无机材料学报 ›› 2020, Vol. 35 ›› Issue (4): 399-406.DOI: 10.15541/jim20190360

所属专题: 结构陶瓷论文精选(二)

• 综述 • 下一篇

包亦望1,2,孙熠2,旷峰华1,李月明2,万德田1,2

收稿日期:2019-07-17

修回日期:2019-08-18

出版日期:2020-04-20

网络出版日期:2019-09-18

作者简介:包亦望(1957-),男,教授. E-mail: ywbao@ctc.ac.cn

基金资助:BAO Yiwang1,2,SUN Yi2,KUANG Fenghua1,LI Yueming2,WAN Detian1,2

Received:2019-07-17

Revised:2019-08-18

Published:2020-04-20

Online:2019-09-18

Supported by:摘要:

同步提升陶瓷材料强度及损伤容限是陶瓷发展的核心问题。一百多年前预应力技术大幅提高混凝土和玻璃的弯曲强度, 并在世界上广泛应用以来, 预应力增强陶瓷材料的设计就成为一个百年梦想。本文总结了增强陶瓷的国内外研究进展, 并提出了全新的高强度高损伤容限复合陶瓷的预应力设计及模型, 通过优化表面预应力设计, 在陶瓷构件表面能够形成一层高度压缩应力, 从而阻止裂纹扩展, 并抵消外加拉应力, 达到提高陶瓷的强度及损伤容限的目的。这种预应力设计理论和规程可应用到结构陶瓷、建筑陶瓷和日用陶瓷等不同领域, 具有明显的通用性和广泛性, 且简单、经济, 不受构件尺寸和形状的限制, 因此极具应用前景。

中图分类号:

包亦望,孙熠,旷峰华,李月明,万德田. 高强度预应力陶瓷的发展与探索[J]. 无机材料学报, 2020, 35(4): 399-406.

BAO Yiwang,SUN Yi,KUANG Fenghua,LI Yueming,WAN Detian. Development and Prospects of High Strength Pre-stressed Ceramics[J]. Journal of Inorganic Materials, 2020, 35(4): 399-406.

| Content of fiber | 28vol% | 32vol% | 43vol% | 55vol% |

|---|---|---|---|---|

| Density /(g·cm-3) | (2.69±0.01) | (2.55±0.02) | (2.44±0.04) | (2.27±0.03) |

| Open porosity/ % | (2.47±0.09) | (2.95±0.01) | (4.31±0.04) | (4.85±0.03) |

| Bending stress/MPa | (198±37) | (259±43) | (325±35) | (500±11) |

表1 不同体积分数纤维对SiC陶瓷机械性能的影响[36]

Table 1 Mechanical properties of composites with different fiber contents[36]

| Content of fiber | 28vol% | 32vol% | 43vol% | 55vol% |

|---|---|---|---|---|

| Density /(g·cm-3) | (2.69±0.01) | (2.55±0.02) | (2.44±0.04) | (2.27±0.03) |

| Open porosity/ % | (2.47±0.09) | (2.95±0.01) | (4.31±0.04) | (4.85±0.03) |

| Bending stress/MPa | (198±37) | (259±43) | (325±35) | (500±11) |

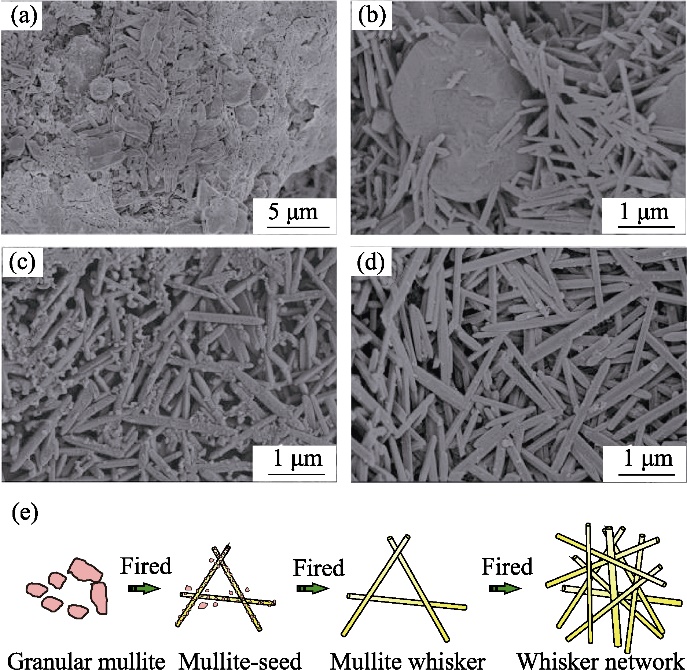

图2 不同配方陶瓷的SEM照片(a~d)及网状莫来石晶须形成过程示意图(e)[37]

Fig. 2 SEM photomicrographs of different compositions (a-d) and formation process of the mullite whisker network (e)[37] (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4

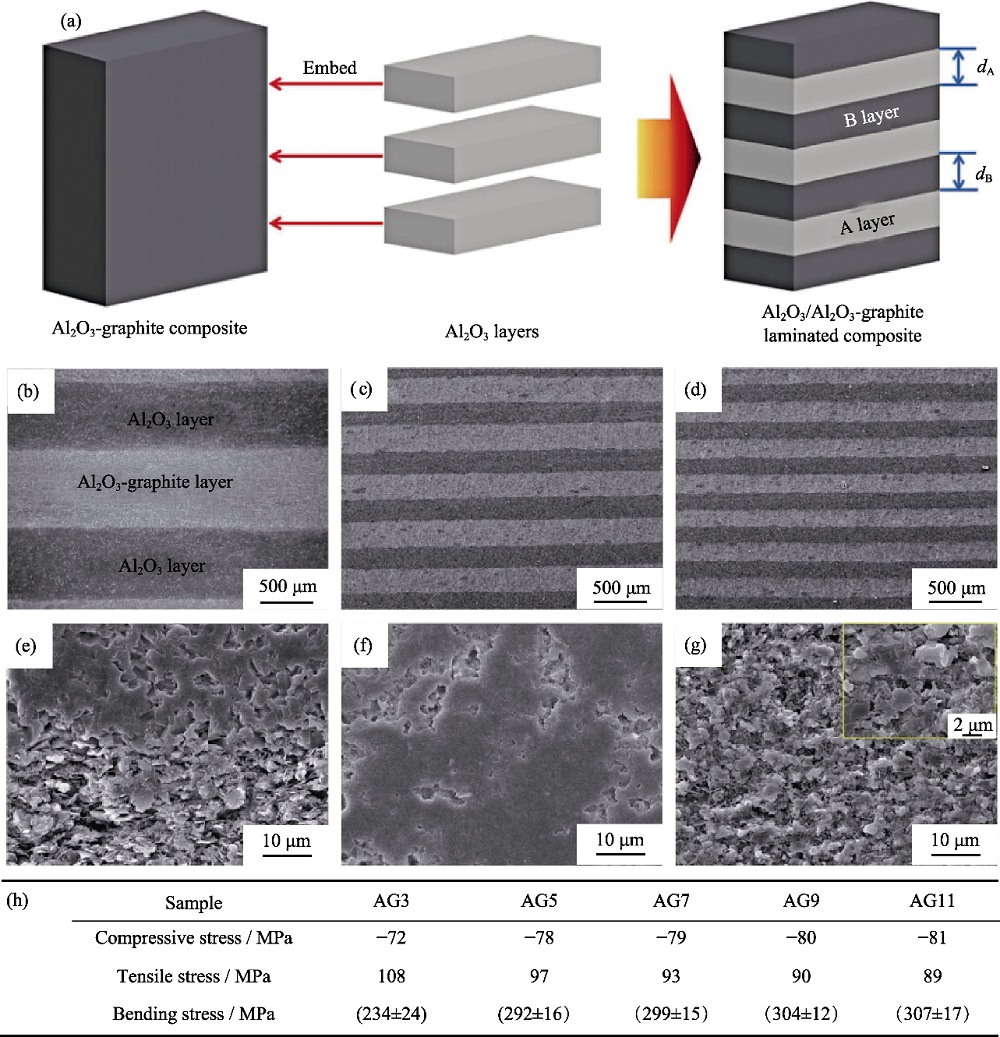

图4 层状复合材料设计及原理示意图(a), 不同参数(层厚、层数等)设计的陶瓷显微结构照片((b)AG3; (c)AG7; (d)AG11; (e)复合材料界面; (f)Al2O3层的显微结构; (g)Al2O3-石墨层的显微结构)及不同层状陶瓷的力学性能(h)[47]

Fig. 4 Schematic diagram of the laminated composites (a), microstructures of different structural composites (b-g) and mechanical properties of different laminate samples (h)[47] (b) AG3; (c)AG7; (d) AG11; (e) Interface of composite; (f) Microscopic structure of Al2O3 layer; (g) Microscopic structure of Al2O3-graphite layer

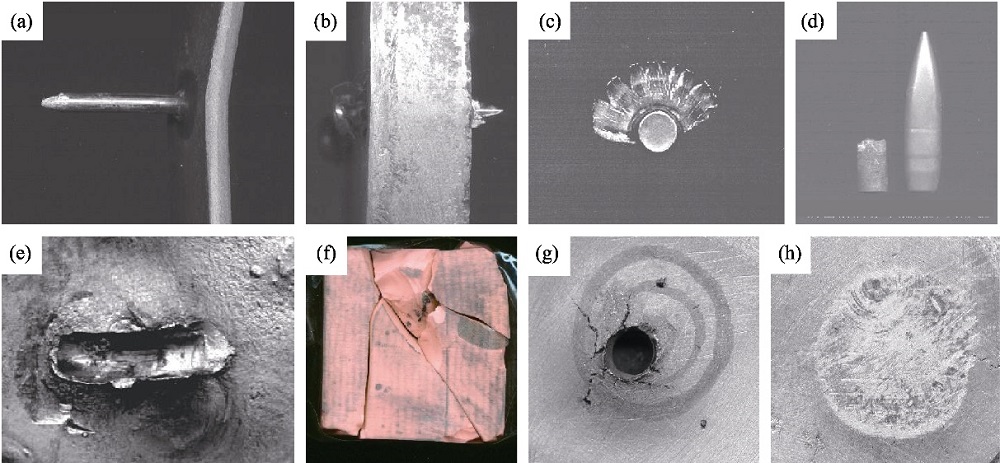

图5 预应力陶瓷和无预应力陶瓷的抗冲击行为及抗穿甲对比试验[50]

Fig. 5 Comparisons of impact resistance and armor piercing resistance between pre-stressed and unpre-stressed ceramics[50] (a) Test of impact resistance performance with the nail gun, which could penetrate the steel plate with a thickness of 6 mm; (b) 30 mm-thick aluminum alloy plate penetrated by nail gun; (c) Mushroom-shaped fragments of pre-stressed composite materials fired by ordinary rifle bullets; (d) Morphologies of the armor-piercing incendiary bullets before and after firing at pre-stressed composite materials; (e) Morphology of aluminum alloy pre-stressed ceramics after shooting; (f) Unpre-stressed ceramic materials being crushed and penetrated after shooting; (g) Frontal morphology of pre-stressed composite materials fired by armor-piercing incendiary bullets; (h) Reverse morphology of the pr-estressed composite materials fired by armor-piercing incendiary bullets, which could not penetrate the pre-stressed composite ceramics

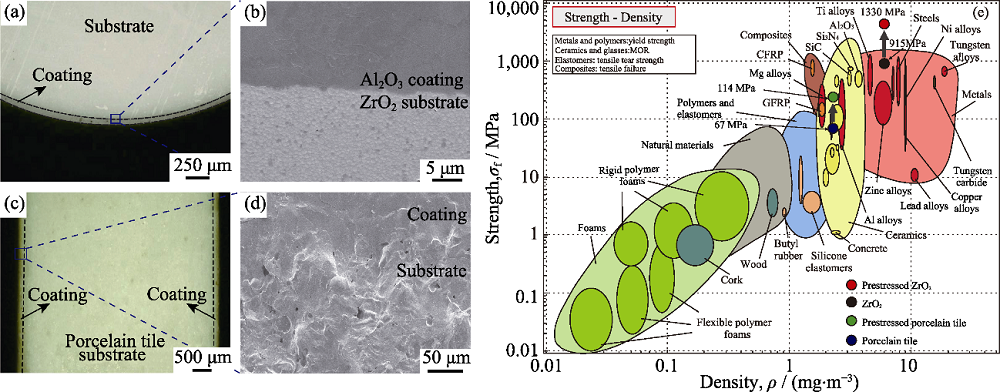

图7 预应力陶瓷样品(a, c)、显微照片(b, d)[51]及Ashby图解(e)[52]

Fig. 7 Pre-stressed ceramics samples(a, c), SEM images(b, d)[51] and Ashby diagram(e)[52] (a, b) Pre-stressed structural ceramics; (c, d) Pre-stressed architectural ceramics

| [1] | KRSTIC Z . Silicon nitride: the engineering material of the future. J. Mater. Sci., 2012,47(2):535-552. |

| [2] | LAUNEY M E, RITCHIE R O . On the fracture toughness of advanced materials. Adv. Mater., 2009,21(21):2103-2110. |

| [3] | GUO J K . Stress design of ceramic grain boundary. J. Inorg. Mater., 1995,1(10):27-31. |

| [4] | GOHARDANI A S, GOHARDANI O . Ceramic engine considerations for future aerospace propulsion. Aircr. Eng. Aerosp. Tec., 2012,84(2):75-86. |

| [5] | GARVIE R C, HANNINK R H, PASCOE R T . Ceramic steel? Nature, 1975,258(5537):703-704. |

| [6] | JOHNSTON R D, CHIPMAN R D, KNAPP W J . Prestressed ceramics as a structural material. J. Am. Ceram. Soc., 1953,36(4):121-126. |

| [7] | GREEN D J . Crack arrest and multiple cracking in glass through the use of designed residual stress profiles. Science, 1999,283(5406):1295-1297. |

| [8] | WONDRACZEK L, MAURO J C, ECKERT J , et al. Towards ultrastrong glasses. Adv. Mater., 2011,23(39):4578-4586. |

| [9] | INSLEY R H, BARCZAK V J . Thermal conditioning of polycrystalline alumina ceramics. J. Am. Ceram. Soc., 2006,47(1):1-4. |

| [10] | CHEN L, WANG A, XIANGBO S , et al. Effect of surface heat transfer coefficient gradient on thermal shock failure of ceramic materials under rapid cooling condition. Ceram. Int., 2018,44:8992-8999. |

| [11] | BARBI S, MUGONI C, MONTORSI M , et al. Chemical hardening of glazed porcelain tiles. J. Am. Ceram. Soc., 2019,102:2853-2862. |

| [12] | SHAN Z, LIU J, SHI F , et al. A new strengthening theory for improving the fracture strength of lithium disilicate glass-ceramics by introducing Rb or Cs ions. J. Non-Cryst. Solids, 2018,481:479-485. |

| [13] | RICHERSON D W, DEKKER M . Modern ceramic engineering, process, processing and use in design. New York, 2nd edition revised , 1992: 21-33. |

| [14] | GRIFFITH A A . The phenomena of rupture and flow in solids. Phil. Trans., 1921,221(2):163-198. |

| [15] | 关振铎, 张中太, 焦金生 . 无机材料物理性能. 北京: 清华大学出版社, 1992: 92-93. |

| [16] | MESSING G L, STEVENSON A J . Toward pore-free ceramics. Science, 2008,322(5900):383-384. |

| [17] | ALFORD N M, BIRCHALL J D, KENDALL K . High-strength ceramics through colloidal control to remove defects. Nature, 1987,330(6143):51-53. |

| [18] | WANG W, FU Z, WANG H , et al. Influence of hot pressing sintering temperature and time on microstructure and mechanical properties of TiB2 ceramics. J. Eur. Ceram. Soc., 2002,22(7):1045-1049. |

| [19] | HUANG Y H, JIANG D L, ZHANG X F , et al. Enhancing toughness and strength of SiC ceramics with reduced graphene oxide by HP sintering. J. Eur. Ceram. Soc., 2018,38(13):4329-4337. |

| [20] | HAN Y, LI S, ZHU T , et al. An oscillatory pressure sintering of zirconia powder: densification trajectories and mechanical properties. J. Am. Ceram. Soc., 2018,101(5):1824-1829. |

| [21] | LI S, XIE Z P, XUE W J . Microstructure and mechanical properties of zirconia ceramics consolidated by a novel oscillatory pressure sintering. Ceram. Int., 2015,41(8):10281-10286. |

| [22] | LI S, XIE Z P . Preparation of zirconia ceramics with high density and fine grains by oscillatory pressure sintering. J. Inorg. Mater., 2016,31(2):207-212. |

| [23] | ZHU T, XIE Z, HAN Y , et al. Improved mechanical properties of Al2O3-25vol% SiCw composites prepared by oscillatory pressure sintering. Ceram. Int., 2017,43:15437-15441. |

| [24] | FURUKAWA, IWAHASHI, HORITA,et al. Structural evolution and the Hall-Petch relationship in an Al-Mg-Li-Zr alloy with ultra-fine grain size. Acta Mater., 1997,45(11):4751-4757. |

| [25] | HIRATA Y, SUZUE N, MATSUNAGA N , et al. Particle size effect of starting SiC on processing, microstructures and mechanical properties of liquid phase-sintered SiC. J. Eur. Ceram. Soc., 2010,30(9):1945-1954. |

| [26] | 刘维良, 喻佑华 . 先进陶瓷工艺学. 武汉: 武汉理工大学出版社, 2004: 636-664. |

| [27] | ZhAN G D, KUNTZ J D, WAN J , et al. Single-wall carbon nanotubes as attractive toughening agents in alumina-based nanocomposites. Nat. Mater., 2003,2(1):38-42. |

| [28] | PADTURE N P . Multifunctional composites of ceramics and single walled carbon nanotubes. Adv. Mater., 2010,21(17):1767-1770. |

| [29] | OSTEEN K G, BRUNER K L, ONG D , et al. Single-crystal SiC nanowires with a thin carbon coating for stronger and tougher ceramic composites. Adv. Mater., 2010,17(12):1519-1523. |

| [30] | ZHANG L, BEN Y, WU J , et al. Alumina assisted grain refinement and physical performance enhancement of yttria transparent ceramics by two-step sintering. Mat. Sci. Eng. A, 2017,684:466-469. |

| [31] | FISHER E S, MANGHNANI M H, WANG J F , et al. Elastic properties of Al2O3 and Si3N4 matrix composites with SiC whisker reinforcement. J. Am. Ceram. Soc., 1992,75(4):908-914. |

| [32] | KHODAEIA M, YAGHOBIZADEHB O, ALHOSSEINI S H N ,et al. The effect of oxide, carbide, nitride and boride additives on properties of pressureless sintered SiC: a review. J. Eur. Ceram. Soc., 2019,39(7):2215-2231. |

| [33] | KUMAR S, SAIRAM K, SONBER J K , et al. Hot-pressing of MoSi2, reinforced B4C composites. Ceram. Int., 2014,40(10):16099-16105. |

| [34] | YU H, CHEN Y, GUO X , et al. Study on mechanical properties of hot pressing sintered mullite-ZrO2 composites with finite element method. Ceram. Int., 2018,44(7):7509-7514. |

| [35] | GUO X, YANG H, ZHANG L , et al. Sintering behavior, microstructure and mechanical properties of silicon carbide ceramics containing different nano-TiN additive. Ceram. Int., 2010,36(1):161-165. |

| [36] | DING Y, DONG S, ZHOU Q , et al. Preparation of C/SiC composites by hot pressing, using different C fiber content as reinforcement. J. Am. Ceram. Soc., 2006,89(4):1447-1449. |

| [37] | CHEN X, LI T, REN Q , et al. Mullite whisker network reinforced ceramic with high strength and lightweight. J. Alloy Compd., 2017,700:37-42. |

| [38] | 李国平 . 预应力混凝土结构设计原理. 北京: 人民交通出版社, 2000: 1-10. |

| [39] | NAWY E . Reinforced concrete: a fundamental approach. Prentice-Hall, 2nd edition revised, 1996: 1-15. |

| [40] | MAURO J C, PHILIP C S, VAUGHN D J , et al. Glass science in the united states: current status and future directions. Int. J. Appl. Glass. Sci., 2014,5(1):2-15. |

| [41] | OLCOTT J S . Chemical strengthening of glass. Science, 1963,140(3572):1189-1193. |

| [42] | CHAUDHRI M M, LIANGYI C . The catastrophic failure of thermally tempered glass caused by small-particle impact. Nature, 1986,320(6057):48-50. |

| [43] | 包亦望, 郑元善, 苏盛彪 , 等. 预应力陶瓷及其抗冲击与穿甲性能. 材料导报, 2000,14:110-112. |

| [44] | AURELIO I L, DORNELES L S, MAY L G . Extended glaze firing on ceramics for hard machining: crack healing, residual stresses, optical and microstructural aspects. Dent Mater., 2017,33(2):226-240. |

| [45] | SHAN Z, LIU J, LIU M , et al. Surface strengthening of lithium disilicate glass-ceramic by ion-exchange using Rb, Cs nitrates. Ceram. Int., 2018,44:12466-12471. |

| [46] | DAL BÓ M, DOMINGUINI L, ZIMMER A , et al. Chemical tempering of porcelain tiles. Ceram. Int., 2016,42:15199-15202. |

| [47] | SONG J, YANG H, BERMEJO R , et al. Enhanced thermal shock response of Al2O3-graphite composites through a layered architectural design. J. Am. Ceram. Soc., 2019,102:3673-3684. |

| [48] | QIAN S, LIU F, MA M , et al. Mechanical strength enhancement of low temperature co-fired multilayer ceramic substrates by introducing residual stress. Ceram. Int., 2019,45(8):10982-10990. |

| [49] | BAO Y, SU S, YANG J , et al. Pre-stressed ceramics and improvement of impact resistance. Mater. Lett., 2002,57(2):518-524. |

| [50] | 包亦望 . 先进陶瓷力学性能评价方法与技术. 北京: 中国建材工业出版社, 2017: 140-187. |

| [51] | BAO Y, KUANG F, SUN Y , et al. A simple way to make pre-stressed ceramics with high strength. J. Materiomics., 2019,5:657-662. |

| [52] | ASHBY, M F . Materials Selection in Mechanical Design. Oxford, 4th edition revised, 2011: 60-68. |

| [1] | 丁玲, 蒋瑞, 唐子龙, 杨运琼. MXene材料的纳米工程及其作为超级电容器电极材料的研究进展[J]. 无机材料学报, 2023, 38(6): 619-633. |

| [2] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [3] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [4] | 林俊良, 王占杰. 铁电超晶格的研究进展[J]. 无机材料学报, 2023, 38(6): 606-618. |

| [5] | 牛嘉雪, 孙思, 柳鹏飞, 张晓东, 穆晓宇. 铜基纳米酶的特性及其生物医学应用[J]. 无机材料学报, 2023, 38(5): 489-502. |

| [6] | 罗淑文, 马名生, 刘峰, 刘志甫. Ca-B-Si体系LTCC材料腐蚀行为及腐蚀机理[J]. 无机材料学报, 2023, 38(5): 553-560. |

| [7] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [8] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [9] | 杨洋, 崔航源, 祝影, 万昌锦, 万青. 柔性神经形态晶体管研究进展[J]. 无机材料学报, 2023, 38(4): 367-377. |

| [10] | 吴俊林, 丁继扬, 黄新友, 朱丹阳, 黄东, 代正发, 杨文钦, 蒋兴奋, 周健荣, 孙志嘉, 李江. Gd2O2S:Tb闪烁陶瓷的制备与结构: 水浴合成中H2SO4/Gd2O3摩尔比的影响[J]. 无机材料学报, 2023, 38(4): 452-460. |

| [11] | 游钧淇, 李策, 杨栋梁, 孙林锋. 氧化物双介质层忆阻器的设计及应用[J]. 无机材料学报, 2023, 38(4): 387-398. |

| [12] | 陈昆峰, 胡乾宇, 刘锋, 薛冬峰. 多尺度晶体材料的原位表征技术与计算模拟研究进展[J]. 无机材料学报, 2023, 38(3): 256-269. |

| [13] | 张超逸, 唐慧丽, 李宪珂, 王庆国, 罗平, 吴锋, 张晨波, 薛艳艳, 徐军, 韩建峰, 逯占文. 新型GaN与ZnO衬底ScAlMgO4晶体的研究进展[J]. 无机材料学报, 2023, 38(3): 228-242. |

| [14] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| [15] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||