无机材料学报 ›› 2019, Vol. 34 ›› Issue (9): 953-960.DOI: 10.15541/jim20180536

收稿日期:2018-11-19

修回日期:2019-03-04

出版日期:2019-09-20

网络出版日期:2019-05-13

作者简介:罗 清(1996-), 男, 本科生. E-mail: 2792206808@qq.com

基金资助:

LUO Qing1,YUAN Qing1,2( ),JIANG Qian-Qin1,YU Nai-Sen1

),JIANG Qian-Qin1,YU Nai-Sen1

Received:2018-11-19

Revised:2019-03-04

Published:2019-09-20

Online:2019-05-13

Supported by:摘要:

太阳能电池硅片切割工艺中使用碳化硅作为切割硅片的磨料, 切割后会形成大量的废料-一种碳化硅基混合物(HT-SiC), 其中含有少量金属等杂质。本工作开发了一种新型催化剂, 将Cu-SSZ-13分子筛和HT-SiC通过水热法结合离子交换制备成一种复合材料Cu-SSZ-13/HT-SiC, 并应用于脱硝催化反应。在合成Cu-SSZ-13分子筛时使用两种模板剂: N, N, N-三甲基-1-铵金刚烷(TMAdaOH)和铜胺络合物(Cu-TEPA)。实验结果表明, 在HT-SiC的参与下, TMAdaOH模板成功得到SSZ-13晶体, 而使用Cu-TEPA模板得到的可能是非晶态结构。在NH3-SCR反应中, 结果显示, Cu-SSZ-13/HT-SiC在中高温区间相比纯相Cu-SSZ-13更加出色, 在500 ℃时, 前者的NO消耗量约为后者的11倍。另外, 相比于用纯相SiC(α-SiC)合成的Cu-SSZ-13/α-SiC催化剂, Cu-SSZ-13/HT-SiC在整个温度区间的催化活性表现更佳。这些良好的性能不仅归因于SiC良好的导热性和热稳定性, 而且归因于HT-SiC中存在的少量Fe组分, 在脱硝催化反应中充当了还原NO的活性位点。该方法不仅解决了废弃磨料环境污染的问题, 也为重复利用SiC废料提供了新的途径。

中图分类号:

罗清,苑青,蒋前勤,于乃森. Cu-SSZ-13/碳化硅废料复合材料的合成及其

NH3-SCR性能研究[J]. 无机材料学报, 2019, 34(9): 953-960.

LUO Qing,YUAN Qing,JIANG Qian-Qin,YU Nai-Sen. Cu-SSZ-13/SiC-waste Composite: Synthesis and Application for NH3-SCR[J]. Journal of Inorganic Materials, 2019, 34(9): 953-960.

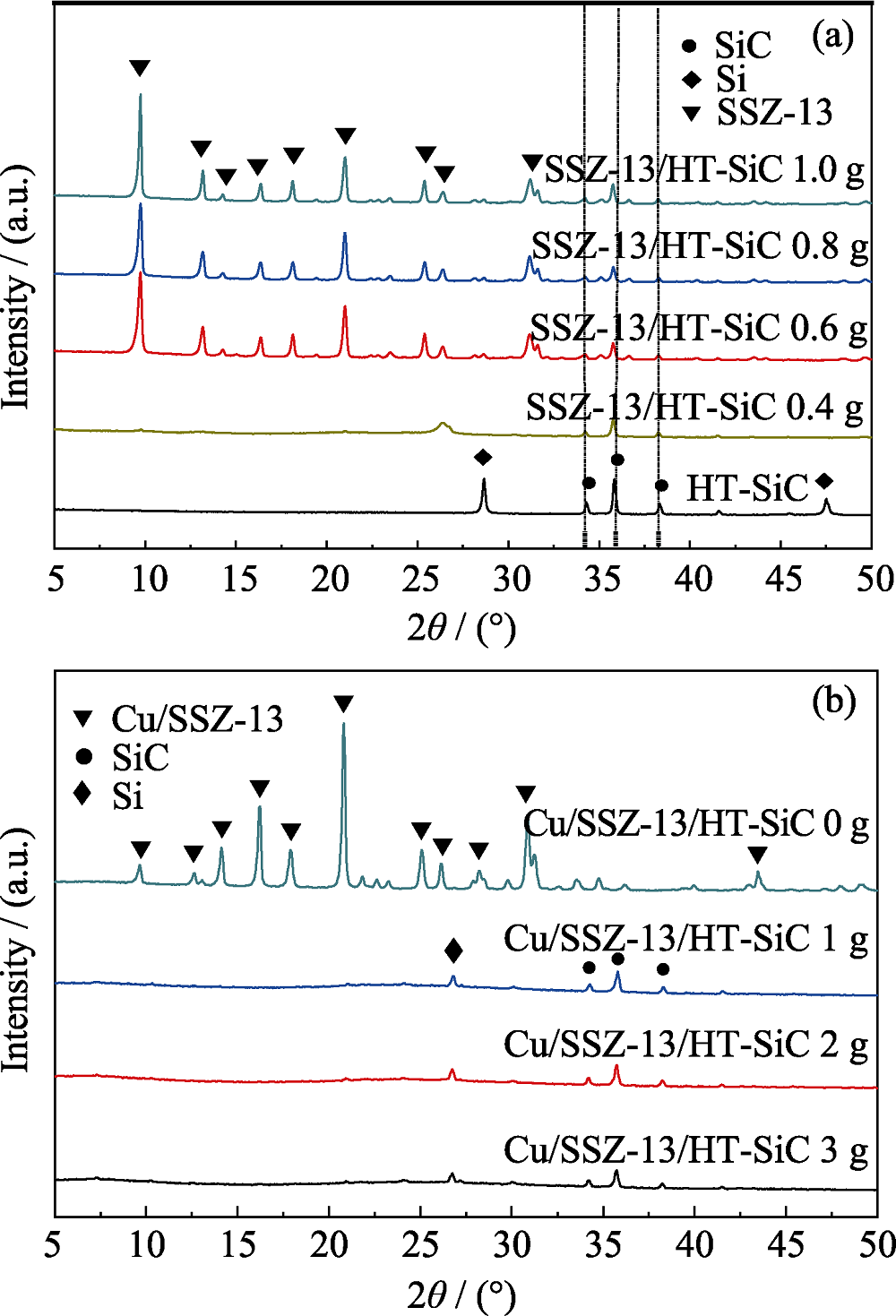

图1 HT-SiC和分别用(a)TMAdaOH、(b)Cu-TEPA为模板合成的SSZ-13/HT-SiC复合物的XRD图谱

Fig. 1 XRD patterns of HT-SiC and SSZ-13/HT-SiC composites synthesized by using (a) TMAdaOH and (b) Cu-TEPA as template

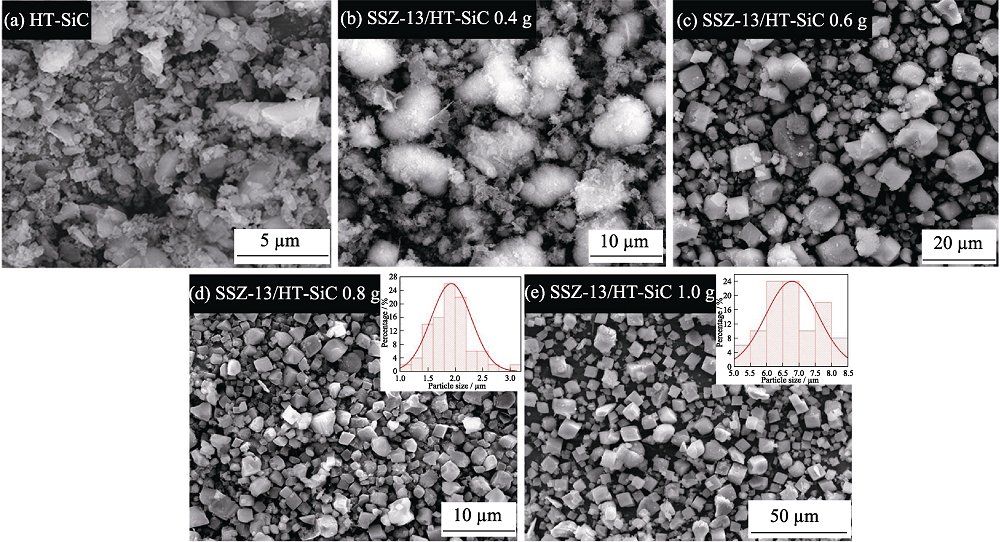

图2 HT-SiC和以TMAdaOH为模板合成的SSZ-13/HT-SiC复合物的SEM照片, 插图为孔径分布图

Fig. 2 SEM images of HT-SiC and SSZ-13/HT-SiC composites synthesized by using TMAdaOH as template with insets showing corresponding partiesize distributions

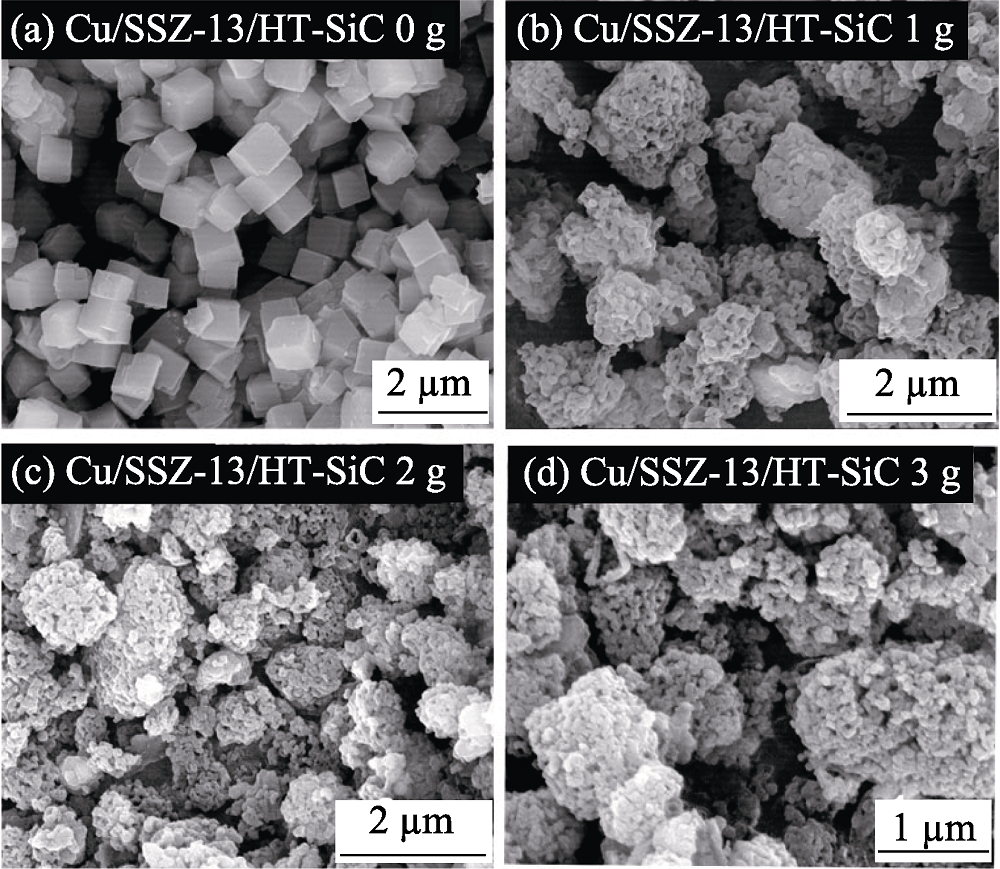

图3 以Cu-TEPA为模板合成的纯相Cu/SSZ-13和Cu/SSZ-13/HT-SiC复合物的SEM照片

Fig. 3 SEM images of pure Cu/SSZ-13 and Cu/SSZ-13/HT-SiC composites prepared by using Cu-TEPA as template

| Sample | SBET/(m2·g-1) | Smic/(m2·g-1) | Sext/(m2·g-1) | Vt/(cm3·g-1)a | Vmic/(cm3·g-1)b |

|---|---|---|---|---|---|

| HT-SiC | 0.5 | 0.4 | 0.006 | - | - |

| SSZ-13 | 567.7 | 560.1 | 7.600 | 0.31 | 0.30 |

| SSZ-13/HT-SiC-0.4 g | 0.9 | 0.8 | 0.010 | - | - |

| SSZ-13/HT-SiC-0.6 g | 226.5 | 223.4 | 3.000 | 0.12 | 0.11 |

| SSZ-13/HT-SiC-0.8 g | 378.5 | 373.4 | 5.100 | 0.21 | 0.20 |

| SSZ-13/HT-SiC-1.0 g | 355.7 | 350.9 | 4.800 | 0.19 | 0.18 |

表1 HT-SiC载体、SSZ-13和SSZ-13/HT-SiC复合材料的结构性质

Table 1 Textural properties of HT-SiC support, SSZ-13 and SSZ-13/HT-SiC composites

| Sample | SBET/(m2·g-1) | Smic/(m2·g-1) | Sext/(m2·g-1) | Vt/(cm3·g-1)a | Vmic/(cm3·g-1)b |

|---|---|---|---|---|---|

| HT-SiC | 0.5 | 0.4 | 0.006 | - | - |

| SSZ-13 | 567.7 | 560.1 | 7.600 | 0.31 | 0.30 |

| SSZ-13/HT-SiC-0.4 g | 0.9 | 0.8 | 0.010 | - | - |

| SSZ-13/HT-SiC-0.6 g | 226.5 | 223.4 | 3.000 | 0.12 | 0.11 |

| SSZ-13/HT-SiC-0.8 g | 378.5 | 373.4 | 5.100 | 0.21 | 0.20 |

| SSZ-13/HT-SiC-1.0 g | 355.7 | 350.9 | 4.800 | 0.19 | 0.18 |

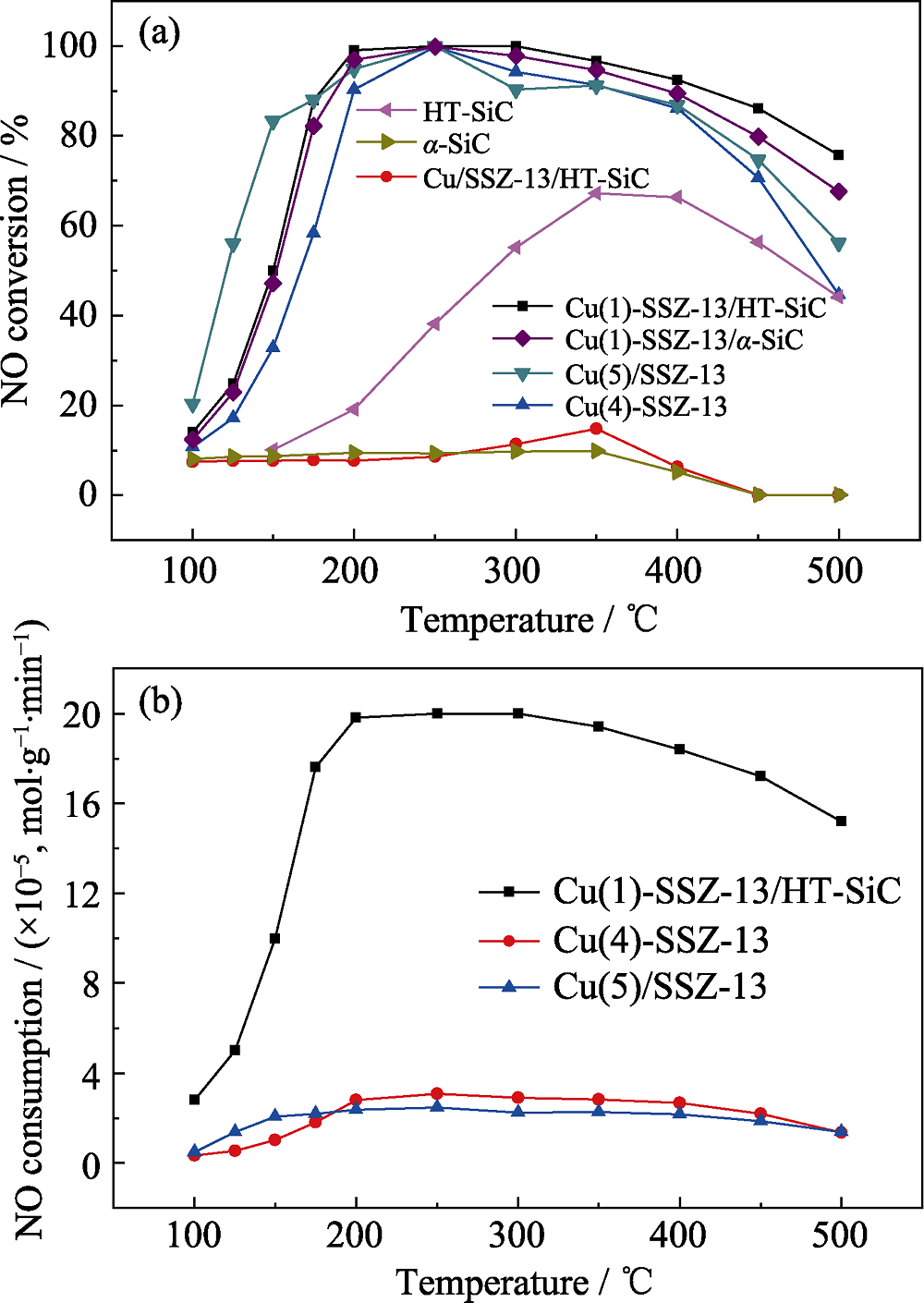

图6 (a) HT-SiC、用TMAdaOH 或 Cu-TEPA模板合成的Cu-SSZ-13和Cu-SSZ-13/HT-SiC复合物的NH3-SCR测试; (b) Cu(1)-SSZ-13/HT-SiC、Cu(4)-SSZ-13和Cu(5)/SSZ-13三种催化剂每克Cu每分钟所消耗NO的摩尔数

Fig. 6 (a) Denitrification activity of HT-SiC, Cu-SSZ-13 and Cu-SSZ-13/HT-SiC catalysts synthesized by using TMAdaOH or Cu-TEPA as template with different Cu contents; (b) The mole of NO consumed (molNO/(gCu·min)) by Cu(1)-SSZ-13/HT-SiC, Cu(4)-SSZ-13 and Cu(5)/SSZ-13 catalysts

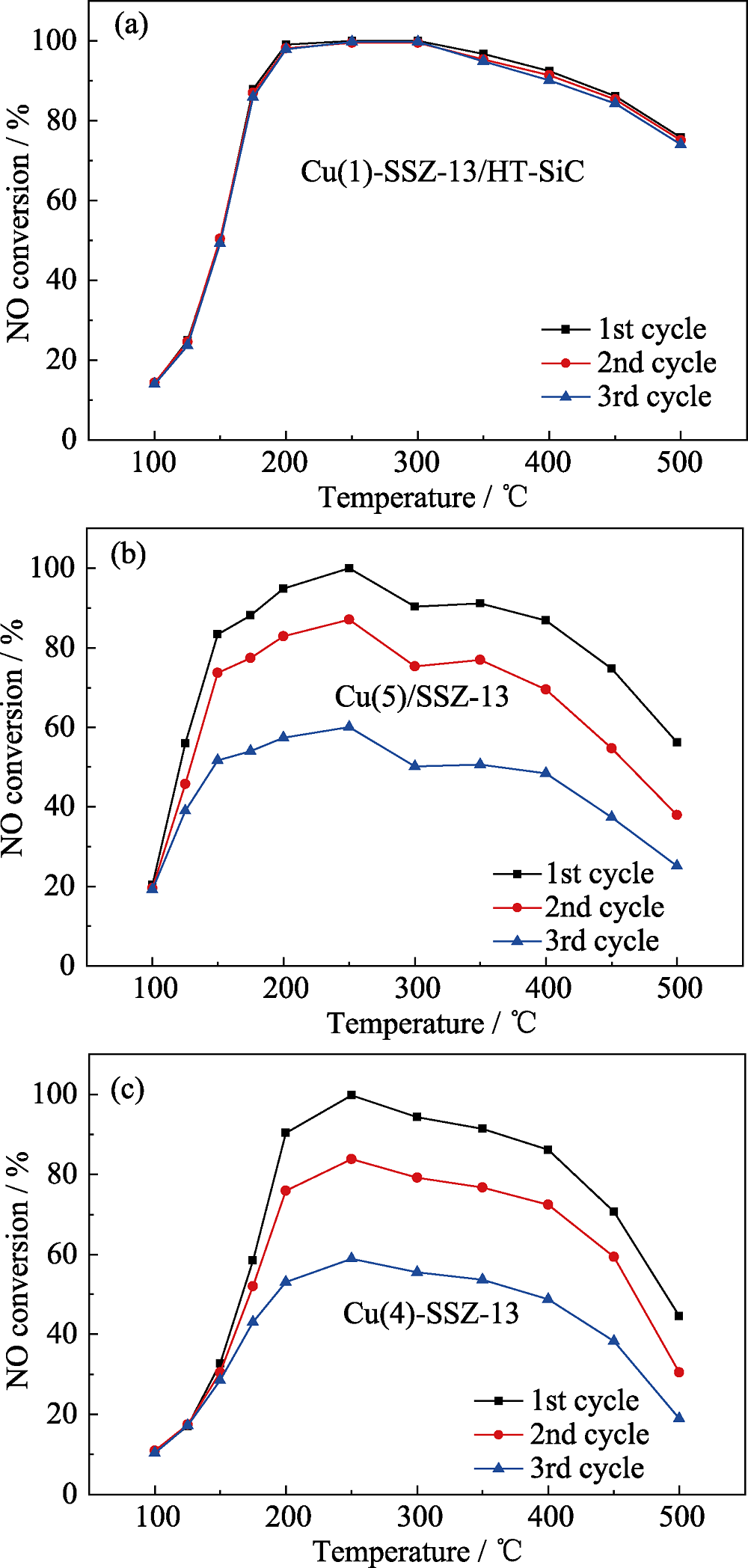

图7 Cu(1)-SSZ-13/HT-SiC, Cu(5)/SSZ-13 和 Cu(4)-SSZ-13 催化剂的热稳定性测试结果

Fig. 7 Thermal stability of Cu(1)-SSZ-13/HT-SiC, Cu(5)/SSZ-13 and Cu(4)-SSZ-13 catalysts

图8 三次循环脱硝测试后Cu(1)-SSZ-13/HT-SiC和Cu(4)-SSZ-13 催化剂的N2吸附/脱附等温线

Fig. 8 N2 adsorption/desorption isotherms of Cu(1)-SSZ-13/HT-SiC and Cu(4)-SSZ-13 catalysts after three-cycle NH3-SCR test

| [1] | LIU H Y, MA X, LI B W ,et al. Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends. Fuel, 2017,209:62-68. |

| [2] | ELSANUSI O A, ROY M M, SIDHU M S . Experimental investigation on a diesel engine fueled by diesel-biodiesel blends and their emulsions at various engine operating conditions. Appl. Energy, 2017,203:582-593. |

| [3] | LIU F D, YU Y B, HE H . Environmentally-benign catalysts for the selective catalytic reduction of Nox from diesel engines: structure- activity relationship and reaction mechanism aspects. Chem. Commun., 2014,50(62):8445-8463 |

| [4] | BEALE A M, GAO F, LEZCANO-GONZALEZ I ,et al. Recent advances in automotive catalysis for NOx emission control by small-pore microporous materials. Chem. Soc. Rev., 2015,44(20):7371-7405. |

| [5] | ANGGARA T, PAOLUCCI C, SCHNEIDER W F . Periodic DFT characterization of NOx adsorption in Cu-Exchanged SSZ-13 zeolite catalysts. J. Phys. Chem. C, 2016,120(49):27934-27943. |

| [6] | SHWAN S, JANSSON J, OLSSON L ,et al. Chemical deactivation of H-BEA and Fe-BEA as NH3-SCR catalysts—effect of potassium. Appl. Catal. B-Environ., 2015,166:277-286. |

| [7] | WANG H Y, WANG B D, SUN Q ,et al. New insights into the promotional effects of Cu and Fe over V2O5-WO3/TiO2 NH3-SCR catalysts towards oxidation of Hg0. Catal. Commun., 2017,100:169-172. |

| [8] | WANG J H, ZHAO H W, HALLER G ,et al. Recent advances in the selective catalytic reduction of NOx with NH3 on Cu-Chabazite catalysts. Appl. Catal. B-Environ., 2017,202:346-354. |

| [9] | FICKEL D W, D'ADDIO E, LAUTERBACH J A , et al. The ammonia selective catalytic reduction activity of copper-exchanged small-pore zeolites. Appl. Catal. B-Environ., 2011,102(3/4):441-448. |

| [10] | SZANYI J, KWAK J H, ZHU H Y ,et al. Characterization of Cu-SSZ-13 NH3 SCR catalysts: an in situ FT-IR study. Phys. Chem. Chem. Phys., 2013,15(7):2368-2380. |

| [11] | GUNTER T, PESEK J, SCHAFER K ,et al. Cu-SSZ-13 as pre-turbine NOx-removal-catalyst: impact of pressure and catalyst poisons. Appl. Catal. B-Environ., 2016,198:548-557. |

| [12] | MASIH D, ROHANI S, KONDO J N ,et al. Low-temperature methanol dehydration to dimethyl ether over various small-pore zeolites. Appl. Catal. B-Environ., 2017,217:247-255. |

| [13] | ZHENG Y H, HU N, WANG H M ,et al. Preparation of steam-stable high-silica CHA (SSZ-13) membranes for CO2/CH4 and C2H4/C2H6 separation. J. Membrane Sci., 2015,475:303-310. |

| [14] | OORD R, TEN HAVE I C, ARENDS J M , et al. Enhanced activity of desilicated Cu-SSZ-13 for the selective catalytic reduction of NOx and its comparison with steamed Cu-SSZ-13. Catal. Sci. Technol., 2017,7(17):3851-3862. |

| [15] | CHINTALA V, SUBRAMANIAN K A . Hydrogen energy share improvement along with NOx(oxides of nitrogen) emission reduction in a hydrogen dual-fuel compression ignition engine using water injection. Energy. Convers. Manage., 2014,83:249-259. |

| [16] | KAWAMURA T, HORI D, KANGAWA Y ,et al. Thermal conductivity of SiC calculated by molecular dynamics. Jpn. J. Appl. Phys., 2008,47(12):8898-8901. |

| [17] | ZHAO L, KONG L P, LIU C Z ,et al. AgCu/SiC-powder: a highly stable and active catalyst for gas-phase selective oxidation of alcohols. Catal. Commun., 2017,98:1-4. |

| [18] | WANG H, SCMACK R, PAUL B ,et al. Porous silicon carbide as a support for Mn/Na/W/SiC catalyst in the oxidative coupling of methane. Appl. Catal. A-Gen., 2017,537:33-39. |

| [19] | DUONG-VIET C, TRUONG-PHUOC L, TRAN-THANH T ,et al. Nitrogen-doped carbon nanotubes decorated silicon carbide as a metal-free catalyst for partial oxidation of H2S. Appl. Catal. A-Gen., 2014,482:397-406. |

| [20] | ZHOU T Y, YUAN Q, PAN X L ,et al. Growth of Cu/SSZ-13 on SiC for selective catalytic reduction of NO with NH3. Chinese J. Catal., 2018,39(1):71-78. |

| [21] | MARTIN N, VENNESTROM P N R, THOGERSEN J R , et al. Fe-containing zeolites for NH3-SCR of NOx: effect of structure, synthesis procedure, and chemical composition on catalytic performance and stability. Chem. -Eur. J., 2017,23(54):13404-13414. |

| [22] | REN Z Y, FAN H, WANG R . A novel ring-like Fe2O3-based catalyst: tungstophosphoric acid modification, NH3-SCR activity and tolerance to H2O and SO2. Catal. Commun., 2017,100:71-75. |

| [23] | SHISHKIN A, KANNISTO H, CARLSSON P A ,et al. Synthesis and functionalization of SSZ-13 as an NH3-SCR catalyst. Catal. Sci. Technol., 2014,4(11):3917-3926. |

| [24] | XU R N, ZHANG R D, LIU N ,et al. Template design and economical strategy for the synthesis of SSZ-13 (CHA-Type) zeolite as an excellent catalyst for the selective catalytic reduction of NOx by ammonia. ChemCatChem, 2015,7(23):3842-3847. |

| [25] | REN L M, ZHU L F, YANG C G , et al. Designed copper-amine complex as an efficient template for one-pot synthesis of Cu-SSZ-13 zeolitewith excellent activity for selective catalytic reduction of NOx by NH3. Chem. Commun., 2011,47(35):9789-9791. |

| [26] | XIE K P, WOO J, BERNIN D ,et al. Insights into hydrothermal aging of phosphorus-poisoned Cu-SSZ-13 for NH3-SCR. Appl. Catal. B-Environ., 2018,241:205-216. |

| [27] | WANG J, SHAO L, WANG C ,et al. Controllable preparation of various crystal size and nature of intra-crystalline diffusion in Cu/SSZ-13 NH3-SCR catalysts. J. Catal., 2018,367:221-228. |

| [28] | HAN L N, ZHAO X G, YU H F ,et al. Preparation of SSZ-13 zeolites and their NH3-selective catalytic reduction activity. Micropor. Mesopor. Mater., 2018,261:126-136. |

| [29] | TAKATA T, TSUNOJI N, TAKAMITSU Y ,et al. Nanosized CHA zeolites with high thermal and hydrothermal stability derived from the hydrothermal conversion of FAU zeolite. Micropor. Mesopor. Mater., 2016,225:524-533. |

| [30] | GE S B, GENG W C, HE X W ,et al. Effect of framework structure, pore size and surface modification on the adsorption performance of methylene blue and Cu2+ in mesoporous silica. Colloid Surface A, 2018,539:154-162. |

| [31] | GAO F, WASHTON N M, WANG Y L ,et al. Effects of Si/Al ratio on Cu/SSZ-13 NH3-SCR catalysts: implications for the active Cu species and the roles of Brønsted acidity. J. Catal., 2015,331:25-38. |

| [32] | OHLIN L, BEREZOVSKY V, OBERG S ,et al. Effect of water on the adsorption of methane and carbon dioxide in zeolite Na-ZSM-5 studied using in situ ATR-FT-IR spectroscopy. J. Phys. Chem. C, 2016,120(51):29144-29152. |

| [33] | GENG W C, GE S B, HE X W ,et al. Volatile organic compound gas-sensing properties of bimodal porous α-Fe2O3 with ultrahigh sensitivity and fast response. ACS Appl. Mater. Interfaces, 2018,10(16):13702-13711. |

| [34] | YU L M, ZHONG Q, ZHANG S L . Research of copper contained SAPO-34 zeolite for NH3-SCR DeNOx by solvent-free synthesis with Cu-TEPA. Micropor. Mesopor. Mater., 2016,234:303-309. |

| [35] | ZHANG T, CHANG H Z, YOU Y C ,et al. Excellent activity and selectivity of one-pot synthesized Cu SSZ-13 catalyst in the selective catalytic oxidation of ammonia to nitrogen. Environ. Sci. Technol., 2018,52(8):4802-4808. |

| [1] | 丁玲, 蒋瑞, 唐子龙, 杨运琼. MXene材料的纳米工程及其作为超级电容器电极材料的研究进展[J]. 无机材料学报, 2023, 38(6): 619-633. |

| [2] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [3] | 马晓森, 张丽晨, 刘砚超, 汪全华, 郑家军, 李瑞丰. 13X@SiO2合成及其甲苯吸附性能[J]. 无机材料学报, 2023, 38(5): 537-543. |

| [4] | 张硕, 付前刚, 张佩, 费杰, 李伟. C/C多孔体的高温热处理对C/C-SiC复合材料摩擦磨损行为的影响[J]. 无机材料学报, 2023, 38(5): 561-568. |

| [5] | 陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162. |

| [6] | 冯静静, 章游然, 马名生, 陆毅青, 刘志甫. 冷烧结技术的研究现状及发展趋势[J]. 无机材料学报, 2023, 38(2): 125-136. |

| [7] | 荆开开, 管皞阳, 朱思雨, 张超, 刘永胜, 王波, 王晶, 李玫, 张程煜. Cansas-II SiCf/SiC复合材料的高温拉伸蠕变行为[J]. 无机材料学报, 2023, 38(2): 177-183. |

| [8] | 胡佳军, 王凯, 侯鑫广, 杨婷, 夏鸿雁. 熔盐法合成高导热磷化硼及其热管理性能研究[J]. 无机材料学报, 2022, 37(9): 933-940. |

| [9] | 欧阳琴, 王艳菲, 徐剑, 李寅生, 裴学良, 莫高明, 李勉, 李朋, 周小兵, 葛芳芳, 张崇宏, 何流, 杨磊, 黄政仁, 柴之芳, 詹文龙, 黄庆. 核用碳化硅纤维增强碳化硅复合材料研究进展[J]. 无机材料学报, 2022, 37(8): 821-840. |

| [10] | 孙铭, 邵溥真, 孙凯, 黄建华, 张强, 修子扬, 肖海英, 武高辉. RGO/Al复合材料界面性质第一性原理研究[J]. 无机材料学报, 2022, 37(6): 651-659. |

| [11] | 张叶, 姚冬旭, 左开慧, 夏咏锋, 尹金伟, 曾宇平. 原位引入BN-SiC燃烧合成Si3N4-BN-SiC复合材料[J]. 无机材料学报, 2022, 37(5): 574-578. |

| [12] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 三维碳化硅纳米线增强碳化硅陶瓷基复合材料的电磁屏蔽性能[J]. 无机材料学报, 2022, 37(5): 579-584. |

| [13] | 王洪达, 冯倩, 游潇, 周海军, 胡建宝, 阚艳梅, 陈小武, 董绍明. SiC/SiC-哈氏合金异质连接机制及其氟熔盐腐蚀特性分析[J]. 无机材料学报, 2022, 37(4): 452-458. |

| [14] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [15] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 碳化硅纳米线增强多孔碳化硅陶瓷基复合材料的制备[J]. 无机材料学报, 2022, 37(4): 459-466. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||