无机材料学报 ›› 2022, Vol. 37 ›› Issue (4): 427-435.DOI: 10.15541/jim20210264

所属专题: 【生物材料】骨骼与齿类组织修复; 【虚拟专辑】增材制造及3D打印(2021-2022)

收稿日期:2021-04-19

修回日期:2021-06-25

出版日期:2022-04-20

网络出版日期:2021-07-20

通讯作者:

朱敏, 副教授. E-mail: mzhu@usst.edu.cn;作者简介:施吉翔(1991-), 男, 硕士研究生. E-mail: 929789873@qq.com

基金资助:

SHI Jixiang1( ), ZHAI Dong2, ZHU Min1(

), ZHAI Dong2, ZHU Min1( ), ZHU Yufang2(

), ZHU Yufang2( )

)

Received:2021-04-19

Revised:2021-06-25

Published:2022-04-20

Online:2021-07-20

Contact:

ZHU Ming, associate professor. E-mail: mzhu@usst.edu.cn;About author:SHI Jixiang (1991-), male, Master candidate. E-mail: 929789873@qq.com

Supported by:摘要:

骨修复支架在植入缺损处后出现的炎症与氧化应激有关, 其中过氧化氢(H2O2)浓度过高是引起氧化应激的主要原因之一。二氧化锰(MnO2)能够通过催化分解H2O2来消除植入物周围环境过量的H2O2, 同时催化H2O2分解产生的氧气(O2)能够缓解骨缺损处因血供不足而导致的缺氧环境, 从而有利于骨组织再生与骨缺损修复。本研究采用简单的氧化还原法在3D打印制备的生物活性玻璃(BG)支架表面原位沉积MnO2颗粒, 得到BG-MnO2复合支架(BGM), 赋予BG支架清除H2O2的同时提供O2的能力。研究结果表明, BGM支架表面沉积MnO2含量随反应溶液中高锰酸钾浓度升高而增加, 其抗压强度随MnO2含量增加而增强, 但这些支架的孔隙率和降解速度基本保持不变。更为重要的是, BGM支架能够在H2O2环境中持续催化分解H2O2产生O2, 当不同Mn含量的BGM (BGM5和BMG9)支架在浓度为2 mmol/L的H2O2溶液中催化分解H2O2产生的O2能使溶液中饱和氧浓度分别达到8.4和11 mg/L。细胞实验结果表明, BGM支架对骨髓间充质干细胞的增殖和碱性磷酸酶活性有一定促进作用。因此, BGM支架在骨组织修复领域具有较大的应用潜力。

中图分类号:

施吉翔, 翟东, 朱敏, 朱钰方. 生物活性玻璃-二氧化锰复合支架的制备与表征[J]. 无机材料学报, 2022, 37(4): 427-435.

SHI Jixiang, ZHAI Dong, ZHU Min, ZHU Yufang. Preparation and Characterization of Bioactive Glass-Manganese Dioxide Composite Scaffolds[J]. Journal of Inorganic Materials, 2022, 37(4): 427-435.

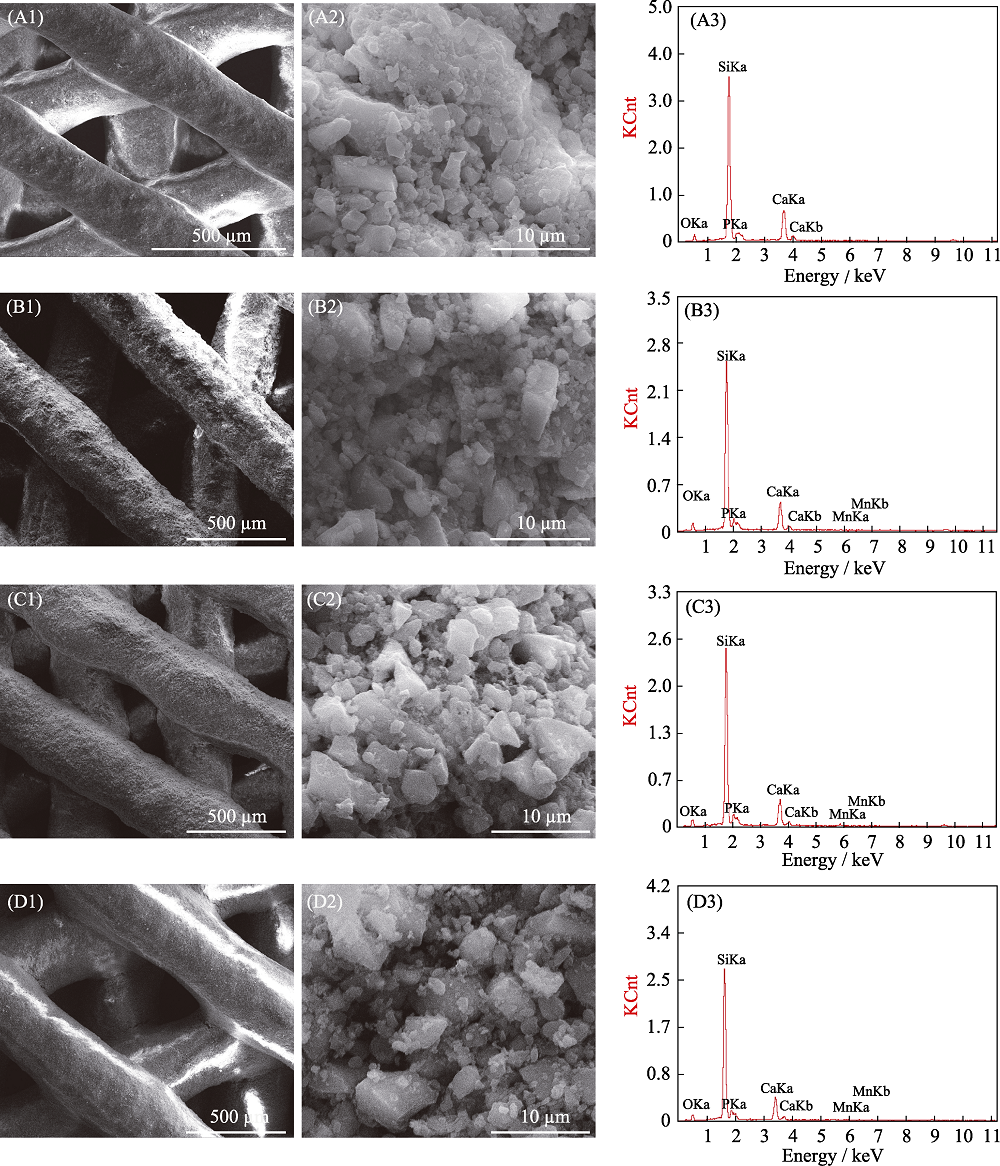

图2 BG和BGM支架的(A1, A2, B1, B2, C1, C2, D1, D2) SEM照片和相应的(A3, B3, C3, D3)EDS图谱

Fig. 2 (A1, A2, B1, B2, C1, C2, D1, D2) SEM images and corresponding (A3, B3, C3, D3) EDS spectra of BG and BGM scaffolds (A1, A2, A3) BG scaffold; (B1, B2, B3) BGM1 scaffold; (C1, C2, C3) BGM5 scaffold; (D1, D2, D3) BGM9 scaffold

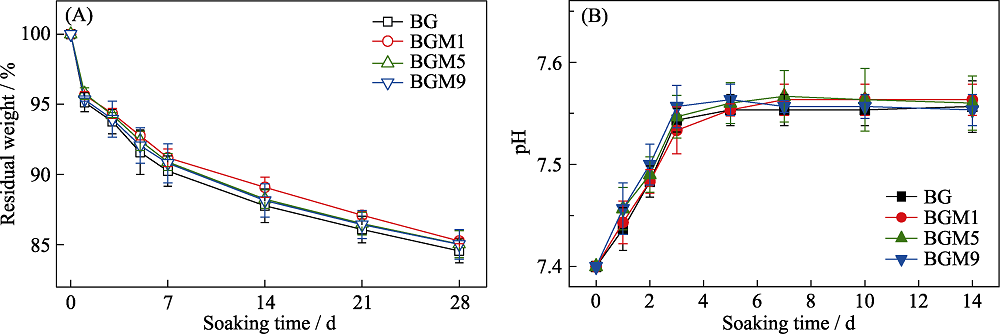

图5 (A)BG和BGM支架在Tris-HCl中浸泡28 d的降解曲线及(B)BG和BGM支架在SBF中浸泡14 d的pH变化曲线

Fig. 5 (A) Degradation curves of BG and BGM scaffolds in Tris-HCl for 28 d, and (B) pH change curves of SBF after BG and BGM scaffolds soaking for 14 d

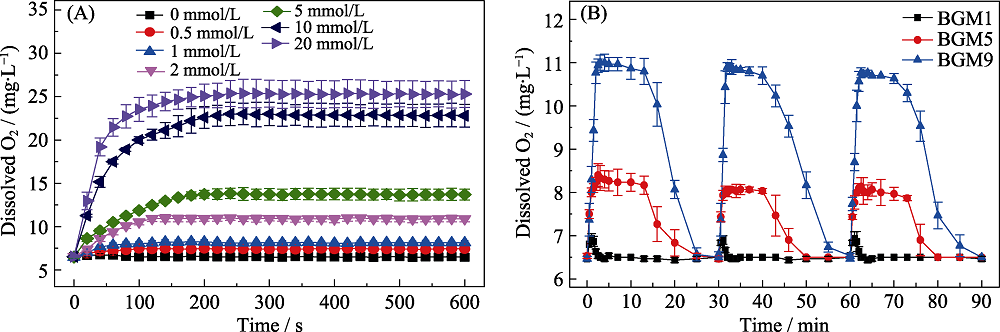

图6 (A)BGM9支架在不同浓度H2O2溶液中的溶解氧水平和(B)BGM支架在 2 mmol/L H2O2溶液中溶解氧变化曲线(连续循环测试3次)

Fig. 6 (A) Dissolved oxygen levels in different concentrations of H2O2 solution after immersing BGM9 scaffolds, and (B) dissolved oxygen change curves in 2 mmol/L H2O2 solutions after immersing BGM scaffolds (cycle test for 3 times)

| [1] | SHIEKH P A, SINGH A, KUMAR A. Oxygen releasing antioxidant cryogel scaffolds with sustained oxygen delivery for tissue engineering applications. ACS Applied Materials & Interfaces, 2018, 10(22): 18458-18469. |

| [2] |

LOVETT M, LEE K, EDWARDS A, et al. Vascularization strategies for tissue engineering. Tissue Engineering Part B: Reviews, 2009, 15(3): 353-370.

DOI URL |

| [3] |

BECQUART P, CAMBON-BINDER A, MONFOULET L E, et al. Ischemia is the prime but not the only cause of human multipotent stromal cell death in tissue-engineered constructs in vivo. Tissue Engineering Part A, 2012, 18(19/20): 2084-2094.

DOI URL |

| [4] |

PISU M, LAI N, CINCOTTI A, et al. Modeling of engineered cartilage growth in rotating bioreactors. Chemical Engineering Science, 2004, 59: 5035-5040.

DOI URL |

| [5] |

TOURI M, MOZTARZADEH F, OSMAN N A A, et al. 3D-printed biphasic calcium phosphate scaffolds coated with an oxygen generating system for enhancing engineered tissue survival. Material Science and Engineering C, 2018, 84: 236-242.

DOI URL |

| [6] |

LÜ X G, LI Z, CHEN S Y, et al. Structural and functional evaluation of oxygenating keratin/silk fibroin scaffold and initial assessment of their potential for urethral tissue engineering. Biomaterials, 2016, 84: 99-110.

DOI URL |

| [7] |

LEE E M, JUNG J I, ALAM Z, et al. Effect of an oxygen- generating scaffold on the viability and insulin secretion function of porcine neonatal pancreatic cell clusters. Xenotransplantation, 2018, 25(2):e12378.

DOI URL |

| [8] |

KUMAR S, ADJEI I M, BROWN S, et al. Manganese dioxide nanoparticles protect cartilage from inflammation-induced oxidative stress. Biomaterials, 2019, 224: 119467.

DOI URL |

| [9] |

BIZEAU J, TAPEINOS C, MARELLA C, et al. Synthesis and characterization of hyaluronic acid coated manganese dioxide microparticles that act as ROS scavengers. Colloids and Surfaces B: Biointerfaces, 2017, 159: 30-38.

DOI URL |

| [10] |

LI Q, REN J J, CHEN Q B, et al. A HMCuS@MnO2 nanocomplex responsive to multiple tumor environmental clues for photoacoustic/ fluorescence/magnetic resonance trimodal imaging-guided and enhanced photothermal/photodynamic therapy. Nanoscale, 2020, 12(23): 12508-12521.

DOI URL |

| [11] |

WANG Y D, SONG S Z, LU T, et al. Oxygen-supplementing mesoporous polydopamine nanosponge with WS2 QDs-embedded for CT/MSOT/MR imaging and thermoradiotherapy of hypoxic cancer. Biomaterials, 2019, 220: 119405.

DOI URL |

| [12] |

ANAND A, LALZAWMLIANA V, KUMAR V, et al. Preparation and in vivo biocompatibility studies of different mesoporous bioactive glasses. Journal of the Mechanical Behavior of Biomedical Materials, 2019, 89: 89-98.

DOI URL |

| [13] |

KARGOZAR S, MONTAZERIAN M, HAMZEHLOU S, et al. Mesoporous bioactive glasses: promising platforms for antibacterial strategies. Acta Biomaterialia, 2018, 81: 1-19.

DOI URL |

| [14] | SAEID K, FRANCESCO B, SEPIDEH H, et al. Bioactive glasses entering the mainstream. Drug Discovery Today, 2018, 23: S1359644618300394. |

| [15] |

MUBINA M S K, SHAILAJHA S, SANKARANARAYANAN R, et al. In vitro bioactivity, mechanical behavior and antibacterial properties of mesoporous SiO2-CaO-Na2O-P2O5 nano bioactive glass ceramics. Journal of the Mechanical Behavior of Biomedical Materials, 2019, 100: 103379.

DOI URL |

| [16] |

FU S Y, ZHU M, ZHU Y F. Organosilicon polymer-derived ceramics: an overview. Journal of Advanced Ceramics, 2019, 8(4): 457-478.

DOI URL |

| [17] |

CHEN Z, SUN X H, SHANG Y P, et al. Dense ceramics with complex shape fabricated by 3D printing: a review. Journal of Advanced Ceramics, 2021, 10(2): 195-218.

DOI URL |

| [18] |

YANG L L, ZENG X J, DITTA A, et al. Preliminary 3D printing of large inclined-shaped alumina ceramic parts by direct ink writing. Journal of Advanced Ceramics, 2020, 9(3): 312-319.

DOI URL |

| [19] |

ZHAO Z, ZHOU G X, YANG Z H, et al. Direct ink writing of continuous SiO2 fiber reinforced wave-transparent ceramics. Journal of Advanced Ceramics, 2020, 9(4): 403-412.

DOI URL |

| [20] |

WU C T, LUO Y X, CUNIBERTI G, et al. Three-dimensional printing of hierarchical and tough mesoporous bioactive glass scaffolds with a controllable pore architecture, excellent mechanical strength and mineralization ability. Acta Biomaterialia, 2011, 7(6): 2644-2650.

DOI URL |

| [21] |

LI L, HU H X, ZHU Y F, et al. 3D-printed ternary SiO2-CaO-P2O5 bioglass-ceramic scaffolds with tunable compositions and properties for bone regeneration. Ceramics International, 2019, 45(8): 10997-11005.

DOI URL |

| [22] |

YE X, JIANG X, CHEN L, et al. Effect of manganese dioxide crystal structure on adsorption of SO2 by DFT and experimental study. Applied Surface Science, 2020, 521: 146477.

DOI URL |

| [23] |

REN L L, ZHOU D Y, WANG J J, et al. Biomaterial-based flower-like MnO2@carbon microspheres for rapid adsorption of amoxicillin from wastewater. Journal of Molecular Liquids, 2020, 309: 113074.

DOI URL |

| [24] |

CHEN Y, YE D L, WU M Y, et al. Break-up of two-dimensional MnO2nanosheets promotes ultrasensitive pH-triggered theranostics of cancer. Advanced Materials, 2014, 26(41): 7019-7026.

DOI URL |

| [25] |

HU X N, SHI L Y, ZHANG D S, et al. Accelerating the decomposition of KMnO4 by photolysis and auto-catalysis: a green approach to synthesize a layered birnessite-type MnO2 assembled hierarchical nanostructure. RSC Advances, 2016, 6(17): 14192-14198.

DOI URL |

| [26] |

SHAABANI A, AFARIDOUN H, SHAABANI S. Natural hydroxyapatite-supported MnO2: a green heterogeneous catalyst for selective aerobic oxidation of alkylarenes and alcohols. Applied Organometallic Chemistry, 2016, 30(9): 772-776.

DOI URL |

| [27] |

HAO X L, ZHAO J Z, SONG Y H, et al. Surfactant-assisted synthesis of birnessite-type MnO2 nanoflowers. Journal of Nano Research, 2018, 53: 1-6.

DOI URL |

| [28] |

JING X N, XU Y Z, LIU D M, et al. Intelligent nanoflowers: a full tumor microenvironment-responsive multimodal cancer theranostic nanoplatform. Nanoscale, 2019, 11(33): 15508-15518.

DOI URL |

| [29] |

HE D G, HE X X, WANG K, et al. Redox-responsive degradable honeycomb manganese oxide nanostructures as effective nanocarriers for intracellular glutathione-triggered drug release. Chemical Communications, 2014, 51(4): 776-779.

DOI URL |

| [30] |

CHEN B, WANG F. NaYbF4@CaF2 core-satellite upconversion nanoparticles: one-pot synthesis and sensitive detection of glutathione. Nanoscale, 2018, 10(42): 19898-19905.

DOI URL |

| [31] |

WANG Z Z, ZHANG Y, JU E G, et al. Biomimetic nanoflowers by self-assembly of nanozymes to induce intracellular oxidative damage against hypoxic tumors. Nature Communications, 2018, 9(1):3334.

DOI URL |

| [32] | YAN X X, YU C Z, ZHOU X F, et al. Highly ordered mesoporous bioactive glasses with superior in vitro bone-forming bioactivities. Angewandte Chemie International Edition, 2004, 116: 6106-6110. |

| [33] |

DENG R R, XIE X J, VENDRELL M, et al. Intracellular glutathione detection using MnO2-nanosheet-modified upconversion nanoparticles. Journal of the American Chemical Society, 2011, 133(50): 20168-20171.

DOI URL |

| [34] |

ZHANG L H, LIAN J S, WU L Y, et al. Synthesis of a thin-layer MnO2 nanosheet-coated Fe3O4 nanocomposite as a magnetically separable photocatalyst. Langmuir, 2014, 30(23): 7006-7013.

DOI URL |

| [35] | FRÖHLICH M, GRAYSON W L, WAN L Q, et al. Tissue engineered bone grafts: biological requirements, tissue culture and clinical relevance. Current Stem Cell Research & Therapy, 2008, 3(4): 254-264. |

| [36] |

AZIZI F, HEIDARI F, FAHIMIPOUR F, et al. Evaluation of mechanical and biocompatibility properties of hydroxyapatite/manganese dioxide nanocomposite scaffolds for bone tissue engineering application. International Journal of Applied Ceramic Technology, 2020, 17(5): 2439-2449.

DOI URL |

| [37] |

HSIEH T E, LIN S J, CHEN L C, et al. Optimizing an injectable composite oxygen-generating system for relieving tissue hypoxia. Frontiers in Bioengineering and Biotechnology, 2020, 8: 511.

DOI URL |

| [38] |

LACY F, KAILASAM M T, O'CONNOR D T, et al. Plasma hydrogen peroxide production in human essential hypertension role of heredity, gender, and ethnicity. Hypertension, 2000, 36(5): 878-884.

DOI URL |

| [39] | BURGOYNE J R, OKA S I, ALE-AGHA N, et al. Hydrogen peroxide sensing and signaling by protein kinases in the cardiovascular system. Antioxidants & Redox Signaling, 2013, 18(9): 1042-1052. |

| [40] |

WANG J Q, ZHANG Y Q, ARCHIBONG E, et al. Leveraging H2O2 levels for biomedical applications. Advanced Biosystems, 2017, 1(9):1700084.

DOI URL |

| [41] | TAPEINOS C, LARRAÑAGA A, SARASUA J R, et al. Functionalised collagen spheres reduce H2O2 mediated apoptosis by scavenging overexpressed ROS. Nanomedicine, 2018, 14(7): 2397-2405. |

| [42] |

JÄGER E, HÖCHERL A, JANOUŠKOVÁ O, et al. Fluorescent boronate-based polymer nanoparticles with reactive oxygen species (ROS)-triggered cargo release for drug-delivery applications. Nanoscale, 2016, 8(13): 6958-6963.

DOI URL |

| [43] |

DEEPAGAN V G, KWON S, YOU D G, et al. In situ diselenide- crosslinked polymeric micelles for ROS-mediated anticancer drug delivery. Biomaterials, 2016, 103: 56-66.

DOI URL |

| [44] |

WU C T, RAMASWAMY Y, ZHU Y F, et al. The effect of mesoporous bioactive glass on the physiochemical, biological and drug-release properties of poly(DL-lactide-co-glycolide) films. Biomaterials, 2009, 30(12): 2199-2208.

DOI URL |

| [45] |

WU C T, CHANG J. Degradation, bioactivity, and cytocompatibility of diopside, akermanite, and bredigite ceramics. Journal of Biomedical Materials Research Part B Applied Biomaterials, 2010, 83B(1): 153-160.

DOI URL |

| [46] |

NAWAZ Q, REHMAN M A U, ROETHER J A, et al. Bioactive glass based scaffolds incorporating gelatin/manganese doped mesoporous bioactive glass nanoparticle coating. Ceramics International, 2019, 45(12): 14608-14613.

DOI URL |

| [1] | 吴重草, 郇志广, 朱钰方, 吴成铁. 3D打印HA微球支架的制备与表征[J]. 无机材料学报, 2021, 36(6): 601-607. |

| [2] | 董少杰,王旭东,沈国芳,王晓虹,林开利. 生物陶瓷支架的功能改性及应用研究进展[J]. 无机材料学报, 2020, 35(8): 867-881. |

| [3] | 王金敏, 于红玉, 马董云. 纳米二氧化锰的制备及其应用研究进展[J]. 无机材料学报, 2020, 35(12): 1307-1314. |

| [4] | 李学林, 朱建锋, 焦宇鸿, 黄家璇, 赵倩楠. 二氧化锰形貌对Ti3C2Tx@MnO2复合材料电化学性能的影响[J]. 无机材料学报, 2020, 35(1): 119-125. |

| [5] | 傅声扬, 俞斌, 丁惠锋, 石国栋, 朱钰方. 二氧化锆掺入对三维打印的硅酸二钙支架物理化学和生物学性能的影响[J]. 无机材料学报, 2019, 34(4): 444-454. |

| [6] | 辛 晨, 齐 鑫, 朱 敏, 赵世昌, 朱钰方. 三维打印羟基磷灰石晶须增强复合骨修复支架[J]. 无机材料学报, 2017, 32(8): 837-844. |

| [7] | 侯 渊, 张邦文, 邢瑞光, 布林朝克. 一步合成还原氧化石墨烯/MnO2复合材料及其电化学性能[J]. 无机材料学报, 2015, 30(8): 855-860. |

| [8] | 肖兴中, 易清风. MnO2/SMWCNT/PANI三元复合材料的合成及其电化学电容性能[J]. 无机材料学报, 2013, 28(8): 825-830. |

| [9] | 黄幼菊, 李伟善. 水热法合成锌空气电池氧还原二氧化锰催化剂[J]. 无机材料学报, 2013, 28(3): 341-346. |

| [10] | 文建国,阮湘元,周震涛. 超临界干燥法制备MnO2气凝胶及其表征[J]. 无机材料学报, 2009, 24(3): 521-524. |

| [11] | 肖斌,周大利,杨为中,欧俊,唐艳娟,陈槐卿. 磷灰石-硅灰石/β-磷酸三钙复合多孔支架材料的制备和表征[J]. 无机材料学报, 2006, 21(2): 427-432. |

| [12] | 朱立才,袁中直,李伟善. 化学组成对EMD电化学行为的影响[J]. 无机材料学报, 2005, 20(2): 489-493. |

| [13] | 周大利,杨为中,尹光福,郑昌琼,陈锐,陈槐卿. β-磷酸三钙/聚L-乳酸与大鼠骨膜成骨细胞复合骨修复材料的研究[J]. 无机材料学报, 2005, 20(1): 105-111. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||