无机材料学报 ›› 2022, Vol. 37 ›› Issue (7): 764-772.DOI: 10.15541/jim20210616

收稿日期:2021-10-08

修回日期:2021-11-10

出版日期:2022-07-20

网络出版日期:2021-11-18

通讯作者:

林国强, 教授. E-mail: gqlin@dlut.edu.cn作者简介:程玮杰(1997-), 男, 硕士研究生. E-mail: 737289840@qq.com

基金资助:

CHENG Weijie1,2( ), WANG Minglei1,2, LIN Guoqiang1,2(

), WANG Minglei1,2, LIN Guoqiang1,2( )

)

Received:2021-10-08

Revised:2021-11-10

Published:2022-07-20

Online:2021-11-18

Contact:

LIN Guoqiang, professor. E-mail: gqlin@dlut.edu.cnAbout author:CHENG Weijie (1997-), male, Master candidate. E-mail: 737289840@qq.com

Supported by:摘要:

为了改善CrAlN薄膜的摩擦性能, 本研究在增强磁过滤脉冲偏压电弧离子镀设备上, 用分离靶弧流调控技术在硬质合金基体上分别制备了不同成分的CrAlN-DLC硬质复合薄膜, 并采用不同手段表征了薄膜的表面形貌、成分、相结构以及力学和摩擦性能。结果表明, 不同成分薄膜表面均平整致密, 膜厚均在1.05 μm左右。随着靶弧流比IC/ICrAl的升高, 薄膜中碳的原子分数由33.1%升至74.6%。薄膜的相结构主要由晶体相和非晶相复合组成, 其晶体相主要为c-(Cr,Al)N相, 且随着碳含量增大晶体相减少、晶粒尺寸减小, 其非晶相主要为DLC, 其中sp2/sp3的比值随碳含量增大而减小。相应地, 薄膜的硬度随着碳含量增大而提高, 当碳的原子分数为74.6%时, 达到最大值(26.2±1.4) GPa, 且该成分点处薄膜摩擦系数也降至最小值0.107, 磨损率仅为3.3×10-9 mm3/Nm。综合而言, 当非晶DLC相最多时, CrAlN-DLC复合薄膜的综合性能达到最佳, 较之CrAlN薄膜, 摩擦性能显著提高。

中图分类号:

程玮杰, 王明磊, 林国强. 电弧离子镀CrAlN-DLC硬质复合薄膜的成分、结构与性能[J]. 无机材料学报, 2022, 37(7): 764-772.

CHENG Weijie, WANG Minglei, LIN Guoqiang. Composition, Structure and Properties of CrAlN-DLC Hard Composite Films Deposited by Arc Ion Plating[J]. Journal of Inorganic Materials, 2022, 37(7): 764-772.

| Sample | Arc current/A | Arc current ratio, IC/ICrAl | Gas flow/sccm | Pulsed bias | Deposition time/min | ||||

|---|---|---|---|---|---|---|---|---|---|

| CrAl | C | N2 | Ar | Frequency/Hz | Amplitude/V | Duty cycle/% | |||

| CrAlN-DLC 1# | 90 | 30 | 0.33 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 2# | 80 | 40 | 0.5 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 3# | 70 | 50 | 0.71 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 4# | 55 | 65 | 1.18 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 5# | 50 | 70 | 1.4 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 6# | 40 | 80 | 2 | 10 | 90 | 30 | -200 | 40 | 90 |

表1 CrAlN-DLC薄膜的沉积参数

Table 1 Deposition parameters of CrAlN-DLC films

| Sample | Arc current/A | Arc current ratio, IC/ICrAl | Gas flow/sccm | Pulsed bias | Deposition time/min | ||||

|---|---|---|---|---|---|---|---|---|---|

| CrAl | C | N2 | Ar | Frequency/Hz | Amplitude/V | Duty cycle/% | |||

| CrAlN-DLC 1# | 90 | 30 | 0.33 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 2# | 80 | 40 | 0.5 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 3# | 70 | 50 | 0.71 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 4# | 55 | 65 | 1.18 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 5# | 50 | 70 | 1.4 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 6# | 40 | 80 | 2 | 10 | 90 | 30 | -200 | 40 | 90 |

| Sample | IC/ICrAl | Thickness/μm |

|---|---|---|

| CrAlN-DLC 1# | 0.33 | (0.99±0.03) |

| CrAlN-DLC 2# | 0.50 | (1.09±0.02) |

| CrAlN-DLC 3# | 0.71 | (1.09±0.02) |

| CrAlN-DLC 4# | 1.18 | (1.08±0.01) |

| CrAlN-DLC 5# | 1.40 | (1.02±0.02) |

| CrAlN-DLC 6# | 2.00 | (1.04±0.02) |

表2 不同弧流比下CrAlN-DLC薄膜的厚度

Table 2 Thickness of CrAlN-DLC films with different arc current ratios

| Sample | IC/ICrAl | Thickness/μm |

|---|---|---|

| CrAlN-DLC 1# | 0.33 | (0.99±0.03) |

| CrAlN-DLC 2# | 0.50 | (1.09±0.02) |

| CrAlN-DLC 3# | 0.71 | (1.09±0.02) |

| CrAlN-DLC 4# | 1.18 | (1.08±0.01) |

| CrAlN-DLC 5# | 1.40 | (1.02±0.02) |

| CrAlN-DLC 6# | 2.00 | (1.04±0.02) |

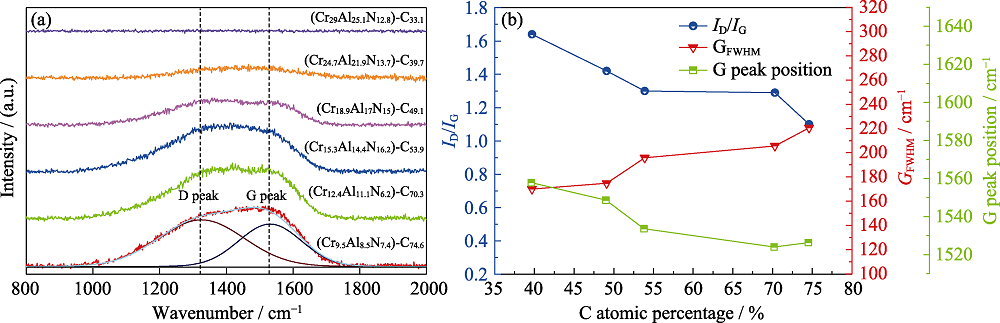

图6 (a) CrAlN-DLC薄膜的Raman谱图和(b)薄膜中ID/IG、G峰峰位以及GFWHM随碳含量的变化曲线

Fig. 6 (a) Raman spectra of CrAlN-DLC films and (b) ID/IG, G peak position and gFWHM changed with C content in the films

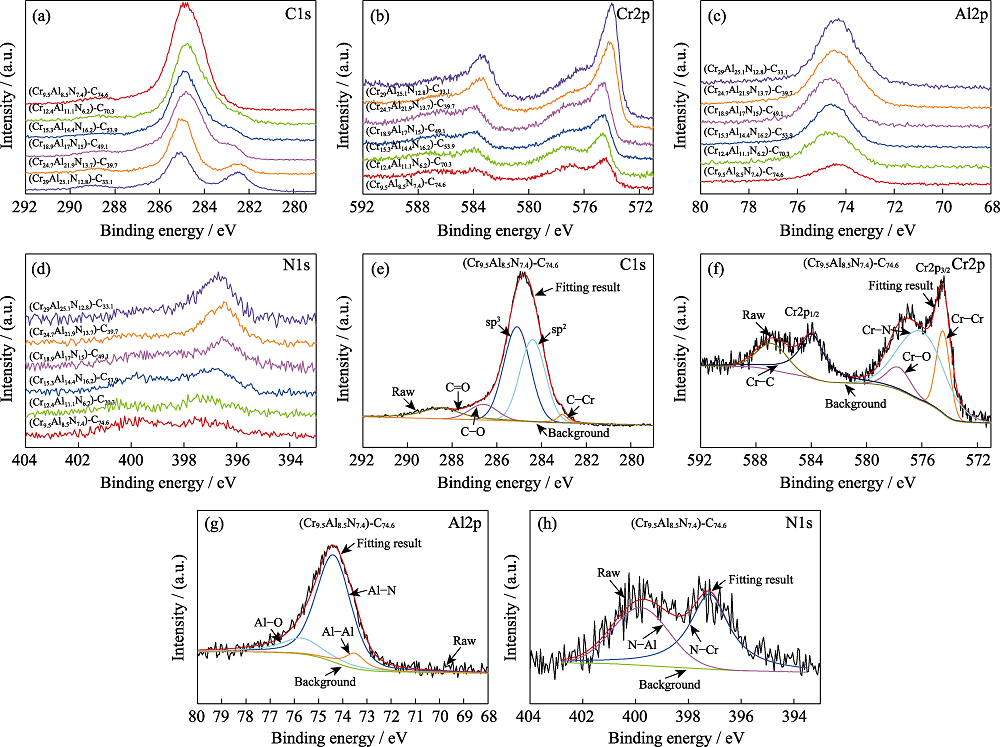

图7 CrAlN-DLC薄膜的(a) C1s, (b) Cr2p, (c) Al2p, (d) N1s XPS图谱以及(Cr9.5Al8.5N7.4)-C74.6薄膜(e) C1s, (f) Cr2p, (g) Al2p, (h) N1s XPS峰的拟合结果

Fig. 7 (a) C1s, (b) Cr2p, (c) Al2p, and (d) N1s XPS spectra of CrAlN-DLC films, and fitting results of (e) C1s, (f) Cr2p, (g) Al2p, and (h) N1s XPS peaks for (Cr9.5Al8.5N7.4)-C74.6 film

| Area Sample | C1s | Cr2p | Al2p | N1s | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-Cr | C-C | C-O | Cr-N | Cr-C | Cr-O | Cr-Cr | Al-N | Al-O | Al-Al | Cr | N-Al | ||

| sp2 | sp3 | ||||||||||||

| (Cr29Al25.1N12.8)-C33.1 | 18.9 | 42.3 | 33.8 | 5.0 | 40.5 | 32.8 | 6.2 | 20.5 | 64.5 | 15.5 | 20.0 | 79.4 | 20.6 |

| (Cr24.7Al21.9N13.7)-C39.7 | 15.4 | 43.3 | 36.0 | 5.3 | 42.6 | 35.5 | 6.9 | 16.0 | 70.9 | 14.8 | 14.3 | 73.9 | 26.1 |

| (Cr18.9Al17N15)-C49.1 | 12.5 | 42.6 | 38.0 | 6.8 | 44.2 | 35.4 | 6.3 | 14.1 | 76.2 | 13.0 | 10.8 | 67.4 | 32.6 |

| (Cr15.3Al14.4N16.2)-C53.9 | 9.8 | 42.7 | 40.0 | 7.5 | 47.7 | 34.6 | 6.1 | 11.6 | 78.3 | 14.2 | 7.5 | 62.8 | 37.2 |

| (Cr12.4Al11.1N6.2)-C70.3 | 7.5 | 41.4 | 42.3 | 8.7 | 40.4 | 36.0 | 7.3 | 18.3 | 63.8 | 17.9 | 18.6 | 59.2 | 40.8 |

| (Cr9.5Al8.5N7.4)-C74.6 | 4.3 | 39.0 | 47.0 | 10.0 | 45.0 | 31.6 | 7.7 | 15.7 | 71.7 | 17.3 | 11.0 | 55.5 | 44.5 |

表3 CrAlN-DLC薄膜C1s、Cr2p、Al2p以及N1s的XPS峰拟合结果(原子分数/%)

Table 3 Fitting results of C1s, Cr2p, Al2p and N1s XPS peak of CrAlN-DLC films (atomic percentage/%)

| Area Sample | C1s | Cr2p | Al2p | N1s | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-Cr | C-C | C-O | Cr-N | Cr-C | Cr-O | Cr-Cr | Al-N | Al-O | Al-Al | Cr | N-Al | ||

| sp2 | sp3 | ||||||||||||

| (Cr29Al25.1N12.8)-C33.1 | 18.9 | 42.3 | 33.8 | 5.0 | 40.5 | 32.8 | 6.2 | 20.5 | 64.5 | 15.5 | 20.0 | 79.4 | 20.6 |

| (Cr24.7Al21.9N13.7)-C39.7 | 15.4 | 43.3 | 36.0 | 5.3 | 42.6 | 35.5 | 6.9 | 16.0 | 70.9 | 14.8 | 14.3 | 73.9 | 26.1 |

| (Cr18.9Al17N15)-C49.1 | 12.5 | 42.6 | 38.0 | 6.8 | 44.2 | 35.4 | 6.3 | 14.1 | 76.2 | 13.0 | 10.8 | 67.4 | 32.6 |

| (Cr15.3Al14.4N16.2)-C53.9 | 9.8 | 42.7 | 40.0 | 7.5 | 47.7 | 34.6 | 6.1 | 11.6 | 78.3 | 14.2 | 7.5 | 62.8 | 37.2 |

| (Cr12.4Al11.1N6.2)-C70.3 | 7.5 | 41.4 | 42.3 | 8.7 | 40.4 | 36.0 | 7.3 | 18.3 | 63.8 | 17.9 | 18.6 | 59.2 | 40.8 |

| (Cr9.5Al8.5N7.4)-C74.6 | 4.3 | 39.0 | 47.0 | 10.0 | 45.0 | 31.6 | 7.7 | 15.7 | 71.7 | 17.3 | 11.0 | 55.5 | 44.5 |

| [1] |

SOROKA E, LYASHENKO B, QIAO S, et al. Tribological behaviour and cutting performance of PVD-TiN coating/substrate system with discontinuous surface architecture. Rare Metal Materials and Engineering, 2011, 40(4): 580-584.

DOI URL |

| [2] |

CHANG Z K, WAN X S, PEI Z L, et al. Microstructure and mechanical properties of CrN coating deposited by arc ion plating on Ti6Al4V substrate. Surface & Coatings Technology, 2011, 205(19): 4690-4696.

DOI URL |

| [3] |

BERTRAND G, SAVALL C, MEUNIER C, et al. Properties of reactively RF magnetron-sputtered chromium nitride coatings. Surface & Coatings Technology, 1997, 96(2): 323-329.

DOI URL |

| [4] |

WANG L, ZHANG G, WOOD R, et al. Fabrication of CrAlN nanocomposite films with high hardness and excellent anti-wear performance for gear application. Surface & Coatings Technology, 2010, 204(21): 3517-3524.

DOI URL |

| [5] | KIM M W, KIM K H, KANG M C, et al. Mechanical properties and cutting performance of Cr-Al-N hybrid coated micro-tool for micro high-speed machining of flexible fine die. Current Applied Physics, 2012, 12: S14-S18. |

| [6] |

REN X, ZHU H, LIU M, et al. Comparison of microstructure and tribological behaviors of CrAlN and CrN film deposited by DC magnetron sputtering. Rare Metal Materials and Engineering, 2018, 47(4): 1100-1106.

DOI URL |

| [7] |

DING X Z, ZENG X T, LIU Y C, et al. Cr1-xAlxN coatings deposited by lateral rotating cathode arc for high speed machining applications. Thin Solid Films, 2007, 516(8): 1710-1715.

DOI URL |

| [8] |

MO J L, ZHU M H, LEI B, et al. Comparison of tribological behaviours of AlCrN and TiAlN coatings-deposited by physical vapor deposition. Wear, 2007, 263(7): 1423-1429.

DOI URL |

| [9] |

SCHEERER H, HOCHE H, BROSZEIT E, et al. Effects of the chromium to aluminum content on the tribology in dry machining using (Cr,Al)N coated tools. Surface & Coatings Technology, 2005, 200(1-4): 203-207.

DOI URL |

| [10] | JFCA B, WA C, JCC A, et al. Structural, mechanical and tribological behavior of TiCN, CrAlN and BCN coatings in lubricated and non-lubricated environments in manufactured devices. Materials Chemistry and Physics, 2020, 252: 123164. |

| [11] | MO Y J, WANG M L, CHEN W J. Composition, structure and properties of the Cr1-xAlxN hard films deposited by arc ion plating. Journl of Inorgamic Materials, 2020, 35(6): 675-681. |

| [12] | ROBERTSON J. Diamond-like amorphous carbon. Materials Science & Engineering R, 2002, 37(4): 129-281. |

| [13] |

TILLMANN W, STANGIER D, SCHRDER P, et al. Investigation and optimization of the tribo-mechanical properties of CrAlCN coatings using design of experiments. Surface & Coatings Technology, 2016, 308: 147-157.

DOI URL |

| [14] |

ZHANG M, ZHOU F, FANG H, et al. Structure and tribological properties of CrTiAlCN coatings with various carbon contents. Journal of Materials Engineering and Performance, 2019, 28(3): 1509-1521.

DOI URL |

| [15] | LIN G Q, ZHAO Y H, GUO H M, et al. Experiments and theoretical explanation of droplet elimination phenomenon in pulsed-bias arc deposition. Acta Ophthalmologica, 2004, 22(4): 288-303. |

| [16] | 赵彦辉, 林国强, 董闯, 等. 脉冲工艺在薄膜制备中的应用. 中国真空学会. 薄膜技术学术研讨会论文集. 中国真空学会: 中国真空学会, 2003: 5. |

| [17] |

DAI W, HE Z, WU G, et al. Effect of bias voltage on growth property of Cr-DLC film prepared by linear ion beam deposition technique. Vacuum, 2010, 85(2): 231-235.

DOI URL |

| [18] |

FERRARI A C. Determination of bonding in diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater., 2002, 11: 1053-1061.

DOI URL |

| [19] |

ZHOU Y, GUO P, SUN L, et al. Microstructure and property evolution of diamond-like carbon films co-doped by Al and Ti with different ratios. Surface & Coatings Technology, 2019, 361: 83-90.

DOI URL |

| [20] |

CHOI J H, LEE S C, LEE K R. A first-principles study on the bond characteristics in carbon containing Mo, Ag, or Al impurity atoms. Carbon, 2007, 46(2): 185-188.

DOI URL |

| [21] |

WU D, REN S, PU J, et al. A comparative study of tribological characteristics of hydrogenated DLC film sliding against ceramic mating materials for helium applications. Applied Surface Science, 2018, 441: 884-894.

DOI URL |

| [1] | 苏东良, 崔锦, 翟朋博, 郭向欣. 石榴石型Li6.4La3Zr1.4Ta0.6O12对Si/C负极表面固体电解质中间相的调控机制研究[J]. 无机材料学报, 2022, 37(7): 802-808. |

| [2] | 彭军辉, TIKHONOV Evgenii. 空位对Hf-Ta-C体系的结构、力学性质及电子性质影响的第一性原理研究[J]. 无机材料学报, 2022, 37(1): 51-57. |

| [3] | 莫亚杰,王明磊,程玮杰,林国强. 电弧离子镀Cr1-xAlxN硬质薄膜的成分、结构与性能[J]. 无机材料学报, 2020, 35(6): 675-681. |

| [4] | 张丽艳, 李洪, 胡丽丽, 王亚杰. 玻璃成分-结构-性质的“基因结构”模拟法[J]. 无机材料学报, 2019, 34(8): 885-892. |

| [5] | 郭胜强, 王皓, 涂兵田, 王斌, 徐鹏宇, 王为民, 傅正义. 细晶MgO·1.44Al2O3透明陶瓷的制备及其性能研究[J]. 无机材料学报, 2019, 34(10): 1067-1071. |

| [6] | 崔凤单, 马 天, 李伟萍, 吴国清. SiC和B4C防弹插板抗多发弹打击损伤特性研[J]. 无机材料学报, 2017, 32(9): 967-972. |

| [7] | 陈宇方, 李宇杰, 郑春满, 谢 凯, 陈重学. 富锂层状氧化物正极材料研究进展[J]. 无机材料学报, 2017, 32(8): 792-800. |

| [8] | 李淼磊, 王恩青, 岳建岭, 黄小忠. TiAlN/VN纳米多层膜的微结构与力学和摩擦学性能[J]. 无机材料学报, 2017, 32(12): 1280-1284. |

| [9] | 马 剑, 张波萍, 陈建银. Bi过量以及冷却方式对BiFeO3-BaTiO3陶瓷的相结构及电学性能的影响[J]. 无机材料学报, 2017, 32(10): 1035-1041. |

| [10] | 鲁媛媛, 李贺军, 杨冠军. 氢稀释比对氢化硅薄膜两相结构和电学性能的影响[J]. 无机材料学报, 2015, 30(5): 474-478. |

| [11] | 吴志立, 李玉阁, 吴 彼, 雷明凯. 高功率调制脉冲磁控溅射沉积TiAlSiN纳米复合涂层结构调控与性能研究[J]. 无机材料学报, 2015, 30(12): 1254-1260. |

| [12] | 梅兴志, 罗永春, 张国庆, 康 龙. 稀土系A2B7型La1-xScxNi2.6Co0.3Mn0.5Al0.1(x = 0~0.5)储氢合金相结构和电化学性能研究[J]. 无机材料学报, 2015, 30(10): 1049-1055. |

| [13] | 李戈扬. 评Veprek的nc-TiN/a-Si3N4模型和其“超过金刚石硬度”的实验基础[J]. 无机材料学报, 2015, 30(1): 1-8. |

| [14] | 胡海龙, 曾宇平, 左开慧, 夏咏锋,姚冬旭. 烧结助剂种类对Si3N4/SiC陶瓷力学与摩擦性能的影响[J]. 无机材料学报, 2014, 29(8): 885-890. |

| [15] | 王孝笑, 杨 琳, 刘 洪, 陈 强, 肖定全, 朱建国. 低温水热法制备ZnS:Co+Cr纳米晶及其光学性能研究[J]. 无机材料学报, 2014, 29(10): 1049-1054. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||