无机材料学报 ›› 2019, Vol. 34 ›› Issue (5): 493-501.DOI: 10.15541/jim20180218

余汉青1,2,董志军1,2( ),袁观明1,2,丛野1,2,李轩科3(

),袁观明1,2,丛野1,2,李轩科3( ),罗永明4

),罗永明4

收稿日期:2018-05-04

修回日期:2018-12-17

出版日期:2019-05-20

网络出版日期:2019-05-14

作者简介:余汉青(1991-), 男, 硕士研究生. E-mail:HQYusmile1207@163.com

基金资助:

Han-Qing YU1,2,Zhi-Jun DONG1,2( ),Guan-Ming YUAN1,2,Ye CONG1,2,Xuan-Ke LI3(

),Guan-Ming YUAN1,2,Ye CONG1,2,Xuan-Ke LI3( ),Yong-Ming LUO4

),Yong-Ming LUO4

Received:2018-05-04

Revised:2018-12-17

Published:2019-05-20

Online:2019-05-14

Supported by:摘要:

以聚碳硅烷、聚硼硅氮烷和二甲苯可溶沥青为原料通过低温共混得到了一种B-C掺杂SiC前驱体, 再经熔融纺丝、预氧化以及高温热处理制得B-C掺杂SiC纤维。采用红外光谱(IR)、X射线衍射(XRD)、扫描电镜(SEM)等手段对B-C掺杂SiC前驱体及其纤维的组成和微观结构进行了分析和表征, 主要研究了热处理温度对纤维组成、结构、力学性能和抗氧化性能的影响。结果表明: 硼的引入有效地抑制了高温热处理过程中SiC晶粒的长大, 提高了C掺杂SiC纤维的稳定性; B-C掺杂碳化硅纤维经1600 ℃处理后主要由β-SiC组成, 并含有少量的O、B和N。B-C掺杂SiC纤维抗氧化性能优于C掺杂SiC纤维, 这主要归因于掺杂纤维在高温氧化过程中形成的硼硅酸盐玻璃膜对其内部的沥青炭起到了很好的氧化防护作用。

中图分类号:

余汉青, 董志军, 袁观明, 丛野, 李轩科, 罗永明. B-C掺杂SiC纤维的制备及其性能研究[J]. 无机材料学报, 2019, 34(5): 493-501.

Han-Qing YU, Zhi-Jun DONG, Guan-Ming YUAN, Ye CONG, Xuan-Ke LI, Yong-Ming LUO. Boron-carbon doped Silicon Carbide Fibers: Preparation and Property[J]. Journal of Inorganic Materials, 2019, 34(5): 493-501.

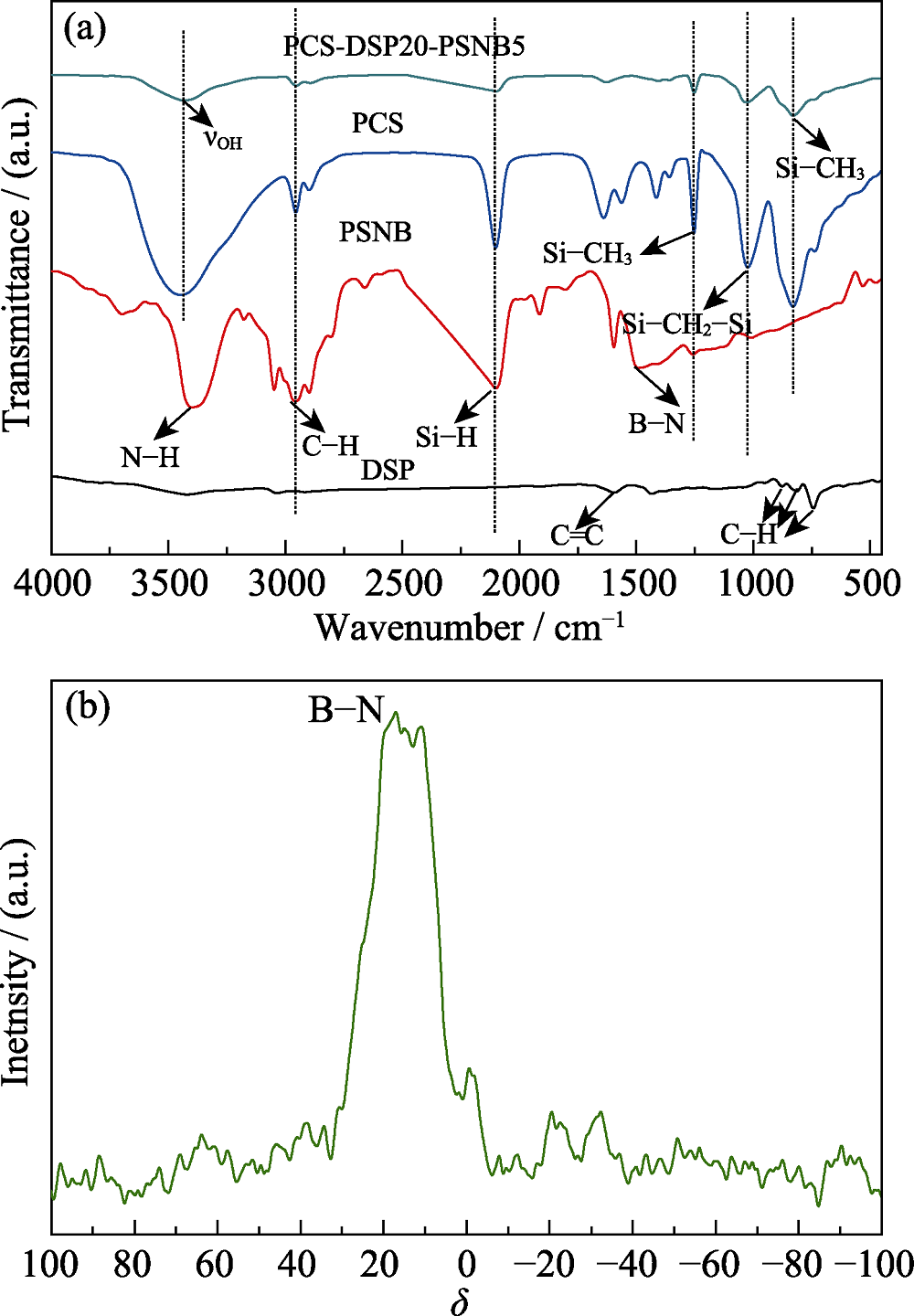

图1 原料及B-C掺杂SiC前驱体的FT-IR谱图(a)及B-C掺杂SiC前驱体的11B NMR谱图(b)

Fig. 1 FT-IR spectra of raw materials and B-C-doped SiC precursor (a) and 11B NMR spectra of B-C-doped SiC precursor (b)

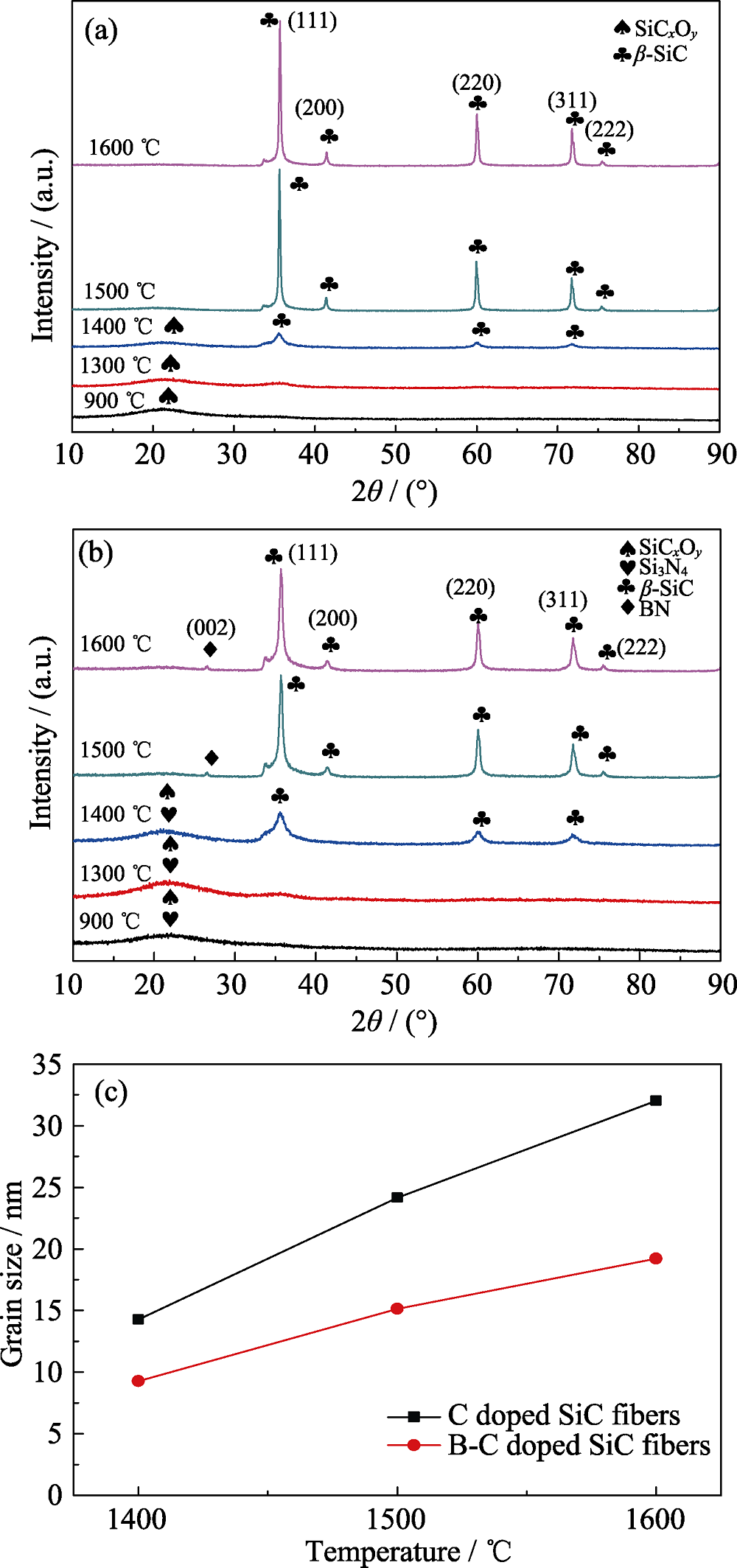

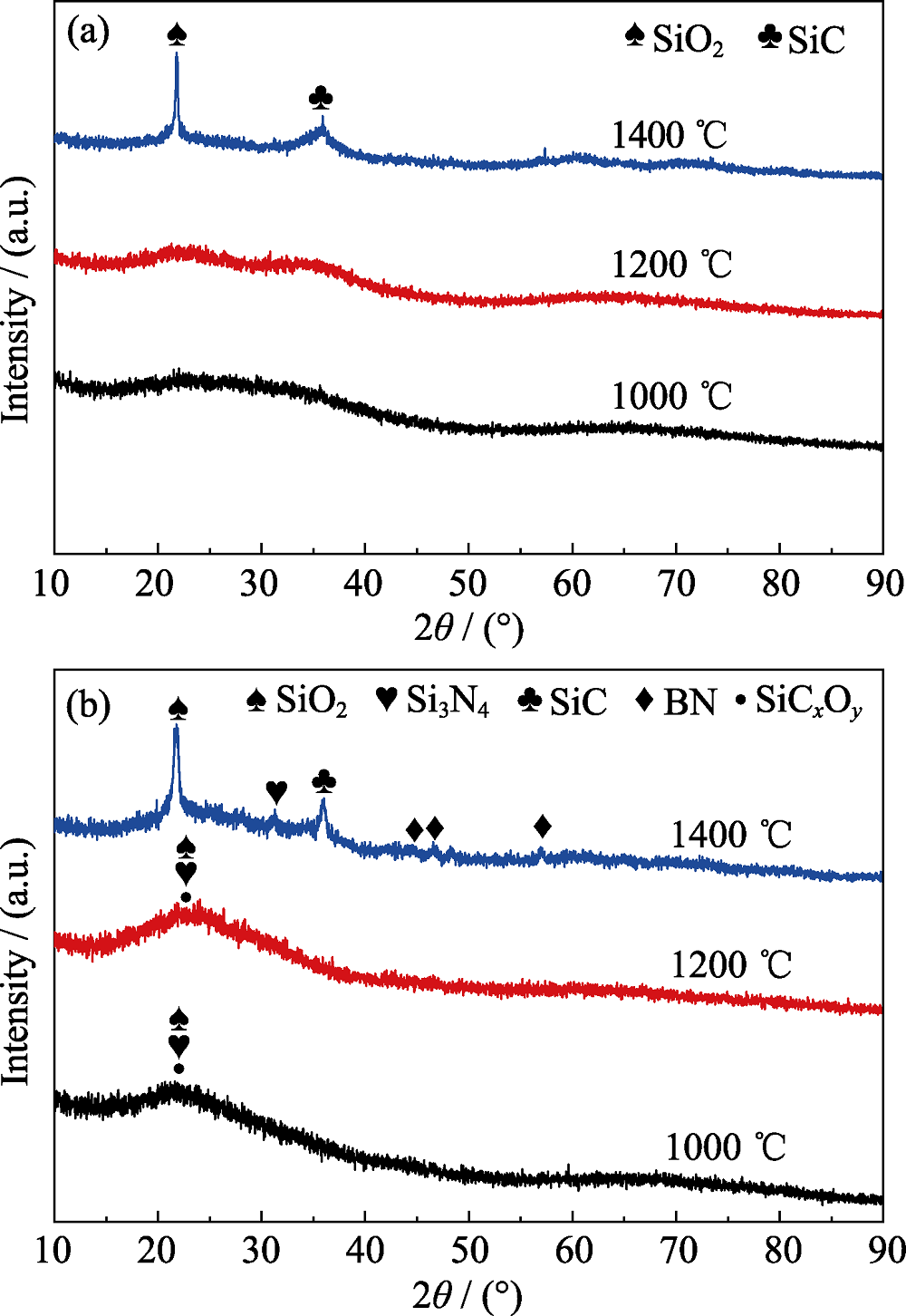

图2 不同温度热处理得到的C掺杂SiC纤维(a)、B-C掺杂SiC纤维(b)的XRD谱图及热处理温度对掺杂SiC纤维晶粒尺寸的影响(c)

Fig. 2 XRD patterns of C doped SiC fibers (a) and B-C doped SiC fibers (b), dependence of grain size on the heat-treatment temperature for the doped SiC fibers (c)

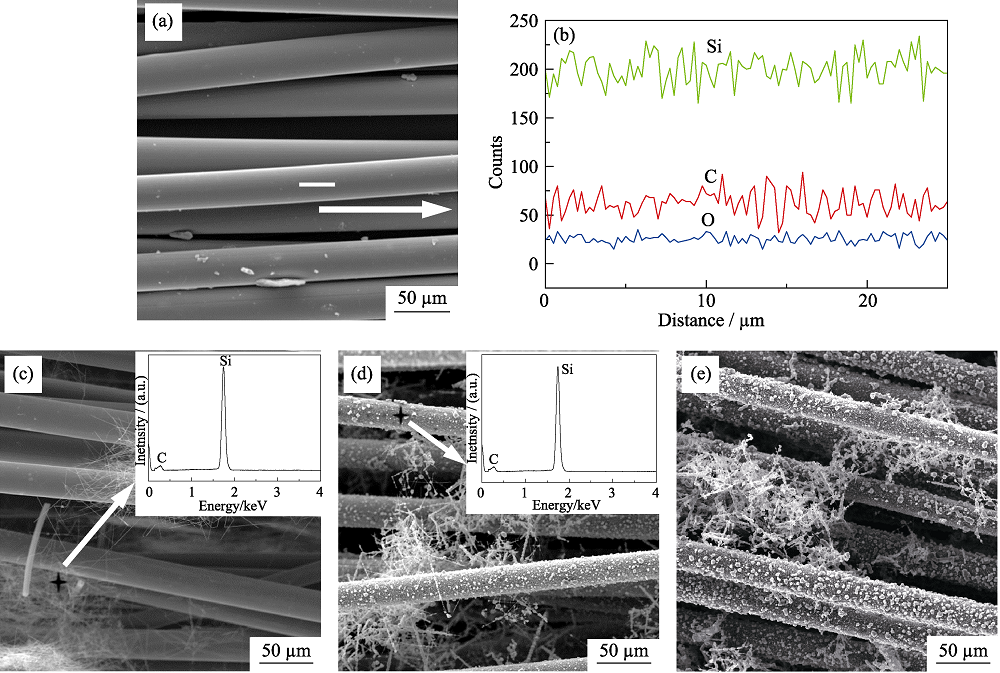

图3 不同温度热处理得到的C掺杂SiC纤维的SEM照片及EDS图谱 Figure (b) is line scanning for sample in (a), and insets in (c, d) are the corresponding EDS patterns

Fig. 3 SEM images and EDS patterns of C doped SiC fibers after heat treatment at (a, b) 1300,(c) 1400, (d) 1500, and (e) 1600 ℃

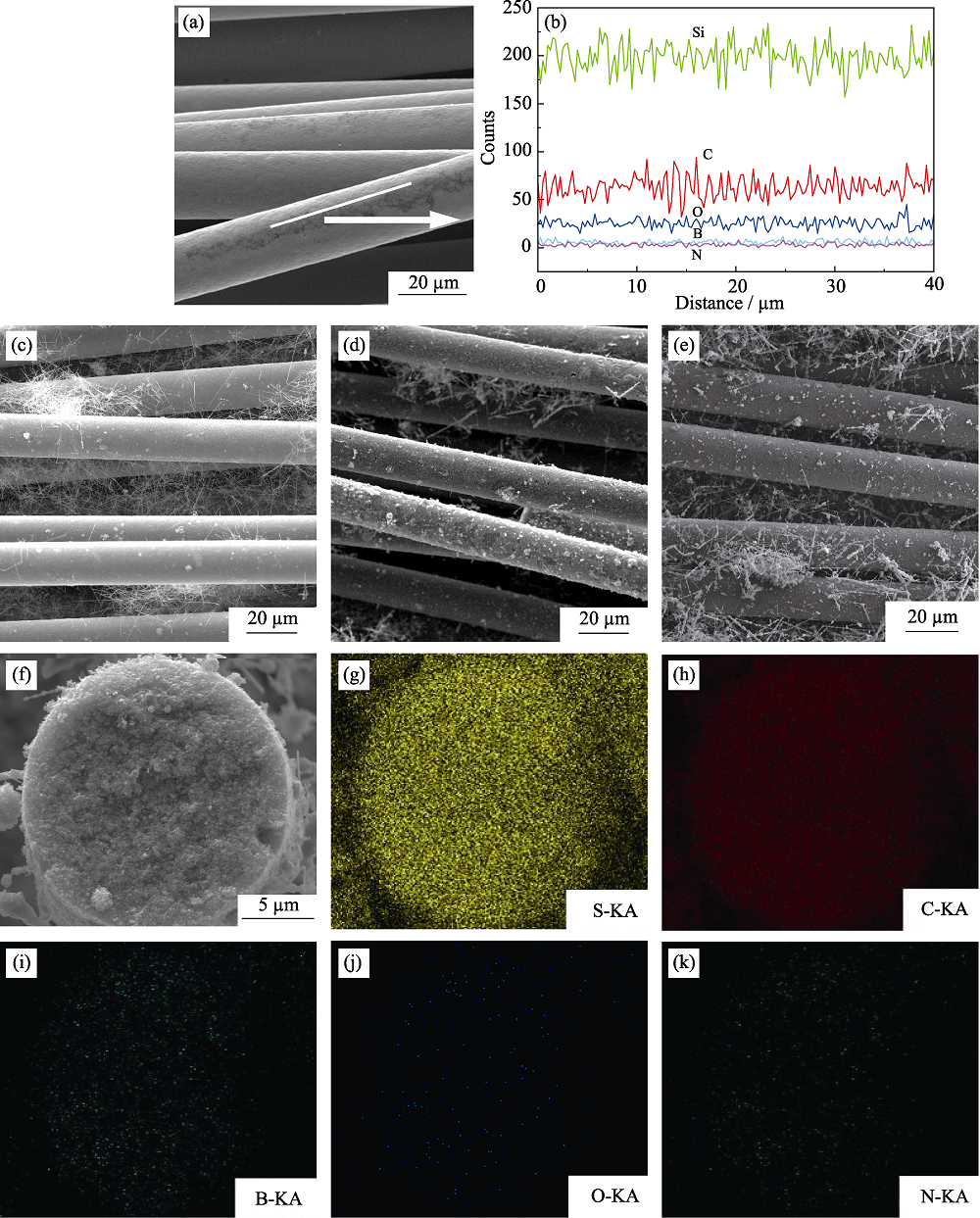

图4 不同温度热处理得到的B-C掺杂SiC纤维的SEM照片(a,c~f)、EDS图谱(b)及EDS面扫描元素分布图(g~k) (a, b) 1300 ℃; (c) 1400 ℃; (d) 1500 ℃; (e-k) 1600 ℃

Fig. 4 SEM image s(a, c-f), EDS patterns (b) and EDS mapping (g~k) of B-C doped SiC fibers after heat-treatment at different temperatures

| Composition/wt% | 900 ℃ | 1300 ℃ | 1400 ℃ | 1500 ℃ |

|---|---|---|---|---|

| Si | 42.68 | 51.82 | 54.98 | 64.54 |

| C | 36.46 | 31.76 | 30.87 | 25.75 |

| O | 20.68 | 16.42 | 14.15 | 9.71 |

表1 不同温度热处理得到的C掺杂SiC纤维的组成

Table 1 Chemical composition of C doped SiC fibers after heat-treatment at different temperatures

| Composition/wt% | 900 ℃ | 1300 ℃ | 1400 ℃ | 1500 ℃ |

|---|---|---|---|---|

| Si | 42.68 | 51.82 | 54.98 | 64.54 |

| C | 36.46 | 31.76 | 30.87 | 25.75 |

| O | 20.68 | 16.42 | 14.15 | 9.71 |

| Composition/wt% | 900 ℃ | 1300 ℃ | 1400 ℃ | 1500 ℃ |

|---|---|---|---|---|

| Si | 47.94 | 58.73 | 61.90 | 71.43 |

| C | 34.75 | 30.32 | 28.36 | 23.48 |

| O | 16.95 | 12.58 | 9.34 | 4.80 |

| B | 0.21 | 0.22 | 0.22 | 0.23 |

| N | 0.15 | 0.15 | 0.16 | 0.16 |

表2 不同温度热处理得到的B-C掺杂SiC纤维的组成

Table 2 Chemical composition of B-C doped SiC fibers after heat-treatment at different temperatures

| Composition/wt% | 900 ℃ | 1300 ℃ | 1400 ℃ | 1500 ℃ |

|---|---|---|---|---|

| Si | 47.94 | 58.73 | 61.90 | 71.43 |

| C | 34.75 | 30.32 | 28.36 | 23.48 |

| O | 16.95 | 12.58 | 9.34 | 4.80 |

| B | 0.21 | 0.22 | 0.22 | 0.23 |

| N | 0.15 | 0.15 | 0.16 | 0.16 |

图6 C掺杂(a)、B-C掺杂(b)SiC纤维在空气中1000、1200、1400 ℃等温氧化1 h后的XRD图谱

Fig. 6 XRD patterns of C doped (a) and B-C doped (b) SiC fibers after isothermal oxidation at 1000, 1200 and 1400 ℃ in air for 1 h

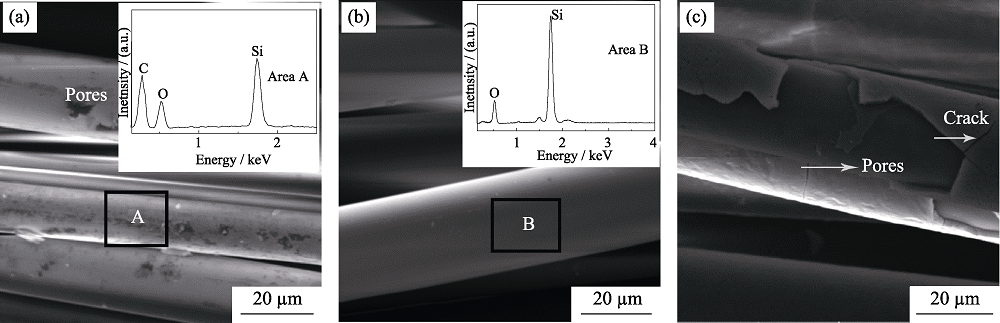

图7 C掺杂SiC纤维在空气中1000 (a)、1200 (b)、1400 ℃ (c)等温氧化1 h后的SEM照片及EDS图谱

Fig. 7 SEM images, EDS patterns of C doped SiC fibers after isothermal oxidation at 1000 ℃ (a), 1200 ℃ (b), and 1400 ℃ (c) in air for 1 h

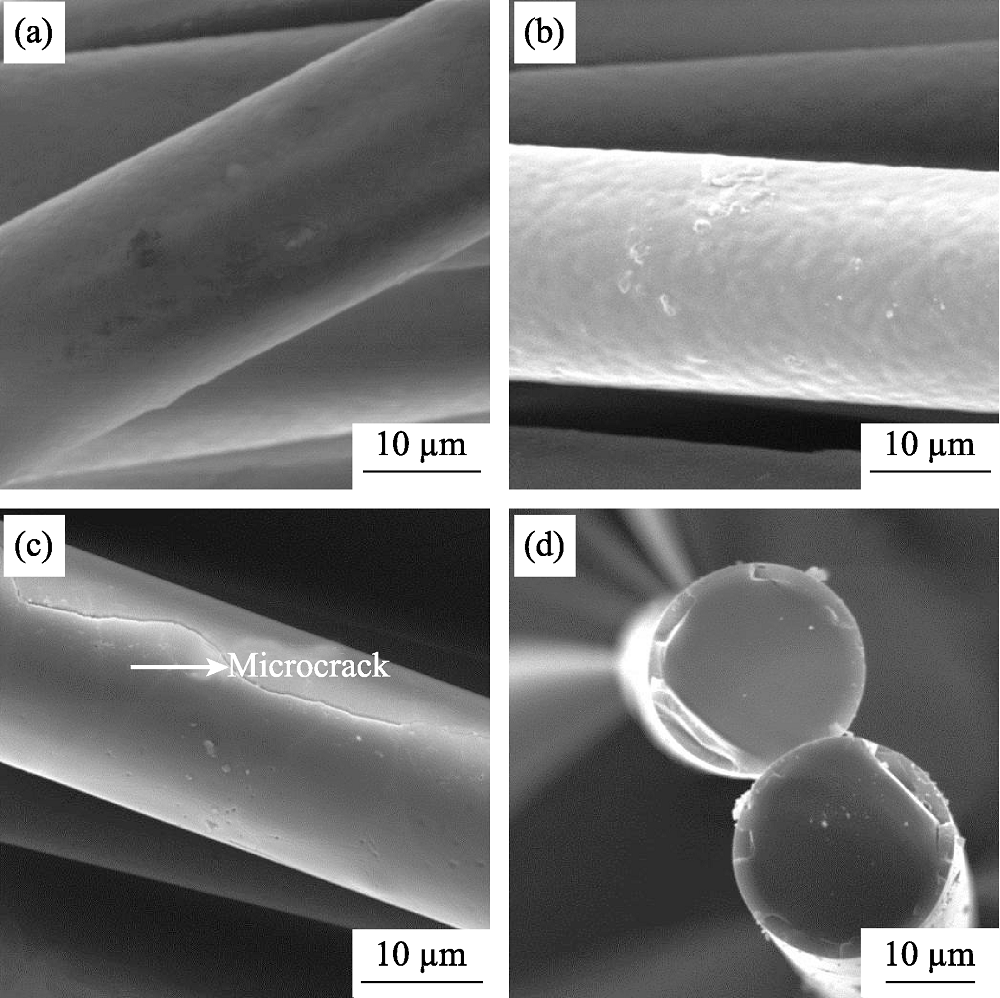

图8 B-C掺杂SiC纤维在1000 (a)、1200 (b)、1400 ℃ (c, d)等温氧化1 h后的SEM照片

Fig. 8 SEM images of B-C doped SiC fibers after isothermal oxidation at 1000 (a), 1200 (b), 1400 ℃ (c, d) in air for 1 h

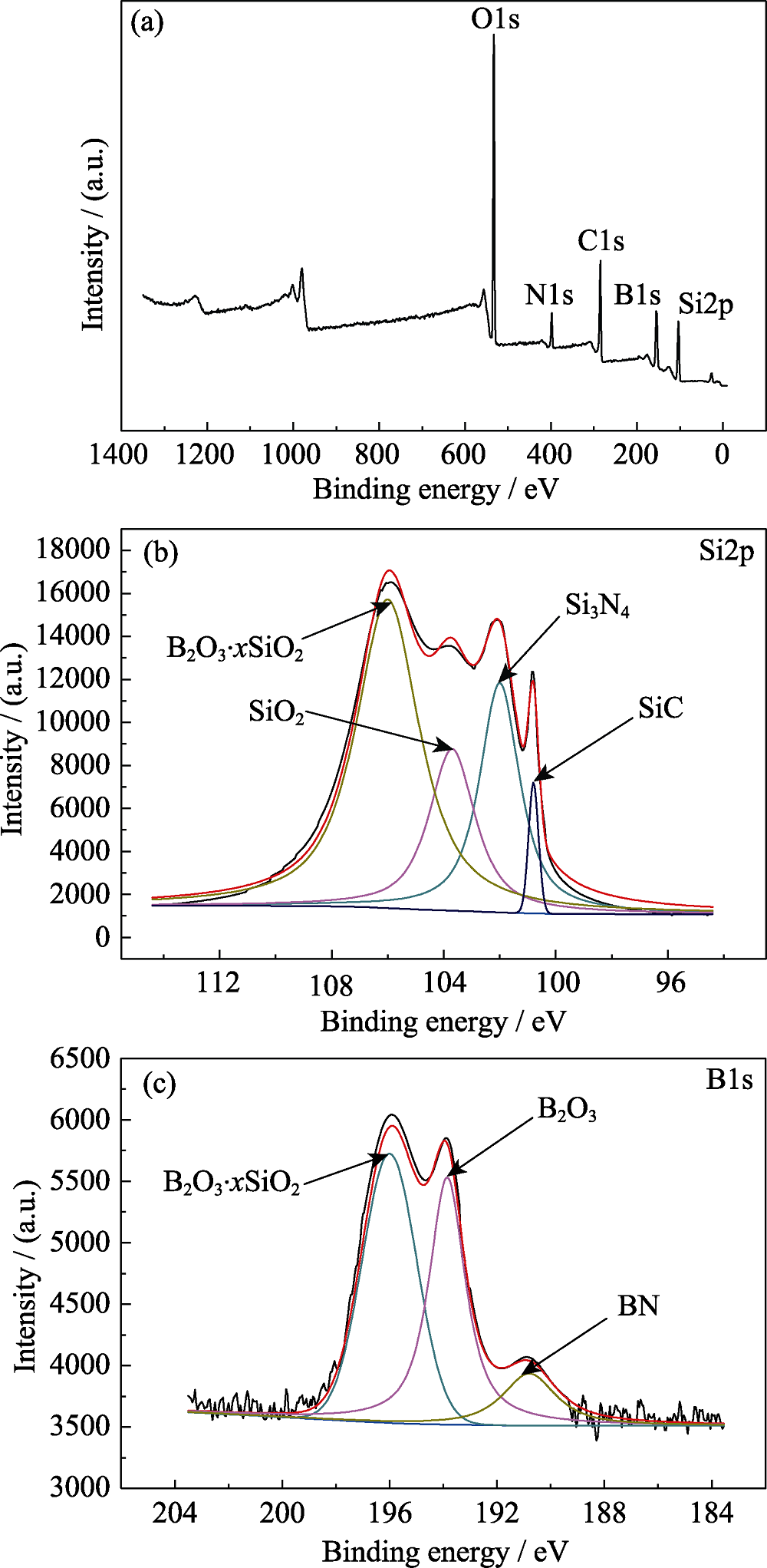

图9 1200 ℃氧化1 h后的B-C掺杂SiC纤维XPS宽扫描谱图(a)及Si2p(b)和B1s(c)的高分辨率谱图

Fig. 9 XPS wide scan spectra (a) and high resolution XPS spectra for B1s (b) and Si2p (c) region of the B-C doped SiC fibers after oxidation at 1200 ℃ for 1 h

| [1] | 杨连, 黎阳, 洪流 , 等. 功能化碳化硅纤维研究进展. 人工晶体学报, 2016,45(5):1397-1403. |

| [2] |

班国东, 刘朝辉, 叶圣天 , 等. 新型涂覆型雷达吸波材料的研究进展. 表面技术, 2016,45(6):140-146.

DOI URL |

| [3] |

宋永才, 王娟, 冯春祥 . 由PDMS与PVC共热解聚碳硅烷制备SiC-C纤维. 材料研究学报, 2004,18(3):295-300.

DOI URL |

| [4] | ZUO X, DONG Z, LI W , et al. Oxidation behavior of carbon-silicon and carbon-boron-silicon alloys derived from solvent-soluble silicon and boron-silicon-doped coal-tar pitches. Materials and Technology, 2014,48(1):59-66. |

| [5] |

BERNARD S, MAJOULET O, SANDRA F , et al. Direct synthesis of periodic mesoporous silicoboron carbonitride frameworks via the nanocasting from ordered mesoporous silica with boron-modified polycarbosilazane. Advanced Engineering Materials, 2013,15(3):134-140.

DOI URL |

| [6] |

HANG S X, HAO S C, ZHU Y . Preparation and properties of pinacolborane modified polycarbosilane as SiC fiber precursor. Journal of Inorganic & Organometallic Polymers & Materials, 2015,25(6):1-5.

DOI URL |

| [7] |

XU X H, MAO Y, CHEN F , et al. Effects of oxidation cross-linking and sintering additives (TiN, B) on the formation and heat-resistant performance of polymer-derived SiC (Ti, B) films. Ceramics International, 2016,42(7):8636-8644.

DOI URL |

| [8] |

LEE J, BUTT D P, BANEY R H , et al. Synthesis and pyrolysis of novel polysilazane to SiBCN ceramic. Journal of Non-Crystalline Solids, 2005,351(37):2995-3005.

DOI URL |

| [9] |

GUO A, ROSO M, MODESTI M , et al. Characterization of porosity, structure, and mechanical properties of electrospun SiOC fiber mats. Journal of Materials Science, 2015,50(12):4221-4231.

DOI URL |

| [10] |

TANG Y, WANG J, LI X D , et al. Preceramic polymer for SiBNC fiber via one-step condensation of silane, BCl3, and silazane. Journal of Applied Polymer Science, 2010,110(2):921-928.

DOI URL |

| [11] |

FU Q, LI H, S HI X , et al. Microstructure and growth mechanism of SiCw hiskers on carbon/carbon composites prepared by CVD. Materials Letters, 2005,59(19/20):2593-2597.

DOI URL |

| [12] | HEMIDA A T, TENAILLEAU H, BARDEAU L , et al. A quasi-stoic hiometric SiC-based experimental fibre obtained from a boron- doped polycarbosilane precursor. Journal of Materials Science, 1997,32(21):5791-5796. |

| [13] |

CAO F, LI X D, KIM D P . Efficient curing of polymet hylsilane by borazine and reaction mechanism study. Journal of Organometallic Chemistry, 2003,688(1):125-131.

DOI URL |

| [14] |

YUAN QIN, SONG YONG-CAI . Effect of SiCxOy decompositim on densification of SiCO(Al) fibers during sintering process. Journal of Inorganic Materials, 2016,31(12):1320-1326.

DOI URL |

| [15] |

CHOLLON G, CZERNIAK M, PAILLER R , et al. A model SiC- based fibre with a low oxygen content prepared from a polycarbosilane precursor. Journal of Materials Science, 1997,32(4):893-911.

DOI URL |

| [16] |

CINIBULK M K, PART HASARAT HY T A . Characterization of oxidized polymer-derived SiBCN fibers. Journal of the American Ceramic Society, 2001,84(10):2197-2202.

DOI URL |

| [17] |

MULLER A, ZERN A, GERSTEL P , et al. Boron-modified poly (propenylsilazane)-derived Si-B-C-N ceramics: preparation and high temperature properties. Journal of the European Ceramic Society, 2002,22(9/10):1631-1643.

DOI URL |

| [18] |

LIPOWITZ J . Structure and properties of ceramic fibers prepared from organosilicon polymers. Journal of Inorganic & Organometallic Polymers, 1991,1(3):277-297.

DOI URL |

| [19] |

KOBAYAS HI K, MAEDA K, SANO H , et al. Formation and oxidation resistance of the coating formed on carbon material composed of B4C-SiC powders. Carbon, 1995,33(4):397-403.

DOI URL |

| [20] |

WU H, ZHANG W . Fabrication and properties of ZrB2-SiC-BN machinable ceramics. Journal of the European Ceramic Society, 2010,30(4):1035-1042.

DOI URL |

| [1] | 孔国强, 冷明哲, 周战荣, 夏池, 沈晓芳. Sb掺杂O3型Na0.9Ni0.5Mn0.3Ti0.2O2钠离子电池正极材料[J]. 无机材料学报, 2023, 38(6): 656-662. |

| [2] | 杨颖康, 邵怡晴, 李柏良, 吕志伟, 王路路, 王亮君, 曹逊, 吴宇宁, 黄荣, 杨长. Cl掺杂对CuI薄膜发光性能增强研究[J]. 无机材料学报, 2023, 38(6): 687-692. |

| [3] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [4] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [5] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| [6] | 王志强, 吴济安, 陈昆峰, 薛冬峰. 大尺寸Er,Yb:YAG单晶的生长及其性能[J]. 无机材料学报, 2023, 38(3): 329-334. |

| [7] | 陆晨辉, 葛万银, 宋盼盼, 张盼锋, 徐美美, 张伟. 用于白光LED稀土Eu掺杂SiAlON基荧光粉的发光性能[J]. 无机材料学报, 2023, 38(1): 97-104. |

| [8] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [9] | 柳琪, 朱璨, 谢贵震, 王俊, 张东明, 邵刚勤. Ce掺杂SrMgF4超结构多晶体的吸收/光致发光光谱[J]. 无机材料学报, 2022, 37(8): 897-902. |

| [10] | 邹顺, 何夕云, 曾霞, 仇萍荪, 凌亮, 孙大志. 掺铋钇铁石榴石磁光陶瓷的热压烧结及其性能研究[J]. 无机材料学报, 2022, 37(7): 773-779. |

| [11] | 焦博新, 刘兴翀, 全子威, 彭永姗, 周若男, 李海敏. L-精氨酸掺杂钙钛矿太阳电池性能研究[J]. 无机材料学报, 2022, 37(6): 669-675. |

| [12] | 王新健, 朱逸璇, 张鹏, 杨文龙, 王挺, 郇宇. (Ba0.85Ca0.15)(Ti0.9Zr0.1-xSnx)O3无铅压电陶瓷的相结构与压电性能[J]. 无机材料学报, 2022, 37(5): 513-519. |

| [13] | 安琳, 吴淏, 韩鑫, 李耀刚, 王宏志, 张青红. 非贵金属Co5.47N/N-rGO助催化剂增强TiO2光催化制氢性能[J]. 无机材料学报, 2022, 37(5): 534-540. |

| [14] | 娄许诺, 邓后权, 李爽, 张青堂, 熊文杰, 唐国栋. Ge掺杂MnTe材料的热电输运性能[J]. 无机材料学报, 2022, 37(2): 209-214. |

| [15] | 李高然, 李红阳, 曾海波. 硼基材料在锂硫电池中的研究进展[J]. 无机材料学报, 2022, 37(2): 152-162. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||