无机材料学报 ›› 2020, Vol. 35 ›› Issue (5): 549-555.DOI: 10.15541/jim20190190

所属专题: 2020年能源材料论文精选(三) :太阳能电池、热电材料及其他

收稿日期:2019-04-30

修回日期:2019-08-02

出版日期:2020-05-20

网络出版日期:2019-09-18

作者简介:郑 坤(1992-), 男, 硕士研究生. E-mail: 425970528@qq.com<br/>ZHENG Kun(1992-), male, Master candidate. E-mail: 425970528@qq.com

基金资助:

ZHENG Kun1,LUO Yongchun1,2( ),DENG Anqiang1,YANG Yang1,ZHANG Haiming1

),DENG Anqiang1,YANG Yang1,ZHANG Haiming1

Received:2019-04-30

Revised:2019-08-02

Published:2020-05-20

Online:2019-09-18

Supported by:摘要:

采用真空电弧熔炼和均匀化退火制备La0.3Y0.7Ni3.4-xMnxAl0.1(x=0~0.5)储氢合金, 采用不同方法系统研究了Mn元素对合金微观结构、储氢和电化学性能的影响规律和作用。结果表明, 退火合金微观组织与Mn含量关系密切, 提高Mn含量有利于合金组织形成Ce2Ni7型相, 当x≥0.3时, 合金形成Ce2Ni7型结构单相组织。随Mn含量增加, Ce2Ni7型主相晶胞参数a、c及晶胞体积V均依次增大, 导致合金吸氢平台压从0.079 MPa降至0.017 MPa, 储氢量达到1.268wt%~1.367wt%。添加Mn元素能显著改善合金的电化学性能, x=0.1的合金电极的放电容量最高(390.4 mAh·g -1); x=0.15和0.5的合金电极的容量保持率S100分别为86.1%和88.5%, 具有较好的循环稳定性。上述合金电极的高倍率放电性能HRD900为71.53%~87.73%。分析结果表明, 合金电极反应动力学过程由电极/溶液界面的电子转移与体相中的氢原子扩散共同控制。

中图分类号:

郑坤, 罗永春, 邓安强, 杨洋, 张海民. A2B7型La0.3Y0.7Ni3.4-xMnxAl0.1储氢合金微观结构和电化学性能研究[J]. 无机材料学报, 2020, 35(5): 549-555.

ZHENG Kun, LUO Yongchun, DENG Anqiang, YANG Yang, ZHANG Haiming. Microstructure and Electrochemical Property of A2B7-type La0.3Y0.7Ni3.4-xMnxAl0.1 Hydrogen Storage Alloys[J]. Journal of Inorganic Materials, 2020, 35(5): 549-555.

| Alloy | Element/wt% | Stoichiometric B/A ratio | ||||

|---|---|---|---|---|---|---|

| La | Y | Ni | Mn | Al | ||

| x=0 | 6.73 | 15.33 | 75.75 | 0.00 | 2.19 | 3.53 |

| x=0.15 | 6.82 | 15.56 | 72.38 | 2.90 | 2.34 | 3.47 |

| x=0.2 | 6.86 | 15.47 | 71.57 | 3.86 | 2.24 | 3.48 |

| x=0.3 | 6.91 | 15.71 | 68.61 | 6.41 | 2.37 | 3.42 |

| x=0.5 | 6.94 | 15.77 | 65.02 | 10.11 | 2.17 | 3.40 |

表1 退火合金中各元素含量ICP分析结果

Table 1 Elements content of the annealed alloys by ICP analysis

| Alloy | Element/wt% | Stoichiometric B/A ratio | ||||

|---|---|---|---|---|---|---|

| La | Y | Ni | Mn | Al | ||

| x=0 | 6.73 | 15.33 | 75.75 | 0.00 | 2.19 | 3.53 |

| x=0.15 | 6.82 | 15.56 | 72.38 | 2.90 | 2.34 | 3.47 |

| x=0.2 | 6.86 | 15.47 | 71.57 | 3.86 | 2.24 | 3.48 |

| x=0.3 | 6.91 | 15.71 | 68.61 | 6.41 | 2.37 | 3.42 |

| x=0.5 | 6.94 | 15.77 | 65.02 | 10.11 | 2.17 | 3.40 |

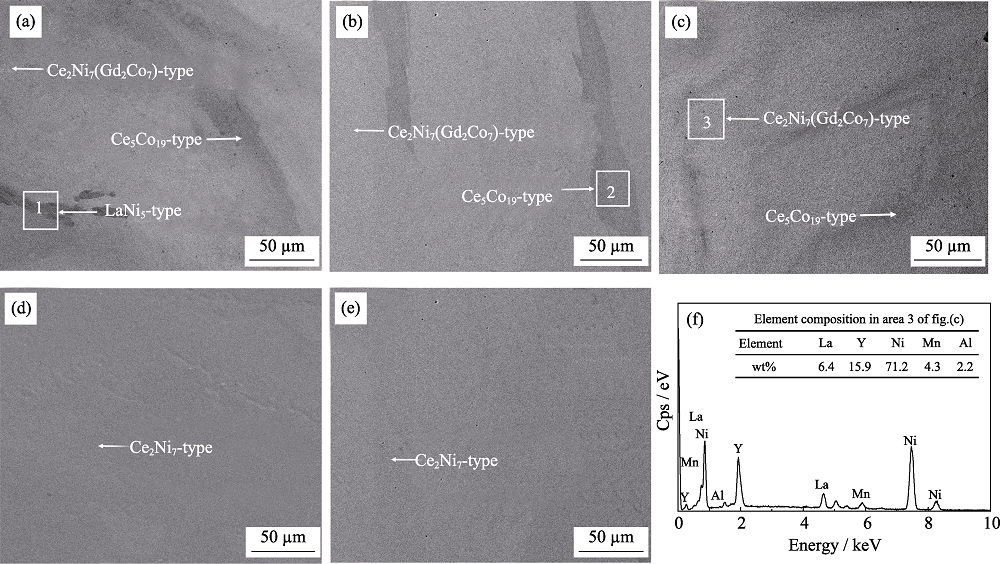

图1 退火合金微观组织SEM照片(a~e)及图(c)区域3中A2B7型相的EDS能谱分析(f)

Fig. 1 SEM images of the annealed alloys (a-e) and EDS pattern of A2B7-type phase in area 3 (a)x=0; (b)x=0.15; (c)x=0.2; (d)x=0.3; (e)x=0.5; (f) EDS pattern of A2B7-type phase in area 3 of fig.(c)

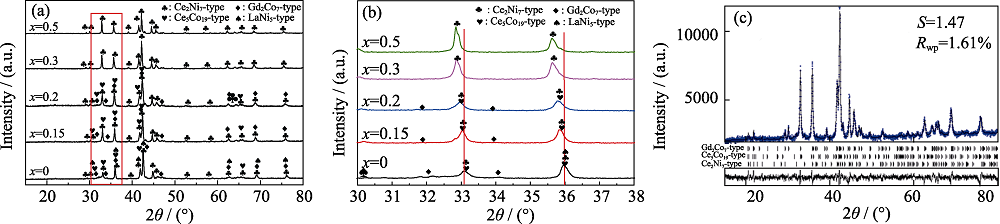

图2 退火合金的XRD图谱(a)、局部放大图(b)及x=0.15试样的Rietveld全谱拟合图(c)

Fig. 2 XRD patterns (a) and local enlarge XRD patterns (b) of the annealed alloys (a, b) and Rietveld refinement XRD profile of the sample x=0.15(c)

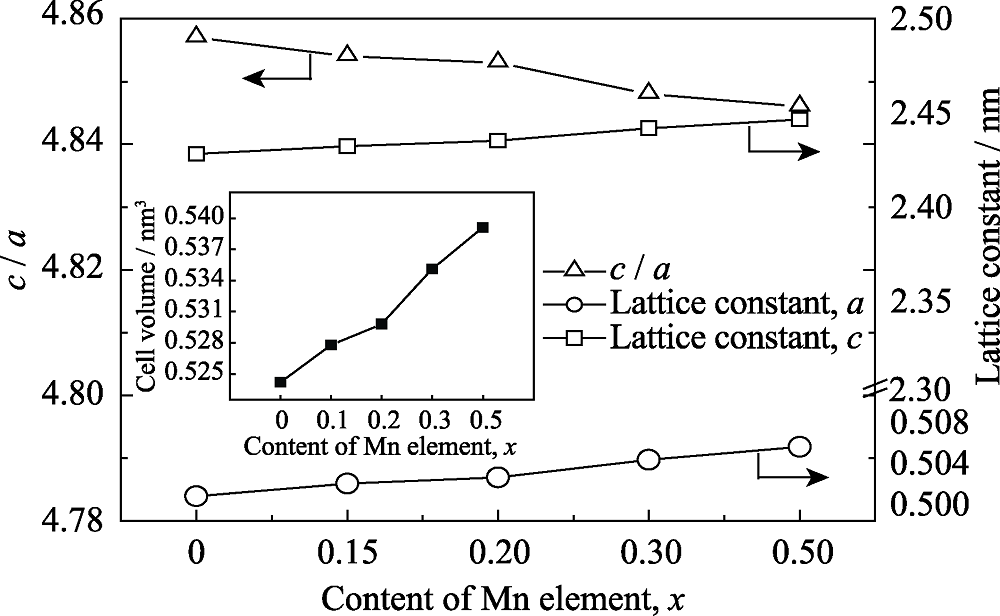

图4 退火合金中Ce2Ni7型主相的晶胞参数(a, c)、轴比c/a和(插图)晶胞体积V

Fig. 4 Lattice parameters (a, c), c/a ratio and (insert)cell volume, V of Ce2Ni7 type phase for the annealed alloys

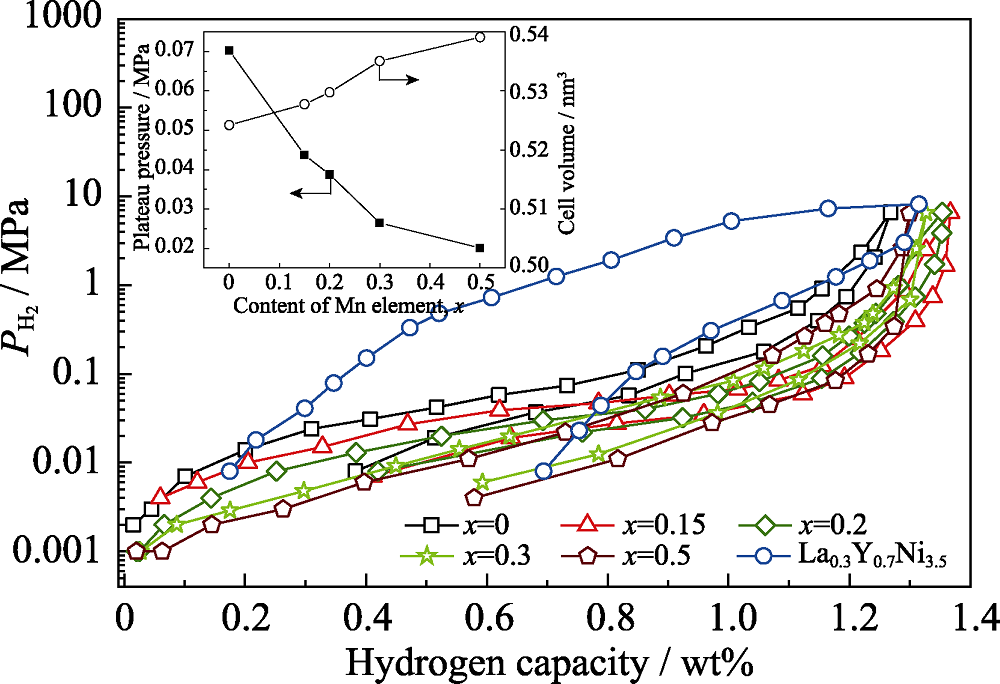

图5 退火合金的吸放氢PCT曲线(300 K)以及(插图)吸氢平台压, 晶胞体积与Mn含量的关系曲线

Fig. 5 PCT curves and (insert) the relationships between plateau pressure, cell volume and Mn content of the alloys at 300 K

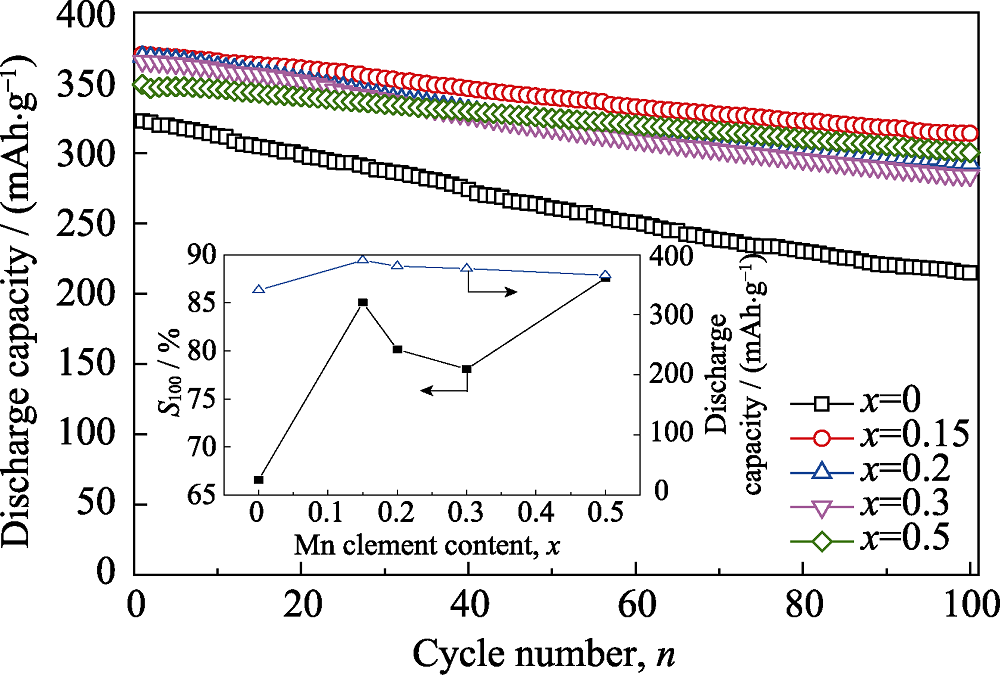

图8 合金电极的充放电循环曲线及(插图)S100、放电容量与Mn含量的关系曲线

Fig. 8 Electrochemical cycling curves and (insert) the relationshipsbetween S100, discharge capacity and Mn content of the alloy electrodes

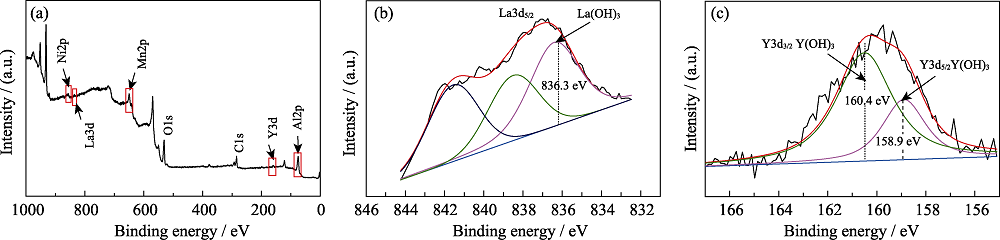

图11 经100次电化学循环后合金电极表面的XPS全谱(a)及其La3d(b)和Y3d(c)高分辨谱图

Fig. 11 Total XPS spectrum (a) and high resolution La3d(b) and Y3d(c) XPS spectra of the alloy electrodes after 100 electrochemical cycles

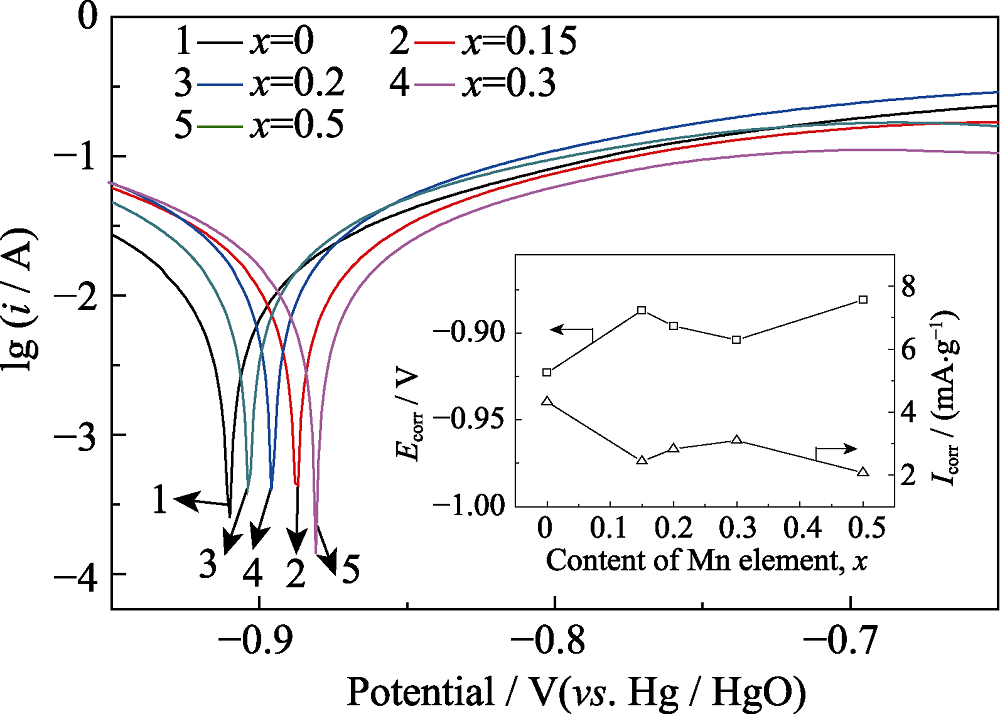

图12 合金电极的Tafel腐蚀极化曲线以及(插图)Ecorr、Icorr与Mn含量的关系曲线

Fig. 12 Tafel polarization curves and (insert) the relationshipsbetween Ecorr, Icorr and Mn content of the alloy electrodes

| [1] | YASUOKA S, MAGARI Y, MURTA T , et al. Development of high- capacity nickel-metal hydride batteries using superlattice hydrogen- absorbing alloys. Journal of Power Sources, 2006,156(2):662-666. |

| [2] | YING YAN-JUN, CHEN LI-FANG, ZENG XIAO-QING , et al. Theoretical and experimental investigations of the effect of Co addition on the structural and properties of AB3.5-type hydrogen storage alloys. Journal of Inorganic Materials, 2012,27(9):568-574. |

| [3] | LIU J, LI Y, HAN D , et al. Electrochemical performance and capacity degradation mechanism of single-phase La-Mg-Ni-based hydrogen storage alloys. Journal of Power Sources, 2015,300:77-86. |

| [4] | BADDOUR-HADJEAN R, MEYER L, PEREIRA-RAMOS J P , et al. An electrochemical study of new La1-xCexY2Ni9( 0≤x≤1) hydrogen storage alloys. Electrochimica Acta, 2001,46(15):2385-2393. |

| [5] | BEREZOVETS’ V V, DENYS R V, RYABOV O B , et al. Hydrides of substituted derivatives based on the YNi3 compound. Materials Science, 2007,43(4):499-507. |

| [6] | CHARBONNIER V, ZHANG J, MONNIER J , et al. Structural and hydrogen storage properties of Y2Ni7 deuterides studied by neutron powder diffraction. Journal of Physical Chemistry C, 2015,119(22):12218-12225. |

| [7] | CHARBONNIER V, ZHANG J, MONNIER J , et al. Relationship between H2, sorption properties and aqueous corrosion mechanisms in A2Ni7, hydride forming alloys (A=Y, Gd or Sm). Journal of Power Sources, 2016,326:146-155. |

| [8] | XIONG W, YAN H Z, WANG L , et al. Characteristics of A2B7-type La-Y-Ni-based hydrogen storage alloys modified by partially substituting Ni with Mn. International Journal of Hydrogen Energy, 2017,42(15):10131-10141. |

| [9] | ZHAO LEI, LUO YONG-CHUN, DENG AN-QIANG , et al. Hydrogen storage and electrochemical properties of the Mg-free A2B7-type La1-xYxNi3.25Mn0.15Al0.1 alloys with superlattice structure. Chemical Journal of Chinese Universities, 2018,39(9):1993-2002. |

| [10] | LIU J, HAN S, LI Y , et al. An investigation on phase transformation and electrochemical properties of as-cast and annealed La0.75Mg0.25Nix,( x=3.0, 3.3, 3.5, 3.8) alloys. Journal of Alloys & Compounds, 2013,552(3):119-126. |

| [11] | YOUN R A, The Rietveld Method. London: Oxford University Press, 1995: 1-75. |

| [12] | ZHENG G, POPOV B N, WHITE R E . Electrochemical determination of the diffusion coefficient of hydrogen through an LaNi4.25Al0.25 electrode in alkaline aqueous solution. Journal of The Electrochemical Society, 1995,142(8):2695-2698. |

| [13] | NOTTEN P H L, HOKKEL P . Double phase hydride forming compounds: a new class of highly electrocatalytic materials. Journal of The Electrochemical Society, 1991,138(7):1877-1885. |

| [14] |

ZHANG J, ZHOU G, CHEN G , et al. Relevance of hydrogen storage properties of ANi3 intermetallics (A=La, Ce, Y) to the ANi2 subunits in their crystal structures. Acta Materilia, 2008,56(19):5388-5394.

DOI URL PMID |

| [15] | GUZIK M N, HAUBACK B C, YVON K , et al. Hydrogen atom distribution and hydrogen induced site depopulation for the La2-xMgxNi7H system. Journal of Solid State Chemistry, 2012,186(2):9-16. |

| [16] | YAN H, XIONG W, WANG L , et al. Investigations on AB3, A2B7 and A5B19-type La-Y-Ni system hydrogen storage alloys. International Journal of Hydrogen Energy, 2017,42(4):2257-2264. |

| [17] | DENYS R V, RIABOV B, YARTYS V A , et al. Hydrogen storage properties and structure of La1-xMgx( Ni1-yMny)3 intermetallics and their hydrides. Journal of Alloys and Compounds, 2006,137:446-447. |

| [18] |

FANG F, CHEN Z L, WU D Y , et al. Subunit volume control mechanism for dehydrogenation performance of AB3-type superlattice intermetallics. Journal of Power Sources, 2019,427:145-153.

DOI URL |

| [19] | LIU J J, HAN S M, LI Y , et al. Effect of Pr on phase structure and cycling stability of La-Mg-Ni-based alloy with A2B7 and A5B19-type superlattice structures. Electrochimica Acta, 2015,184:257-263. |

| [20] |

WANG HAO, LUO YONG-CHUN, DENG AN-QIANG , et al. Annealing temperature on structural and electrochemical property of Mg-free La-Y-Ni based A2B7-type hydrogen storage alloys. Journal of Inorganic Material, 2018,33(4):434-440.

DOI URL |

| [21] | YANG C C, WANG C C, LI M M , et al. A start of the renaissance for nickel metal hydride batteries: a hydrogen storage alloy series with an ultra-long cycle life. Journal of Materials Chemistry A, 2017,5:1145-1152. |

| [1] | 刘芳芳, 传秀云, 杨扬, 李爱军. 氮/硫共掺杂对纤水镁石模板碳纳米管电化学性能的影响[J]. 无机材料学报, 2021, 36(7): 711-717. |

| [2] | 张亚萍,雷宇轩,丁文明,于濂清,朱帅霏. 双铁电复合材料的制备及其光电化学性能研究[J]. 无机材料学报, 2020, 35(9): 987-992. |

| [3] | 湛菁,徐昌藩,龙怡宇,李启厚. 聚丙烯酰胺凝胶法制备Bi2Mn4O10及其电化学性能[J]. 无机材料学报, 2020, 35(7): 827-833. |

| [4] | 朱泽阳,魏济时,黄健航,董向阳,张鹏,熊焕明. 晶格空位ZnO纳米棒的制备及其在镍锌电池中的应用[J]. 无机材料学报, 2020, 35(4): 423-430. |

| [5] | 李学林, 朱建锋, 焦宇鸿, 黄家璇, 赵倩楠. 二氧化锰形貌对Ti3C2Tx@MnO2复合材料电化学性能的影响[J]. 无机材料学报, 2020, 35(1): 119-125. |

| [6] | 张亚萍, 丁文明, 朱海丰, 黄承兴, 于濂清, 王永强, 李哲, 徐飞. 电还原MoSe2修饰TiO2纳米管光电化学性能研究[J]. 无机材料学报, 2019, 34(8): 797-802. |

| [7] | 孙晓璐,宋肖飞,刘艳华,吴越,蔡以兵,赵宏梅. 电纺FeMnO3纳米纤维毛毡的制备及电化学性能研究[J]. 无机材料学报, 2019, 34(7): 709-714. |

| [8] | 冯晓晶, 王恭凯, 王晓然, 何珺, 王新, 彭会芬. Cr 3+掺杂LiSn2(PO4)3负极材料的电化学性能研究[J]. 无机材料学报, 2019, 34(4): 358-364. |

| [9] | 王家虎, 王文馨, 杜鹏, 胡芳东, 姜晓蕾, 杨剑. Na3V2(PO4)2F3@V2O5-x复合材料的制备及储钠性能研究[J]. 无机材料学报, 2019, 34(10): 1097-1102. |

| [10] | 范广新, 刘泽萍, 闻寅, 刘宝忠. 硅烷偶联剂表面处理对LiNi0.8Co0.15Al0.05O2结构和性能的影响[J]. 无机材料学报, 2018, 33(7): 749-755. |

| [11] | 王浩, 罗永春, 邓安强, 赵磊, 姜婉婷. 退火温度对无镁La-Y-Ni系A2B7型合金相结构和电化学性能的影响[J]. 无机材料学报, 2018, 33(4): 434-440. |

| [12] | 罗凌虹, 胡佳幸, 程亮, 徐序, 吴也凡, 林囿辰. Ba0.5Sr0.5Co0.8Fe0.2O3-δ-Ce0.9Gd0.1O2-δ中低温固体氧化物燃料电池复相阴极的研究[J]. 无机材料学报, 2018, 33(4): 441-446. |

| [13] | 张国雄, 陈月梅, 何臻妮, 林川, 陈益钢, 郭海波. 表面活性剂对NiCo2S4纳米薄膜的电化学性能影响的研究[J]. 无机材料学报, 2018, 33(3): 289-294. |

| [14] | 刘灿军, 陈述, 李洁. CdS/TiO2纳米晶薄膜的原位法制备及光电化学性能研究[J]. 无机材料学报, 2018, 33(12): 1343-1348. |

| [15] | 王佳玮, 杨艳青, 高泽宇, 梁颖, 邓钏, 张卫珂. 水热法合成Bi2WO6/CNOs纳米材料及其电化学性能[J]. 无机材料学报, 2018, 33(11): 1208-1212. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||