无机材料学报 ›› 2019, Vol. 34 ›› Issue (3): 269-278.DOI: 10.15541/jim20180248

所属专题: 热电材料与器件

胡晓凯1,4, 张双猛1, 赵府1,2, 刘勇1,3, 刘玮书1

收稿日期:2018-06-21

修回日期:2018-08-23

出版日期:2019-03-20

网络出版日期:2019-02-26

作者简介:胡晓凯(1978-), 男, 博士. E-mail: xiaokai.hu@deakin.edu.au

基金资助:HU Xiao-Kai1,4, ZHANG Shuang-Meng1, ZHAO Fu1,2, LIU Yong1,3, LIU Wei-Shu1

Received:2018-06-21

Revised:2018-08-23

Published:2019-03-20

Online:2019-02-26

Supported by:摘要:

基于塞贝克效应的热电转换技术, 在大量分散的低品位废热转换电能方面有着不可替代的优势。以热电优值ZT为性能指标的热电材料研发成为新能源材料领域研究的热点之一。近年来, 大量新型中温热电材料被相继发现, 然而新型热电材料的产业化应用, 尤其是在温差发电方面的进展尤为缓慢, 其中热电器件中的材料界面问题严重制约了热电转换技术的应用进程。本文从Bi2Te3型器件在温差发电方面所遇到的技术瓶颈为例, 阐述热电器件中的界面关键技术, 并归纳出电极接触界面需要综合考虑低的界面电阻、高的结合强度、以及好的高温稳定性能。然后总结了与Bi2Te3、PbTe、CoSb3基三种热电材料相关的界面材料研究进展。

中图分类号:

胡晓凯, 张双猛, 赵府, 刘勇, 刘玮书. 热电器件的界面和界面材料[J]. 无机材料学报, 2019, 34(3): 269-278.

HU Xiao-Kai, ZHANG Shuang-Meng, ZHAO Fu, LIU Yong, LIU Wei-Shu. Thermoelectric Device: Contact Interface and Interface Materials[J]. Journal of Inorganic Materials, 2019, 34(3): 269-278.

| T range /℃ | Compositions/wt% | Liquidus T/℃ | Solidus T/℃ |

|---|---|---|---|

| 100-200 | 52 In+48 Sn | 118 | 118 |

| 85 Sn+10 Bi+5 Zn | 190 | 168 | |

| 63 Sn+37 Pb | 183 | 183 | |

| 91.2 Sn+8.8 Zn | 198.5 | 198.5 | |

| 200-300 | 50 Sn+50 Pb | 212 | 183 |

| 96.5 Sn+3 Ag+0.5 Cu | 220 | 217 | |

| 95 Sn+5 Sb | 240 | 232 | |

| 300-400 | 5 Sn+95 Pb | 312 | 305 |

| 95 Pb+5 Ag | 364 | 305 | |

| 75 Sn+0.25 Sb+ 0.25 Bi+24.5 Pb | 380 | 370 | |

| 400-500 | 94 Sn+0.2 Pb+5.8 Sb | 461 | 450 |

| 88 Pb+11.75 Sb+0.25 Bi | 473 | 473 | |

| 500-600 | 97 Pb+0.4 Sb + 2.35 Ag+0.25 Bi | 580 | 580 |

| 8.5 Sn+90 Pb+1.5 Ag | 588 | 588 |

表1 一些焊料的成分和液相线、固相线温度[16]

Table 1 Compositions of some solders as well as the temperature (T) at liquidus and solidus[16]

| T range /℃ | Compositions/wt% | Liquidus T/℃ | Solidus T/℃ |

|---|---|---|---|

| 100-200 | 52 In+48 Sn | 118 | 118 |

| 85 Sn+10 Bi+5 Zn | 190 | 168 | |

| 63 Sn+37 Pb | 183 | 183 | |

| 91.2 Sn+8.8 Zn | 198.5 | 198.5 | |

| 200-300 | 50 Sn+50 Pb | 212 | 183 |

| 96.5 Sn+3 Ag+0.5 Cu | 220 | 217 | |

| 95 Sn+5 Sb | 240 | 232 | |

| 300-400 | 5 Sn+95 Pb | 312 | 305 |

| 95 Pb+5 Ag | 364 | 305 | |

| 75 Sn+0.25 Sb+ 0.25 Bi+24.5 Pb | 380 | 370 | |

| 400-500 | 94 Sn+0.2 Pb+5.8 Sb | 461 | 450 |

| 88 Pb+11.75 Sb+0.25 Bi | 473 | 473 | |

| 500-600 | 97 Pb+0.4 Sb + 2.35 Ag+0.25 Bi | 580 | 580 |

| 8.5 Sn+90 Pb+1.5 Ag | 588 | 588 |

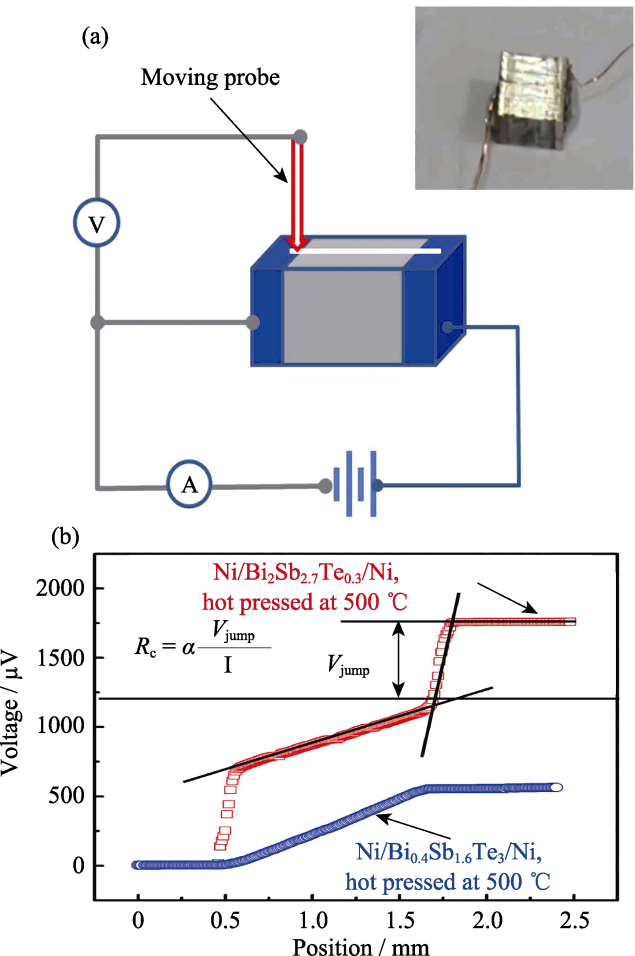

图4 通过粉末热压法连接的Ni/Bi2Te3界面接触电阻的扫描探针测试方法示意图(a)(插图为Bi2Te3基接触脚照片), Ni/Bi2Te2.7Se0.3/Ni和Ni/Bi0.4Sb1.6Te3/Ni的电势曲线以及接触电阻计算方法(b)[21]

Fig. 4 Schematic diagram of a scanning voltage probe for contact resistance measurement, and a Bi2Te3-based leg (inset) (a); contact resistance measurement for both n-type Ni/Bi2Te2.7Se0.3/Ni and p-type Ni/Bi0.4Sb1.6Te3/Ni(b)[21]

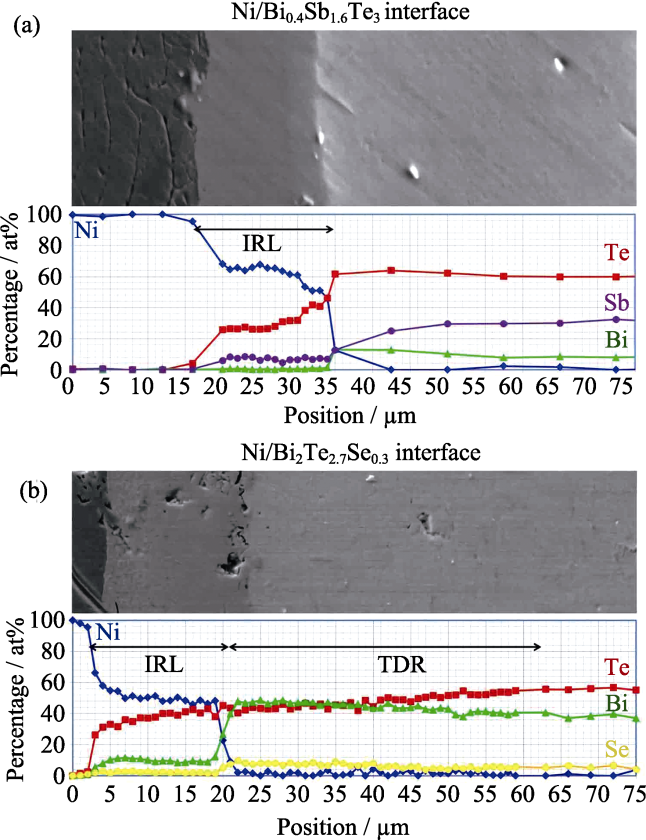

图5 Ni/Bi0.4Sb1.6Te3界面(a)和Ni/Bi2Te2.7Se0.3界面(b)附近元素百分浓度分布[21]

Fig.5 Comparison of composition profile between Ni/Bi0.4Sb1.6Te3 interface (a)and Ni/Bi2Te2.7Se0.3Interface (b) obtained from a selected area SEM-EDS[21]IRL: interface reaction layer, TDR: Te-deficient region

图7 聚光太阳能热电发电器件: 新型NiFe基合金用于n型Bi2Te3的金属化[12]

Fig. 7 Concentrating solar thermoelectric generators: new type of NiFe-based alloy applied to metallization of n-type Bi2Te3[12]

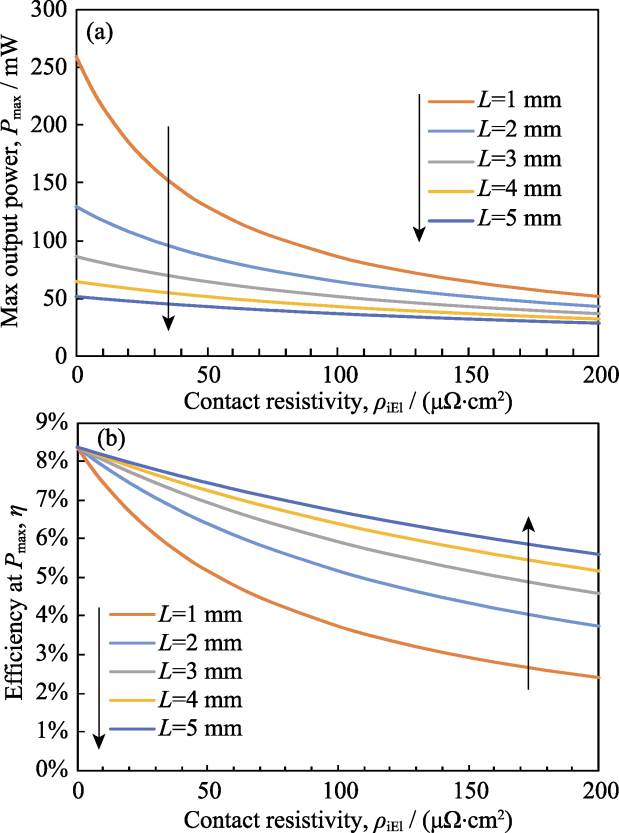

图8 虚拟的碲化铋热电偶臂最大输出功率(a)和效率(b)随界面接触电阻率的变化情况, 其中l为热电臂高度

Fig.8 The maximum output power (a) and efficiency (b) vs. interface contact resistivity for the simulated Bi2Te3 leg (l is the leg height)

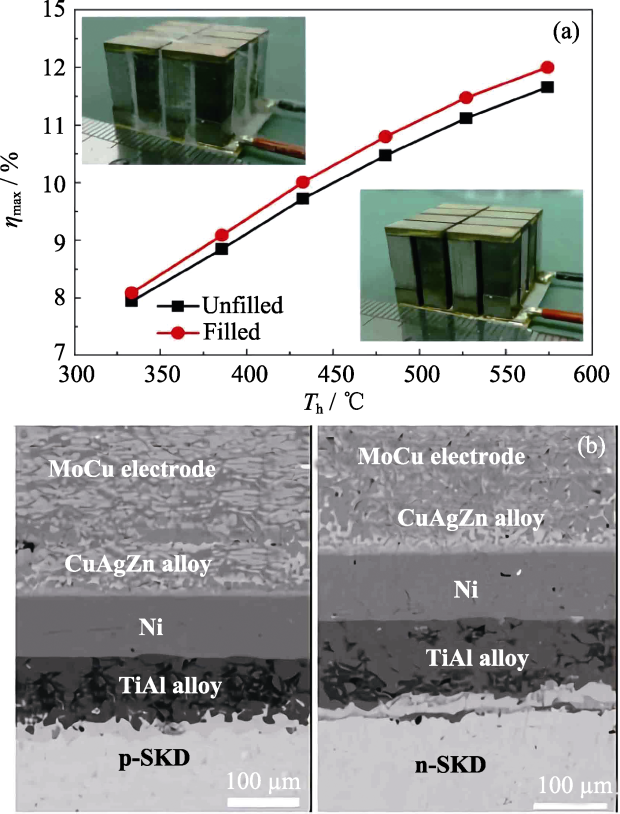

图9 碲化铋-方钴矿两段式热电器件的发电效率(a)和器件热端SKD/Ti0.88Al0.12/Ni界面与电极扫描电镜照片(b) [13]

Fig.9 (a) Power generation efficiency of segmented BT/SKD modules and (b) scanning electron microscopy image of SKD/Ti0.88Al0.12/Ni interface and electrode on hot side[13]

| [1] | 中国建筑节能协会. 中国建筑能耗研究报告(2017年), 上海, 2017. |

| [2] | 陈立东, 刘睿恒, 史迅. 热电材料与器件. 北京:科学出版社, 2018:1-14. |

| [3] | LIU W S, HU J Z, ZHANG S M,et al. New trends, strategies and opportunities in thermoelectric materials: a perspective. Mater. Today Phys., 2017, 1: 50-60. |

| [4] | ZHU T J, LIU Y T, FU C G,et al. Compromise and synergy in high efficiency thermoelectric materials. Adv. Mater, 2017, 29(14): 1605884. |

| [5] | LI J F, LIU W S, ZHAO L D,et al. High-performance nanostructured thermoelectric materials. NPGAsia Mater., 2010, 2(4):152-158. |

| [6] | ZEBARJADI M, ESFARJANI K, DRESSELHAUS M S,et al. Perspectives on thermoelectrics: from fundamentals to device applications. Energy Environ. Sci., 2012,5(1): 5147-5162. |

| [7] | CHEN L D, XIONG Z, BAI S Q.Recent progress of thermoelectric nano-composites.Journal ofInorganic Materials, 2010, 25(6): 561-568. |

| [8] | ZHAN B, LAN J Z, LIU Y C,et al. Research progress of oxides thermoelectric materials. Journal ofInorganic Materials, 2014, 29(3): 237-244. |

| [9] | CHEN G, LIU T X, TANG X F,et al. Optimization of electrode material and connecting process for Mg-Si-Sn based thermoelectric device. Journal ofInorganic Materials, 2015, 30(6): 639-646. |

| [10] | FU C, BAI S, LIU Y,et al. Realizing high figure of merit in heavy band p-type half-Heusler thermoelectric materials. Nat. Comm., 2015, 6: 8144-8151. |

| [11] | HU X, JOOD P, OHTA M,et al. Power genaration of nanostructured PbTe-based thermoelectrics: comprehensive development from materials to modules. Energy Environ. Sci., 2016, 9(2): 517-529. |

| [12] | KRAEMER D, JIE Q, MCENANEY K,et al. Concentrating solar thermoelectric generator with a peak efficiency of 7.4%. Nature Energy, 2016, 1: 1-8. |

| [13] | ZHANG Q, LIAO J, TANG Y,et al. Realizing a thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy-loss minimized integration. Energy Environ. Sci., 2017, 10(4): 956-963. |

| [14] | HAO F, QIU P, TANG Y,et al. High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300℃. Energy Environ. Sci.,2016, 9(10): 3120-3127. |

| [15] | 张建中. 温差电技术. 天津:天津科学技术出版社, 2013:131-135, 219-224. |

| [16] | 张文典. 实用表面组装技术, 4版. 北京:电子工业出版社, 2015:162-247. |

| [17] | HATZIKRANIOTIS E, ZORBAS K T, SAMARAS I,et al. Efficiency study of a commercial thermoelectric power generator (TEG) under thermal cycling. J. Electron. Mater., 2010,39(9): 2112-2116. |

| [18] | PARK W, BARAKO M T, MARCONNET A M, et al. Effect of thermal cycling on commercial thermoelectric modules. 13th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, 2012, 16(12): 107-112. |

| [19] | CLIN TH, TURENNE S, VASILEVSKIY D,et al. Numerical simulation of the thermomechanical behavior of extruded bismuth telluride alloy module. J. Electro. Mater.,2009,38(7): 994-1001. |

| [20] | KIM H S, WANG T, LIU W S,et al.Engineering thermal conductivity for balancing between reliability and performance of bulk thermoelectric generators. Adv. Funct. Mater.,2016, 26(21): 3678-3686. |

| [21] | LIU W S, WANG H, WANG L,et al. Understanding of the contact of nanostructured thermoelectric n-type Bi2Te2.7Se0.3 legs for power generation applications.J. Mater. Chem. A, 2013, 1(42): 13093-13100. |

| [22] | LAN Y C, WANG D Z, CHEN G, REN Z F. Diffusion of nickel and tin in p-type (Bi,Sb)2Te3 and n-type Bi2(Te,Se)3 thermoelectric materials. Appl. Phys. Lett., 2008, 92(10): 101910-1-3. |

| [23] | ROWE D M.CRC Handbook of Thermoelectrics. USA: CRC Press LLC, 1995: 479-485. |

| [24] | LIU W S, QING J, KIM H S,et al. Current progress and future challenges in thermoelectric power generation: from materials to devices. Acta Materialia, 2015, 87: 357-376. |

| [25] | HABA V. Method and Materials For Obtaining Low Resistance Bond to Bismuth Telluride. US Patent, 3017693, 1962. US Patent, 3079455, 1963. |

| [26] | ROSI F D, BERNOFF R A.Method and Materials for Obtaining Low Resistance Bonds to Thermoelectric Bodies. US Patent, 3037064, 1962. |

| [27] | LIAO C N, LEE C H, CHEN W J.Effect of interfacial compound formation on contact resistivity of soldered junction between bismuth telluride based thermoelements and copper.Electrochem. Solid-State Lett., 2007,10(9): 23-25. |

| [28] | MENGALI O J, SEILER M R.Contact resistance studies on thermoelectric materials.Adv. Energy Conversion, 1962, 2(62): 59-68. |

| [29] | WEITZMAN L H. Etching Bismuth Telluride.US Patent, 3338765, 1967. |

| [30] | TALOR P J, MADDUX J R, MEISSNER G, ,et al. Controlled improvement in specific contact resistivity for thermoelectric materials by ion implantation. Appl. Phys. Lett.. Controlled improvement in specific contact resistivity for thermoelectric materials by ion implantation. Appl. Phys. Lett., 2013, 103(4): 043902-1-4. |

| [31] | LIN W P, WESOLOWSKI D E, LEE C C.Barrier/bonding layers on bismuth telluride for high temperature thermoelectric modules.J. Mater. Sci.: Mater. Electron., 2011,22(9): 1313-1320. |

| [32] | IYORE O D.Interface Characterization of Contacts to Bulk Bismuth Telluride Alloys. Richardson, TX: University of Texas at Dallas, Master’s Thesis, UMI No. 1470835, 2009. |

| [33] | FENG H P, YU B, CHEN S,et al. Studies on surface preparation and smoothness of nanostructured Bi2Te3-based alloys by electrochemical and mechanical methods. Electrochimica Acta, 2011, 56(8): 3079-3084. |

| [34] | IYORE O D, LEE T H, GUPTA R P,et al. Interface characterization of nickel contact to bulk bismuth telluride selenide. Surf. Interface Analysis, 2009,41(5): 440-444. |

| [35] | WEINSTEIN M, MLAVSKY A I.Bonding of lead telluride to pure iron electrodes.Rev. Sci. Instrum., 1962, 33(10): 1119-1120. |

| [36] | SINGH A, BHATTACHARYA S, THINAHARAN C, ,et al. Development of low resistance electrical contacts for thermoelectric devices based on n-type PbTe and p-type TAGS-85 ((AgSbTe2)0.15(GeTe)0.85). J. Phys. D: Appl. Phys., 2008, 42(1): 015502- 1-6. |

| [37] | LEAVITT F A, MCCOY J W, MARUDHACHALAM P, ,et al. Segmented Thermoelectric Module with Bonded Legs. US Patent. Segmented Thermoelectric Module with Bonded Legs. US Patent, 2012/0103381 A1, 2012. |

| [38] | XIA H, DRYMIOTIS F, CHEN C L,et al. Bonding and high-temperature reliability of NiFeMo alloy/n-type PbTe joints for thermoelectric module applications. J. Mater. Sci., 2015, 50(7): 2700-2708. |

| [39] | XIA H, DRYMIOTIS F, CHEN C L,et al. Bonding and interfacial reaction between Ni foil and n-type PbTe thermoelectric materials for thermoelectric module applications. J. Mater. Sci., 2014, 49(4): 1716-1723. |

| [40] | XIA H, CHEN C L, DRYMIOTIS F,et al. Interfacial reaction between Nb foil and n-type PbTe thermoelectric materials during thermoelectric contact fabrication. J. Electro. Mater.,2014,43(11): 4064-4069. |

| [41] | ORIHASHI M, NODA Y, CHEN L,et al. Ni/n-PbTe and Ni/p-Pb0.5Sn0.5Te Joining by Plasma Activated Sintering. 17th International Conference on Thermoelectrics, Nagoya, 1998: 543-546. |

| [42] | FERRERES X R, YAMINI S A, NANCARROW M,et al. One-step bonding of Ni electrode to n-type PbTe — a step towards fabrication of thermoelectric generators. Materials and Design, 2016, 107: 90-97. |

| [43] | LI C C, DRYMIOTIS F, LIAO L L,et al. Interfacial reactions between PbTe-based thermoelectric materials and Cu and Ag bonding materials. J. Mater. Chem. C,2015, 3(40): 10590-10596. |

| [44] | GARCIA-CANADAS J, POWELL A V, KALTZOGLOU A,et al. Fabrication and evaluation of a skutterudite-based thermoelectric module for high-temperature applications. J. Electro. Mater., 2013, 42(7): 1369-1374. |

| [45] | FAN X C, GU M, SHI X,et al. Fabrication and reliability evaluation of Yb0.3Co4Sb12/Mo-Ti/Mo-Cu/Ni thermoelectric joints. Ceramics International, 2015, 41(6): 7590-7595. |

| [46] | SALVADOR J R, CHO J Y, YE Z,et al. Conversion efficiency of skutterudite-based thermoelectric modules. Phys. Chem. Chem. Phys., 2014, 16(24): 12510-12520. |

| [47] | FAN J F, CHEN L D, BAI S Q,et al. Joining of Mo to CoSb3 by spark plasma sintering by inserting a Ti interlayer. Materials Letters, 2004, 58(30): 3876-3878. |

| [48] | ZHAO D G, GENG H R, TENG X Y.Fabrication and reliabilityevaluation of CoSb3/W-Cu thermoelectric element.J. Alloys Compd., 2012, 517(7): 198-203. |

| [49] | ZHAO D G, LI X Y, JIANG W,et al. Fabrication of CoSb3/MoCu thermoelectric joint by one-step SPS and evaluation. Journal of Inorganic Materials, 2009, 24(3): 545-548. |

| [50] | GU M, XIA X G, LI X Y,et al. Microstructural evolution of the interfacial layer in the Ti-Al/Yb0.6Co4Sb12 thermoelectric joints at high temperature. J. Alloys Compd., 2014, 610: 665-670. |

| [51] | TANG Y S, BAI S Q, REN D D,et al. Interface structure and electrical property of Yb0.3Co4Sb12/Mo-Cu element prepared by welding using Ag-Cu-Zn solder. Journal of Inorganic Materials, 2015, 30(3): 256-260. |

| [52] | GU M, XIA X G, HUANG X Y, BAI S Q,et al. Study on the interfacial stability of p-type Ti/CeyFexCo4-xSb12 thermoelectric joints at high temperature. J. Alloys Compd., 2016, 671: 238-244. |

| [53] | CAILLAT T, FLEURIAL J P, SNYDER G J, et al. Development of High Efficiency Segmented Thermoelectric Unicouples. Proceedings of 20th Int. Conf. on Thermoelectrics, Beijing, 2001, 504(1): 282-285. |

| [54] | FLEURIAL J P, CAILLAT T, CHI S C.Electrical Contacts for Skutterudite Thermoelectric Materials.US Patent, 20120006376 A1, 2012. |

| [55] | GUO J Q, GENG H Y, OCHI T,et al. Development of skutterudite thermoelectric materials and modules. J. Electro. Mater., 2012, 41(6): 1036-1042. |

| [56] | MUTO A, YANG J, POUDEL B, et al. Skutterudite unicouple characterization for energy harvesting applications. Adv. Energy Mater., 2013, 3(2): 245-251. |

| [1] | 丁玲, 蒋瑞, 唐子龙, 杨运琼. MXene材料的纳米工程及其作为超级电容器电极材料的研究进展[J]. 无机材料学报, 2023, 38(6): 619-633. |

| [2] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [3] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [4] | 林俊良, 王占杰. 铁电超晶格的研究进展[J]. 无机材料学报, 2023, 38(6): 606-618. |

| [5] | 牛嘉雪, 孙思, 柳鹏飞, 张晓东, 穆晓宇. 铜基纳米酶的特性及其生物医学应用[J]. 无机材料学报, 2023, 38(5): 489-502. |

| [6] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [7] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [8] | 杨洋, 崔航源, 祝影, 万昌锦, 万青. 柔性神经形态晶体管研究进展[J]. 无机材料学报, 2023, 38(4): 367-377. |

| [9] | 游钧淇, 李策, 杨栋梁, 孙林锋. 氧化物双介质层忆阻器的设计及应用[J]. 无机材料学报, 2023, 38(4): 387-398. |

| [10] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| [11] | 张超逸, 唐慧丽, 李宪珂, 王庆国, 罗平, 吴锋, 张晨波, 薛艳艳, 徐军, 韩建峰, 逯占文. 新型GaN与ZnO衬底ScAlMgO4晶体的研究进展[J]. 无机材料学报, 2023, 38(3): 228-242. |

| [12] | 陈昆峰, 胡乾宇, 刘锋, 薛冬峰. 多尺度晶体材料的原位表征技术与计算模拟研究进展[J]. 无机材料学报, 2023, 38(3): 256-269. |

| [13] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [14] | 刘岩, 张珂颖, 李天宇, 周菠, 刘学建, 黄政仁. 陶瓷材料电场辅助连接技术研究现状及发展趋势[J]. 无机材料学报, 2023, 38(2): 113-124. |

| [15] | 谢兵, 蔡金峡, 王铜铜, 刘智勇, 姜胜林, 张海波. 高储能密度聚合物基多层复合电介质的研究进展[J]. 无机材料学报, 2023, 38(2): 137-147. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||