无机材料学报 ›› 2019, Vol. 34 ›› Issue (6): 653-659.DOI: 10.15541/jim20180359

收稿日期:2018-08-02

修回日期:2018-10-10

出版日期:2019-06-20

网络出版日期:2019-05-23

作者简介:黄长兴(1994-), 男, 硕士研究生. E-mail:201621180072@mail.bnu.edu.cn

基金资助:

Chang-Xing HUANG,Jun CUI,Yuan-Sheng PEI( )

)

Received:2018-08-02

Revised:2018-10-10

Published:2019-06-20

Online:2019-05-23

Supported by:摘要:

为优化工艺参数、减少原料损失和控制生产成本, 本研究采用单因素法研究不同升温速率、保温时间、熔制温度和起始温度对硼酸盐缓释材料(BCRM)在制备过程中B2O3挥发量和气泡生成情况的影响规律。运用X射线衍射分析、红外光谱和X射线光电子能谱仪表征缓释前后BCRM理化性质变化, 通过Korsmeyer-Peppas模型分析BCRM缓释机理。结果表明, 在起始温度1050 ℃、保温时间2 h和熔制温度1050 ℃的最优工艺参数下, B2O3挥发量可降低至1.08%, BCRM澄清透明, 无气泡生成, 缓释性能良好。此外, 温度会影响BCRM的缓释机理, 在30和35 ℃时, 释放机理为Super Case II转运; 在40 ℃时, 释放机制为non-Fickian扩散。但在不同温度下, 硼累积释放率均高于95%。

中图分类号:

黄长兴, 崔骏, 裴元生. B2O3-SiO2-Na2O缓释材料的合成工艺参数优化及其缓释机理[J]. 无机材料学报, 2019, 34(6): 653-659.

Chang-Xing HUANG, Jun CUI, Yuan-Sheng PEI. B2O3-SiO2-Na2O Controlled-release Material: Synthetic Parameters Optimization and Release Mechanisms Exploration[J]. Journal of Inorganic Materials, 2019, 34(6): 653-659.

| Components | Na2B4O7·10H2O | H3BO3 | SiO2 |

|---|---|---|---|

| Weight/g | 33.02 | 32.16 | 14.82 |

表1 BCRM的合成配方

Table 1 Chemical components and their corresponding composition per 80 g BCRM

| Components | Na2B4O7·10H2O | H3BO3 | SiO2 |

|---|---|---|---|

| Weight/g | 33.02 | 32.16 | 14.82 |

| Release exponent, n | Release mechanism |

|---|---|

| Cylinder | |

| n ≤ 0.45 | Fickian diffusion |

| 0.45 < n < 0.89 | Non-Fickian diffusion |

| n = 0.89 | Case II transport |

| n > 0.89 | Super Case II transport |

表2 Korsmeyer-Peppas模型中圆柱形聚合物缓释系统中扩散指数n值[18]

Table 2 Values of diffusional exponent, n, for polymer matrices with cylinder in Korsmeyer-Peppas model[18]

| Release exponent, n | Release mechanism |

|---|---|

| Cylinder | |

| n ≤ 0.45 | Fickian diffusion |

| 0.45 < n < 0.89 | Non-Fickian diffusion |

| n = 0.89 | Case II transport |

| n > 0.89 | Super Case II transport |

| Conditions | Parameters | Boron concentration /(mg·L-1) | Recovery/% | Theoretical values of B2O3 /wt% | Test values of B2O3 /wt% | B2O3 volatilization/% |

|---|---|---|---|---|---|---|

| Heating rate/ (℃?min-1) | 4 | 91.728 | 95.02-102.32 | 60 | 59.08 | 1.53 |

| 6 | 90.657 | 58.39 | 2.68 | |||

| 8 | 89.278 | 57.50 | 4.17 | |||

| 10 | 87.638 | 56.44 | 5.93 | |||

| Holding time/h | 0.5 | 92.372 | 95.41-104.29 | 60 | 59.49 | 0.85 |

| 1 | 91.808 | 59.13 | 1.45 | |||

| 1.5 | 90.491 | 58.28 | 2.87 | |||

| 2 | 90.442 | 58.25 | 2.92 | |||

| Melting temperature/℃ | 1025 | 90.612 | 100.27-105.42 | 60 | 58.36 | 2.73 |

| 1050 | 90.144 | 58.06 | 3.23 | |||

| 1075 | 88.986 | 57.31 | 4.48 | |||

| Initial temperature/℃ | 300 | 90.404 | 100.63-106.42 | 60 | 58.22 | 2.97 |

| 800 | 91.300 | 58.80 | 2.00 | |||

| 1050 | 92.148 | 59.35 | 1.08 |

表3 各个工艺条件下各样品的测试及计算数据

Table 3 The test and calculation data of samples under various process parameters

| Conditions | Parameters | Boron concentration /(mg·L-1) | Recovery/% | Theoretical values of B2O3 /wt% | Test values of B2O3 /wt% | B2O3 volatilization/% |

|---|---|---|---|---|---|---|

| Heating rate/ (℃?min-1) | 4 | 91.728 | 95.02-102.32 | 60 | 59.08 | 1.53 |

| 6 | 90.657 | 58.39 | 2.68 | |||

| 8 | 89.278 | 57.50 | 4.17 | |||

| 10 | 87.638 | 56.44 | 5.93 | |||

| Holding time/h | 0.5 | 92.372 | 95.41-104.29 | 60 | 59.49 | 0.85 |

| 1 | 91.808 | 59.13 | 1.45 | |||

| 1.5 | 90.491 | 58.28 | 2.87 | |||

| 2 | 90.442 | 58.25 | 2.92 | |||

| Melting temperature/℃ | 1025 | 90.612 | 100.27-105.42 | 60 | 58.36 | 2.73 |

| 1050 | 90.144 | 58.06 | 3.23 | |||

| 1075 | 88.986 | 57.31 | 4.48 | |||

| Initial temperature/℃ | 300 | 90.404 | 100.63-106.42 | 60 | 58.22 | 2.97 |

| 800 | 91.300 | 58.80 | 2.00 | |||

| 1050 | 92.148 | 59.35 | 1.08 |

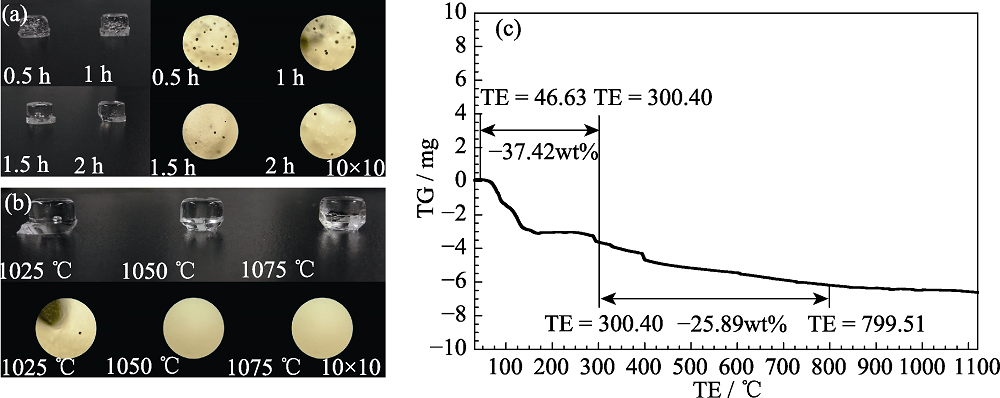

图1 (a)不同保温时间和(b)熔制温度下BCRM实物照片与气泡生成状况及(c)配合料的热重分析

Fig. 1 BCRM and bubble generation at (a) different holding time and (b) melting temperatures, and (c) thermogravimetric analysis of batch

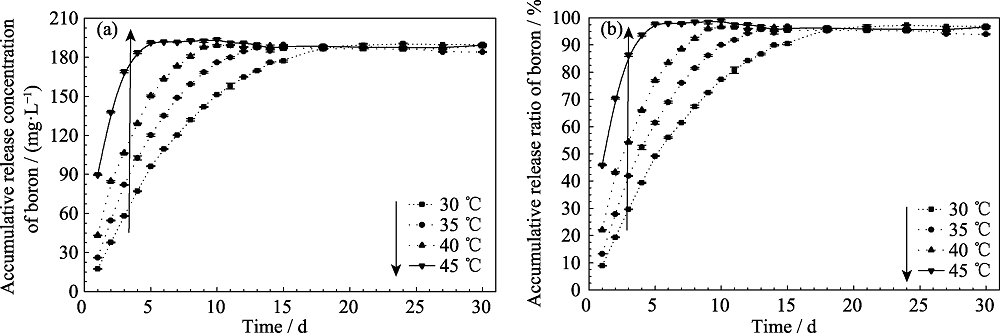

图2 不同温度下BCRM在去离子水中的(a)硼累积释放浓度和(b)硼累积释放率

Fig. 2 (a) Accumulative release concentration and (b) accumulative release rate of boron from the BCRM in deionized water under different temperatures

图3 缓释前后BCRM的(a) X射线衍射图、(b)红外光谱图和(c~d) XPS图

Fig. 3 (a) XRD patterns, (b) FT-IR spectra, and (c, d) XPS survey spectra of the BCRM before and after controlled-release

| Before controlled-release | After controlled-release | ||

|---|---|---|---|

| Wavenumber/cm-1 | Corresponding characteristic vibrations ascription | Wavenumber/cm-1 | Corresponding characteristic vibrations ascription |

| 463.46 | Si-O-Si bending vibrations | 466.53 | Si-O-Si bending vibrations |

| 694.02 | [BO3] bending vibrations | 798.51 | O-Si-O stretching vibrations |

| 1061.16 | Si-O-Si asymmetric stretching vibrations | 1083.89 | Si-O-Si asymmetric stretching vibrations |

| 1268.39 | [BO3] stretching vibrations | 1637.42 | H2O |

| 1392.97 | [BO3] antisymmetry stretching vibrations | 3448.34 | H-O stretching vibrations |

| 3448.20 | H-O stretching vibrations | ||

表4 缓释前后BCRM各基团的红外吸收光谱特征振动

Table 4 Characteristic vibrations reflected by infrared absorption spectrum of each group in the BCRM before and after controlled-release

| Before controlled-release | After controlled-release | ||

|---|---|---|---|

| Wavenumber/cm-1 | Corresponding characteristic vibrations ascription | Wavenumber/cm-1 | Corresponding characteristic vibrations ascription |

| 463.46 | Si-O-Si bending vibrations | 466.53 | Si-O-Si bending vibrations |

| 694.02 | [BO3] bending vibrations | 798.51 | O-Si-O stretching vibrations |

| 1061.16 | Si-O-Si asymmetric stretching vibrations | 1083.89 | Si-O-Si asymmetric stretching vibrations |

| 1268.39 | [BO3] stretching vibrations | 1637.42 | H2O |

| 1392.97 | [BO3] antisymmetry stretching vibrations | 3448.34 | H-O stretching vibrations |

| 3448.20 | H-O stretching vibrations | ||

| Temperature/℃ | Models | R2 |

|---|---|---|

| 30 | ${{M}_{t}}/{{M}_{\infty }}=10.06{{t}^{0.97}}$ | 0.9959 |

| 35 | ${{M}_{t}}/{{M}_{\infty }}=14.33{{t}^{0.95}}$ | 0.9935 |

| 40 | ${{M}_{t}}/{{M}_{\infty }}=23.75{{t}^{0.77}}$ | 0.9574 |

| 45 | - | - |

表5 不同温度下BCRM的释放动力学拟合结果

Table 5 Release kinetics model fitting of the BCRM at different temperatures

| Temperature/℃ | Models | R2 |

|---|---|---|

| 30 | ${{M}_{t}}/{{M}_{\infty }}=10.06{{t}^{0.97}}$ | 0.9959 |

| 35 | ${{M}_{t}}/{{M}_{\infty }}=14.33{{t}^{0.95}}$ | 0.9935 |

| 40 | ${{M}_{t}}/{{M}_{\infty }}=23.75{{t}^{0.77}}$ | 0.9574 |

| 45 | - | - |

| [1] |

BENGISU M . Borate glasses for scientific and industrial applications: a review. Journal of Materials Science, 2016,51(5):2199-2242.

DOI URL |

| [2] |

YIN HAI-RONG, YANG CHEN, GAO YANG , et al. Fabrication and characterization of strontium-doped borate-based bioactive glass scaffolds for bone tissue engineering. Journal of Alloys and Compounds, 2018,743:564-569.

DOI URL |

| [3] |

BALASUBRAMANIAN P BÜTTNER T, MIGUEZ PACHECO V, , et al. Boron-containing bioactive glasses in bone and soft tissue engineering. Journal of the European Ceramic Society, 2018,38(3):855-869.

DOI URL |

| [4] | LÓPEZ-NARANJO E J, ALZATE-GAVIRIA L M, HERNÁNDEZ- ZÁRATE G , et al. Termite resistance of wood-plastic composites treated with zinc borate and borax. Journal of Thermoplastic Composite Materials, 2014,29(2):281-293. |

| [5] | RAHIMNEJAD YAZDI A, TOWLER M . The effect of the addition of gallium on the structure of zinc borate glass with controlled gallium ion release. Materials & Design, 2016,92:1018-1027. |

| [6] |

ZHANG XING, JIA WEI-TAO, GU YI-FEI , et al. Borate bioglass based drug delivery of teicoplanin for treating osteomyelitis. Journal of Inorganic Materials, 2010,25(3):293-298.

DOI URL |

| [7] | CUI JUN, YUAN WEN-JIAO, YUAN DONG-HAI , et al. Effect of pH on the passivation of carbon steel by sodium borosilicate controlled-release inhibitor in simulated recirculating cooling water. Industrial & Engineering Chemistry Research, 2017,56(25):7239-7252. |

| [8] |

SHI RUI-RUI, LI MENG, PEI YUAN-SHENG . Synthesis and characterizations of B2O3-SiO2-Na2O controlled-release antibacterial agent. Journal of Inorganic Materials, 2017,32(5):529-534.

DOI URL |

| [9] | CUI JUN, YANG YAN-GE, LI XIU-QING , et al. Toward a slow-release borate inhibitor to control mild steel corrosion in simulated recirculating water. ACS Applied Materials & Interfaces, 2018,10(4):4183-4197. |

| [10] | LIU XIAO-QING, HE FENG, FANG YU , et al. Technical researches on volatilization reduction of B2O3 in borosilicate glasses. Journal of Wuhan University of Technology, 2013,35(5):13-17. |

| [11] | QIAN DA-XING, ZHOU NAI, SUN DAO-BING , et al. Factors on volatilization of B2O3 in glass melting. Journal of Building Materials, 1998(2):93-96. |

| [12] |

SNYDER M J, MESKO M G, SHELBY J E . Volatilization of boron from E-glass melts. Journal of Non-Crystalline Solids, 2006,352(6/7):669-673.

DOI URL |

| [13] |

PEDRO R D O, PEREIRA S, GOYCOOLEA F M , et al. Self-aggregated nanoparticles of N-dodecyl, N°-glycidyl(chitosan) as pH-responsive drug delivery systems for quercetin. Journal of Applied Polymer Science, 2018,135(2):45678.

DOI URL |

| [14] | RUIZ-CARO R, GAGO-GUILLAN M, OTERO-ESPINAR F J , et al. Mucoadhesive tablets for controlled release of acyclovir. Chemical & Pharmaceutical Bulletin, 2012,60(10):1249-1257. |

| [15] |

SINHA P, UBAIDULLA U, HASNAIN M S , et al. Alginate-okra gum blend beads of diclofenac sodium from aqueous template using ZnSO4 as a cross-linker. International Journal of Biological Macromolecules, 2015,79:555-563.

DOI URL |

| [16] | XU XIAO-YUN, JIA DE-HUA, LIU JUN , et al. Determination of boron in silica refractory raw materials by ICP-OES. Chemical Analysis and Meterage, 2015(4):29-31. |

| [17] |

KIM YOUNG-JAE, YANABA YUTAKA, MORITA KAZUKI . The effect of borate and silicate structure on thermal conductivity in the molten Na2O-B2O3-SiO2 system. Journal of Non-Crystalline Solids, 2015,415:1-8.

DOI URL |

| [18] |

SITTA D L A, GUILHERME M R, DA SILVA E P , et al. Drug release mechanisms of chemically cross-linked albumin microparticles: effect of the matrix erosion. Colloids and Surfaces B: Biointerfaces, 2014,122:404-413.

DOI URL |

| [19] | VARNER J R SEWARD III T P, SCHAEFFER H A, . Boron chemistry in flue gases from borosilicate glass furnaces. Advances in Fusion and Processing of Glass III, John Wiley & Sons,Inc, 2012, 387-395. |

| [20] | VARNER J R SEWARD III T P, SCHAEFFER H A, . Effect of water in the melting atmosphere on the transformation temperature of commercial glasses. Advances in Fusion and Processing of Glass III, John Wiley & Sons,Inc, 2012, 345-354. |

| [21] |

BOLORÉ D, PIGEONNEAU F . Spatial distribution of nucleated bubbles in molten glasses undergoing coalescence and growth. Journal of the American Ceramic Society, 2018,101(5):1892-1905.

DOI URL |

| [22] | KRAXNER J, KLEMENT R, LIŠKA M . High-temperature viscosity and density of alumino-borosilicate glasses as a model system for commercial E-glass. Ceramics Silikaty, 2008,52(3):148-154. |

| [23] |

GAO XIANG-LONG, ZHANG QIAN, YU JING-BO , et al. Effect of replacement of Al2O3 by Y2O3 on the structure and properties of alkali-free boro-aluminosilicate glass. Journal of Non-Crystalline Solids, 2018,481:98-102.

DOI URL |

| [24] |

FERREIRA E B, ZANOTTO E D, FELLER S , et al. Critical analysis of glass stability parameters and application to lithium borate glasses. Journal of the American Ceramic Society, 2011,94(11):3833-3841.

DOI URL |

| [25] |

MARCHAND B, LANIER S, DAVY C A , et al. Are calcium silicate hydrates (C-S-H) present in alkali-activated glass cullet cement? Materials Letters, 2018,219:104-108.

DOI URL |

| [26] |

NING JIA, YAO AI-HUA, WANG DE-PING , et al. Synthesis and in vitro bioactivity of a borate-based bioglass. Materials Letters, 2007,61(30):5223-5226.

DOI URL |

| [27] |

HUANG YUN-YUN, ZHANG YI-JUN, LIN SAI , et al. Sol-Gel synthesis of NiO nanoparticles doped sodium borosilicate glass with third-order nonlinear optical properties. Journal of Alloys and Compounds, 2016,686:564-570.

DOI URL |

| [28] | HAN JUAN, HE FENG, MEI SHU-XIA , et al. Effect of Na2O/B2O3 on structure and properties of borosilicate glass. Journal of Wuhan University of Technology, 2015,37(3):1-4. |

| [29] |

OTHMAN H A, ELTABEY M M, IBRAHIM S E , et al. Synthesis, electrical and magnetic properties of sodium borosilicate glasses containing Co-ferrites nanoparticles. Physica B: Condensed Matter, 2017,506:115-121.

DOI URL |

| [30] |

HASSAAN M Y, OSMAN H M, HASSAN H H , et al. Optical and electrical studies of borosilicate glass containing vanadium and cobalt ions for smart windows applications. Ceramics International, 2017,43(2):1795-1801.

DOI URL |

| [31] |

ROHNKE M, PFITZENREUTER S, MOGWITZ B , et al. Strontium release from Sr 2+-loaded bone cements and dispersion in healthy and osteoporotic rat bone . Journal of Controlled Release, 2017,262:159-169.

DOI URL |

| [32] |

BARBOSA J, CORREIA D M, GONÇALVES R , et al. Magnetically controlled drug release system through magnetomechanical actuation. Advanced Healthcare Materials, 2016,5(23):3027-3034.

DOI URL |

| [33] |

SONAWANE S J, KALHAPURE R S, RAMBHAROSE S , et al. Ultra-small lipid-dendrimer hybrid nanoparticles as a promising strategy for antibiotic delivery: in vitro and in silico studies. International Journal of Pharmaceutics, 2016,504(1/2):1-10.

DOI URL |

| [34] |

FAYYAZBAKHSH F, SOLATI-HASHJIN M, KESHTKAR A , et al. Release behavior and signaling effect of vitamin D3 in layered double hydroxides-hydroxyapatite/gelatin bone tissue engineering scaffold: an in vitro evaluation. Colloids and Surfaces B: Biointerfaces, 2017,158:697-708.

DOI URL |

| [35] |

JIN XIAO-QI, WANG QIAN, SUN JI-HONG , et al. Dual (pH- and temperature-) stimuli responsive nanocarrier with bimodal mesoporous silica nanoparticles core and copolymer shell for controlled ibuprofen-releasing: fractal feature and diffusion mechanism. Microporous and Mesoporous Materials, 2017,254:77-85.

DOI URL |

| [1] | 李海滨, 王德平, 吴莹莹, 姚爱华, 叶 松. 柠檬酸浓度对硼酸盐玻璃骨水泥性能的影响[J]. 无机材料学报, 2017, 32(8): 831-836. |

| [2] | 吴莹莹, 叶 松, 姚爱华, 李海滨, 贾伟涛, 黄文旵, 王德平. 气体发泡剂—NaHCO3和C6H8O7对可注射多孔硼酸盐玻璃基骨水泥性能的影响[J]. 无机材料学报, 2017, 32(7): 777-784. |

| [3] | 朱开平, 王德平, 范宏圆, 王 会, 姚爱华, 叶 松. 硼酸盐玻璃的原位转化及对浸泡液酸碱度的影响[J]. 无机材料学报, 2015, 30(10): 1069-1074. |

| [4] | 张 欣,贾伟涛,顾刈非,张长青,黄文旵,王德平,. 载替考拉宁治疗骨髓炎症的硼酸盐生物玻璃药物载体的研究[J]. 无机材料学报, 2010, 25(3): 293-298. |

| [5] | 余 静,赵 荻,黄文旵,周 萘,王德平,尹 卫,陈亚青. 用作关节腔滑膜切除的放射性镝锂硼玻璃微球的性能研究[J]. 无机材料学报, 2010, 25(1): 58-62. |

| [6] | 姚爱华,艾凡荣,刘 欣,王德平,黄文旵. 硼酸盐玻璃转化制备中空羟基磷灰石微球的研究[J]. 无机材料学报, 2010, 25(1): 53-57. |

| [7] | 潘尚可,陆 晟,丁栋舟,杨 帆,任国浩,王国富. 不同掺杂对Ba3Y(BO3)3晶体的生长和相变的影响[J]. 无机材料学报, 2009, 24(3): 567-570. |

| [8] | 张巍巍,谢平波,张慰萍,尹民,楼立人,夏上达. PDP荧光粉GdBO3:Eu格位选择激发下的光致发光及其相变研究[J]. 无机材料学报, 2001, 16(3): 470-474. |

| [9] | 乔玉林,徐滨士,马世宁,刘维民,薛群基. 含氮化合物修饰的超细无机硼酸盐润滑油添加剂的结构和性能[J]. 无机材料学报, 1998, 13(1): 122-126. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||