无机材料学报 ›› 2021, Vol. 36 ›› Issue (6): 652-658.DOI: 10.15541/jim20200508

所属专题: 【结构材料】超高温结构陶瓷

孙鲁超1( ), 周翠1,2, 杜铁锋1, 吴贞1, 雷一明1,2, 李家麟1, 苏海军3(

), 周翠1,2, 杜铁锋1, 吴贞1, 雷一明1,2, 李家麟1, 苏海军3( ), 王京阳1(

), 王京阳1( )

)

收稿日期:2020-09-01

修回日期:2020-09-29

出版日期:2021-06-20

网络出版日期:2020-10-10

通讯作者:

王京阳, 研究员. E-mail: jywang@imr.ac.cn; 苏海军, 教授. E-mail: shjnpu@nwpu.edu.cn

作者简介:孙鲁超(1984-), 男, 副研究员. E-mail: lcsun@imr.ac.cn

SUN Luchao1( ), ZHOU Cui1,2, DU Tiefeng1, WU Zhen1, LEI Yiming1,2, LI Jialin1, SU Haijun3(

), ZHOU Cui1,2, DU Tiefeng1, WU Zhen1, LEI Yiming1,2, LI Jialin1, SU Haijun3( ), WANG Jingyang1(

), WANG Jingyang1( )

)

Received:2020-09-01

Revised:2020-09-29

Published:2021-06-20

Online:2020-10-10

Contact:

WANG Jingyang, professor. E-mail: jywang@imr.ac.cn; SU Haijun, professor. E-mail: shjnpu@nwpu.edu.cn

About author:SUN Luchao(1984-), male, associate professor. E-mail: lcsun@imr.ac.cn

Supported by:摘要:

本研究探索了光悬浮区熔法制备Al2O3/Er3Al5O12(ErAG)和Al2O3/Yb3Al5O12(YbAG) 定向凝固共晶陶瓷。在10 mm/h的抽拉速率下成功获得了凝固组织均匀、内部无裂纹或孔洞的高质量共晶陶瓷。通过高分辨三维X射线衍射仪研究了Al2O3和RE3Al5O12在三维空间的分布与组织结构; 利用电子背散射衍射技术分析了定向凝固末期Al2O3和RE3Al5O12两相的晶体学择优取向和相界面关系。力学性能表征结果显示, Al2O3/ErAG和Al2O3/YbAG具有优异的力学性能, 二者的维氏硬度分别为(13.5±0.4)和(12.8±0.1) GPa;断裂韧性分别为(3.0±0.2)和(3.2±0.1) MPa·m1/2。

中图分类号:

孙鲁超, 周翠, 杜铁锋, 吴贞, 雷一明, 李家麟, 苏海军, 王京阳. 光悬浮区熔定向凝固Al2O3/Er3Al5O12和Al2O3/Yb3Al5O12共晶陶瓷的制备与性能研究[J]. 无机材料学报, 2021, 36(6): 652-658.

SUN Luchao, ZHOU Cui, DU Tiefeng, WU Zhen, LEI Yiming, LI Jialin, SU Haijun, WANG Jingyang. Directionally Solidified Al2O3/Er3Al5O12 and Al2O3/Yb3Al5O12 Eutectic Ceramics Prepared by Optical Floating Zone Melting[J]. Journal of Inorganic Materials, 2021, 36(6): 652-658.

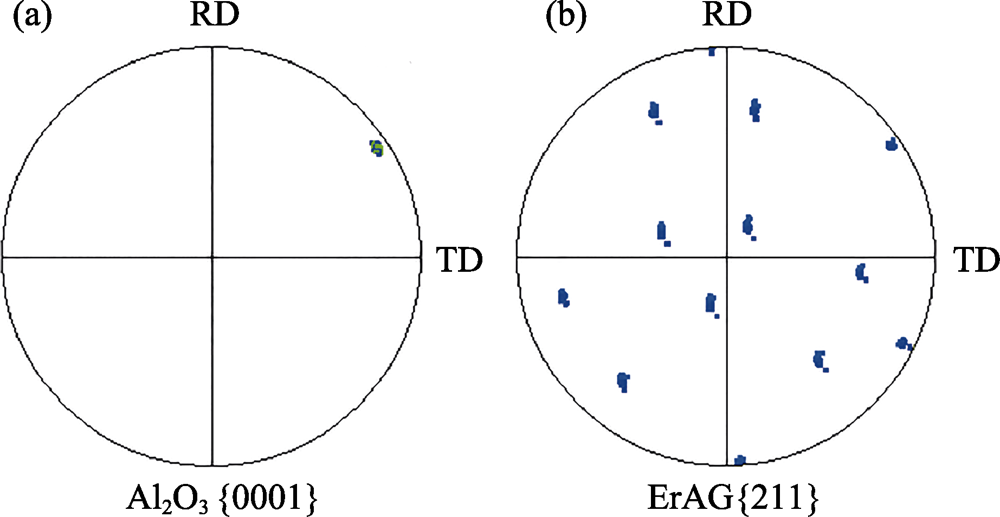

Fig. 5 Pole figures of Al2O3/ErAG: (a) Al2O3 in {0001} orientation and (b) ErAG in {211} orientation corresponding to the inverse pole figures in Fig. 4 (a) and (b)

| Eutectic system | Growth method | Growth directions | Orientation relationships |

|---|---|---|---|

| Al2O3/ErAG | OFZ | <$10\bar{1}0$> Al2O3//<111> ErAG | {0001} Al2O3//{211} ErAG |

| Al2O3/REAG | OFZ | <$10\bar{1}0$> Al2O3//<101> REAG | {0001} Al2O3//{211} REAG |

| RE=Er/Yb[ | <$10\bar{1}0$> Al2O3//<$2\bar{1}0$> REAG | ||

| Al2O3/YAG[ | OFZ | <$10\bar{1}0$> Al2O3//<101> YAG | {0001} Al2O3//{211} YAG |

| Al2O3/YAG[ | LFZ | <$1\bar{1}00$> Al2O3//<111> YAG | {0001} Al2O3//{$1\bar{1}2$} YAG |

| Al2O3/YAG[ | Bridgman | <$1\bar{1}20$> Al2O3//<110> YAG | - |

| <$01\bar{1}0$> Al2O3//<110> YAG | |||

| Al2O3/YAG[ | LSP | <$10\bar{1}0$> Al2O3//<101> YAG | {0001} Al2O3//{211} YAG |

Table 1 Growth directions and orientation relationships of some eutectic ceramics

| Eutectic system | Growth method | Growth directions | Orientation relationships |

|---|---|---|---|

| Al2O3/ErAG | OFZ | <$10\bar{1}0$> Al2O3//<111> ErAG | {0001} Al2O3//{211} ErAG |

| Al2O3/REAG | OFZ | <$10\bar{1}0$> Al2O3//<101> REAG | {0001} Al2O3//{211} REAG |

| RE=Er/Yb[ | <$10\bar{1}0$> Al2O3//<$2\bar{1}0$> REAG | ||

| Al2O3/YAG[ | OFZ | <$10\bar{1}0$> Al2O3//<101> YAG | {0001} Al2O3//{211} YAG |

| Al2O3/YAG[ | LFZ | <$1\bar{1}00$> Al2O3//<111> YAG | {0001} Al2O3//{$1\bar{1}2$} YAG |

| Al2O3/YAG[ | Bridgman | <$1\bar{1}20$> Al2O3//<110> YAG | - |

| <$01\bar{1}0$> Al2O3//<110> YAG | |||

| Al2O3/YAG[ | LSP | <$10\bar{1}0$> Al2O3//<101> YAG | {0001} Al2O3//{211} YAG |

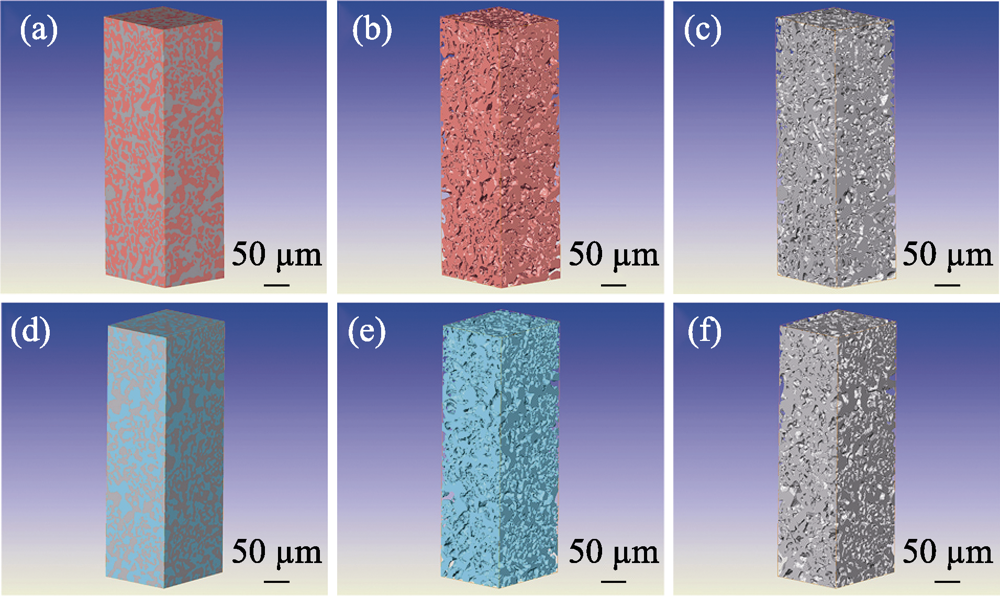

Fig. 6 3D-XRT images of directionally solidified (a) Al2O3/ErAG and (d) Al2O3/YbAG eutectics, (b, c) spatial distribution of ErAG and Al2O3 in Al2O3/ErAG, (e, f) spatial distribution of YbAG and Al2O3 in Al2O3/YbAG

| Eutectic system | Preparation method | Vickers hardness /GPa | Fracture toughness /(MPa·m1/2) |

|---|---|---|---|

| Al2O3/ErAG | OFZ | (13.5±0.4) | (3.0 ± 0.2) |

| Al2O3/YbAG | OFZ | (12.8±0.1) | (3.2 ± 0.1) |

| Al2O3/ErAG[ | LFZ | (14.5-16.0) | 1.9 |

| Al2O3/ErAG[ | LFZ | (14.9±0.7) | (1.8 ± 0.3) |

| Al2O3/YbAG[ | LFZ | (14.8±0.6) | (2.2 ± 0.5) |

| Al2O3/YAG[ | OFZ | 13.5 | (3.1±0.3) |

Table 2 Comparison of Vickers hardness and fracture toughness of some Al2O3/REAG eutectic ceramics

| Eutectic system | Preparation method | Vickers hardness /GPa | Fracture toughness /(MPa·m1/2) |

|---|---|---|---|

| Al2O3/ErAG | OFZ | (13.5±0.4) | (3.0 ± 0.2) |

| Al2O3/YbAG | OFZ | (12.8±0.1) | (3.2 ± 0.1) |

| Al2O3/ErAG[ | LFZ | (14.5-16.0) | 1.9 |

| Al2O3/ErAG[ | LFZ | (14.9±0.7) | (1.8 ± 0.3) |

| Al2O3/YbAG[ | LFZ | (14.8±0.6) | (2.2 ± 0.5) |

| Al2O3/YAG[ | OFZ | 13.5 | (3.1±0.3) |

| [1] |

WAKU Y, NAKAGAWA N, WAKAMOTO T, et al. High temperature strength and thermal stability of a unidirectionally solidified Al2O3/YAG eutectic composite. Journal of Materials Science, 1998,33:1217-1225.

DOI URL |

| [2] |

WAKU Y, NAKAGAWA N, WAKAMOTO T, et al. A ductile ceramic eutectic composite with high strength. Nature, 1997,389:49-52.

DOI URL |

| [3] |

LLORCA J, ORERA V M. Directionally solidified eutectic oxide ceramics. Progress in Materials Science, 2006,51:711-809.

DOI URL |

| [4] |

PASTOR J Y, LLORCA J, SALAZAR A, et al. Mechanical properties of melt-grown alumina-yttrium aluminum garnet eutectics up to 1900 K. Journal of the American Ceramic Society, 2005,88:1488-1495.

DOI URL |

| [5] |

OLIETE P B, PENA J I, LARREA A, et al. Ultra-high-strength nanofibrillar Al2O3-YAG-YSZ eutectics. Advanced Materials, 2007,19:2313-2318.

DOI URL |

| [6] |

ZHANG J, SU H J, SONG K, et al. Microstructure, growth mechanism and mechanical property of Al2O3-based eutectic ceramic in situ composites. Journal of the European Ceramic Society, 2011,31:1191-1198.

DOI URL |

| [7] |

WAKU Y, NAKAGAWA N, OHTSUBO H, et al. Fracture and deformation behaviour of melt growth composites at very high temperatures. Journal of Materials Science, 2001,36:1585-1594.

DOI URL |

| [8] |

MARTINEZ FERNANDEZ J, SAYIR A, FARMER S C. High temperature creep deformation of directionally solidified Al2O3/ Er3Al5O12. Acta Materialia, 2003,51:1705-1720.

DOI URL |

| [9] |

MESA M C, OLIETE P B, ORERA V M, et al. Microstructure and mechanical properties of Al2O3/Er3Al5O12 eutectic rods grown by the laser-heated floating zone method. Journal of the European Ceramic Society, 2011,31:1241-1250.

DOI URL |

| [10] |

MESA M C, OLIETE P B, LARREA A. Microstructural stability at elevated temperatures of directionally solidified Al2O3/Er3Al5O12 eutectic ceramics. Journal of Crystal Growth, 2012,360:119-122.

DOI URL |

| [11] |

REN Q, SU H J, ZHANG J, et al. Microstructure control, competitive growth and precipitation rule in faceted Al2O3/Er3Al5O12 eutectic in situ composite ceramics prepared by laser floating zone melting. Journal of the European Ceramic Society, 2019,39:1900-1908.

DOI URL |

| [12] |

REN Q, SU H J, ZHANG J, et al. Halo formation in directionally solidified Al2O3-Er3Al5O12 off-eutectic in situ composite ceramics. Materials Characterization, 2019,150:31-37.

DOI URL |

| [13] |

REN Q, SU H J, ZHANG J, et al. Eutectic growth behavior with regular arrangement in the faceted Al2O3/Er3Al5O12 irregular eutectic system at low growth rate. Scripta Materialia, 2019,162:49-53.

DOI URL |

| [14] |

REN Q, SU H J, ZHANG J, et al. Effect of an abrupt change in pulling rate on microstructures of directionally solidified Al2O3- Er3Al5O12 eutectic and off-eutectic composite ceramics. Ceramics International, 2019,45:6632-6638.

DOI URL |

| [15] |

SAI H, YUGAMI H, NAKAMURA K, et al. Selective emission of Al2O3/Er3Al5O12 eutectic composite for thermophotovoltaic generation of electricity. Japanese Journal of Applied Physics, 2000,39:1957-1961.

DOI URL |

| [16] | ADACHI Y, YUGAMI H, SHIBATA K, et al. Compact TPV generation system using Al2O3/Er3Al5O12 eutectic ceramics selective emitters. AIP Conference Proceedings, 2004,738:198-205. |

| [17] |

NAKAGAWA N, OHTSUBO H, WAKU Y, et al. Thermal emission properties of Al2O3/Er3Al5O12 eutectic ceramics. Journal of the European Ceramic Society, 2005,25:1285-1291.

DOI URL |

| [18] |

OLIETE P B, MESA M C, MERINO R I, et al. Directionally solidified Al2O3-Yb3Al5O12 eutectics for selective emitters. Solar Energy Materials and Solar Cells, 2016,144:405-410.

DOI URL |

| [19] | OLIETE P B, MANUEL J, ROBLEDO L, et al. Directionally solidified Al2O3-ME3Al5O12( ME: Y, Er and Yb) eutectic coatings for thermophotovoltaic systems. Ceramics International, 2017,43:16270-16275. |

| [20] |

LAKIZA S M. Directionally solidified eutectics in the Al2O3-ZrO2- Ln(Y)2O3 systems. Powder Metallurgy and Metal Ceramics, 2009,48:1-2.

DOI URL |

| [21] |

YOSHIKAWA A, HASEGAWA K, LEE J H, et al. Phase identification of Al2O3/RE3Al5O12 and Al2O3/REAlO3(RE=Sm-Lu, Y) eutectics. Journal of Crystal Growth, 2000,218:67-73.

DOI URL |

| [22] |

ANSTIS G R, CHANTIKUL P, LAWN B R, et al. A critical- evaluation of indentation techniques for measuring fracture- toughness: I, direct crack measurements. Journal of the American Ceramic Society, 1981,64:533-538.

DOI URL |

| [23] |

WANG X, WANG J Y, SUN L C, et al. Microstructure evolution of Al2O3/Y3Al5O12 eutectic crystal during directional solidification. Scripta Materialia, 2015,108:31-34.

DOI URL |

| [24] |

MAZEROLLES L, PERRIERE L, LARTIGUE-KORINEK S, et al. Microstructures, crystallography of interfaces, and creep behavior of melt-growth composites. Journal of the European Ceramic Society, 2008,28:2301-2308.

DOI URL |

| [25] |

WANG X, TIAN Z L, ZHANG W, et al. Mechanical properties of directionally solidified Al2O3/Y3Al5O12 eutectic ceramic prepared by optical floating zone technique. Journal of the European Ceramic Society, 2018,38:3610-3617.

DOI URL |

| [26] |

FRAZER C S, DICKEY E C, SAYIR A. Crystallographic texture and orientation variants in Al2O3-Y3Al5O12 directionally solidified eutectic crystals. Journal of Crystal Growth, 2001,233:187-195.

DOI URL |

| [27] |

SAKATA S, MITANI A, SHIMIZU K, et al. Crystallographic orientation analysis and high temperature strength of melt growth composite. Journal of the European Ceramic Society, 2005,25:1441-1445.

DOI URL |

| [28] |

SU H J, ZHANG J, MA W D, et al. In situ fabrication of highly-dense Al2O3/YAG nanoeutectic composite ceramics by a modified laser surface processing. Journal of the European Ceramic Society, 2014,34:739-744.

DOI URL |

| [29] |

WANG X, WANG D, ZHANG H, et al. Mechanism of eutectic growth in directional solidification of an Al2O3/Y3Al5O12 crystal, Scripta Materialia, 2016,116:44-48.

DOI URL |

| [1] | 安文然, 黄晶琪, 卢祥荣, 蒋佳宁, 邓龙辉, 曹学强. 热处理温度对LaMgAl11O19涂层热/力学性能的影响[J]. 无机材料学报, 2022, 37(9): 925-932. |

| [2] | 张叶, 曾宇平. 自蔓延高温合成氮化硅多孔陶瓷的研究进展[J]. 无机材料学报, 2022, 37(8): 853-864. |

| [3] | 夏乾, 孙是昊, 赵义亮, 张翠萍, 茹红强, 王伟, 岳新艳. 碳化硼颗粒级配对硅反应结合碳化硼复合材料结构与性能的影响[J]. 无机材料学报, 2022, 37(6): 636-642. |

| [4] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [5] | 徐谱昊, 张相召, 刘桂武, 张明芬, 桂新易, 乔冠军. Al-Ti合金钎焊SiC陶瓷接头界面微观结构与力学性能[J]. 无机材料学报, 2022, 37(6): 683-690. |

| [6] | 丁健翔, 张凯歌, 柳东明, 郑伟, 张培根, 孙正明. Ti3AlC2陶瓷及其衍生物Ti3C2Tx增强的Ag基电接触材料[J]. 无机材料学报, 2022, 37(5): 567-573. |

| [7] | 刘海方, 苏海军, 申仲琳, 姜浩, 赵迪, 刘园, 张军, 刘林, 傅恒志. 激光增材制造超高温氧化物共晶陶瓷研究进展[J]. 无机材料学报, 2022, 37(3): 255-266. |

| [8] | 蔚海浪, 曹学强, 邓龙辉, 蒋佳宁. LaMeAl11O19/YSZ热障涂层热力学性能和热循环寿命[J]. 无机材料学报, 2022, 37(12): 1259-1266. |

| [9] | 孙扬善, 杨治华, 蔡德龙, 张正义, 柳琪, 房树清, 冯良, 石丽芬, 王友乐, 贾德昌. 粉末烧结法制备α-堇青石基玻璃陶瓷的析晶动力学和性能[J]. 无机材料学报, 2022, 37(12): 1351-1357. |

| [10] | 吴西士, 朱云洲, 黄庆, 黄政仁. 树脂基多孔碳孔结构对Cf/SiC复合材料连接性能的影响[J]. 无机材料学报, 2022, 37(12): 1275-1280. |

| [11] | 王皓轩, 刘巧沐, 王一光. 高熵过渡金属碳化物陶瓷的研究进展[J]. 无机材料学报, 2021, 36(4): 355-364. |

| [12] | 吕莎莎, 祖宇飞, 陈国清, 赵伯俊, 付雪松, 周文龙. 陶瓷颗粒增强Cr0.5MoNbWTi难熔高熵合金复合材料的制备及其力学性能[J]. 无机材料学报, 2021, 36(4): 386-392. |

| [13] | 金敏, 白旭东, 赵素, 张如林, 陈玉奇, 周丽娜. 坩埚下降法生长SnSe单晶及其力学性能研究[J]. 无机材料学报, 2021, 36(3): 313-318. |

| [14] | 李陇彬, 薛玉冬, 胡建宝, 杨金山, 张翔宇, 董绍明. 碳化硅纳米线增韧碳化硅纤维/碳化硅基体损伤行为研究[J]. 无机材料学报, 2021, 36(10): 1111-1117. |

| [15] | 马登浩, 侯振华, 李军平, 孙新, 金恩泽, 尹健. 界面相对3D-SiC/SiC复合材料静态力学性能及内耗特征的影响[J]. 无机材料学报, 2021, 36(1): 55-60. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||