无机材料学报 ›› 2022, Vol. 37 ›› Issue (4): 459-466.DOI: 10.15541/jim20210230

所属专题: 【结构材料】陶瓷基复合材料

阮景1,2,3( ), 杨金山1,2(

), 杨金山1,2( ), 闫静怡1,2,4, 游潇1,2,4, 王萌萌1,2,4, 胡建宝1,2, 张翔宇1,2, 丁玉生1,2, 董绍明1,2,5(

), 闫静怡1,2,4, 游潇1,2,4, 王萌萌1,2,4, 胡建宝1,2, 张翔宇1,2, 丁玉生1,2, 董绍明1,2,5( )

)

收稿日期:2021-04-07

修回日期:2021-06-27

出版日期:2022-04-20

网络出版日期:2021-06-30

通讯作者:

杨金山, 研究员. E-mail: jyang@mail.sic.ac.cn;作者简介:阮景(1993–), 男, 博士研究生. E-mail: ruanjing@shanghaitech.edu.cn

RUAN Jing1,2,3( ), YANG Jinshan1,2(

), YANG Jinshan1,2( ), YAN Jingyi1,2,4, YOU Xiao1,2,4, WANG Mengmeng1,2,4, HU Jianbao1,2, ZHANG Xiangyu1,2, DING Yusheng1,2, DONG Shaoming1,2,5(

), YAN Jingyi1,2,4, YOU Xiao1,2,4, WANG Mengmeng1,2,4, HU Jianbao1,2, ZHANG Xiangyu1,2, DING Yusheng1,2, DONG Shaoming1,2,5( )

)

Received:2021-04-07

Revised:2021-06-27

Published:2022-04-20

Online:2021-06-30

Contact:

YANG Jinshan, professor. E-mail: jyang@mail.sic.ac.cn;About author:RUAN Jing (1993–), male, PhD candidate. E-mail: ruanjing@shanghaitech.edu.cn

Supported by:摘要:

构建多孔碳化硅纳米线(SiCNWs)网络并控制化学气相渗透(CVI)过程,可设计并获得轻质、高强度和低导热率SiC复合材料。首先将SiCNWs和聚乙烯醇(PVA)混合,制备具有最佳体积分数(15.6%)和均匀孔隙结构的SiCNWs网络;通过控制CVI参数获得具有小而均匀孔隙结构的SiCNWs增强多孔SiC(SiCNWs/SiC)陶瓷基复合材料。SiC基体形貌受沉积参数(如温度和反应气体浓度)的影响,从球状颗粒向六棱锥颗粒形状转变。SiCNWs/SiC陶瓷基复合材料的孔隙率为38.9%时,强度达到(194.3±21.3) MPa,导热系数为(1.9 ± 0.1) W/(m∙K),显示出增韧效果,并具有低导热系数。

中图分类号:

阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 碳化硅纳米线增强多孔碳化硅陶瓷基复合材料的制备[J]. 无机材料学报, 2022, 37(4): 459-466.

RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity[J]. Journal of Inorganic Materials, 2022, 37(4): 459-466.

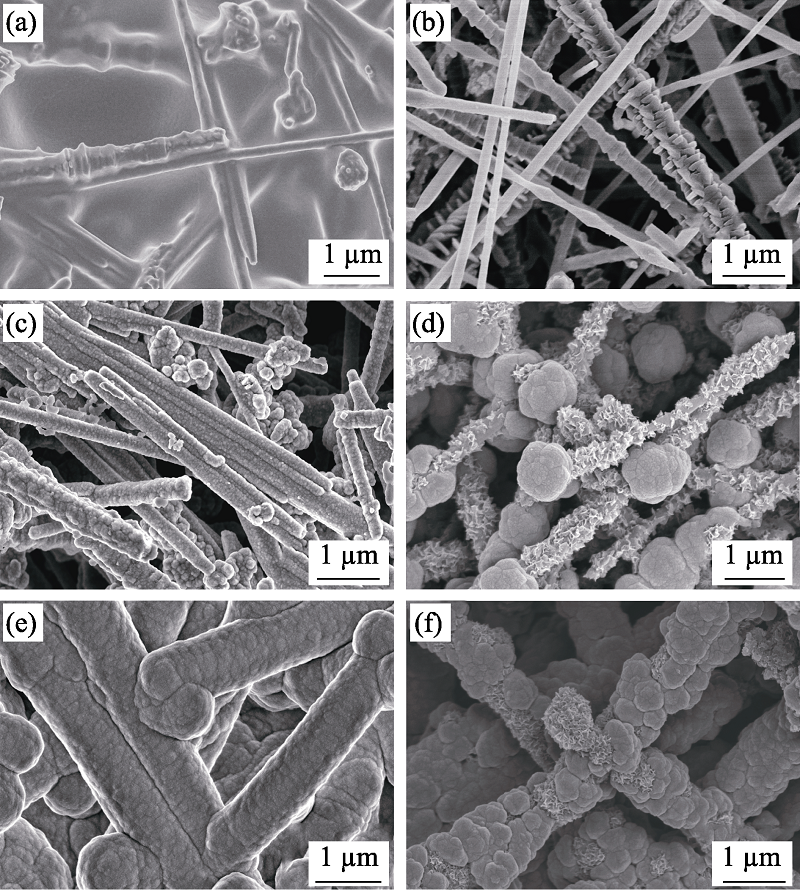

Fig. 1 Surface morphologies of the SiCNWs/PVA film (a), SiCNWs network without PyC and SiC deposition (b), surface morphologies of sample without (c) and with (d) PyC interphase after short time CVI process, and without (e) and with (f) PyC interphase after a long time CVI process

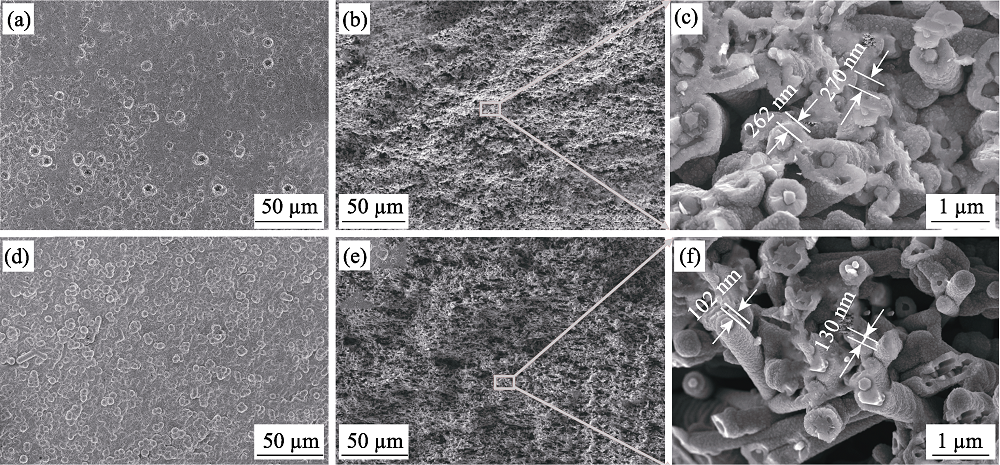

Fig. 3 SEM images of the prepared SiCNWs/SiC ceramic matrix composites (a) External surface view of the sample under 8 h CVI process at 1030 ℃; (b) Fracture surface view and (c) corresponding enlarged region of the sample under 8 h CVI process at 1030 ℃; (d) External surface view of the sample under 8 h CVI process at 1100 ℃; (e) Fracture surface view and (f) corresponding enlarged region of the sample under 8 h CVI process at 1100 ℃

| Materials | Porosity/% | Strength /MPa | Thermal conductivity/(W·m-1·K-1) | Ref. |

|---|---|---|---|---|

| Porous SiC-SiO2 ceramic | ~72 | ~2.7 | 0.066 | [ |

| Sc-doped porous SiC ceramic | ~61% | 10.5 | 7.700 | [ |

| Porous Al2O3-SiC | ~38 | 28.0 | - | [ |

| Porous ZrB2-SiC ceramics | ~59% | ~78.0 | - | [ |

| Porous SiC ceramic | ~40% | ~10.7 | 0.580 | [ |

| Porous SiCNWs/SiC ceramic matrix composite | ~39% | ~194.3 | 1.900 | This work |

| Porous SiCNWs/SiC ceramic matrix composite | ~62% | ~49.0 | 1.600 | This work |

Table 1 Strength and thermal conductivity of different materials

| Materials | Porosity/% | Strength /MPa | Thermal conductivity/(W·m-1·K-1) | Ref. |

|---|---|---|---|---|

| Porous SiC-SiO2 ceramic | ~72 | ~2.7 | 0.066 | [ |

| Sc-doped porous SiC ceramic | ~61% | 10.5 | 7.700 | [ |

| Porous Al2O3-SiC | ~38 | 28.0 | - | [ |

| Porous ZrB2-SiC ceramics | ~59% | ~78.0 | - | [ |

| Porous SiC ceramic | ~40% | ~10.7 | 0.580 | [ |

| Porous SiCNWs/SiC ceramic matrix composite | ~39% | ~194.3 | 1.900 | This work |

| Porous SiCNWs/SiC ceramic matrix composite | ~62% | ~49.0 | 1.600 | This work |

| [1] |

LI S, ZENG X, CHEN H, et al. Porous hexagonal boron nitride nanosheets from g-C3N4 templates with a high specific surface area for CO2 adsorption. Ceramics International, 2020, 46(17): 27627-27633.

DOI URL |

| [2] | SARAVANAN S, CHIDAMBARAM R K, GEO V E. An experimental study to analyze influence of porous media combustor on performance and emission characteristics of a DI diesel engine. Fuel, 2020, 280: 118645-1-8. |

| [3] | BICY K, KALARIKKAL N, STEPHEN A M, et al. Facile fabrication of microporous polypropylene membrane separator for lithium-ion batteries. Materials Chemistry and Physics, 2020, 255: 123473-1-9. |

| [4] | PAN B, CHEN J, ZHANG F, et al. Porous TiO2 aerogel-modified SiC ceramic membrane supported MnOx catalyst for simultaneous removal of NO and dust. Journal of Membrane Science, 2020, 611: 118366-1-10. |

| [5] |

SONG X, JIAN B, JIN J. Preparation of porous ceramic membrane for gas-solid separation. Ceramics International, 2018, 44(16): 20361-20366.

DOI URL |

| [6] |

WANG Z, PAN Z. Preparation of hierarchical structured nano-sized/ porous poly (lactic acid) composite fibrous membranes for air filtration. Applied Surface Science, 2015, 356: 1168-1179.

DOI URL |

| [7] |

LIU X, MARTIN C L, BOUVARD D, et al. Strength of highly porous ceramic electrodes. Journal of the American Ceramic Society, 2011, 94(10): 3500-3508.

DOI URL |

| [8] |

HUO W, ZHANG X, CHEN Y, et al. Mechanical strength of highly porous ceramic foams with thin and lamellate cell wall from particle-stabilized foams. Ceramics International, 2018, 44(5): 5780-5784.

DOI URL |

| [9] |

SAUCEDO M L, LOWE T, ZHAO S, et al. In situ observation of mechanical damage within a SiC-SiC ceramic matrix composite. Journal of Nuclear Materials, 2016, 481: 13-23.

DOI URL |

| [10] |

SONG C, LIU X, YE F, et al. Mechanical and dielectric properties of SiCf/BN/SiBCN composites via different synthesis technologies. Journal of the European Ceramic Society, 2019, 39(14): 4417-4423.

DOI URL |

| [11] |

WANG H, ZHOU X, YU J, et al. Fabrication of SiCf/SiC composites by chemical vapor infiltration and vapor silicon infiltration. Materials Letters, 2010, 64(15): 1691-1693.

DOI URL |

| [12] |

WONG E W, SHEEHAN P E, LIEBER C M. Nanobeam mechanics: elasticity, strength, and toughness of nanorods and nanotubes. Science, 1997, 277(5334): 1971-1975.

DOI URL |

| [13] |

ZHANG Y, HAN X, ZHENG K, et al. Direct observation of super- plasticity of beta-SiC nanowires at low temperature. Advanced Functional Materials, 2007, 17(17): 3435-3440.

DOI URL |

| [14] |

VIVEKCHAND S R C, RAMAMURTY U, RAO C N R. Mechanical properties of inorganic nanowire reinforced polymer-matrix composites. Nanotechnology, 2006, 17(11):344-S350.

DOI URL |

| [15] |

XIN L, YANG W, ZHAO Q, et al. Strengthening behavior in SiC nanowires reinforced pure Al composite. Journal of Alloys and Compounds, 2017, 695: 2406-2412.

DOI URL |

| [16] | SHEN Q L, LI H J, LI L, et al. SiC nanowire reinforced carbon/ carbon composites with improved interlaminar strength. Materials Science and Engineering: A, 2016, 651: 583-589. |

| [17] | DONG L H, ZHANG H J, ZHANG J, et al. Carbon nanotube modified sepiolite porous ceramics for high-efficient oil/water separation. Journal of Inorganic Materials, 2020, 35(6): 689-696. |

| [18] |

ZHANG K J, YADAV A, KIM K H, et al. Thermal and electrical transport in ultralow density single-walled carbon nanotube networks. Advanced Materials, 2013, 25(21): 2926-2931.

DOI URL |

| [19] | ZHAO X, HUANG C, LIU Q, et al. Thermal conductivity model for nanofiber networks. Journal of Applied Physics, 2018, 123(8): 085103-1-10. |

| [20] |

MA R, CHENG X, YE W. SiC fiber and yttria-stabilized zirconia composite thick thermal barrier coatings fabricated by plasma spray. Applied Surface Science, 2015, 357: 407-412.

DOI URL |

| [21] |

ZHUANG L, FU Q G, LIU T Y, et al. In-situ PIP-SiC NWs- toughened SiC-CrSi2-Cr3C2-MoSi2-Mo2C coating for oxidation protection of carbon/carbon composites. Journal of Alloys and Compounds, 2016, 675: 348-354.

DOI URL |

| [22] |

CHU Y, LI H, FU Q, et al. Toughening by SiC nanowires in a dense SiC-Si ceramic coating for oxidation protection of C/C composites. Journal of the American Ceramic Society, 2012, 95(11): 3691-3697.

DOI URL |

| [23] |

WANG D, XUE C, BAI H, et al. Silicon carbide nanowires grown on graphene sheets. Ceramics International, 2015, 41(4): 5473-5477.

DOI URL |

| [24] |

NGUYEN V H, DELBARI S A, AHMADI Z, et al. Electron microscopy characterization of porous ZrB2-SiC-AlN composites prepared by pressureless sintering. Ceramics International, 2020, 46(16): 25415-25423.

DOI URL |

| [25] |

LI X, YAO D, ZUO K, et al. Microstructure and permeability of porous YSZ ceramics fabricated by freeze casting of oil-in-water suspension. Journal of the European Ceramic Society, 2020, 40(15): 5845-5851.

DOI URL |

| [26] | FITZER E, HEGEN D. Chemical vapor-deposition of silicon- carbide and silicon-nitride-chemistrys contribution to modern silicon ceramics. Angewandte ChemieInternational Edition, 1979, 18(4): 295-304. |

| [27] | NASLAIN R, ROSSGNOL J Y, HAGENMULLER P, et al. Synthesis and properties of new composite-materials for high-temperature applications based on carbon-fibers and C-SiC or C-TiC hybrid matrices. Revue De ChimieMinerale, 1981, 18(5): 544-564. |

| [28] |

RUAN J, YANG J S, DONG S M, et al. Interfacial optimization of SiC nanocomposites reinforced by SiC nanowires with high volume fraction. Journal of the American Ceramic Society, 2019, 102(9): 5033-5037.

DOI URL |

| [29] | ZHU Y, ZHANG Y, YAN L S. Interface between multi-layered CVD SiC coating and its graphite substrate. Equipment Environmetal Engineering, 2019, 16(10): 59-63. |

| [30] |

CHIN J, GANTZEL P K, HUDSON R G. The structure of chemical vapor deposition sillicon carbide. Thin Solid Films, 1977, 40: 57-72.

DOI URL |

| [31] |

MASLOV M M, OPENOV L A, PODILIVAEV A I. On the vineyard formula for the pre-exponential factor in the Arrhenius law. Physics of the Solid State, 2014, 56(6): 1239-1244.

DOI URL |

| [32] |

TIEGS T N. Fission product Pd-SiC interaction in irradiated coated-particle fuels. Nuclear Technology, 2017, 57(3): 389-398.

DOI URL |

| [33] |

KINGON A I, LUTZ L J, LIAW P, et al. Thermodynamic calculations for the chemical vapor deposition of silicon carbide. Journal of the American Ceramic Society, 1983, 66(8): 558-566.

DOI URL |

| [34] |

KAZUO M, KOUSAKU F. Structure of chemically vapour deposited silicon carbide for coated fuel particles. Journal of Materials Science, 1998, 23: 699-706.

DOI URL |

| [35] |

BYUNG J C, DONG W P, DAI R K. Chemical vapour deposition of silicon carbide by pyrolysis of methylchlorosilanes. Journal of Materials Science Letters, 1997, 16: 33-36.

DOI URL |

| [36] |

HAN D Y, MEI H, XIAO S S, et al. Porous SiCnw/SiC ceramics with unidirectionally aligned channels produced by freeze-drying and chemical vapor infiltration. Journal of the European Ceramic Society, 2017, 37(3): 915-921.

DOI URL |

| [37] |

KANG E S, KIM Y W, NAM H. Multiple thermal resistance induced extremely low thermal conductivity in porous SiC-SiO2 ceramics with hierarchical porosity. Journal of the European Ceramic Society, 2021, 41(2): 1171-1180.

DOI URL |

| [38] |

KULTAYEVA S, KIM Y W, SONG I H. Effects of dopants on electrical, thermal, and mechanical properties of porous SiC ceramics. Journal of the European Ceramic Society, 2021, 41(7): 4006-4015.

DOI URL |

| [39] | DEY A, KAYAL N, CHAKRABARTI O, et al. Studies on processing of layered oxide-bonded porous SiC ceramic filter materials. International Journal of Applied Ceramic Technology, 2021, 18(3): 869-879. |

| [40] |

QI Y S, JIANG K, ZHOU C L, et al. Preparation and properties of high-porosity ZrB2-SiC ceramics by water-based freeze casting. Journal of the European Ceramic Society, 2021, 41(4): 2239-2246.

DOI URL |

| [41] |

RAJPOOT S, HA J H, KIMY W. Effects of initial particle size on mechanical, thermal, and electrical properties of porous SiC ceramics. Ceramics International, 2021, 47(6): 8668-8676.

DOI URL |

| [1] | 付师, 杨增朝, 李宏华, 王良, 李江涛. 复合烧结助剂对Si3N4陶瓷力学性能和热导率的影响[J]. 无机材料学报, 2022, 37(9): 947-953. |

| [2] | 胡佳军, 王凯, 侯鑫广, 杨婷, 夏鸿雁. 熔盐法合成高导热磷化硼及其热管理性能研究[J]. 无机材料学报, 2022, 37(9): 933-940. |

| [3] | 王鹏将, 康慧君, 杨雄, 刘颖, 程成, 王同敏. 熵调控抑制ZrNiSn基half-Heusler热电材料的晶格热导率[J]. 无机材料学报, 2022, 37(7): 717-723. |

| [4] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 三维碳化硅纳米线增强碳化硅陶瓷基复合材料的电磁屏蔽性能[J]. 无机材料学报, 2022, 37(5): 579-584. |

| [5] | 娄许诺, 邓后权, 李爽, 张青堂, 熊文杰, 唐国栋. Ge掺杂MnTe材料的热电输运性能[J]. 无机材料学报, 2022, 37(2): 209-214. |

| [6] | 王为得, 陈寰贝, 李世帅, 姚冬旭, 左开慧, 曾宇平. 以YbH2-MgO体系为烧结助剂制备高热导率高强度氮化硅陶瓷[J]. 无机材料学报, 2021, 36(9): 959-966. |

| [7] | 桑玮玮, 张红松, 陈华辉, 温斌, 李新春. (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7高熵陶瓷的制备及热物理性能[J]. 无机材料学报, 2021, 36(4): 405-410. |

| [8] | 牟庭海, 许文涛, 凌军荣, 董天文, 秦梓轩, 周有福. 微波烧结制备ZrO2-AlN复合陶瓷的微观结构与性能研究[J]. 无机材料学报, 2021, 36(11): 1231-1236. |

| [9] | 李陇彬, 薛玉冬, 胡建宝, 杨金山, 张翔宇, 董绍明. 碳化硅纳米线增韧碳化硅纤维/碳化硅基体损伤行为研究[J]. 无机材料学报, 2021, 36(10): 1111-1117. |

| [10] | 张志锋,王凤娟,武胜萍,蒋金洋. X-CT无损测试技术用于陶瓷涂层三维重构和孔隙率计算[J]. 无机材料学报, 2020, 35(9): 1059-1063. |

| [11] | 邱小小,周细应,傅赟天,孙晓萌,王连军,江莞. Ge1-xInxTe微观结构对热电性能的影响[J]. 无机材料学报, 2020, 35(8): 916-922. |

| [12] | 周星圆, 柳伟, 张程, 华富强, 张敏, 苏贤礼, 唐新峰. Nb掺杂Mo1-xWxSeTe固溶体的热-电输运性能优化[J]. 无机材料学报, 2020, 35(12): 1373-1379. |

| [13] | 何端鹏,高鸿,张静静,吴杰,刘泊天,王向轲. 氮化铝覆铜板在空间热场下热学性能的模拟仿真及实验验证[J]. 无机材料学报, 2019, 34(9): 947-952. |

| [14] | 周述光, 国义军, 刘骁. 恒温环境中ZrB2氧化行为模拟[J]. 无机材料学报, 2019, 34(6): 660-666. |

| [15] | 马伯乐, 马文, 黄威, 白玉, 贾瑞灵, 董红英. 单相双稀土改性SrZrO3热障涂层的热物理性能[J]. 无机材料学报, 2019, 34(4): 394-400. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||