无机材料学报 ›› 2017, Vol. 32 ›› Issue (11): 1147-1153.DOI: 10.15541/jim20170050

郑金煌1, 李贺军1, 崔红1,2, 王毅2, 邓海亮2, 殷忠义2, 姚冬梅2, 苏红2

收稿日期:2017-01-22

修回日期:2017-03-19

出版日期:2017-11-20

网络出版日期:2017-10-20

作者简介:郑金煌(1973-), 男, 高级工程师. E-mail: zjh114@sohu.com

基金资助:ZHENG Jin-Huang1, LI He-Jun1, CUI Hong1,2, WANG Yi2, DENG Hai-Liang2, YIN Zhong-Yi2, YAO Dong-Mei2, SU Hong2

Received:2017-01-22

Revised:2017-03-19

Published:2017-11-20

Online:2017-10-20

摘要:

采用Design-expert软件设计预制体不同针刺成型参数组合试验, 研究预制体针刺成型参数对针刺碳/碳(C/C)复合材料拉伸强度的影响, 并构建了响应曲面数学模型, 实现对针刺C/C复合材料拉伸强度的优化与预测, 其模型显著性P=0.0206, 各试验实测值与预测值相对误差≤10.82%, 模型具有较高的拟合度。响应曲面回归分析表明: 针刺深度对拉伸强度有极显著影响, 针刺密度对拉伸强度有显著影响, 在本研究的针刺成型参数取值范围内, 拉伸强度的预测区间为42.31~91.87 MPa。通过模型优化出的针刺成型参数组合为: 针刺密度11 pin/cm2、针刺深度 11 mm、网胎面密度50 g/m2, 相应拉伸强度预测值为88.62 MPa, 验证值为90.71 MPa, 相对误差2.36%。

中图分类号:

郑金煌, 李贺军, 崔红, 王毅, 邓海亮, 殷忠义, 姚冬梅, 苏红. C/C复合材料拉伸强度与针刺成型参数相关性研究[J]. 无机材料学报, 2017, 32(11): 1147-1153.

ZHENG Jin-Huang, LI He-Jun, CUI Hong, WANG Yi, DENG Hai-Liang, YIN Zhong-Yi, YAO Dong-Mei, SU Hong. Relations between Needling Processing Parameters and Tensile Strength of C/C Composites[J]. Journal of Inorganic Materials, 2017, 32(11): 1147-1153.

| No. | X1 | X2 | X3 | Tensile strength /MPa |

|---|---|---|---|---|

| 1 | 8 | 10 | 100 | 89.80 |

| 2 | 16 | 16 | 100 | 47.30 |

| 3 | 12 | 13 | 100 | 87.56 |

| 4 | 16 | 13 | 50 | 69.44 |

| 5 | 12 | 10 | 150 | 86.72 |

| 6 | 12 | 13 | 100 | 90.00 |

| 7 | 16 | 13 | 150 | 83.70 |

| 8 | 8 | 13 | 50 | 74.13 |

| 9 | 16 | 10 | 100 | 72.83 |

| 10 | 12 | 16 | 50 | 61.46 |

| 11 | 12 | 13 | 100 | 79.66 |

| 12 | 8 | 13 | 150 | 82.73 |

| 13 | 12 | 13 | 100 | 93.10 |

| 14 | 12 | 16 | 150 | 73.90 |

| 15 | 12 | 13 | 100 | 80.73 |

| 16 | 12 | 10 | 50 | 89.00 |

| 17 | 8 | 16 | 100 | 70.96 |

表1 预制体针刺参数及拉伸强度试验结果

Table 1 Needling parameters and tested tensile strengths of C/C composites

| No. | X1 | X2 | X3 | Tensile strength /MPa |

|---|---|---|---|---|

| 1 | 8 | 10 | 100 | 89.80 |

| 2 | 16 | 16 | 100 | 47.30 |

| 3 | 12 | 13 | 100 | 87.56 |

| 4 | 16 | 13 | 50 | 69.44 |

| 5 | 12 | 10 | 150 | 86.72 |

| 6 | 12 | 13 | 100 | 90.00 |

| 7 | 16 | 13 | 150 | 83.70 |

| 8 | 8 | 13 | 50 | 74.13 |

| 9 | 16 | 10 | 100 | 72.83 |

| 10 | 12 | 16 | 50 | 61.46 |

| 11 | 12 | 13 | 100 | 79.66 |

| 12 | 8 | 13 | 150 | 82.73 |

| 13 | 12 | 13 | 100 | 93.10 |

| 14 | 12 | 16 | 150 | 73.90 |

| 15 | 12 | 13 | 100 | 80.73 |

| 16 | 12 | 10 | 50 | 89.00 |

| 17 | 8 | 16 | 100 | 70.96 |

| Source | Sum of squares | df | Mean square | F Value | P-value prob > F |

|---|---|---|---|---|---|

| Model | 1978.209000 | 9 | 219.800900 | 5.180009 | 0.0206 |

| X1 | 245.865300 | 1 | 245.865300 | 5.794263 | 0.0470 |

| X2 | 897.290700 | 1 | 897.290700 | 21.146290 | 0.0025 |

| X3 | 136.248800 | 1 | 136.248800 | 3.210950 | 0.1163 |

| X1X2 | 11.172310 | 1 | 11.172310 | 0.263296 | 0.6237 |

| X1X3 | 8.023056 | 1 | 8.023056 | 0.189078 | 0.6768 |

| X2X3 | 54.169600 | 1 | 54.169600 | 1.276605 | 0.2958 |

| X12 | 299.220600 | 1 | 299.220600 | 7.051679 | 0.0327 |

| X22 | 280.274500 | 1 | 280.274500 | 6.605179 | 0.0370 |

| X32 | 3.269901 | 1 | 3.269901 | 0.077061 | 0.7893 |

| Residual | 297.027800 | 7 | 42.432540 | - | - |

| Lack of Fit | 192.536200 | 3 | 64.178730 | 2.456799 | 0.2027 |

| Pure Error | 104.491600 | 4 | 26.122900 | - | - |

| Cor Total | 2275.236000 | 16 | - | - | - |

| R-Squared | 0.869500 | - | - | - | - |

| Adj R-Squared | 0.701600 | - | - | - | - |

表2 针刺C/C拉伸强度响应曲面模型回归方程及相关系数显著性分析表

Table 2 Analysis of signification for response surface model and its correlation coefficient of tensile strength

| Source | Sum of squares | df | Mean square | F Value | P-value prob > F |

|---|---|---|---|---|---|

| Model | 1978.209000 | 9 | 219.800900 | 5.180009 | 0.0206 |

| X1 | 245.865300 | 1 | 245.865300 | 5.794263 | 0.0470 |

| X2 | 897.290700 | 1 | 897.290700 | 21.146290 | 0.0025 |

| X3 | 136.248800 | 1 | 136.248800 | 3.210950 | 0.1163 |

| X1X2 | 11.172310 | 1 | 11.172310 | 0.263296 | 0.6237 |

| X1X3 | 8.023056 | 1 | 8.023056 | 0.189078 | 0.6768 |

| X2X3 | 54.169600 | 1 | 54.169600 | 1.276605 | 0.2958 |

| X12 | 299.220600 | 1 | 299.220600 | 7.051679 | 0.0327 |

| X22 | 280.274500 | 1 | 280.274500 | 6.605179 | 0.0370 |

| X32 | 3.269901 | 1 | 3.269901 | 0.077061 | 0.7893 |

| Residual | 297.027800 | 7 | 42.432540 | - | - |

| Lack of Fit | 192.536200 | 3 | 64.178730 | 2.456799 | 0.2027 |

| Pure Error | 104.491600 | 4 | 26.122900 | - | - |

| Cor Total | 2275.236000 | 16 | - | - | - |

| R-Squared | 0.869500 | - | - | - | - |

| Adj R-Squared | 0.701600 | - | - | - | - |

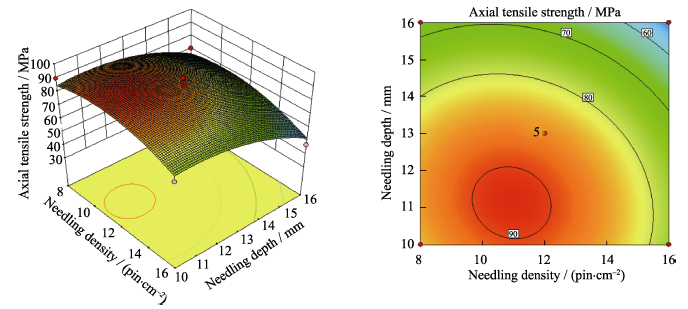

图1 针刺密度、针刺深度交互作用拉伸强度响应曲面及等高线图(网胎面密度100 g/m2)

Fig. 1 Response surface and contour of tensile strength influenced by the interaction of needling density and needling depth (The density of non-woven is 100 g/m2)

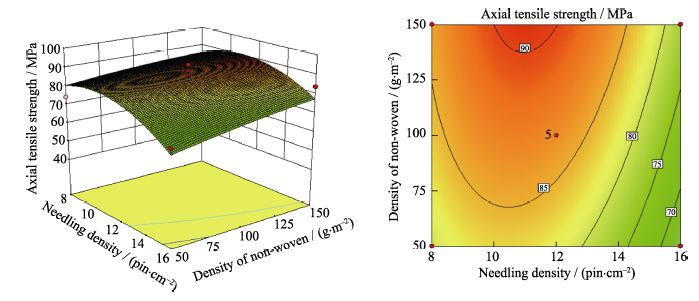

图2 针刺密度、网胎面密度交互作用拉伸强度响应曲面及等高线图(针刺深度13 mm)

Fig. 2 Response surface and contour of tensile strength influenced by the interaction of needling density and density of non-woven (The needling depth is 13 mm)

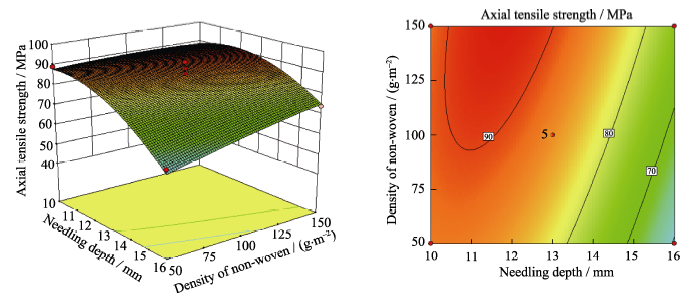

图3 针刺深度、网胎面密度交互作用拉伸强度响应曲面及等高线图(针刺密度12 pin/cm2)

Fig. 3 Response surface and contour of tensile strength influenced by interaction of needling depth and density of non-woven (The needling density is 12 pin/cm2)

| Actual value | Predicted value | Residual | Relative error |

|---|---|---|---|

| 89.80 | 84.684375 | 5.115625 | 5.70% |

| 72.83 | 76.939375 | -4.114375 | 5.65% |

| 70.96 | 66.845625 | 4.114375 | 5.80% |

| 47.30 | 52.415625 | -5.115625 | 10.82% |

| 74.13 | 80.331875 | -6.201875 | 8.37% |

| 69.44 | 66.411875 | 3.028125 | 4.36% |

| 82.73 | 85.753125 | -3.028125 | 3.66% |

| 83.70 | 77.498125 | 6.201875 | 7.41% |

| 89.00 | 87.913750 | 1.086250 | 1.22% |

| 61.46 | 59.372500 | 2.087500 | 3.40% |

| 86.72 | 88.807500 | -2.087500 | 2.41% |

| 73.90 | 74.986250 | -1.086250 | 1.47% |

| 90.00 | 86.810000 | 3.190000 | 3.54% |

| 87.56 | 86.810000 | 0.750000 | 0.86% |

| 82.66 | 86.810000 | -4.150000 | 5.02% |

| 80.73 | 86.810000 | -6.080000 | 7.53% |

| 93.10 | 86.810000 | 6.290000 | 6.76% |

表3 针刺C/C复合材料拉伸强度响应面拟合值与实际值的对照表

Table 3 Comparison of the fitting values of the fitting equation of response surface with the actual values

| Actual value | Predicted value | Residual | Relative error |

|---|---|---|---|

| 89.80 | 84.684375 | 5.115625 | 5.70% |

| 72.83 | 76.939375 | -4.114375 | 5.65% |

| 70.96 | 66.845625 | 4.114375 | 5.80% |

| 47.30 | 52.415625 | -5.115625 | 10.82% |

| 74.13 | 80.331875 | -6.201875 | 8.37% |

| 69.44 | 66.411875 | 3.028125 | 4.36% |

| 82.73 | 85.753125 | -3.028125 | 3.66% |

| 83.70 | 77.498125 | 6.201875 | 7.41% |

| 89.00 | 87.913750 | 1.086250 | 1.22% |

| 61.46 | 59.372500 | 2.087500 | 3.40% |

| 86.72 | 88.807500 | -2.087500 | 2.41% |

| 73.90 | 74.986250 | -1.086250 | 1.47% |

| 90.00 | 86.810000 | 3.190000 | 3.54% |

| 87.56 | 86.810000 | 0.750000 | 0.86% |

| 82.66 | 86.810000 | -4.150000 | 5.02% |

| 80.73 | 86.810000 | -6.080000 | 7.53% |

| 93.10 | 86.810000 | 6.290000 | 6.76% |

| Needling density /(pin·cm-2) | Needling depth/mm | Density of non-woven /(g·m-2) | Tensile strength /MPa | |

|---|---|---|---|---|

| Max | 11.17 | 11.79 | 150.00 | 91.87 |

| Min | 16.00 | 16.00 | 50.00 | 42.31 |

表4 拉伸强度取值范围

Table 4 Scope of tensile strength

| Needling density /(pin·cm-2) | Needling depth/mm | Density of non-woven /(g·m-2) | Tensile strength /MPa | |

|---|---|---|---|---|

| Max | 11.17 | 11.79 | 150.00 | 91.87 |

| Min | 16.00 | 16.00 | 50.00 | 42.31 |

| Needling density /(pin·cm-2) | Needling depth /mm | Density of non-woven /(g·m-2) | Tensile strength/ MPa | Relative error | |

|---|---|---|---|---|---|

| Predictive value | Actual value | ||||

| 11 | 12 | 50 | 86.72 | 83.53 | 3.68% |

| 11 | 11 | 50 | 88.62 | 90.71 | 2.36% |

| 12 | 11 | 50 | 87.69 | 85.23 | 2.28% |

| 12 | 12 | 50 | 85.65 | 88.64 | 3.49% |

表5 拉伸强度优化结果

Table 5 Optimization results of tensile strength

| Needling density /(pin·cm-2) | Needling depth /mm | Density of non-woven /(g·m-2) | Tensile strength/ MPa | Relative error | |

|---|---|---|---|---|---|

| Predictive value | Actual value | ||||

| 11 | 12 | 50 | 86.72 | 83.53 | 3.68% |

| 11 | 11 | 50 | 88.62 | 90.71 | 2.36% |

| 12 | 11 | 50 | 87.69 | 85.23 | 2.28% |

| 12 | 12 | 50 | 85.65 | 88.64 | 3.49% |

| [1] | FITZER E, MANOCHA L M.Carbon Reinforcements and Carbon/Carbon Composites. Germany: Springer-verlag Berlin Heidelberg GmbH&Co.K ,1998: 71-95. |

| [2] | MOURITZ A P, BANNISTER M K, FALZON P J,et al. Review of applications for advanced three-dimensional fibre textile composites. Composites: Part A, 1999, 30: 1445-1461. |

| [3] | FAWCETT R, HORNICK J, BACKLUND D, et al. Advanced 3rd Stage Carbon-Carbon Exit Cone. AIAA 2008-4888, 2008. |

| [4] | CHEN XIAO-MING, CHEN LI, ZHANG CHUN-YAN,et al. Three-dimensional needle-punching for composites - A review. Composites: Part A, 2016, 85: 12-30. |

| [5] | RUSSELL A ELLIS.Testing of Novoltex 3D Carbon-Carbon Integral Throat and Cones (ITECs). AIAA-88-3361, 1988. |

| [6] | MONTAUDON M.Arine 5 Carbon-Carbon Nozzle Throat: Development Result. AIAA95-3016, 1995. |

| [7] | BROQUERE B H.Carbon/Carbon Nozzle Exit Cones: SEP’s Experience and New Development. AIAA97-2674, 1997. |

| [8] | BOURY D, FILIPUZZL L.Sepcarb Materials For Solid Rocket Booster Nozzle Components. AIAA 01-3438, 2001. |

| [9] | LACOMBE A, PICHON T, Lacostet M.3D Novoltex and Naxeco Carbon-Carbon Nozzle Extensions: Matured, Industrial and Available Technologies to Reduce Programmatic and Technical Risks and to Increase Performance of Launcher Upper Stage Engines. AIAA 2008-5236, 2008. |

| [10] | LACOMBE A, PICHON T, LACOSTET M.3D Carbon-Carbon Composites are Revolutionizing Upper Stage Liquid Rocket Engine Performances by Allowing Introduction of Large Nozzle Extension. AIAA 2009-2678, 2009. |

| [11] | SU JUN-MING, XIAO ZHI-CHAO, LIU YONG-QIONG,et al. Preparation and characterization of carbon/carbon aircraft brake materials with long service life and good frictional properties. New Carbon Materials, 2010, 25(5): 329-334. |

| [12] | SU JUN-MING, ZHOU SHAO-JIAN, LI RUI-ZHEN,et al. A rewiew of carbon-carbon composites for engineering applications. New Carbon Materials, 2015, 30(2): 107-114. |

| [13] | LI FEI, LIU JIAN-JUN, CHENG WEN,et al. Effect of technology parameters on mechanical performances of C/C composites needling fabrication. Carbon, 2004, (1): 25-27. |

| [14] | JI A-LIN, CUI HONG, LI HE-JUN,et al. Perfomance analysis of a carbon cloth/felt layer needled preform. New Carbon Materials. 2011, 26(2): 11-18. |

| [15] | JI A-LIN, LI HE-JUN, CUI HONG,et al. Axial thermodynamic performance analysis of the different preform C/C composites. Journal of Inorganic Materials, 2010, 09(25): 995-998. |

| [16] | ZHANG XIAO-HU, LI HE-JUN, HAO ZHI-BIAO,et al.Influence of needle-punching processing on mechanical properties of C/C composites reinforced by carbon cloth and carbon fiber net. Journal of Inorgnic Materials. 2007, 22(5): 963-967. |

| [17] | SU JUN-MING, CUI HONG, LI RUI-ZHEN,et al. The structure and property of new needle carbon cloth C/C composite. New Carbon Materials, 2000, 15(2): 11-15. |

| [18] | 徐向宏, 何明珠. 试验设计与Design-Expert、SPSS应用. 北京: 科学出版社, 2010: 146-157. |

| [19] | GEORGIOU S D, STYLIANOU S, AGGARWAL M.A class of composite designs for response surface methodology.Computational Statistics and Data Analysis, 2014, 71: 1124-1133. |

| [20] | ADELEKE A O, LATIFF A B AZIZ A B, AL-GHEETHI A A,et al. Optimization of operating parameters of novel composite adsorbent for organic pollutants removal from POME using response surface methodology. Chemosphere, 2017, 174: 232-242. |

| [21] | THAKRE A A, SONI S.Modeling of burr size in drilling of aluminum silicon carbide composites using response surface methodology.Engineering Science and Technology, 2016, 19: 1199-1205. |

| [22] | BOROOJ M BAGHERY, SHOUSHTARI M AHMAD, HAJI AMINODDIN,et al. Optimization of plasma treatment variables for the improvement of carbon fibres/epoxy composite performance by response surface methodology. Composites Science and Technology, 2016, 128: 215-221. |

| [23] | XU YING, LI MING-LI, ZHAO XUAN-MIN,et al. The response curved surface regression analysis technique - the application of a new regression analysis technique in materials research. Rare Metal Materials and Engineering, 2001, 30(6): 428-432. |

| [1] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [2] | 张爱梅, 朱佳佳, 方天诚, 潘茜茜. Al3+掺杂对La0.8Sr0.2Mn1-xAlxO3电输运性能的影响[J]. 无机材料学报, 2023, 38(2): 148-154. |

| [3] | 陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162. |

| [4] | 孙铭, 邵溥真, 孙凯, 黄建华, 张强, 修子扬, 肖海英, 武高辉. RGO/Al复合材料界面性质第一性原理研究[J]. 无机材料学报, 2022, 37(6): 651-659. |

| [5] | 王路平, 卢占会, 魏鑫, 方明, 王祥科. 改进的灰色模型在光催化数据预测中的应用[J]. 无机材料学报, 2021, 36(8): 871-876. |

| [6] | 冯明星, 王斌, 徐鹏宇, 涂兵田, 王皓. 基于键价模型的MgAl2O4透明陶瓷热机械性能预测[J]. 无机材料学报, 2021, 36(10): 1067-1073. |

| [7] | 吴小军,杨杰,郑蕊,张兆甫,杨毅. 烧蚀型面结构对CVI+HPIC工艺制备针刺C/C喉衬等离子烧蚀性能的影响[J]. 无机材料学报, 2020, 35(6): 654-660. |

| [8] | 胡丽芳,刘柳,何杰,孙志鹏,陈小平. Ni-Ti-LDHs纳米片对阿司匹林的负载与缓释[J]. 无机材料学报, 2020, 35(2): 165-172. |

| [9] | 邵笑,刘睿恒,王亮,初靖,白光辉,柏胜强,顾明,张丽娜,马伟,陈立东. 服役条件下方钴矿基热电元件的界面应力分析[J]. 无机材料学报, 2020, 35(2): 224-230. |

| [10] | 皮慧龙, 张宝鹏, 于新民, 刘伟, 金鑫. 二维C/SiC-ZrC复合材料的低速冲击损伤研究[J]. 无机材料学报, 2020, 35(12): 1327-1332. |

| [11] | 刘宇峰, 俸翔, 王金明, 许正辉, 李同起, 焦星剑, 王雅雷, 熊翔. 高性能针刺碳/碳复合材料的制备与性能[J]. 无机材料学报, 2020, 35(10): 1105-1111. |

| [12] | 王亚楠, 李华, 王正坤, 厉青峰, 练晨, 何鑫. 扩散应力诱导的锂离子电池失效机理研究进展[J]. 无机材料学报, 2020, 35(10): 1071-1087. |

| [13] | 黄烨琰, 徐凯, 吴波, 李朋, 常可可, 黄峰, 黄庆. 亚稳相图研究及其在特种陶瓷涂层中的应用进展[J]. 无机材料学报, 2020, 35(1): 19-28. |

| [14] | 张丽艳, 李洪, 胡丽丽, 王亚杰. 玻璃成分-结构-性质的“基因结构”模拟法[J]. 无机材料学报, 2019, 34(8): 885-892. |

| [15] | 李荣辉, 郏义征, 胡楠楠. 三维层级花状活性氧化铝纳米材料的制备及其除砷性能研究[J]. 无机材料学报, 2019, 34(5): 553-559. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||