无机材料学报 ›› 2021, Vol. 36 ›› Issue (10): 1103-1110.DOI: 10.15541/jim20210091

所属专题: 【结构材料】陶瓷基复合材料

张俊敏1,2,3( ), 陈小武1,2(

), 陈小武1,2( ), 廖春景1,2, 郭斐宇1,2,3, 杨金山1,2, 张翔宇1,2, 董绍明1,2(

), 廖春景1,2, 郭斐宇1,2,3, 杨金山1,2, 张翔宇1,2, 董绍明1,2( )

)

收稿日期:2021-02-09

修回日期:2021-03-24

出版日期:2021-10-20

网络出版日期:2021-04-05

通讯作者:

陈小武, 助理研究员. E-mail: xwchen@mail.sic.ac.cn; 董绍明, 研究员. E-mail: smdong@mail.sic.ac.cn

作者简介:张俊敏(1996–), 男, 博士研究生. E-mail: zhangjm2@shanghaitech.edu.cn

ZHANG Junmin1,2,3( ), CHEN Xiaowu1,2(

), CHEN Xiaowu1,2( ), LIAO Chunjin1,2, GUO Feiyu1,2,3, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2(

), LIAO Chunjin1,2, GUO Feiyu1,2,3, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2( )

)

Received:2021-02-09

Revised:2021-03-24

Published:2021-10-20

Online:2021-04-05

Contact:

CHEN Xiaowu, lecturer. E-mail: xwchen@mail.sic.ac.cn; DONG Shaoming, professor. E-mail: smdong@mail.sic.ac.cn

About author:ZHANG Junmin(1996–), male, PhD candidate. E-mail: zhangjm2@shanghaitech.edu.cn

Supported by:摘要:

反应熔体渗透(RMI)是制备高密度陶瓷基复合材料的有效方法之一, 而熔体的渗透和复合材料的形成主要取决于预制体的孔隙结构。本研究将硅熔体渗透到具有不同孔隙结构的含碳预制体中, 制备了SiC纤维增强SiC基复合材料(SiCf/SiC), 并研究了孔隙结构对熔体浸润和SiCf/SiC复合材料的影响。研究结果表明: 具有较均匀孔径的预制体可以使熔体浸润更充分, 制备的复合材料具有更少的残余孔隙及更优的力学性能。该研究对反应熔渗制备复合材料的孔结构调控具有指导意义。

中图分类号:

张俊敏, 陈小武, 廖春景, 郭斐宇, 杨金山, 张翔宇, 董绍明. SiCf/SiC复合材料的RMI制备方法以及微观结构和性能优化[J]. 无机材料学报, 2021, 36(10): 1103-1110.

ZHANG Junmin, CHEN Xiaowu, LIAO Chunjin, GUO Feiyu, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Optimizing Microstructure and Properties of SiCf/SiC Composites Prepared by Reactive Melt Infiltration[J]. Journal of Inorganic Materials, 2021, 36(10): 1103-1110.

| Preform | Preparing process | Further impregnation | Composites |

|---|---|---|---|

| Pre-1 | Slurry impregnation | None | Com-1 |

| Pre-2 | Slurry impregnation | Pure PF | Com-2 |

| Pre-3 | Slurry impregnation | Polymer blend | Com-3 |

Table 1 Different impregnation treatments to the preforms

| Preform | Preparing process | Further impregnation | Composites |

|---|---|---|---|

| Pre-1 | Slurry impregnation | None | Com-1 |

| Pre-2 | Slurry impregnation | Pure PF | Com-2 |

| Pre-3 | Slurry impregnation | Polymer blend | Com-3 |

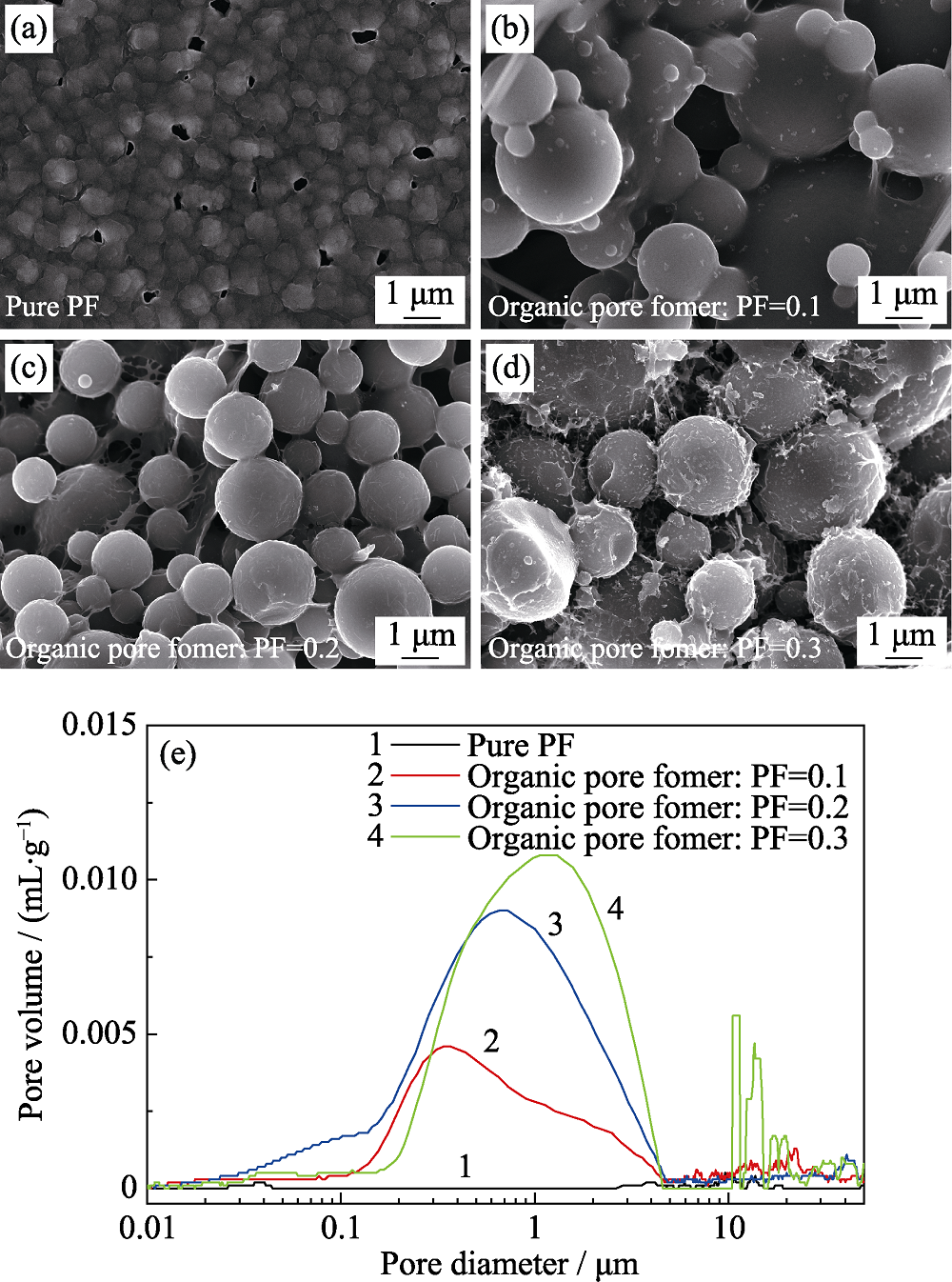

Fig. 2 SEM images of pyrolytic carbon prepared with different organic pore former contents ((a) Pure PF; (b) Organic pore former: PF=0.1; (c) Organic pore former: PF=0.2, (d) Organic pore former: PF=0.3); (e) Pore size distribution of pyrolytic carbon

| Composites | Density/(g·cm-3) | Open porosity/% | Flexural strength/MPa | Elastic modulus/GPa |

|---|---|---|---|---|

| Com-1 | (2.41±0.08) | (10.08±0.50) | (96.04±9.50) | (42.53±0.73) |

| Com-2 | (2.57±0.08) | (8.39±0.58) | (176.76±3.78) | (67.55±0.46) |

| Com-3 | (2.61±0.05) | (7.92±0.61) | (200.50±7.33) | (79.19±0.65) |

Table 2 Comparison of the mechanical properties of the SiCf/SiC composites

| Composites | Density/(g·cm-3) | Open porosity/% | Flexural strength/MPa | Elastic modulus/GPa |

|---|---|---|---|---|

| Com-1 | (2.41±0.08) | (10.08±0.50) | (96.04±9.50) | (42.53±0.73) |

| Com-2 | (2.57±0.08) | (8.39±0.58) | (176.76±3.78) | (67.55±0.46) |

| Com-3 | (2.61±0.05) | (7.92±0.61) | (200.50±7.33) | (79.19±0.65) |

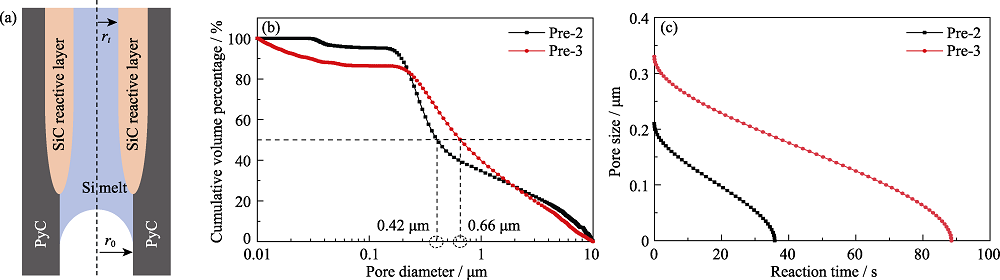

Fig. 8 (a) Schematic of reaction layer generated during the RMI, (b) curves of cumulative volume percentage vs pore diameter of preforms, and (c) variation of pore radius with infiltration time for preforms

| [1] |

ZHU Y, WANG S, LI W, et al. Preparation of carbon fiber-reinforced zirconium carbide matrix composites by reactive melt infiltration at relative low temperature. Scripta Materialia, 2012, 67(10):822-825.

DOI URL |

| [2] |

WANG J, LIN M, XU Z, et al. Microstructure and mechanical properties of C/C-SiC composites fabricated by a rapid processing method. J. Eur. Ceram. Soc., 2009, 29(14):3091-3097.

DOI URL |

| [3] |

TIAN J T, SHOBU K. Fabrication of silicon carbide-mullite composite by melt infiltration. J. Am. Ceram. Soc., 2003, 86(1):39-42.

DOI URL |

| [4] | SINGH M, ALMAN D E, HAWK J A. Microstructure and Wear Behavior of SiC-based Composites Fabricated by Melt Infiltration, in: Alman D E, HAWK J A., SIMMONS J W (Eds.). Roll of Characterization in Understanding Environmental Degradation of Materials, ASM International, 1998: 169-175. |

| [5] |

WANG Y X, TAN S H, JIANG D L. The effect of porous carbon preform and the infiltration process on the properties of reaction- formed SiC. Carbon, 2004, 42(8/9):1833-1839.

DOI URL |

| [6] |

JIANG S Z, XIONG X, CHEN Z K, et al. Influence factors of C/C-SiC dual matrix composites prepared by reactive melt infiltration. Materials & Design, 2009, 30(9):3738-3742.

DOI URL |

| [7] |

WANG D, DONG S M, ZHOU H J, et al. Fabrication and microstructure of 3D Cf/ZrC-SiC composites: through RMI method with ZrO2 powders as pore-making agent. Ceram. Int., 2016, 42(6):6720-6727.

DOI URL |

| [8] |

ROGER J, CHOLLON G. Mechanisms and kinetics during reactive infiltration of molten silicon in porous graphite. Ceram. Int., 2019, 45(7):8690-8699.

DOI URL |

| [9] |

PILLLEE S, KIYOON H, SOOPARK J, et al. Processing and properties of SiC and SiC/SiC composite materials by melt infiltration process. International Journal of Modern Physics B, 2003, 17(8):1833-1838.

DOI URL |

| [10] |

WASHBURN E W. The dynamics of capillary flow. Physical Review, 1921, 17(3):273-283.

DOI URL |

| [11] |

BOUGIOURI V, VOYTOVYCH R, ROJO-CALDERON N, et al. The role of the chemical reaction in the infiltration of porous carbon by NiSi alloys. Scripta Materialia, 2006, 54(11):1875-1878.

DOI URL |

| [12] |

KUMAR S, KUMAR A, SHUKLA A, et al. Capillary infiltration studies of liquids into 3D-stitched C-C preforms Part A: Internal pore characterization by solvent infiltration, mercury porosimetry, and permeability studies. J. Eur. Ceram. Soc., 2009, 29(12):2643-2650.

DOI URL |

| [13] |

KUMAR S, KUMAR A, DEVI R, et al. Capillary infiltration studies of liquids into 3D-stitched C-C preforms Part B: Kinetics of silicon infiltration. J. Eur. Ceram. Soc., 2009, 29(12):2651-2657.

DOI URL |

| [14] |

WANG Y, ZHU X, ZHANG L, et al. C/C-SiC-ZrC composites fabricated by reactive melt infiltration with Si0.87Zr0.13 alloy. Ceram. Int., 2012, 38(5):4337-4343.

DOI URL |

| [15] |

CHEN X W, NI D W, KAN Y M, et al. Reaction mechanism and microstructure development of ZrSi2 melt-infiltrated Cf/SiC-ZrC- ZrB2 composites: the influence of preform pore structures. Journal of Materiomics, 2018, 4(3):266-275.

DOI URL |

| [16] |

CHEN X W, FENG Q, KAN Y M, et al. Effects of preform pore structure on infiltration kinetics and microstructure evolution of RMI-derived Cf/SiC-ZrC-ZrB2 composite. J. Eur. Ceram. Soc., 2020, 40(7):2683-2690.

DOI URL |

| [17] |

ZHONG Q, ZHANG X Y, DONG S M, et al. Reactive melt infiltrated Cf/SiC composites with robust matrix derived from novel engineered pyrolytic carbon structure. Ceram. Int., 2017, 43(7):5832-5836.

DOI URL |

| [18] | LEE S P, PARK J S, KATOH Y, et al. Process, microstructure and flexural properties of reaction sintered Tyranno SA/SiC composites. Journal of Nuclear Materials, 2002, 307:1191-1195. |

| [19] |

ZHAO Y Y, XIA H Y, TANG R, et al. A low cost preparation of C/SiC composites by infiltrating molten Si into gelcasted pure porous carbon preform. Ceram. Int., 2015, 41(5):6478-6487.

DOI URL |

| [20] |

SINGH M, FARMER S C. Morphological characterization of microporous carbon materials. Journal of Materials Science Letters, 1997, 16(11):946-949.

DOI URL |

| [21] | LEVENSPIEL O. Ingenieria de las Reacciones. 2nd ed. Wiley (ed.). Barcelona: Revertre, 1978. |

| [22] |

HON M H, DAVIS R F. Self-diffusion of C-14 in polycrystalline beta-sic. J. Mater. Sci., 1979, 14(10):2411-2421.

DOI URL |

| [1] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [2] | 荆开开, 管皞阳, 朱思雨, 张超, 刘永胜, 王波, 王晶, 李玫, 张程煜. Cansas-II SiCf/SiC复合材料的高温拉伸蠕变行为[J]. 无机材料学报, 2023, 38(2): 177-183. |

| [3] | 吴西士, 朱云洲, 黄庆, 黄政仁. 树脂基多孔碳孔结构对Cf/SiC复合材料连接性能的影响[J]. 无机材料学报, 2022, 37(12): 1275-1280. |

| [4] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [5] | 朱丹阳, 钱康, 陈肖朴, 胡泽望, 刘欣, 李晓英, 潘裕柏, MIHÓKOVÁ Eva, NIKL Martin, 李江. 热等静压烧结制备细晶粒Ce,Y:SrHfO3闪烁陶瓷[J]. 无机材料学报, 2021, 36(10): 1118-1124. |

| [6] | 王西,王克杰,柏辉,宋卓林,王波,张程煜. 化学气相渗透2D-SiCf/SiC复合材料的蠕变性能及损伤机理[J]. 无机材料学报, 2020, 35(7): 817-821. |

| [7] | 吴小军,杨杰,郑蕊,张兆甫,杨毅. 烧蚀型面结构对CVI+HPIC工艺制备针刺C/C喉衬等离子烧蚀性能的影响[J]. 无机材料学报, 2020, 35(6): 654-660. |

| [8] | 董丽佳, 郭筱洁, 李雪, 陈朝贵, 金阳, AHMED Alsaedi, TASAWAr Hayat, 赵轻舟, 盛国栋. 不同pH条件下硫化钼纳米片吸附Cd(II)的微观机制研究[J]. 无机材料学报, 2020, 35(3): 293-300. |

| [9] | 吕晓旭, 姜卓钰, 周怡然, 齐哲, 赵文青, 焦健. BN/SiC复合界面层对SiC纤维和PIP-Mini复合材料力学性能的影响[J]. 无机材料学报, 2020, 35(10): 1099-1104. |

| [10] | 徐维民, 李世波, 胡树郡, 姜吉鹏, 于文波, 周洋. ZrC/Cr2AlC复合材料的微观结构及力学性能研究[J]. 无机材料学报, 2020, 35(1): 61-64. |

| [11] | 焦思怡, 葛万银, 殷立雄, 徐美美, 常哲, 张荔. 新型二维TiSe2纳米片的可控合成及其生长机理[J]. 无机材料学报, 2019, 34(8): 834-838. |

| [12] | 吴青青, 王震, 丁奇, 倪德伟, 阚艳梅, 董绍明. 基于固体聚硅氧烷的前驱体浸渍裂解法(PIP)制备C/SiOC复合材料及其微结构与力学性能研究[J]. 无机材料学报, 2019, 34(12): 1349-1356. |

| [13] | 穆阳, 邓佳欣, 李皓, 周万城. 两种连续SiC纤维的高温介电及吸波性能对比[J]. 无机材料学报, 2018, 33(4): 427-433. |

| [14] | 李家科, 韩效奇, 刘欣, 王艳香, 郭平春, 杨志胜. 低温分相法制备高比表面积微/介孔SiOC陶瓷[J]. 无机材料学报, 2018, 33(12): 1360-1364. |

| [15] | 王梦千, 贾林涛, 李爱军, 彭雨晴, 张方舟. BCl3-NH3-H2-N2前驱体化学气相沉积法制备氮化硼涂层[J]. 无机材料学报, 2018, 33(11): 1179-1185. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||