无机材料学报 ›› 2020, Vol. 35 ›› Issue (5): 593-600.DOI: 10.15541/jim20190213

所属专题: 计算材料论文精选(2020)

收稿日期:2019-05-09

修回日期:2019-07-30

出版日期:2020-05-20

网络出版日期:2019-09-12

作者简介:张勇祯(1994-), 男, 博士研究生. E-mail: zhangyongzhennpu@163.com<br/>ZHANG Yongzhen(1994-), male, PhD candidate. E-mail: zhangyongzhennpu@163.com

基金资助:

ZHANG Yongzhen1,2,TONG Xiaoyan1,YAO Leijiang1( ),LI Bin1,BAI Guodong1,2

),LI Bin1,BAI Guodong1,2

Received:2019-05-09

Revised:2019-07-30

Published:2020-05-20

Online:2019-09-12

Supported by:摘要:

采用层次聚类及基于改进遗传算法的无监督模式识别方法, 对2D-C/SiC复合材料常温拉伸试验过程的声发射数据进行分析, 结合试样断口的扫描电镜(SEM)照片, 得到拉伸过程中5类损伤模式及其典型声发射特征参数。通过对各类损伤的能量分布、累计事件数和累计能量的分析, 研究C/SiC复合材料的损伤演化过程, 发现其过程可分为基体微裂纹和界面失效为主的初始损伤阶段、基体微裂纹停滞导致层间剥离及纤维失效占主导地位的裂纹饱和阶段、基体长裂纹和界面失效为主的损伤积累发展阶段和纤维束大量失效的宏观断裂阶段。

中图分类号:

张勇祯, 童小燕, 姚磊江, 李斌, 白国栋. 基于改进遗传算法的C/SiC拉伸损伤声发射模式识别[J]. 无机材料学报, 2020, 35(5): 593-600.

ZHANG Yongzhen, TONG Xiaoyan, YAO Leijiang, LI Bin, BAI Guodong. Acoustic Emission Pattern Recognition on Tensile Damage Process of C/SiC Composites Using an Improved Genetic Algorithm[J]. Journal of Inorganic Materials, 2020, 35(5): 593-600.

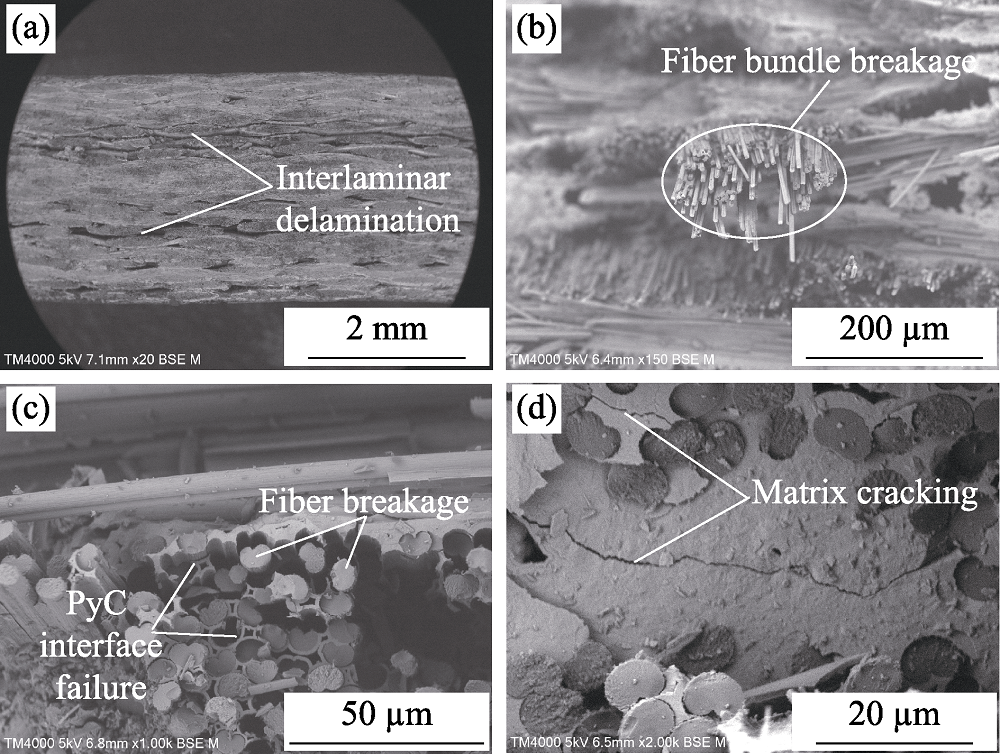

图7 试样的断口SEM照片

Fig. 7 Fracture SEM images of specimen (a) Interlaminar delamination; (b) Fiber bundle breakage; (c) Fiber breakage & PyC interface failure; (d) Matrix cracking

| Cluster | Count | Energy/ (mV·ms) | Amplitude/ mV | Average frequency/ kHz | Damage mode |

|---|---|---|---|---|---|

| 1 | 182 | 28 | 63 | 112 | Matrix cracking |

| 2 | 596 | 90 | 71 | 136 | Interface failure |

| 3 | 303 | 42 | 66 | 189 | Fiber breakage |

| 4 | 1463 | 237 | 77 | 167 | Interlaminar delamination |

| 5 | 10703 | 1628 | 82 | 188 | Fiber bundle breakage |

表1 聚类中心声发射参数值

Table 1 Numerical values of the clustering centers

| Cluster | Count | Energy/ (mV·ms) | Amplitude/ mV | Average frequency/ kHz | Damage mode |

|---|---|---|---|---|---|

| 1 | 182 | 28 | 63 | 112 | Matrix cracking |

| 2 | 596 | 90 | 71 | 136 | Interface failure |

| 3 | 303 | 42 | 66 | 189 | Fiber breakage |

| 4 | 1463 | 237 | 77 | 167 | Interlaminar delamination |

| 5 | 10703 | 1628 | 82 | 188 | Fiber bundle breakage |

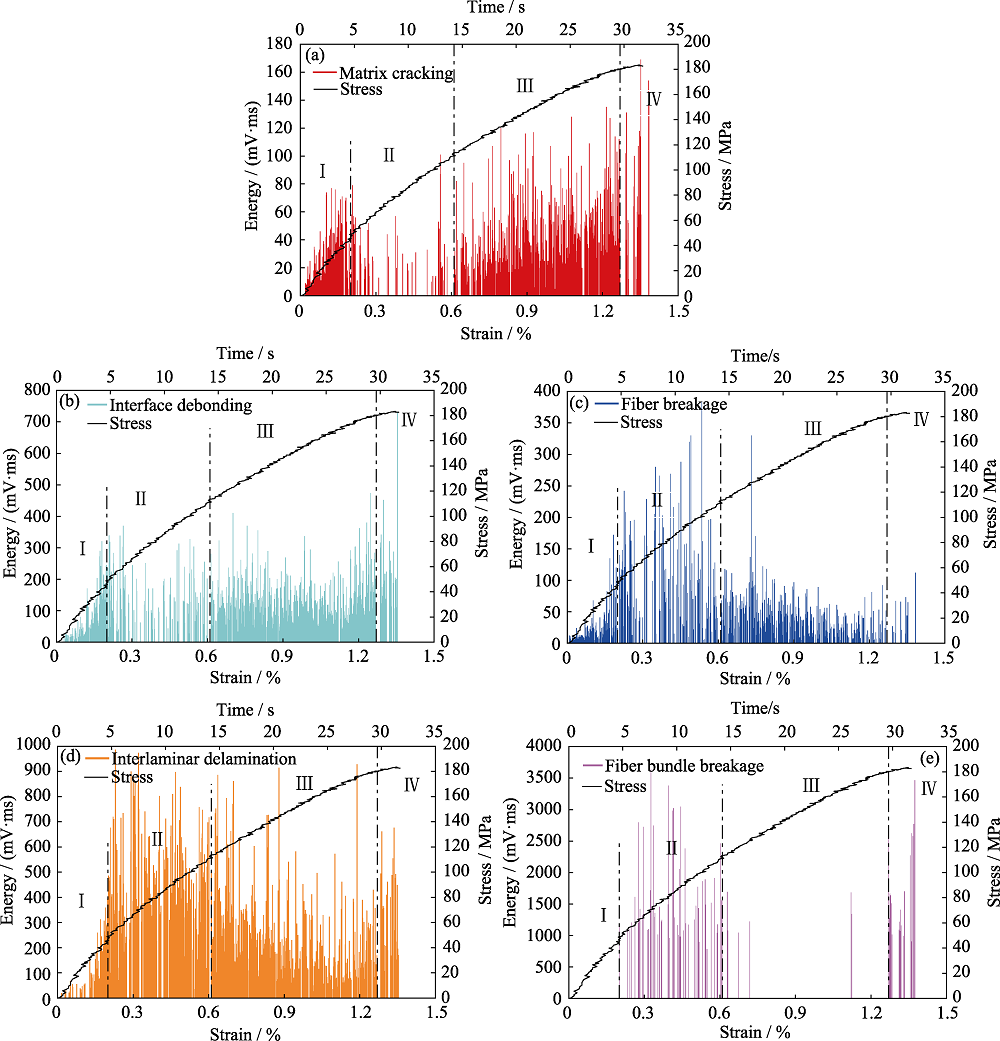

图10 拉伸过程中各类损伤的能量分布

Fig. 10 Energy distributions of different damage modes during the tensile test (a) Matrix cracking; (b) Interface debonding; (c) Fiber breakage;(d) Interlaminar delamination; (e) Fiber bundle breakage

| [1] | NASLAIN R . Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004,64(2):155-170. |

| [2] | CHRISTIN F . Design, fabrication, and application of thermostructural composites (TSC) like C/C, C/SiC, and SiC/SiC composites. Advanced Engineering Materials, 2002,4(12):903-912. |

| [3] | ZHANG LITONG, CHENG LAIFEI . Discussion on strategies of sustainable development of continuous fiber ceramic matrix composites. Acta Materiae Compositae Sinica, 2007,24(2):1-6. |

| [4] |

MORSCHER G N, MAILLET E . Nondestructive evaluation - use of acoustic emission for CMCs. Comprehensive Composite Materials II, 2018,5:308-324.

DOI URL PMID |

| [5] | ZARIF KARIMI N, MINAK G, KIANFAR P . Analysis of damage mechanisms in drilling of composite materials by acoustic emission. Composite Structures, 2015,131:107-114. |

| [6] | MAILLET E, BAKER C, MORSCHER G N , et al. Feasibility and limitations of damage identification in composite materials using acoustic emission. Composites Part A: Applied Science and Manufacturing, 2015,75:77-83. |

| [7] | MORIZET N, GODIN N, TANG J , et al. Classification of acoustic emission signals using wavelets and random forests: application to localized corrosion. Mechanical Systems & Signal Processing, 2016, 70- 71:1026-1037. |

| [8] |

MEI HUI, SUN YUYAO, ZHANG LIDONG , et al. Acoustic emission characterization of fracture toughness for fiber reinforced ceramic matrix composites. Materials Science and Engineering: A (Structural Materials: Properties, Microstructure and Processing), 2013,560:372-376.

DOI URL |

| [9] | MOMON S, GODIN N, REYNAUD P , et al. Unsupervised and supervised classification of AE data collected during fatigue test on CMC at high temperature. Composites Part A: Applied Science and Manufacturing, 2012,43(2):1-260. |

| [10] | TONG XIAOYAN, ZHANG JIALI, YAO LEIJIANG , et al. Cluster analysis of acoustic emission signals of 2D-C/SiC under tensile loading. Chinese Journal of Solid Mechanics, 2014,35(2):109-114. |

| [11] |

HUANG XIPENG, WANG BO, YANG CHENGPENG , et al. Evaluating damage evolution of three-dimension needled C/SiC composite based on acoustic emission signal analysis. Journal of Inorganic Materials, 2018,33(6):609-616.

DOI URL |

| [12] | HUANG XIPENG, WANG BO, YANG CHENGPENG , et al. Damage evolution of C/SiC composite materials with different densities based on acoustic emission signal analysis. Acta Materiae Compositae Sinica, 2019,36(2):425-433. |

| [13] | HARTIGAN J A, WONG M A . Algorithm AS 136: A k-means clustering algorithm. Journal of the Royal Statistical Society. Series C (Applied Statistics), 1979,28(1):100-108. |

| [14] | HOLLAND J H . Genetic algorithms and the optimal allocation of trials. Siam Journal on Computing, 1973,2(2):88-105. |

| [15] | TANG WENYAN . Research and Application of Genetic Algorithm in Structural Optimization. Dalian: Doctoral Thesis of Dalian University of Technology, 2002. |

| [16] | REN ZIWU, SAN YE . Improved adaptive genetic algorithm and its application research in parameter identification. Journal of System Simulation, 2006,18(1):41-43. |

| [17] |

MOEVUS M, GODIN N, R’MILI M , et al. Analysis of damage mechanisms and associated acoustic emission in two SiCf/[Si-B-C] composites exhibiting different tensile behaviours. Part II: Unsupervised acoustic emission data clustering. Composites Science and Technology, 2008,68(6):1258-1265.

DOI URL |

| [18] | ANASTASSOPOULOS A A, PHILIPPIDIS T P . Clustering methodology for the evaluation of acoustic emission from composites. Journal of Acoustic Emission, 1995,13(1/2):11-22. |

| [19] | ANASTASSOPOULOS A A, PHILIPPIDIS T P, PAIPETIS S A . Failure mechanism identification in composite materials by means of acoustic emission: Is it possible. Nondestructive testing, 1996: 143-149. |

| [20] |

DAVIES D L, BOULDIN D W . A cluster separation measure. IEEE Transactions on Pattern Analysis and Machine Intelligence. 1979,1(2):224-227.

URL PMID |

| [21] |

MILLIGAN G W, COOPER M C . An examination of procedures for determining the number of clusters in a data set. Psychometrika, 1985,50(2):159-179.

DOI URL PMID |

| [22] | CALINSKI T, HARABASZ J . A dendrite method for cluster analysis. Communications in Statistics, 1974,3(1):1-27. |

| [23] |

LI L, LOMOV S V, XIONG Y , et al. Cluster analysis of acoustic emission signals for 2D and 3D woven glass/epoxy composites. Composite Structures, 2014,116(1):286-299.

DOI URL |

| [24] |

ECH-CHOUDANY Y, ASSARAR M, SCIDA D , et al. Unsupervised clustering for building a learning database of acoustic emission signals to identify damage mechanisms in unidirectional laminates. Applied Acoustics, 2017,123:123-132.

DOI URL |

| [25] | YANG CHENGPENG, JIAO GUIQIONG, WANG BO . Uniaxial tensile stress-strain behavior and strength of plain woven C/SiC composite. Chinese Journal of Theoretical and Applied Mechanics, 2011,43(2):330-337. |

| [26] | GUAN GUOYANG, JIAO GUIQIONG, ZHANG ZENGGUANG . Uniaxial macro-mechanical property and failure mode of a 2D-woven C/SiC composite. Acta Materiae Compositae Sinica, 2005,22(4):81-85. |

| [27] |

CHANG YANJUN, JIAO GUIQIONG, TAO YONGQIANG , et al. Damage behavior of 2.5D-C/SiC composites under tensile loading. Journal of Inorganic Materials, 2008,23(3):509-514.

DOI URL |

| [28] | MEI HUI, CHENG LAIFEI, ZHANG LITONG , et al. Damage evolution and microstructural characterization of a cross-woven C/SiC composite under tensile loading. Journal of the Chinese Ceramic Society, 2007,35(2):137-143. |

| [29] |

WANG M, LAIRD C . Characterization of microstructure and tensile behavior of a cross-woven C/SiC composite. Acta Materialia, 1996,44(4):1371-1387.

DOI URL |

| [30] | FANG PENG, CHENG LAIFEI, ZHANG LITONG , et al. Acoustic emission characteristics of C/SiC composite during tensile test. Nondestructive Testing, 2006,28(7):358-361. |

| [31] | QIAO SHENGRU, DU SHUANGMING, JI GANGCHANG , et al. Damage mechanism of 3D-C/SiC composite. Journal of Mechanical Strength, 2004,26(3):307-312. |

| [32] |

NIE J, XU Y, ZHANG L , et al. Microstructure and tensile behavior of multiply needled C/SiC composite fabricated by chemical vapor infiltration. Journal of Materials Processing Technology, 2009,209(1):572-576.

DOI URL |

| [33] | WANG YIQIANG, ZHANG LITONG, CHENG LAIFEI . Effects of heat treatment on the tensile behavior and damage evolution of a 3D C/SiC composite. International Journal of Modern Physics B, 2010,24(15/16):2591-2596. |

| [34] | LI L B, SONG Y D, SUN Y C . Modeling the tensile behavior of cross-ply C/SiC ceramic-matrix composites. Mechanics of Composite Materials, 2015,51(3):359-376. |

| [1] | 靳赛, 刘小根, 齐爽, 赵润昌, 李志军. 激光诱导损伤对熔石英玻璃弯曲强度弱化影响及安全设计[J]. 无机材料学报, 2023, 38(6): 671-677. |

| [2] | 王华进, 寇华敏, 王墉哲, 姜大朋, 张博, 钱小波, 王静雅, 朱琳玲, 曾爱军, 杨秋红, 苏良碧. 193 nm激光下不同含量Y杂质CaF2晶体辐照损伤研究[J]. 无机材料学报, 2023, 38(2): 219-224. |

| [3] | 欧阳琴, 王艳菲, 徐剑, 李寅生, 裴学良, 莫高明, 李勉, 李朋, 周小兵, 葛芳芳, 张崇宏, 何流, 杨磊, 黄政仁, 柴之芳, 詹文龙, 黄庆. 核用碳化硅纤维增强碳化硅复合材料研究进展[J]. 无机材料学报, 2022, 37(8): 821-840. |

| [4] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [5] | 李海燕, 郝鸿渐, 田远, 汪长安, 包亦望, 万德田. 残余应力对涂覆Al2O3涂层的ZrO2陶瓷的强度和裂纹扩展阻力的影响[J]. 无机材料学报, 2022, 37(4): 467-472. |

| [6] | 王洪达, 冯倩, 游潇, 周海军, 胡建宝, 阚艳梅, 陈小武, 董绍明. SiC/SiC-哈氏合金异质连接机制及其氟熔盐腐蚀特性分析[J]. 无机材料学报, 2022, 37(4): 452-458. |

| [7] | 张亚晨, 孟佳, 蔡坤, 盛晓晨, 乐军, 宋力昕. 基于声发射技术的Si-Cr-Ti高温抗氧化涂层弯曲失效机理研究[J]. 无机材料学报, 2021, 36(11): 1185-1192. |

| [8] | 李陇彬, 薛玉冬, 胡建宝, 杨金山, 张翔宇, 董绍明. 碳化硅纳米线增韧碳化硅纤维/碳化硅基体损伤行为研究[J]. 无机材料学报, 2021, 36(10): 1111-1117. |

| [9] | 马登浩, 侯振华, 李军平, 孙新, 金恩泽, 尹健. 界面相对3D-SiC/SiC复合材料静态力学性能及内耗特征的影响[J]. 无机材料学报, 2021, 36(1): 55-60. |

| [10] | 张冰玉,王岭,王晓猛,邱海鹏. 不同先驱体制备C/SiC复合材料及其浸渍行为[J]. 无机材料学报, 2020, 35(9): 1017-1022. |

| [11] | 王西,王克杰,柏辉,宋卓林,王波,张程煜. 化学气相渗透2D-SiCf/SiC复合材料的蠕变性能及损伤机理[J]. 无机材料学报, 2020, 35(7): 817-821. |

| [12] | 包亦望,孙熠,旷峰华,李月明,万德田. 高强度预应力陶瓷的发展与探索[J]. 无机材料学报, 2020, 35(4): 399-406. |

| [13] | 皮慧龙, 张宝鹏, 于新民, 刘伟, 金鑫. 二维C/SiC-ZrC复合材料的低速冲击损伤研究[J]. 无机材料学报, 2020, 35(12): 1327-1332. |

| [14] | 李旭勤, 谭志勇, 成来飞, 周灵柯, 高健. 先驱体浸渍裂解C/SiCN复合材料的拉伸行为与基体开裂机制[J]. 无机材料学报, 2020, 35(11): 1227-1233. |

| [15] | 黄喜鹏, 王波, 杨成鹏, 潘文革, 刘小瀛. 基于声发射信号的三维针刺C/SiC复合材料拉伸损伤演化研究[J]. 无机材料学报, 2018, 33(6): 609-616. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||