |

| Compound | C11 /GPa | C22 /GPa | C33 /GPa | C44 /GPa | C55 /GPa | C66 /GPa | C12 /GPa | C13 /GPa | C23 /GPa | B /GPa | G /GPa | E /GPa | Hv /GPa | G/B | μ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hf5TaC5 | 422.9 | 446.8 | 432.1 | 177.0 | 177.0 | 156.1 | 105.3 | 129.0 | 122.5 | 223.8 | 162.7 | 393.0 | 24.09 | 0.7271 | 0.2074 |

| Hf3TaC3 | 382.3 | 407.8 | 403.3 | 156.7 | 156.7 | 121.6 | 102.9 | 123.1 | 121.8 | 209.3 | 141.4 | 346.1 | 19.88 | 0.6754 | 0.2244 |

| Hf6Ta2C7 | 454.5 | 482.0 | 472.3 | 180.9 | 180.9 | 171.3 | 122.2 | 135.9 | 114.0 | 239.1 | 170.6 | 413.4 | 24.23 | 0.7133 | 0.2119 |

| Hf2TaC2 | 365.7 | 399.7 | 384.9 | 136.2 | 136.2 | 108.5 | 121.0 | 118.9 | 112.0 | 205.7 | 128.8 | 319.8 | 16.85 | 0.6265 | 0.2409 |

| Hf4Ta2C5 | 443.4 | 423.5 | 441.2 | 175.4 | 175.4 | 160.2 | 122.8 | 135.9 | 140.4 | 233.9 | 162.6 | 395.9 | 22.68 | 0.6949 | 0.2179 |

| Hf3Ta3C5 | 431.3 | 443.6 | 433.6 | 185.4 | 185.4 | 153.1 | 129.2 | 149.3 | 154.0 | 241.4 | 157.2 | 387.5 | 20.34 | 0.6513 | 0.2325 |

| Hf2Ta4C5 | 476.5 | 446.7 | 477.6 | 199.4 | 199.4 | 161.1 | 141.9 | 163.7 | 155.6 | 257.9 | 168.3 | 414.6 | 21.34 | 0.6525 | 0.2320 |

| HfTa5C5 | 491.9 | 473.8 | 484.4 | 209.8 | 209.8 | 171.5 | 149.6 | 165.6 | 166.9 | 268.2 | 175.7 | 432.6 | 22.08 | 0.6551 | 0.2312 |

表2 (Hf, Ta)C1-x空位有序结构的弹性常数(Cij)、体模量(B)、剪切模量(G)、杨氏模量(E)、泊松比(μ)、维氏硬度(Hv)和Pugh比(G/B)

Table 2 Calculated elastic constants (Cij) and mechanical properties-bulk modulus (B), shear modulus (G/), elastic modulus (E), Poisson’s ratio (μ), Vickers hardness (Hv) and Pugh’s ratio (G/B) of (Hf, Ta)C1-x vacancy ordered structures

| Compound | C11 /GPa | C22 /GPa | C33 /GPa | C44 /GPa | C55 /GPa | C66 /GPa | C12 /GPa | C13 /GPa | C23 /GPa | B /GPa | G /GPa | E /GPa | Hv /GPa | G/B | μ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hf5TaC5 | 422.9 | 446.8 | 432.1 | 177.0 | 177.0 | 156.1 | 105.3 | 129.0 | 122.5 | 223.8 | 162.7 | 393.0 | 24.09 | 0.7271 | 0.2074 |

| Hf3TaC3 | 382.3 | 407.8 | 403.3 | 156.7 | 156.7 | 121.6 | 102.9 | 123.1 | 121.8 | 209.3 | 141.4 | 346.1 | 19.88 | 0.6754 | 0.2244 |

| Hf6Ta2C7 | 454.5 | 482.0 | 472.3 | 180.9 | 180.9 | 171.3 | 122.2 | 135.9 | 114.0 | 239.1 | 170.6 | 413.4 | 24.23 | 0.7133 | 0.2119 |

| Hf2TaC2 | 365.7 | 399.7 | 384.9 | 136.2 | 136.2 | 108.5 | 121.0 | 118.9 | 112.0 | 205.7 | 128.8 | 319.8 | 16.85 | 0.6265 | 0.2409 |

| Hf4Ta2C5 | 443.4 | 423.5 | 441.2 | 175.4 | 175.4 | 160.2 | 122.8 | 135.9 | 140.4 | 233.9 | 162.6 | 395.9 | 22.68 | 0.6949 | 0.2179 |

| Hf3Ta3C5 | 431.3 | 443.6 | 433.6 | 185.4 | 185.4 | 153.1 | 129.2 | 149.3 | 154.0 | 241.4 | 157.2 | 387.5 | 20.34 | 0.6513 | 0.2325 |

| Hf2Ta4C5 | 476.5 | 446.7 | 477.6 | 199.4 | 199.4 | 161.1 | 141.9 | 163.7 | 155.6 | 257.9 | 168.3 | 414.6 | 21.34 | 0.6525 | 0.2320 |

| HfTa5C5 | 491.9 | 473.8 | 484.4 | 209.8 | 209.8 | 171.5 | 149.6 | 165.6 | 166.9 | 268.2 | 175.7 | 432.6 | 22.08 | 0.6551 | 0.2312 |

图2 (a) Hf5TaC5、(b) Hf3TaC3、(c) Hf6Ta2C7、(d) Hf2TaC2、(e) Hf4Ta2C5、(f) Hf3Ta3C5、(g) Hf2Ta4C5和(h) HfTa5C5的声子谱曲线

Fig. 2 Phonon dispersion curves of (a) Hf5TaC5, (b) Hf3TaC3, (c) Hf6Ta2C7, (d) Hf2TaC2, (e) Hf4Ta2C5, (f) Hf3Ta3C5, (g) Hf2Ta4C5, and (h) HfTa5C5 They are all dynamical stable because no imaginary frequencies were found in Brillouin zone

图3 (a) Hf5TaC5、(b) Hf3TaC3、(c) Hf6Ta2C7、(d) Hf2TaC2、(e) Hf4Ta2C5、(f) Hf3Ta3C5、(g) Hf2Ta4C5和(h) HfTa5C5的晶体结构

Fig. 3 Crystal structures of (a) Hf5TaC5, (b) Hf3TaC3, (c) Hf6Ta2C7, (d) Hf2TaC2, (e) Hf4Ta2C5, (f) Hf3Ta3C5, (g) Hf2Ta4C5, and (h) HfTa5C5 All sharing the rock-salt structure; Black square represents the structural vacancy

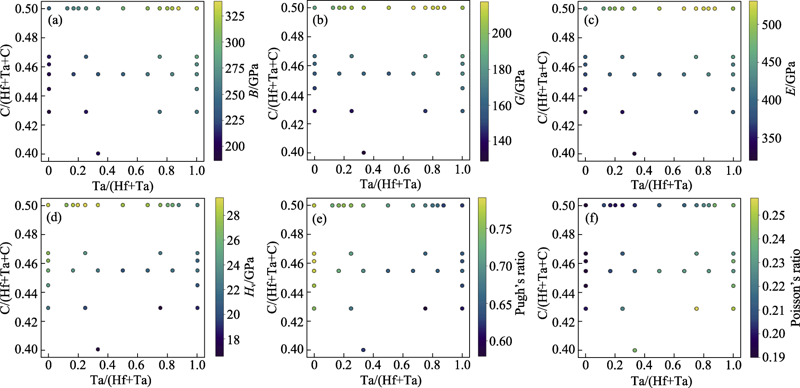

图4 空位对Hf-Ta-C体系力学性质的影响

Fig. 4 Effect of vacancy on mechanical properties for ternary Hf-Ta-C system (a) Bulk modulus (B); (b) Shear modulus (G); (c) Elastic modulus (E); (d) Vickers hardness (HV); (e) Pugh’s ratio (G/B); (f) Poisson’s ratio (μ)

图5 (a) Hf5TaC5、(b) Hf3TaC3、(c) Hf6Ta2C7、(d) Hf2TaC2、(e) Hf4Ta2C5、(f) Hf3Ta3C5、(g) Hf2Ta4C5和(h) HfTa5C5的态密度和分态密度(Fermi能级位于0 eV)

Fig. 5 Density of state (DOS) and partial DOS (PDOS) normalized by per (Hf, Ta)C1-x of (a) Hf5TaC5, (b) Hf3TaC3, (c) Hf6Ta2C7, (d) Hf2TaC2, (e) Hf4Ta2C5, (f) Hf3Ta3C5, (g) Hf2Ta4C5, and (h) HfTa5C5(The Fermi level being set at 0 eV) DOS is density of state / (states/eV); TDOS is total DOS; Hf, Ta, C are PDOS of Hf atom, Ta atom and C atom, respectively Colorful figures are available on the website

| [1] |

KURBATKINA V V, PATSERA E I, LEVASHOV E A, et al. Self-propagating high-temperature synthesis of single-phase binary tantalum-hafnium carbide (Ta, Hf)C and its consolidation by hot pressing and spark plasma sintering. Ceramics International, 2018, 44(4):4320-4329.

DOI URL |

| [2] | ANDRIEVSKII R A, STRELNIKOVA N S, POLTORATSKII N I, et al. Melting point in systems ZrC-HfC, TaC-ZrC, TaC-HfC. Powder Metallurgy and Metal Ceramics, 1967, 6:65-67. |

| [3] | RUDY E. Ternary phase equilibria in transition metal-boron- carbon-silicon systems. Part II. Ternary systems, Vol. I. Air Force Materials Laboratory: Wright-Patterson Air Force Base, 1965: 35-73. |

| [4] |

CEDILLOS-BARRAZA O, MANARA D, BOBORIDIS K, et al. Investigating the highest melting temperature materials: a laser melting study of the TaC-HfC system. Scientific Reports, 2016, 6:37962.

DOI URL |

| [5] |

ZHANG X H, HILMAS G E, FAHRENHOLTZ W G, et al. Hot pressing of tantalum carbide with and without sintering additives. Journal of the American Ceramic Society, 2007, 90(2):393-401.

DOI URL |

| [6] |

CEDILLOS-BARRAZA O, GRASSO S, NASIRI N A, et al. Sintering behaviour, solid solution formation and characterisation of TaC, HfC and TaC-HfC fabricated by spark plasma sintering. Journal of the European Ceramic Society, 2016, 36(7):1539-1548.

DOI URL |

| [7] |

SMITH C J, YU X X, GUO Q, et al. Phase, hardness, and deformation slip behavior in mixed HfxTa1-xC. Acta Materialia, 2018, 145:142-153.

DOI URL |

| [8] |

PENG J, TIKHONOV E. xTaxC and HfC1-xNx. Computational Materials Science, 2021, 195:110464.

DOI URL |

| [9] |

ZHANG J, WANG S, LI W. Consolidation and characterization of highly dense single-phase Ta-Hf-C solid solution ceramics. Journal of the American Ceramic Society, 2019, 102:58-62.

DOI URL |

| [10] |

GABALLA O, COOK B A, RUSSELL A M. Reduced-temperature processing and consolidation of ultra-refractory Ta4HfC5. International Journal of Refractory Metals and Hard Materials, 2013, 41:293-299.

DOI URL |

| [11] |

GHAFFARI S A, FAGHIHI-SANI M A, GOLESTANI-FARD F, et al. Spark plasma sintering of TaC-HfC UHTC via disilicides sintering aids. Journal of the European Ceramic Society, 2013, 33(8):1479-1484.

DOI URL |

| [12] |

PABLO G, LUIS Y, MERCY S, et al. Characterization of the micro-abrasive wear in coatings of TaC-HfC/Au for biomedical implants. Materials, 2017, 10(8):842.

DOI URL |

| [13] |

ZHANG C, GUPTA A, SEAL S, et al. Solid solution synthesis of tantalum carbide-hafnium carbide by spark plasma sintering. Journal of the American Ceramic Society, 2017, 100:1853-1862.

DOI URL |

| [14] |

FOROUGHI P, ZHANG C, AGARWAL A, et al. Controlling phase separation of TaxHf1-xC solid solution nanopowders during carbothermal reduction synthesis. Journal of the American Ceramic Society, 2017, 100:5056-5065.

DOI URL |

| [15] |

KIM J, KWON H, KIM B, et al. Finite temperature thermal expansion and elastic properties of (Hf1-xTax)C ultrahigh temperature ceramics. Ceramics International, 2019, 45:10805-10809.

DOI URL |

| [16] | GUSEV A I, REMPEL A A, MAGERL A J. Disorder and order in strongly nonstoichiometric compounds. Berlin Heidelberg: Springer, 2001: 179-243. |

| [17] |

HOLLECK H. Material selection for hard coatings. Journal of Vacuum Science and Technology A, 1986, 4(6):2661-2669.

DOI URL |

| [18] |

ZENG Q, PENG J, OGANOV A R, et al. Prediction of stable hafnium carbides: stoichiometries, mechanical properties, and electronic structure. Physical Review B, 2013, 88:214107.

DOI URL |

| [19] |

YU X X, WEINBERGER C R, THOMPSON G B. Ab initio investigations of the phase stability in tantalum carbides. Acta Materialia, 2014, 80:341-349.

DOI URL |

| [20] |

OGANOV A R, GLASS C W. Crystal structure prediction using ab initio evolutionary techniques: principles and applications. Journal of Chemical Physics, 2006, 124(24):244704.

DOI URL |

| [21] |

LYAKHOV A O, OGANOV A R, STOKES H T, et al. New developments in evolutionary structure prediction algorithm USPEX. Computer Physics Communications, 2013, 184:1172-1182.

DOI URL |

| [22] |

OGANOV A R, LYAKHOV A O, VALLE M. How evolutionary crystal structure prediction works and why. Accounts of Chemical Research, 2011, 44(3):227-237.

DOI URL |

| [23] |

KRESSE G, FURTHMULLER J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Physical Review B, 1996, 54(16):11169-11186.

DOI URL |

| [24] |

BLOCHL P E. Projector augmented-wave method. Physical Review B, 1994, 50(24):17953-17979.

DOI URL |

| [25] |

PERDEW J P, RUZSINSZKY A, CSONKA G I, et al. Restoring the density-gradient expansion for exchange in solids and surfaces. Physical Review Letters, 2008, 100(13):136406.

DOI URL |

| [26] |

TOGO A, OBA F, TANAKA I. First-principles calculations of the ferroelastic transition between rutile-type and CaCl2-type SiO2 at high pressures. Physical Review B, 2008, 78:134106.

DOI URL |

| [27] |

MOMMA K, IZUMI F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. Journal of Applied Crystallography, 2011, 44:1272-1276.

DOI URL |

| [28] |

COWLEY R A. Acoustic phonon instabilities and structural phase transitions. Physical Review B, 1976, 13(11):4877-4885.

DOI URL |

| [29] |

HILL R. The elastic behavior of a crystalline aggregate. Proceedings of the Physical Society Section A, 1952, 65(5):349-354.

DOI URL |

| [30] |

CHEN X Q, NIU H, LI D, et al. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics, 2011, 19(9):1275-1281.

DOI URL |

| [31] | PUGH S F. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philosophical Magazine, 1954, 45(367):823-843. |

| [32] |

RAZUMOVSKIY V I, POPOV M N, DING H, et al. Formation and interaction of point defects in group IVb transition metal carbides and nitrides. Computational Materials Science, 2015, 104:147-154.

DOI URL |

| [33] |

ZHANG Y, LIU B, WANG J. Self-assembly of carbon vacancies in sub-stoichiometric ZrC1-x. Scientific Reports, 2015, 5:18098.

DOI URL |

| [1] | 彭军辉, TIKHONOVEvgenii. 空位对Hf-Ta-C体系的结构、力学性质及电子性质影响的第一性原理研究[J]. 无机材料学报, 0, (): 179-. |

| [2] | 闫宇星, 汪帆, 张珏璇, 李付绍. 空位缺陷对ZnNb2O6光电特性影响的第一性原理研究[J]. 无机材料学报, 2021, 36(3): 269-276. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||