无机材料学报 ›› 2019, Vol. 34 ›› Issue (6): 611-617.DOI: 10.15541/jim20180398

李凯1,李霄1,李箭2,谢佳苗3

收稿日期:2018-09-03

修回日期:2018-11-12

出版日期:2019-06-20

网络出版日期:2019-05-23

作者简介:李 凯(1985-), 男, 讲师. E-mail: likai3611897@126.com

基金资助:Kai LI1,Xiao LI1,Jian LI2,Jia-Miao XIE3

Received:2018-09-03

Revised:2018-11-12

Published:2019-06-20

Online:2019-05-23

Supported by:摘要:

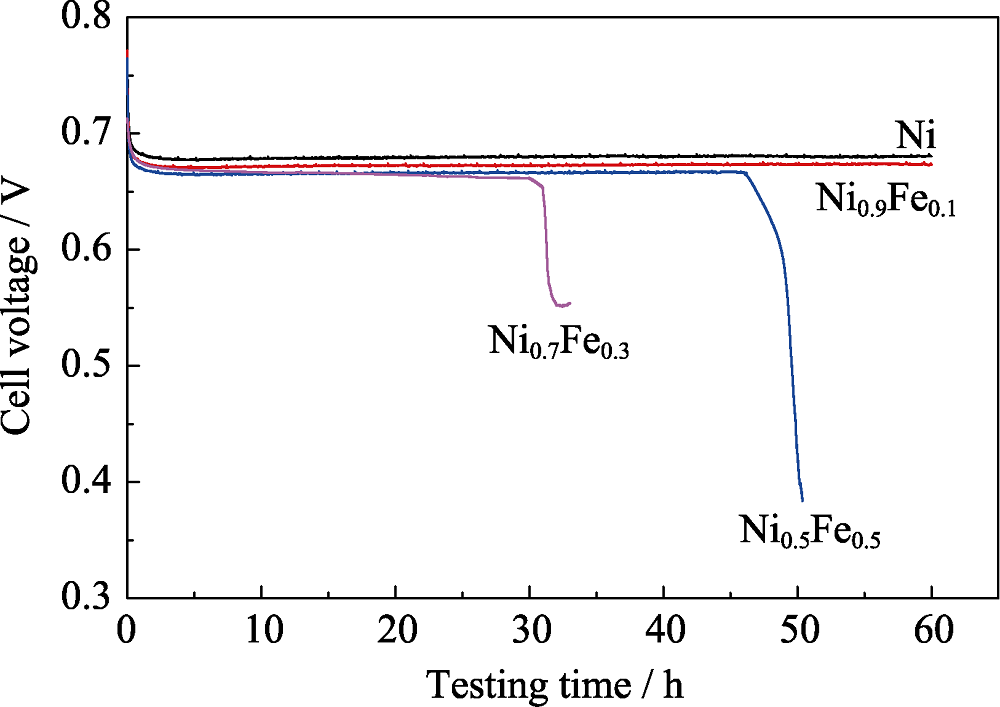

本文以NiO和Fe2O3为原料, 应用流延、丝网印刷、高温共烧结和原位还原的工艺制备多孔金属支撑固体氧化物燃料电池(MS-SOFC)。系统研究了支撑体中Fe含量对MS-SOFC的残余应力、抗弯断裂强度和电化学稳定性的影响。结果表明, 在NiO中加入10at% Fe2O3, 使得支撑体致密化开始温度提高到937 ℃, 残余应力和变形翘曲度分别低至70 MPa和0.15 mm; 电池还原之后, Ni0.9Fe0.1支撑SOFC骨架表面孔隙率为40.22%, 抗弯断裂强度达到最大值62.34 MPa; 电化学测试过程中, Ni0.9Fe0.1支撑SOFC在650 ℃下, 以H2为燃料, 在400 mA·cm -2电流密度下可以稳定运行60 h, 主要因为电池具有较高的抗弯断裂强度, 能够抵抗运行过程中的热应力。该研究工作为MS-SOFC结构设计和性能稳定性优化提供重要的理论依据。

中图分类号:

李凯, 李霄, 李箭, 谢佳苗. 基于应力分析Ni-Fe合金支撑固体氧化物燃料电池结构稳定性研究[J]. 无机材料学报, 2019, 34(6): 611-617.

Kai LI, Xiao LI, Jian LI, Jia-Miao XIE. Structural Stability of Ni-Fe Supported Solid Oxide Fuel Cells Based on Stress Analysis[J]. Journal of Inorganic Materials, 2019, 34(6): 611-617.

| Materials | Temperature/℃ | Elasticity modulus/GPa | Poisson ratio | CTE/ ×10-6 |

|---|---|---|---|---|

| N | 25 | 180 | 0.310 | 16.3 |

| 1350 | 176 | 0.310 | 15.9 | |

| NF91 | 25 | 150 | 0.268 | 14.8 |

| 1350 | 148 | 0.281 | 14.1 | |

| NF73 | 25 | 146 | 0.270 | 14.2 |

| 1350 | 143 | 0.280 | 13.6 | |

| NF55 | 25 | 140 | 0.280 | 14.1 |

| 1350 | 132 | 0.290 | 13.6 | |

| NiO+GDC | 25 | 190 | 0.292 | 14.2 |

| 1350 | 192 | 0.300 | 13.8 | |

| GDC | 25 | 260 | 0.262 | 13.6 |

| 1350 | 290 | 0.264 | 13.1 |

表1 MS-SOFC部件材料属性

Table 1 Material properties of MS-SOFC components

| Materials | Temperature/℃ | Elasticity modulus/GPa | Poisson ratio | CTE/ ×10-6 |

|---|---|---|---|---|

| N | 25 | 180 | 0.310 | 16.3 |

| 1350 | 176 | 0.310 | 15.9 | |

| NF91 | 25 | 150 | 0.268 | 14.8 |

| 1350 | 148 | 0.281 | 14.1 | |

| NF73 | 25 | 146 | 0.270 | 14.2 |

| 1350 | 143 | 0.280 | 13.6 | |

| NF55 | 25 | 140 | 0.280 | 14.1 |

| 1350 | 132 | 0.290 | 13.6 | |

| NiO+GDC | 25 | 190 | 0.292 | 14.2 |

| 1350 | 192 | 0.300 | 13.8 | |

| GDC | 25 | 260 | 0.262 | 13.6 |

| 1350 | 290 | 0.264 | 13.1 |

图9 Ni, Ni0.9Fe0.1, Ni0.7Fe0.3, Ni0.5Fe0.5支撑SOFC在650 ℃及400 mA·cm-2稳定性测试

Fig. 9 Stability tests of SOFC with Ni, Ni0.9Fe0.1, Ni0.7Fe0.3 and Ni0.5Fe0.5 supports at 650 ℃ and a constant current density of 400 mA·cm-2

| [1] |

TUCKER M C . Progress in metal-supported solid oxide fuel cells: a review. Journal of Power Sources, 2010,195(15):4570-4582.

DOI URL |

| [2] |

ZHOU Y C, YE X F, WANG S R . All symmetrical metal supported solid oxide fuel cells. Journal of Inorganic Materials, 2016,31(7):769-772.

DOI URL |

| [3] |

HUI S, YANG D, Wang Z , et al. Metal-supported solid oxide fuel cell operated at 400-600 ℃. Journal of Power Sources, 2007,167(2):336-339.

DOI URL |

| [4] |

ZHANG S L, YU H X, LI C X , et al. Thermally sprayed high performance porous metal-supported solid oxide fuel cells with nanostructured La0.6Sr0.4Co0.2Fe0.8O3 cathodes. Journal of Materials Chemistry A, 2016,4(19):7461-7468.

DOI URL |

| [5] | ZHOU Y C, SONG S D, HAN M F . Development of metal- supported SOFC. Engineering Sciences, 2013,15(2):28-32. |

| [6] |

MORI M, YAMAMOTO T, ITOH H . et al. Thermal expansion of nickel-zirconia anodes in solid oxide fuel cells during fabrication and operation. Journal of Electrochemical Society, 1998,145(4):1374-1381.

DOI URL |

| [7] |

WANG Y, JIANG W, LUO Y , et al. Evolution of thermal stress and failure probability during reduction and reoxidation of solid oxide fuel cell. Journal of Power Sources, 2017,371:65-76.

DOI URL |

| [8] |

XIE J M, WANG F H . Thermal stress analysis of solid oxide fuel cell with anode functional layer. Journal of Inorganic Materials, 2017,32(4):400-406.

DOI URL |

| [9] |

SAIED M, AHMED K, AHMED M . et al. Investigations of solid oxide fuel cells with functionally graded electrodes for high performance and safe thermal stress. International Journal of Hydrogen Energy, 2017,42(24):15887-15902.

DOI URL |

| [10] |

CELIK S, IBRAHIMOGLU B, MAT M , et al. Micro level two dimensional stress and thermal analysis anode/electrolyte interface of a solid oxide fuel cell. International Journal of Hydrogen Energy. 2015,40(24):7895-7902.

DOI URL |

| [11] |

CHARLAS B, FRANDSEN H L, BRODERSEN K , et al. Residual stresses and strength of multilayer tape cast solid oxide fuel and electrolysis half-cells. Journal of Power Sources, 2015,288:243-252.

DOI URL |

| [12] |

VILLANOVA J, SICARDY O, FORTUNIER R , et al. Determination of global and local residual stresses in SOFC by X-ray diffraction. Nuclear Instruments and Methods in Physics Research B, 2010,268(3/4):282-286.

DOI URL |

| [13] |

MALZBENDER J, STEINBRECH RW, SINGHEISER L . A review of advanced techniques for characterising SOFC behaviour. Fuel Cells, 2009,9(6):785-793.

DOI URL |

| [14] |

ZENG S M, PARBEY J, YU G S , et al. Thermal stress analysis of sulfur deactivated solid oxide fuel cells. Journal of Power Sources, 2018,379:134-143.

DOI URL |

| [15] |

WANG K P, HUANG Y Y, CHANDRA A , et al. Interfacial shear stress, peeling stress, and die cracking stress in trilayer electronic assemblies. IEEE Transactions on Components and Packaging Technologies, 2000,23(2):309-316.

DOI URL |

| [16] |

LIU L, KIM G Y, CHANDRA A . Modeling of thermal stresses and lifetime prediction of planar solid oxide fuel cell under thermal cycling conditions. Journal of Power Sources, 2010,195(8):2310-2318.

DOI URL |

| [17] |

CLAGUE R, MARQUIS A J, BRANDON N P . Finite element and analytical stress analysis of a solid oxide fuel cell. Journal of Power Sources, 2012,210:224-232.

DOI URL |

| [18] |

DAMM D L, FEDOROY A G . Reduced-order transient thermal modeling for SOFC heating and cooling. Journal of Power Sources, 2006,159(2):956-967.

DOI URL |

| [19] |

HAJIMOLANA S A, TONEKABONIMAOGHADAM S M, HUSSAIN M A , et al. Thermal stress management of a solid oxide fuel cell using neural network predictive control. Energy, 2013,62(30):320-329.

DOI URL |

| [20] |

CHIANG L K, LIU H C, SHIU Y H , et al. Thermo-electrochemical and thermal stress analysis for an anode-supported SOFC cell. Renew Energy, 2008,33(12):2580-2588.

DOI URL |

| [21] |

VAIDYA S, KIM J H . Finite element thermal stress analysis of solid oxide fuel cell cathode microstructures. Journal of Power Sources, 2013,225:269-276.

DOI URL |

| [22] |

ZENG S, XU M, PARBEY J , et al. Thermal stress analysis of a planar anode-supported solid oxide fuel cell: effects of anode porosity. Internal Journal of Hydrogen Energy, 2017,42:20239-20248.

DOI URL |

| [23] |

LI K, WANG X, JIA L C , et al. High performance Ni-Fe alloy support SOFCs fabricated by low cost tape casting-screen printing- cofiring process. International Journal of Hydrogen Energy, 2014,39(34):19747-19752.

DOI URL |

| [24] |

JU Y W, ETO H, INAGAKI T , et al. Preparation of Ni-Fe bimetallic porous anode support for solid oxide fuel cells using LaGaO3 based electrolyte film with high power density. Journal of Power Sources, 2010,195(19):6294-6300.

DOI URL |

| [25] | ZHU T L, DU X J, BU Y F , et al. Validation and electrochemical characterization of LSCF cathode deposition on metal supported SOFC. Journal of the Electrochemical Society, 2017,164(13):1489-1494. |

| [26] | KONG Y, HUA B, PU J , et al. A cost-effective process for fabrication of metal-supported solid oxide fuel cells. International Journal of Hydrogen Energy, 2010,35(10):4592-4596. |

| [27] |

WANG X, LI K, JIA L C , et al. Porous Ni-Fe alloys as anode support for intermediate temperature solid oxide fuel cells: I. Fabrication, redox and thermal behaviors. Journal of Power Sources, 2015,277:474-479.

DOI URL |

| [28] |

LI K, JIA L C, WANG X , et al. Methane on-cell reforming in nickel-iron alloy supported solid oxide fuel cells. Journal of Power Sources, 2015,284:446-451.

DOI URL |

| [29] | LI K, JIA L C, WANG X , et al. Enhanced methane steam reforming activity and electrochemical performance of Ni0.9Fe0.1- supported solid oxide fuel cells with infiltrated Ni-TiO2 particles. Scientific Reports, 2016, 6: 35981-1-9. |

| [30] |

MENG L, WANG F Z, WANG A , et al. High performance La0.8Sr0.2MnO3-coated Ba0.5Sr0.5Co0.8Fe0.2O3 cathode prepared by a novel solid-solution method for intermediate temperature solid oxide fuel cells. Chinese Journal of Catalysis, 2014,35(1):38-42.

DOI URL |

| [31] |

MOON H, KIM S, HYUN S , et al. Development of IT-SOFC unit cells with anode-supported thin electrolytes via tape casting and co-firing. International Journal of Hydrogen Energy, 2008,33(6):1758-1768.

DOI URL |

| [32] |

MOLLA TT BJØRK R, OLEVSKY E, , et al. Multi-scale modeling of shape distortions during sintering of bilayers. Computational Materials Science, 2014,88(20):28-36.

DOI URL |

| [1] | 王诗阳, 傅宇东, 陈磊, 王玉金. W-Y2O3复合材料和梯度材料的制备及力学性能[J]. 无机材料学报, 2018, 33(6): 596-602. |

| [2] | 谢佳苗, 王峰会. 基于热应力分析的固体氧化物燃料电池阳极功能层优化设计[J]. 无机材料学报, 2017, 32(4): 400-406. |

| [3] | 华佳捷, 张丽鹏, 刘紫微, 王墉哲, 林初城, 曾 毅, 郑学斌 . 热障涂层失效机理研究进展[J]. 无机材料学报, 2012, 27(7): 680-686. |

| [4] | 丁栋舟, 李焕英, 秦来顺, 陆 晟, 潘尚可, 任国浩. LuxY1-xAlO3:Ce晶体的缺陷研究[J]. 无机材料学报, 2010, 25(10): 1020-1024. |

| [5] | 陈 弦,杨 杰,蒲 健,李 箭. 平板式SOFC结构热应力的有限元分析[J]. 无机材料学报, 2007, 22(2): 339-343. |

| [6] | 易法军,孟松鹤,韩杰才,杜善义. 碳毡/碳复合材料超高温力学性能实验研究[J]. 无机材料学报, 2001, 16(6): 1229-1234. |

| [7] | 王永国,艾兴,李兆前,邓建新,赵军. 新型陶瓷刀具材料的热应力分析[J]. 无机材料学报, 2001, 16(5): 999-1003. |

| [8] | 储成林,尹钟大,朱景川,王世栋. HA-Ti生物功能梯度材料微观组织及热应力缓和特性[J]. 无机材料学报, 1999, 14(5): 775-782. |

| [9] | 王引真,孙永兴,鄢君辉,郑修麟,阎国超. 热障涂层热震失效寿命定量计算的研究[J]. 无机材料学报, 1999, 14(1): 138-142. |

| [10] | 常程康,丁传贤. 氧化锆基羟基磷灰石梯度涂层材料的研究[J]. 无机材料学报, 1998, 13(1): 71-77. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||