无机材料学报 ›› 2020, Vol. 35 ›› Issue (6): 689-696.DOI: 10.15541/jim20190382

收稿日期:2019-07-24

修回日期:2019-09-24

出版日期:2020-06-20

网络出版日期:2019-12-29

作者简介:董龙浩(1992-), 男, 硕士研究生. E-mail: donglonghao1125@163.com;基金资助:

DONG Longhao1,ZHANG Haijun1( ),ZHANG Jun1,WU Wenhao1,JIA Quanli2

),ZHANG Jun1,WU Wenhao1,JIA Quanli2

Received:2019-07-24

Revised:2019-09-24

Published:2020-06-20

Online:2019-12-29

Supported by:摘要:

为了有效地从油/水混合液体中回收油, 本工作以纤维状海泡石为原料, 硝酸镍为催化剂前驱体, 聚乙烯粉体为造孔剂和碳源, 采用冷冻干燥结合催化裂解法制备了超疏水/超亲油碳纳米管(CNTs)改性海泡石多孔陶瓷, 研究了固含量和催化热解温度对改性多孔陶瓷形貌的影响, 并表征了其在pH=1的强酸、pH=14的强碱、373 K高温和77 K低温等极端环境中的表面润湿性能及水油分离性能。结果表明: 催化剂前驱体溶液浓度为0.5 mol/L、海泡石的固含量为15wt%、催化热解温度为973 K且保温时间为2 h时所制备的CNTs改性多孔陶瓷具有最好的超疏水/超亲油性能, 其对柴油、白油、植物油和真空泵油的最高吸附量分别是其自身质量的15.7、20.8、23和25倍; 其连续油水分离时油通量高达250 kg·s -1·m -2, 且在5 h内分离效率及选择性不发生明显降低。

中图分类号:

董龙浩,张海军,张俊,吴文浩,贾全利. 碳纳米管改性海泡石多孔陶瓷及其高效油水分离性能研究[J]. 无机材料学报, 2020, 35(6): 689-696.

DONG Longhao,ZHANG Haijun,ZHANG Jun,WU Wenhao,JIA Quanli. Carbon Nanotube Modified Sepiolite Porous Ceramics for High-efficient Oil/Water Separation[J]. Journal of Inorganic Materials, 2020, 35(6): 689-696.

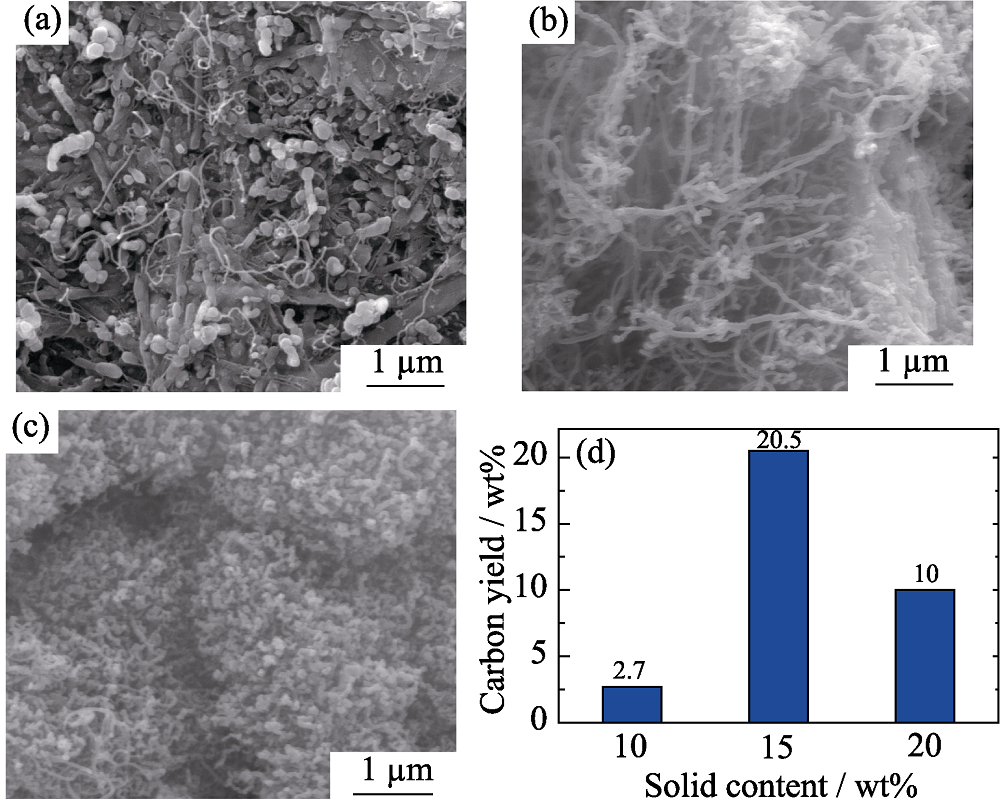

图2 不同固含量的CNTs改性海泡石多孔陶瓷的SEM照片和碳含量变化

Fig. 2 SEM micrographs and carbon content change of CNTs modified sepiolite porous ceramics with various solid contents (a) 10wt%; (b) 15wt%; (c) 20wt%; (d) Carbon content change

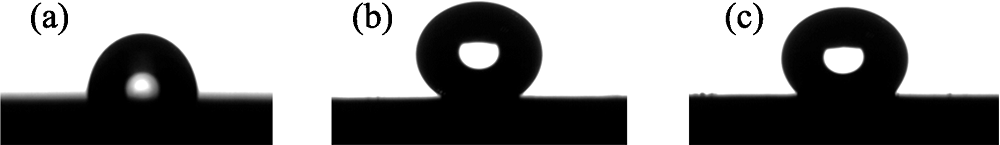

图3 不同固含量的CNTs改性海泡石多孔陶瓷的表面水润湿角

Fig. 3 The static water contact angle of CNTs modified sepiolite porous ceramics with various solid contents (a) 10wt%; (b) 15wt%; (c) 20wt%

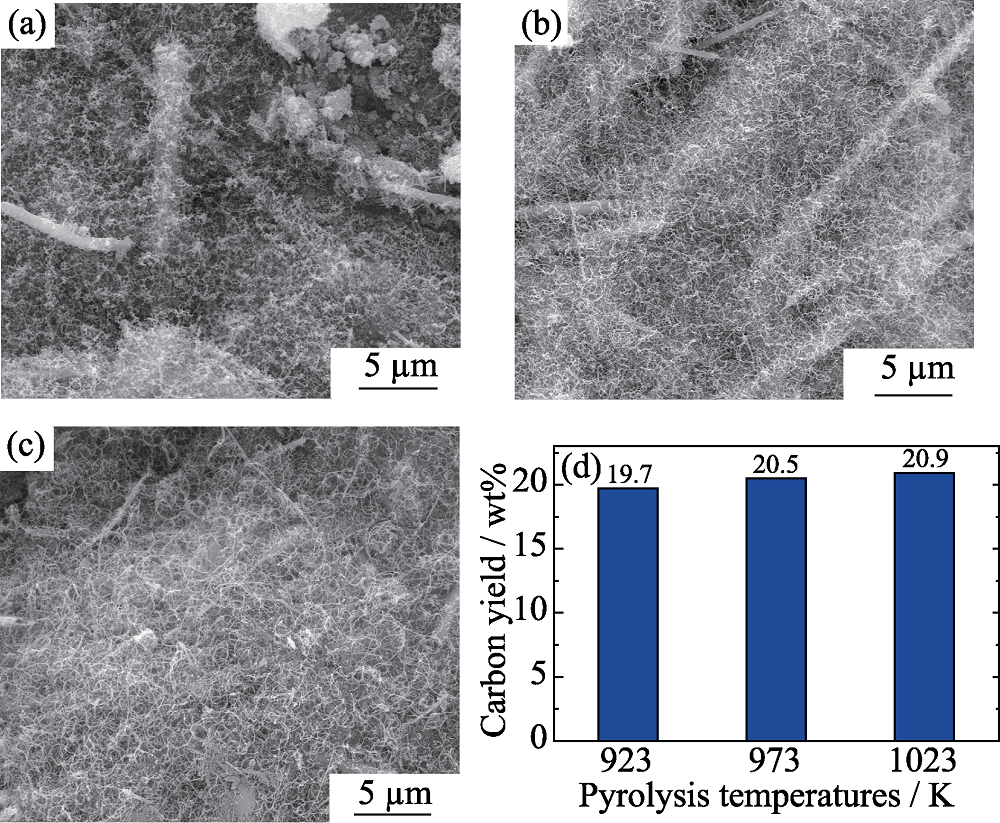

图4 不同催化裂解温度时CNTs改性海泡石多孔陶瓷的SEM照片和碳含量变化

Fig. 4 SEM micrographs and carbon content change of CNTs modified sepiolite porous ceramics prepared at various pyrolysis temperatures (a) 923 K; (b) 973 K; (c) 1023 K; (d) Carbon content change

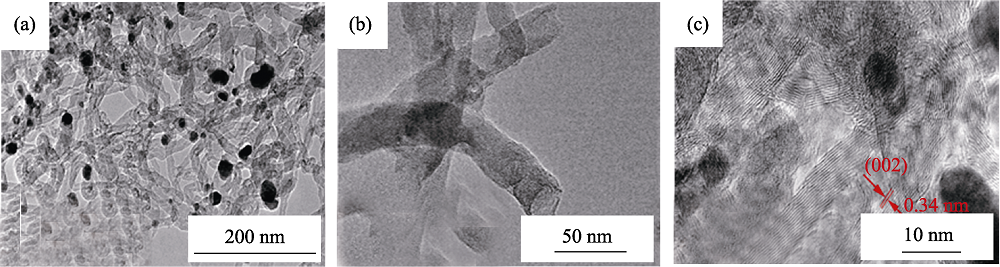

图5 973 K/2 h催化裂解聚乙烯所制备CNTs的TEM和HRTEM照片

Fig. 5 TEM and HRTEM images of CNTs resultant from pyrolysis of polyethylene at 973 K for 2 h under the optimal condition (a) Low transmission electron microscopy; (b) Tip of CNTs; (c) HRTEM images of the walls of CNTs

| Adsorbent material | Adsorbate | Modified substance | Adsorption capacity (g?g-1) | Ref. |

|---|---|---|---|---|

| Sepiolite powders | Motor oil | - | 0.174-0.184 | [29] |

| Modified silica powders | Motor oil | 1, 7-octadiene | 0.330 | [30] |

| Diatomite/silicalite-Ⅰcomposite powders | Benzene | Silicalite-Ⅰ | 0.095-0.246 | [31] |

| Modified diatomite porous ceramics | Toluene | Graphene/carbon nanobelts | 1.090 | [19] |

| Modified diatomite porous ceramics | Vacuum pump oil | Graphene/carbon nanobelts | 1.025 | [19] |

| Boron nitride aerogel | Salad oil | - | 5 | [32] |

| Modified alumina porous ceramics | Hexane | Polydimethylsiloxane | 2 | [33] |

| Modified rock wool | Diesel oil | Polydimethylsiloxane/silica | 7 | [34] |

| Polymethylsilsesquioxane aerogel | Hexane | - | 6.2 | [35] |

| Modified sepiolite porous ceramics | Hiesel oil | CNTs | 15.7 | This work |

| Modified sepiolite porous ceramics | Haraffin oil | CNTs | 20.8 | This work |

| Modified sepiolite porous ceramics | Vegetable oil | CNTs | 23 | This work |

| Modified sepiolite porous ceramics | Vacuum pump oil | CNTs | 25 | This work |

表1 各种吸附材料吸附量的比较

Table 1 Comparison of adsorption capacity values of various adsorbent materials developed to date

| Adsorbent material | Adsorbate | Modified substance | Adsorption capacity (g?g-1) | Ref. |

|---|---|---|---|---|

| Sepiolite powders | Motor oil | - | 0.174-0.184 | [29] |

| Modified silica powders | Motor oil | 1, 7-octadiene | 0.330 | [30] |

| Diatomite/silicalite-Ⅰcomposite powders | Benzene | Silicalite-Ⅰ | 0.095-0.246 | [31] |

| Modified diatomite porous ceramics | Toluene | Graphene/carbon nanobelts | 1.090 | [19] |

| Modified diatomite porous ceramics | Vacuum pump oil | Graphene/carbon nanobelts | 1.025 | [19] |

| Boron nitride aerogel | Salad oil | - | 5 | [32] |

| Modified alumina porous ceramics | Hexane | Polydimethylsiloxane | 2 | [33] |

| Modified rock wool | Diesel oil | Polydimethylsiloxane/silica | 7 | [34] |

| Polymethylsilsesquioxane aerogel | Hexane | - | 6.2 | [35] |

| Modified sepiolite porous ceramics | Hiesel oil | CNTs | 15.7 | This work |

| Modified sepiolite porous ceramics | Haraffin oil | CNTs | 20.8 | This work |

| Modified sepiolite porous ceramics | Vegetable oil | CNTs | 23 | This work |

| Modified sepiolite porous ceramics | Vacuum pump oil | CNTs | 25 | This work |

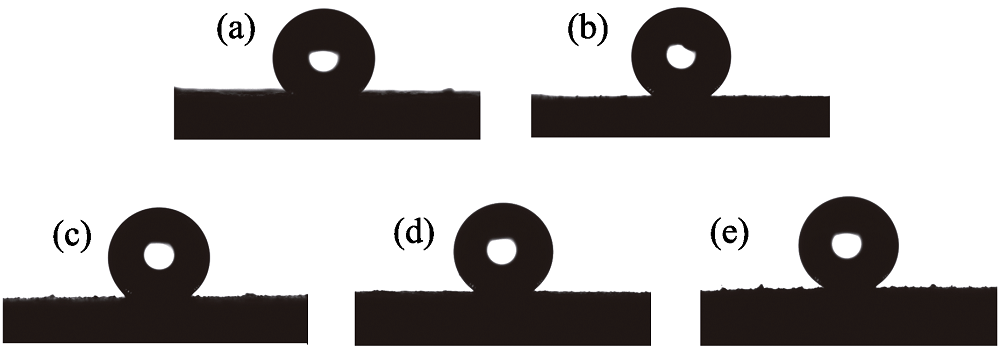

图10 CNTs改性多孔陶瓷在不同环境下的水接触角

Fig. 10 The static water contact angles of CNTs modified sepiolite porous ceramics in various environments (a) As-synthesized ceramic; (b) pH=1; (c) pH=13; (d) 373 K; (e) 77 K

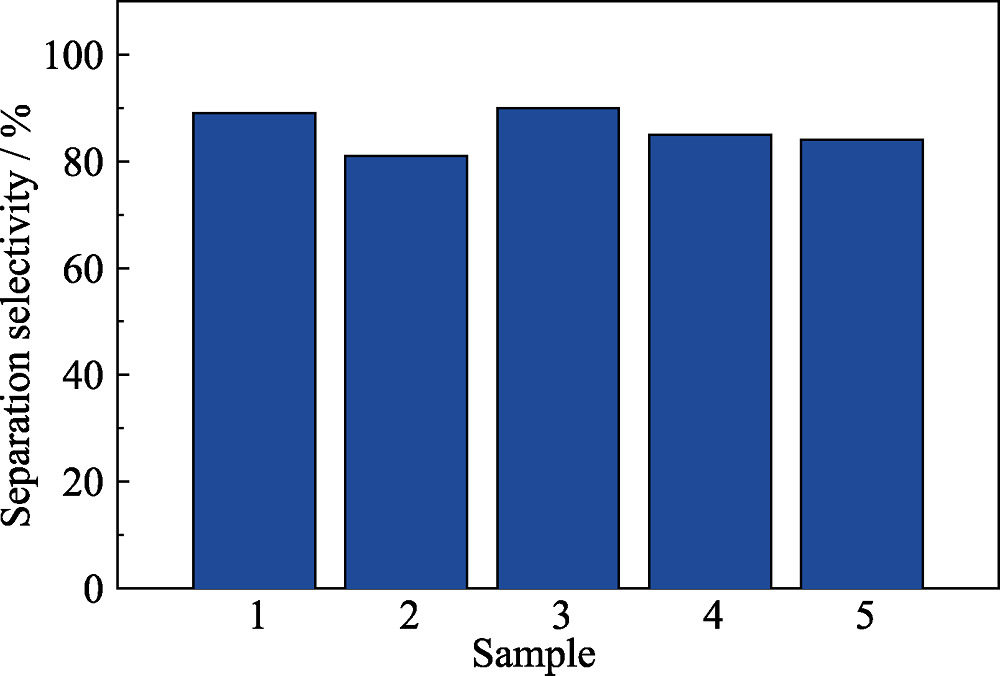

图11 不同环境下CNTs改性多孔陶瓷的油水分离选择性

Fig. 11 Oil/water separation selectiviies of CNTs modified porous ceramics in various environments (1) As-synthesized ceramic; (2) pH =1; (3) pH=13; (4) Heating at 373 K for 4 h; (5) Freezing at 77 K for 4 h

| [1] | ZHANG JUN, HAN LEI, ZHANG HAI-JUN , et al. Selective oil/water separation materials. Progress in Chemistry, 2019,31(1):146-155. |

| [2] |

LIU KE-SONG, YAO XI, JIANG LEI . Recent developments in bio-inspired special wettability. Chemical Society Reviews, 2010,39(8):3240-3255.

DOI URL |

| [3] |

SU CHUN-PING, YANG HAO, SONG SHUANG , et al. A magnetic super-hydrophilic/oleophobic sponge for continuous oil-water separation. Chemical Engineering Journal, 2017,309:366-373.

DOI URL |

| [4] |

ZHANG LIN, LI HONG-QIANG, LAI XUE-JUN , et al. Thiolated graphene-based superhydrophobic sponges for oil-water separation. Chemical Engineering Journal, 2017,316:736-743.

DOI URL |

| [5] |

LIU CAN, YANG JIN, TANG YONG-CAI , et al. Versatile fabrication of the magnetic polymer-based graphene foam and applications for oil-water separation. Colloids and Surfaces A, 2015,468:10-16.

DOI URL |

| [6] |

SHI ZHUN, ZHANG WEN-BIN, ZHANG FENG , et al. Ultrafast separation of emulsified oil/water mixtures by ultrathin free- standing single-walled carbon nanotube network films. Advanced Materials, 2013,25(17):2422-2427.

DOI URL |

| [7] |

GUI XU-CHUN, ZENG ZHI-PING, LIN ZHI-QING , et al. Magnetic and highly recyclable macroporous carbon nanotubes for spilled oil sorption and separation. ACS Applied Materials & Interfaces, 2013,5(12):5845-5850.

DOI URL |

| [8] |

HAN LEI, DENG XIAN-GONG, LI FA-LIANG , et al. Preparation of high strength porous mullite ceramics via combined foam- gelcasting and microwave heating. Ceramics International, 2018,44(12):14728-14733.

DOI URL |

| [9] |

HAN LEI, LI FA-LIANG, HUANG LANG , et al. Preparation of Si3N4 porous ceramics via foam-gelcasting and microwave-nitridation method. Ceramics International, 2018,44(15):17675-17680.

DOI URL |

| [10] |

DENG XIAN-GONG, RAN SONG-LIN, HAN LEI , et al. Foam-gelcasting preparation of high-strength self-reinforced porous mullite ceramics. Journal of the European Ceramic Society, 2017,37(13):4059-4066.

DOI URL |

| [11] |

SHANG SHAN SHAN, HE XIONG, YANG YI , et al. Preparation of Ti2AlN porous ceramics by organic foam impregnation process. Key Engineering Materials, 2016,697:163-168.

DOI URL |

| [12] |

QIAN HAO-RAN, CHENG XU-DONG, ZHANG HE-PING , et al. Preparation of porous mulliteceramics using fly ashcenosphere as a pore-forming agent by gelcastingprocess. International Journal of Applied Ceramic Technology, 2014,11(5):858-863.

DOI URL |

| [13] |

GE SHENG-TAO, LIN LIANG-XU, ZHANG HAI-JUN , et al. Synthesis of hierarchically porous mullite ceramics with improved thermal insulation via foam-gelcasting combined with pore former addition. Advances in Applied Ceramics, 2018,117(8):493-499.

DOI URL |

| [14] |

CHAU TRANG THE LIEU, LE DUNG QUANG TIEN, LE HOA THI , et al. Chitin liquid-crystal-templated oxide semiconductor aerogels. ACS Applied Materials & Interfaces, 2017,9(36):30812-30820.

DOI URL |

| [15] |

JESÚS M RODRÍGUEZ-PARRA, RODRIGO MORENO, MARÍA ISABEL NIETO . Effect of cooling rate on the microstructure and porosity of alumina produced by freeze casting. Serbian Chemical Society Journal, 2012,77(12):1775-1785.

DOI URL |

| [16] |

DU JIAN-CONG, ZHANG XING-HONG, HONG CHANG-QING , et al. Microstructure and mechanical properties of ZrB2-SiC porous ceramic by camphene-based freeze casting. Ceramics International, 2013,39(2):953-957.

DOI URL |

| [17] | XIA YONG-FENG, ZENG YU-PING, JIANG DONG-LIANG . Microstructure and mechanical properties of porous Si3N4 ceramics prepared by freeze-casting. Materials & Design, 2012,33:98-103. |

| [18] |

REN LIN-LIN, ZENG YU-PING, JIANG DONG-LIANG . Preparation of porous TiO2 by a novel freeze casting. Ceramics International, 2009,35(3):1267-1270.

DOI URL |

| [19] |

BI YU-BAO, HAN LEI, ZHENG YANG-FAN , et al. Lotus- seedpod-bioinspired 3D superhydrophobic diatomite porous ceramics comodified by graphene and carbon nanobelts. ACS Applied Materials & Interfaces, 2018,10(32):27416-27423.

DOI URL |

| [20] | MA YING, ZHANG GAO-KE . Sepiolite nanofiber-supported platinum nanoparticle catalysts toward the catalytic oxidation of formaldehyde at ambient temperature: efficient and stable performance and mechanism. Applied Clay Science, 2016,288:70-78. |

| [21] | SUÁREZ M, GARCÍA-ROMERO E . Variability of the surface properties of sepiolite. Applied Clay Science, 2012,67:72-82. |

| [22] |

LI TIAN, WANG LI-JUAN, WANG KAI-LEI , et al. The preparation and properties of porous sepiolite ceramics. Scientific Reports, 2019,9(1):7337.

DOI URL |

| [23] |

VICTORIA BERNARDO, FREDERIK VAN LOOCK, JUDITH MARTIN-DE LEON, et al. Mechanical properties of PMMA- sepiolite nanocellular materials with a bimodal cellular structure. Macromolecular Materials and Engineering, 2019,304(7):1900041.

DOI URL |

| [24] | GUO ZHEN-HUA, LIU ZHONG-TAO, YANG FAN , et al. Application of sepiolite in wastewater treatment. Environmental Protection and Circular Economy, 2016,36(10):30-32. |

| [25] | MILT V G, BANUS E D, MIRÓ E E , et al. Structured catalysts containing Co, Ba and K supported on modified natural sepiolite for the abatement of diesel exhaust pollutants. Chemical Engineering Journal, 2010,157(2/3):530-538. |

| [26] | WANG JUN-KAI, DENG XIAN-GONG, ZHANG HAI-JUN , et al. Synthesis of carbon nanotubes via Fe-catalyzed pyrolysis of phenolic resin. Physica E, 2017,86:24-35. |

| [27] | WANG JUN-KAI, DENG XIAN-GONG, ZHANG HAI-JUN , et al. Carbon nanotube preparation by catalytic pyrolysis of phenolic resin with nickel nitrate. Materials for Mechanical Engineering, 2016,40(8):30-33. |

| [28] | SONG JIAN-BO, ZHANG HAI-JUN, WANG JUN-KAI , et al. High-yield production of large aspect ratio carbon nanotubes via catalytic pyrolysis of cheap coal tar pitch. Carbon, 2018,130:701-713. |

| [29] | RAJAKOVIĆ-OGNJANOVIĆ V, ALEKSIĆ G, RAJAKOVIĆ L . Governing factors for motor oil removal from water with different sorption materials. Journal of Hazardous Materials, 2008,154(1/2/3):558-563. |

| [30] | AKHAVAN B, JARVIS K, MAJEWSKI P . Hydrophobic plasma polymer coated silica particles for petroleum hydrocarbon removal. ACS Applied Materials & Interfaces, 2013,5(17):8563-8571. |

| [31] | YUAN WEI-WEI, YUAN PENG, LIU DONG , et al. A hierarchically porous diatomite/silicalite-1 composite for benzene adsorption/desorption fabricated via a facile pre-modification in situ synthesis route. Chemical Engineering Journal, 2016,294:333-342. |

| [32] | XUE YANG-MING, DAI PENG-CHENG, JIANG XIANG-FEN , et al. Template-free synthesis of boron nitride foam-like porous monoliths and their high-end applications in water purification. Journal of Materials Chemistry A, 2016,4(4):1469-1478. |

| [33] | DONG BING-BING, YANG MING-YE, WANG FEI-HONG , et al. Porous Al2O3 plates prepared by combing foaming and gel-tape casting methods for efficient collection of oil from water. Chemical Engineering Journal, 2019,370:658-665. |

| [34] | HAO WEN-TAO, XU JIAN, LI RAN , et al. Developing superhydrophobic rock wool for high-viscosity oil/water separation. Chemical Engineering Journal, 2019,368:837-846. |

| [35] | GEN HAYASE, KAZUYOSHI KANAMORI, MASASHI FUKUCHI , et al. Facile synthesis of marshmallow-like macroporous gels usable under harsh conditions for the separation of oil and water. Angewandte Chemie International Edition, 2013,52(7):1986-1989. |

| [36] | ZHANG AI-LI, ZHAI XIU-JING, FU YAN , et al. Reach on electrochemical lithium storage performance of carbon nanotubes. Journal of Inorganic Materials, 2004,19(1):244-248. |

| [37] | ZHENG YANG-FAN, ZHANG HAI-JUN, GE SHENG-TAO , et al. Synthesis of carbon nanotube arrays with high aspect ratio via Ni-catalyzed pyrolysis of waste polyethylene. Nanomaterials, 2018,8(7):556. |

| [38] | WENZEL ROBERT N . Resistance of solid surfaces to wetting by water. Industrial & Engineering Chemistry, 1936,28(8):988-994. |

| [39] | CAO SU-JIAO, QIU FANG, XIONG CHEN , et al. Superhydrophobic PES/PDA/ODTS fibrous mat prepared by electrospinning and silanization modification for oil/water separation. Journal of Applied Polymer Science, 2018,135(12):45923. |

| [40] | CHENG PENG, JING PENG, ZHANG SHI-YUAN , et al. A macroporous metal-organic framework with enhanced hydrophobicity for efficient oil adsorption. Chemistry-A European Journal, 2018,24(15):3754-3759. |

| [41] |

GUPTA SHIVAM, TAI NYAN-HWA . Carbon materials as oil sorbents: a review on the synthesis and performance. Journal of Materials Chemistry A, 2016,4(5):1550-1565.

DOI URL |

| [1] | 吴秋琴, 姚奋发, 金传洪, 郑遗凡. 碳纳米管内填充生长超细一维亚化学计量比氧化钨纳米线[J]. 无机材料学报, 2022, 37(4): 413-419. |

| [2] | 刘芳芳, 传秀云, 杨扬, 李爱军. 氮/硫共掺杂对纤水镁石模板碳纳米管电化学性能的影响[J]. 无机材料学报, 2021, 36(7): 711-717. |

| [3] | 罗燚,冯军宗,冯坚,姜勇刚,李良军. 新型碳材料质子交换膜燃料电池Pt催化剂载体的研究进展[J]. 无机材料学报, 2020, 35(4): 407-415. |

| [4] | 佟威, 熊党生. 仿生超疏水表面的发展及其应用研究进展[J]. 无机材料学报, 2019, 34(11): 1133-1144. |

| [5] | 刘甜甜, 王庆华, 刘希莉, 高凤, 汪庆祥. 近球状钼酸镍/多壁碳纳米管复合材料的制备及其赝电容性能[J]. 无机材料学报, 2018, 33(7): 735-740. |

| [6] | 徐顺建, 肖宗湖, 罗晓瑞, 钟炜, 罗永平, 欧惠. 碳纳米管和二甲基亚砜对钙钛矿太阳电池中PEDOT:PSS空穴传输层的协同影响[J]. 无机材料学报, 2018, 33(6): 641-647. |

| [7] | 张欣, 张建峰, 杨水仙, 曹惠杨, 黄华杰, 江莞. 碳纳米管复合二维碳化钛负载钯粒子电催化性能研究[J]. 无机材料学报, 2018, 33(2): 206-212. |

| [8] | 邓敏, 江奇, 方渊, 李欢, 邱家欣, 卢晓英. 碳纳米管/聚苯胺化学修饰电极的制备及其对抗坏血酸的检测[J]. 无机材料学报, 2018, 33(1): 53-59. |

| [9] | 郑 譞,龚春丽, 刘 海, 汪广进, 程 凡, 郑根稳, 文 胜, 熊传溪. 磷钼酸负载碳纳米管复合物的制备及其超级电容性能[J]. 无机材料学报, 2017, 32(2): 127-134. |

| [10] | 黄 维, 朱家艺, 李 浩, 杨 曦, 王朝阳, 付志兵. 滴涂法制备石墨烯/碳纳米管复合薄膜及其表征[J]. 无机材料学报, 2017, 32(2): 203-209. |

| [11] | 杨 超, 李 莹, 闫 璐, 曹韫真. 原子层沉积工艺制备催化薄膜厚度对生长碳纳米管阵列的影响[J]. 无机材料学报, 2016, 31(7): 681-686. |

| [12] | 齐乐华, 舒 扬, 李贺军, 黎云玉, 马海丽, 宋 强. 电泳沉积CNTs掺杂C/C复合材料的微观组织与弯曲性能[J]. 无机材料学报, 2016, 31(2): 201-206. |

| [13] | 陈 健, 郑玉婴, 张延兵, 邹海强, 卢秀恋. 氧化还原沉淀法制备MnO2/MWCNTs催化剂及其低温SCR活性[J]. 无机材料学报, 2016, 31(12): 1347-1354. |

| [14] | 邹斯浩, 辛世刚, 宋力昕. 电沉积法制备碳纳米管/黑镍复合涂层的光学与结构特性[J]. 无机材料学报, 2016, 31(12): 1370-1374. |

| [15] | 徐明丽, 段 奔, 张英杰, 杨国涛, 董 鹏, 夏书标, 杨显万. 碳纳米管载体改性条件对Pt纳米粒子电催化氧化性能的影响[J]. 无机材料学报, 2015, 30(9): 931-936. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||