无机材料学报 ›› 2019, Vol. 34 ›› Issue (7): 768-774.DOI: 10.15541/jim20180450

谢玲玲1,2,3,牛亚然2( ),王亮2,陈文亮1,郑学斌2(

),王亮2,陈文亮1,郑学斌2( ),黄贞益3

),黄贞益3

收稿日期:2018-09-21

修回日期:2018-11-28

出版日期:2019-07-20

网络出版日期:2019-06-26

作者简介:谢玲玲(1978-), 女, 博士研究生. E-mail:xll@ahut.edu.cn

基金资助:

XIE Ling-Ling1,2,3,NIU Ya-Ran2( ),WANG Liang2,CHEN Wen-Liang1,ZHENG Xue-Bin2(

),WANG Liang2,CHEN Wen-Liang1,ZHENG Xue-Bin2( ),HUANG Zhen-Yi3

),HUANG Zhen-Yi3

Received:2018-09-21

Revised:2018-11-28

Published:2019-07-20

Online:2019-06-26

Supported by:摘要:

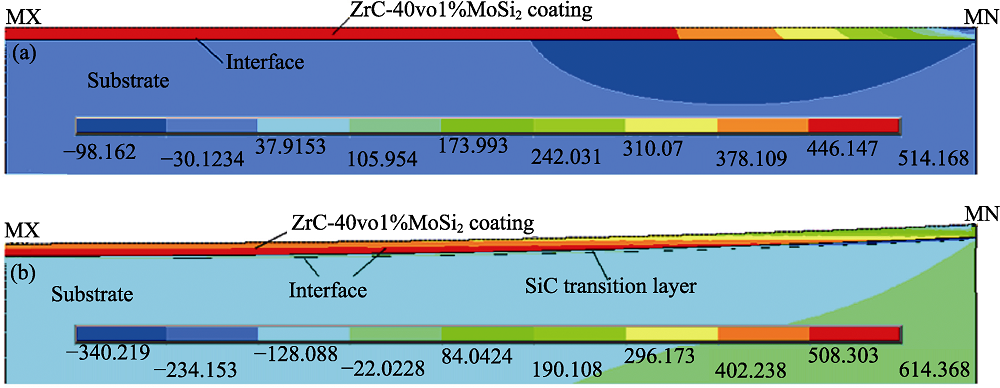

采用商用ANSYS14.5软件, 依据复合梁增层力学模型, 采用逐道逐层累积模型模拟了C/C复合材料表面等离子喷涂ZrC基涂层沉积残余应力的特征, 分析了SiC过渡层、第二相(SiC, MoSi2)和涂层厚度对ZrC基涂层残余应力的影响, 并进行了实验验证。结果表明, SiC过渡层有效缓解了涂层与基体的热失配应力。涂层体系的应力随着涂层厚度的增加逐渐减小, 符合应力松弛和叠加规律。在涂层内部的径向应力以拉应力为主, 基体中主要为压应力, 且在界面边缘存在压应力集中的极限区域, 易使涂层产生裂纹并沿界面扩展。该模拟采用逐道逐层累积的方法更逼近实际喷涂过程, 能更准确预测涂层的残余应力。

中图分类号:

谢玲玲, 牛亚然, 王亮, 陈文亮, 郑学斌, 黄贞益. 等离子喷涂ZrC基涂层逐道逐层沉积残余应力模拟与实验验证[J]. 无机材料学报, 2019, 34(7): 768-774.

XIE Ling-Ling, NIU Ya-Ran, WANG Liang, CHEN Wen-Liang, ZHENG Xue-Bin, HUANG Zhen-Yi. Residual Stresses of Plasma Sprayed ZrC-Based Coatings during Path-by-path and Layer-by-layer Deposition: Simulation and Experimental Verification[J]. Journal of Inorganic Materials, 2019, 34(7): 768-774.

| Material | T/ ℃ | Ε/GPa | ρ/(kg·m-3) | α/(×10-6, K-1) | ν | k/(W·m-1·K-1) | C/(J·kg-1·K-1) |

|---|---|---|---|---|---|---|---|

| C/C | 25 | 70 | 1800 | 1.00 | 0.340 | 8.00 | 800 |

| 200 | - | - | 3.58 | - | 8.13 | 934 | |

| 400 | - | - | 3.70 | - | 7.95 | 1115 | |

| 600 | - | - | 3.94 | - | 7.77 | 1239 | |

| 800 | - | - | 4.08 | - | 7.76 | 1344 | |

| 1000 | - | - | 4.20 | - | 8.21 | 1522 | |

| SiC | 2300 | 448 | 3050 | 4.50 | 0.142 | 16.70 | 670 |

| ZrC | 20 | 348 | 6730 | 6.70 | 0.180 | 20.50 | 366 |

| 3540 | 355 | 6730 | 6.70 | 0.191 | 20.50 | 366 | |

| MoSi2 | 2030 | 440 | 6240 | 8.10 | 0.115 | 45.00 | 540 |

表1 模型中基体与涂层材料的热物理性能参数[16,17]

Table 1 Thermo-physical performance parameters of the substrate and coating[16,17]

| Material | T/ ℃ | Ε/GPa | ρ/(kg·m-3) | α/(×10-6, K-1) | ν | k/(W·m-1·K-1) | C/(J·kg-1·K-1) |

|---|---|---|---|---|---|---|---|

| C/C | 25 | 70 | 1800 | 1.00 | 0.340 | 8.00 | 800 |

| 200 | - | - | 3.58 | - | 8.13 | 934 | |

| 400 | - | - | 3.70 | - | 7.95 | 1115 | |

| 600 | - | - | 3.94 | - | 7.77 | 1239 | |

| 800 | - | - | 4.08 | - | 7.76 | 1344 | |

| 1000 | - | - | 4.20 | - | 8.21 | 1522 | |

| SiC | 2300 | 448 | 3050 | 4.50 | 0.142 | 16.70 | 670 |

| ZrC | 20 | 348 | 6730 | 6.70 | 0.180 | 20.50 | 366 |

| 3540 | 355 | 6730 | 6.70 | 0.191 | 20.50 | 366 | |

| MoSi2 | 2030 | 440 | 6240 | 8.10 | 0.115 | 45.00 | 540 |

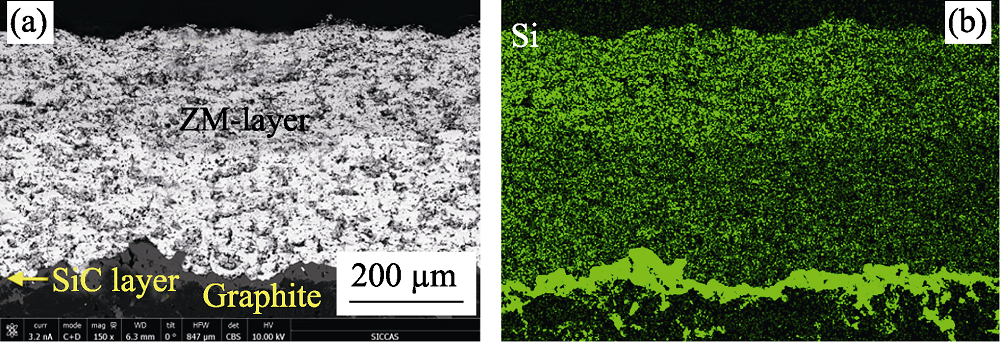

图13 C/C复合材料涂层的截面SEM照片(a)和涂层中Si的EDS面分析结果(b)

Fig. 13 Cross-section morphologies of coating on the C/C composites (a) and EDS mapping of Si distribution in the coating (b)

图14 径向应力在ZM4涂层表面的分布

Fig. 14 Radial residual stress distribution in the ZM4 coating surface (a) Without SiC transition layer; (b) With SiC transition layer

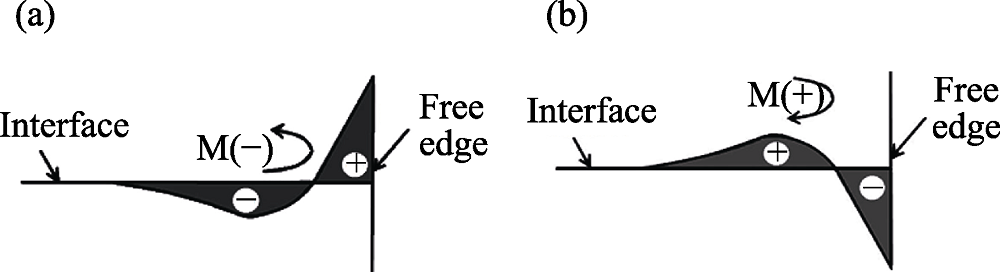

图15 涂层结构界面剥离应力示意图

Fig. 15 Schematic of interfacial peeling stress distributions of the coating (a) The maximum tensile stress at the edge; (b) The maximum compressive stress at the edge

| [1] | LI HE-JUN, XUE HUI, FU QIAN-GANG , et al. Research status and prospect of anti-oxidation coatings for carbon/carbon composites. Journal of Inorganic Materials, 2010,25(4):338-343. |

| [2] |

WANG YA-LEI, XIONG XIANG, LI GUO-DONG , et al. Preparation and ablation properties of Hf(Ta)C co-deposition coating for carbon/carbon composites. Corrosion Science, 2013,66:177-182.

DOI URL |

| [3] | FU QIAN-GANG, LI HE-JUN, WANG YONG-JIE , et al. Multilayer oxidation protective coating for C/C composites from room temperature 1500 ℃. Surface & Coating Technology, 2010,204:1831-1835. |

| [4] |

ZENG YI, XIONG XIANG, GUO SHUN , et al. SiC/SiC- YAG-YSZ oxidation protective coatings for carbon/carbon composites. Corrosion Science, 2013,70:68-73.

DOI URL |

| [5] | WANG SHAO-LEI, LI HONG, REN MU-SU , et al. Fabrication and ablation performances of ZrC-SiC-C/C composites. Acta Materiae Compositae Sinica, 2017,34(5):1040-1047. |

| [6] | NIU YA-RAN, ZHENG XU-EBIN, DING CHUAN-XIAN . Fabrication and characterization of plasma-sprayed oxidation-resistant coatings. Thermal Spray Technology, 2011,3(3):1-9. |

| [7] |

NIU YA-RAN, WANG HONG-YAN, LI HONG , et al. Dense ZrB2-MoSi2 composite coating fabricated by low pressure plasma spray (LPPS). Ceramics International, 2013,39(8):9773-9777.

DOI URL |

| [8] |

YAO DONG-JIA, LI HE-JUN, WU HENG , et al. Ablation resistance of ZrC/SiC gradient coating for SiC-coated carbon/carbon composites prepared by supersonic plasma spraying. Journal of the European Ceramic Society, 2016,36(15):3739-3746.

DOI URL |

| [9] |

JIA YU-JUN, LI HE-JUN, FU QIAN-GANG , et al. Ablation resistance of supersonic atmosphere plasma spraying ZrC coating doped with ZrO2 for SiC-coated carbon/carbon composites. Corrosion Science, 2017,123:40-54.

DOI URL |

| [10] | ARAUJO P, CHICOT D, STAIA M , et al. Residual stresses and adhesion of thermal spray coatings. Surface Engineering, 2013,21(1):35-40. |

| [11] |

KURODA S, DENDO T, KITAHARA S . Quenching stress in plasma sprayed coatings and its correlation with the deposit microstructure. Journal of Thermal Spray Technology, 1995,4(1):75-84.

DOI URL |

| [12] | WANG L, ZHONG X H, ZHAO Y X , et al. Design and optimization of coating structure for the thermal barrier coatings fabricated by atmospheric plasma spraying via finite element method. Journal of Asian Ceramic Societies, 2014(2):102-116. |

| [13] | LI YAN-PING, ZHAO WAN-HUA, LU BING-HENG . Prediction and control of residual stresses in thermal sprayed coatings. Engineering Mechanics, 2005,22(5):236-240. |

| [14] |

GHAFOURHI-AZAR R, MOSTAGHIMIJ, CHANDRA S . Modeling development of residual stresses in thermal spray coatings. Computational Materials Science, 2006,35(1):13-26.

DOI URL |

| [15] | YANG JIA-SHENG, YU JIAN-HUA, ZHONG XING-HUA , et al. Experimental and numerical investigation of residual stresses in plasma-sprayed thermal barrier coatings. Journal of Inorganic Materials, 2013,28(12):1381-1386. |

| [16] | BANSAL N P . Handbook of ceramic composites. Springer, 2006: 207. |

| [17] | YI FA-JUN, ZHANG WEI, MENG SONG-HE , et al. An experimental study on thermophysical properties of C/C composites at elevated temperature. Journal of Astronautics, 2002,23(5):85-88. |

| [18] | LI ZHAN-CHANG, JIA HONG-SHENG, MA HONG-AN , et al. FEM analysis on the effect of cobalt content on thermal residual stress in polycrystalline diamond compact (PDC). Science China: Physics, Mechanics&Astronomy, 2012(55):639-643. |

| [19] | LU PING, LIU ZUOMING . Mixed-mode of elastic modulus composites based on the α factor. Journal of Wuhan University of Technology, 2008,9(30):19-22. |

| [20] | ZHANG XIAN-CHENG, GONG JIAN-MING, TU SHAN-DONG , et al. The effect of coating size and material property on the residual stress in plasma spraying. Journal of Nanjing University of Technology, 2003,25(1):63-68. |

| [21] | 徐少辉 . 等离子喷涂工艺参数对ZrB2-SiC-ZrC涂层组织及结合强度的影响. 哈尔滨: 哈尔滨理工大学硕士学位论文, 2017,3:33. |

| [22] | NIU LI-PING, ZHANG TING-AN, SHI GUAN-YONG , et al. Residual stresses of plasma-spraying coating of thin-walled part. Journal of Northeastern University (Natural Science), 2011,32(10):1448-1451. |

| [23] | SINGH H, SIDHU B S, PURI D , et al. Use of plasma spray technology for deposition of high temperature oxidation/corrosion resistant coatings-a review. Mater. Corros., 2015,58(2):92-102. |

| [24] | SCHNEIBEL J H, RAWN C J, PAYZANT E A , et al. Controlling the thermal expansion anisotropy of Mo5Si3 and Ti5Si3 silicides. Intermetallics, 2014,12(7/8/9):845-850. |

| [25] | FEI XIAO-AI, NIU YA-RAN, JI HENG , et al. A comparative study of MoSi2 coatings manufactured by atmospheric and vacuum plasma spray processes. Ceramics International, 2011(37):813-817. |

| [26] | 张显程 . 面向再制造的等离子喷涂结构完整性及寿命预测基础研究. 上海: 上海交通大学博士学位论文, 2007,6:89-90. |

| [1] | 潘洋洋, 梁波, 洪督, 祁志祥, 牛亚然, 郑学斌. TiAl合金表面TiAlCrY/YSZ涂层高温长时间服役性能[J]. 无机材料学报, 2023, 38(1): 105-112. |

| [2] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [3] | 代钊,王铭,王双,李静,陈翔,汪大林,祝迎春. 氧化锆基微量元素共掺杂羟基磷灰石增韧涂层研究[J]. 无机材料学报, 2020, 35(2): 179-186. |

| [4] | 范佳锋,张小锋,周克崧,刘敏,邓畅光,邓春明,牛少鹏,邓子谦. 镀铝改性对PS-PVD 7YSZ热障涂层抗CMAS腐蚀影响机制[J]. 无机材料学报, 2019, 34(9): 938-946. |

| [5] | 周炎哲, 刘敏, 杨焜, 曾威, 宋进兵, 邓春明, 邓畅光. 大气等离子喷涂MoSi2-30Al2O3电热涂层的组织结构及性能[J]. 无机材料学报, 2019, 34(6): 646-652. |

| [6] | 陈书赢, 马国政, 何鹏飞, 刘喆, 刘明, 邢志国, 王海斗, 王海军. 基于粒子飞行特性及铺展行为的WC-10Co4Cr涂层孔隙形成机理研究[J]. 无机材料学报, 2018, 33(8): 895-902. |

| [7] | 张小锋, 周克崧, 刘敏, 邓春明, 牛少鹏, 许世鸣. 等离子喷涂-物理气相沉积Si/莫来石/Yb2SiO5环境障涂层[J]. 无机材料学报, 2018, 33(3): 325-330. |

| [8] | 孙旭轩, 陈宏飞, 杨光, 刘斌, 高彦峰. YSZ-Ti3AlC2热障涂层及其高温自愈合行为[J]. 无机材料学报, 2017, 32(12): 1269-1274. |

| [9] | 朱明康, 董显林, 陈 莹, 丁国际, 王根水. 残余应力对SrRuO3薄膜磁学及电输运性能的影响[J]. 无机材料学报, 2017, 32(1): 75-80. |

| [10] | 于方丽, 白 宇, 吴秀英, 王海军, 吴九汇. 等离子喷涂镍基可磨耗封严涂层抗腐蚀及耐磨性能分析[J]. 无机材料学报, 2016, 31(7): 687-693. |

| [11] | 包亦望, 刘正权. 钢化玻璃自爆机理与自爆准则及其影响因素[J]. 无机材料学报, 2016, 31(4): 401-406. |

| [12] | 毛金元, 刘 敏, 毛 杰, 邓春明, 曾德长, 徐 林. 等离子喷涂制备ZrB2-MoSi2复合涂层及其抗氧化性能[J]. 无机材料学报, 2015, 30(3): 282-286. |

| [13] | 张小锋, 周克崧, 宋进兵, 邓春明, 牛少鹏, 邓子谦. 等离子喷涂-物理气相沉积7YSZ热障涂层沉积机理及 其CMAS腐蚀失效机制[J]. 无机材料学报, 2015, 30(3): 287-293. |

| [14] | 陈 丹, 王 玉, 白 宇, 王运会, 赵 蕾, 付倩倩, 王海军, 韩志海. 等离子喷涂中雷诺数对熔滴扁平化行为的影响[J]. 无机材料学报, 2015, 30(1): 65-70. |

| [15] | 易德亮, 吴成铁, 马旭兵, 季 珩, 郑学斌, 常 江. 真空和大气等离子喷涂镁黄长石生物活性涂层的对比研究[J]. 无机材料学报, 2014, 29(2): 172-178. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||