无机材料学报 ›› 2017, Vol. 32 ›› Issue (8): 837-844.DOI: 10.15541/jim20160628

辛 晨1, 齐 鑫2, 朱 敏1, 赵世昌2, 朱钰方1

收稿日期:2016-11-15

修回日期:2016-12-21

出版日期:2017-08-15

网络出版日期:2017-07-19

作者简介:辛 晨(1990–), 男, 硕士研究生. E-mail: xinchen517@163.com

基金资助:XIN Chen1, QI Xin2, ZHU Min1, ZHAO Shi-Chang2, ZHU Yu-Fang1

Received:2016-11-15

Revised:2016-12-21

Published:2017-08-15

Online:2017-07-19

About author:XIN Chen. E-mail: xinchen517@163.com

Supported by:摘要:

利用三维打印技术成功制备羟基磷灰石晶须(HAPw)增强的聚己内酯(PCL)复合骨修复支架。通过改变三维打印的挤出速度和挤出气压, 使不同含量HAPw均能在PCL基材中一致排列并均匀分布。PCL支架的机械强度随HAPw含量增加显著提高, 添加33wt%HAPw使PCL支架强度提升了高达3倍。此外, HAPw使PCL支架表面与水的接触角从近100º降低至约50º, 有效改善了细胞表面粘附。经过体外人类骨髓间充质干细胞(hBMSC)在支架上的培养实验, 发现添加HAPw的复合支架具有更好的生物相容性, 能够有效促进hBMSC的增殖生长, 且HAPw-PCL复合支架上细胞具有更高的碱性磷酸酶(ALP)活性和OCN、RUNX2等相关成骨基因表达, 显示出hBMSCs向成骨方向更好的分化及成骨活性。

中图分类号:

辛 晨, 齐 鑫, 朱 敏, 赵世昌, 朱钰方. 三维打印羟基磷灰石晶须增强复合骨修复支架[J]. 无机材料学报, 2017, 32(8): 837-844.

XIN Chen, QI Xin, ZHU Min, ZHAO Shi-Chang, ZHU Yu-Fang. Hydroxyapatite Whisker-reinforced Composite Scaffolds Through 3D Printing for Bone Repair[J]. Journal of Inorganic Materials, 2017, 32(8): 837-844.

| Samples | HAPw /g | HAPnp /g | PCL /g | CHCl3 /mL | DMSO /mL |

|---|---|---|---|---|---|

| HAPnp-2PCL | 0 | 0.5 | 1 | 3.8 | 0.2 |

| HAPw-2PCL | 0.5 | 0 | 1 | 3.8 | 0.2 |

| HAPw-5PCL | 0.2 | 0 | 1 | 3.8 | 0.2 |

| HAPw-10PCL | 0.1 | 0 | 1 | 3.8 | 0.2 |

| PCL | 0 | 0 | 1 | 3.8 | 0.2 |

表1 复合支架编号及打印浆料组成

Table1 Composite scaffold number and composition of printing paste

| Samples | HAPw /g | HAPnp /g | PCL /g | CHCl3 /mL | DMSO /mL |

|---|---|---|---|---|---|

| HAPnp-2PCL | 0 | 0.5 | 1 | 3.8 | 0.2 |

| HAPw-2PCL | 0.5 | 0 | 1 | 3.8 | 0.2 |

| HAPw-5PCL | 0.2 | 0 | 1 | 3.8 | 0.2 |

| HAPw-10PCL | 0.1 | 0 | 1 | 3.8 | 0.2 |

| PCL | 0 | 0 | 1 | 3.8 | 0.2 |

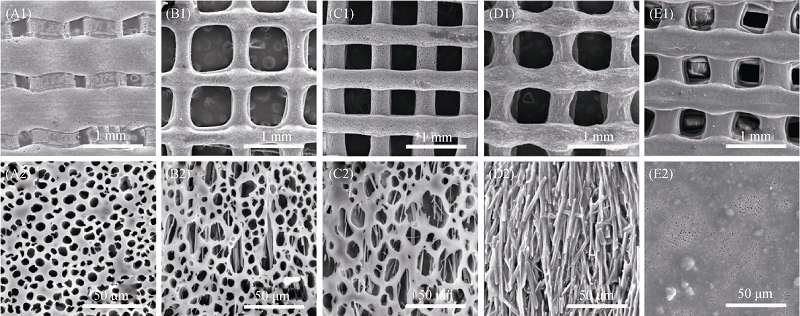

图3 三维打印的PCL(A1, A2), HAPw-10PCL(B1, B2), HAPw-5PCL(C1, C2), HAPw-2PCL(D1, D2)和HAPnp-2PCL支架的SEM照片

Fig. 3 SEM images of 3D-printed PCL(A1,A2), HAPw-10PCL (B1,B2), HAPw-5PCL (C1,C2), HAPw-2PCL (D1,D2) and HAPnp-2PCL scaffolds

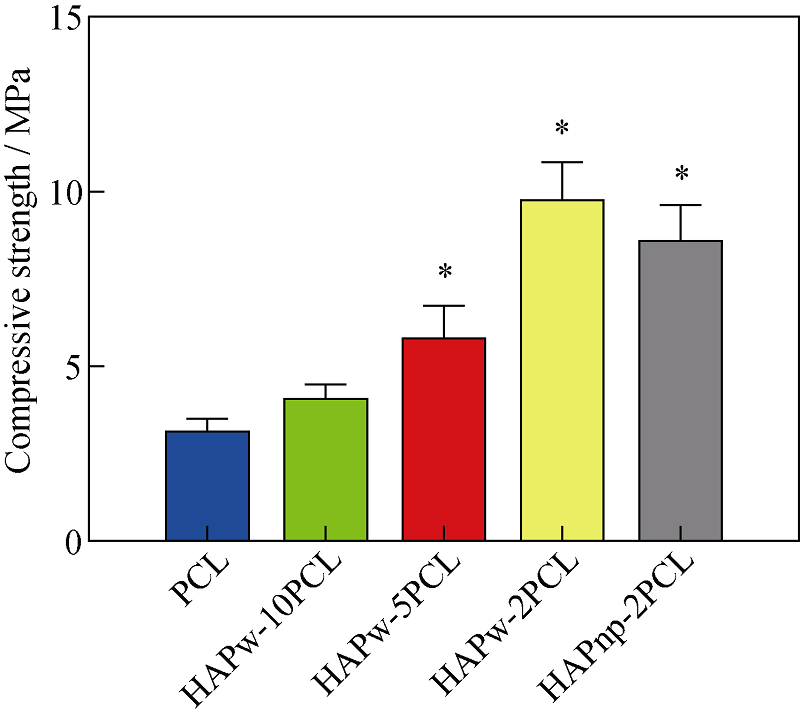

图5 PCL、HAPnp-PCL和HAPw-PCL 支架的抗压能力测试结果

Fig. 5 Compressive strength of the PCL, HAPw-PCL and HAPnp-PCL scaffold(*p<0.05 if compared with the PCL scaffold control)

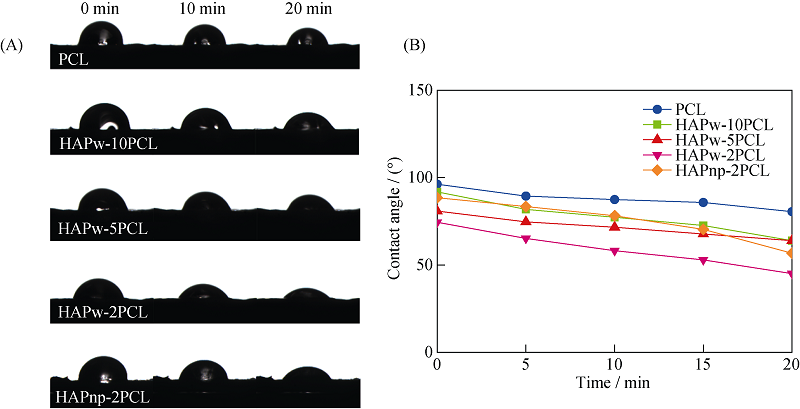

图6 (A) PCL, HAPw-10PCL, HAPw-5PCL, HAPw-2PCL和 HAPnp-2PCL复合支架表面水滴在不同时间(0、10、20 min)的状态, (B)复合支架表面接触角室内空气下随时间的变化

Fig. 6 (A) Water contact angle of PCL scaffolds (first panel), HAPw-10PCL scaffolds (second panel), HAPw-5PCL scaffolds (third panel), HAPw-2PCL scaffolds (fourth panel), and HAPnp-2PCL. Ascending contact angles measured at varying times (0, 10, and 20 min), and (B) quantification of the contact angle with time

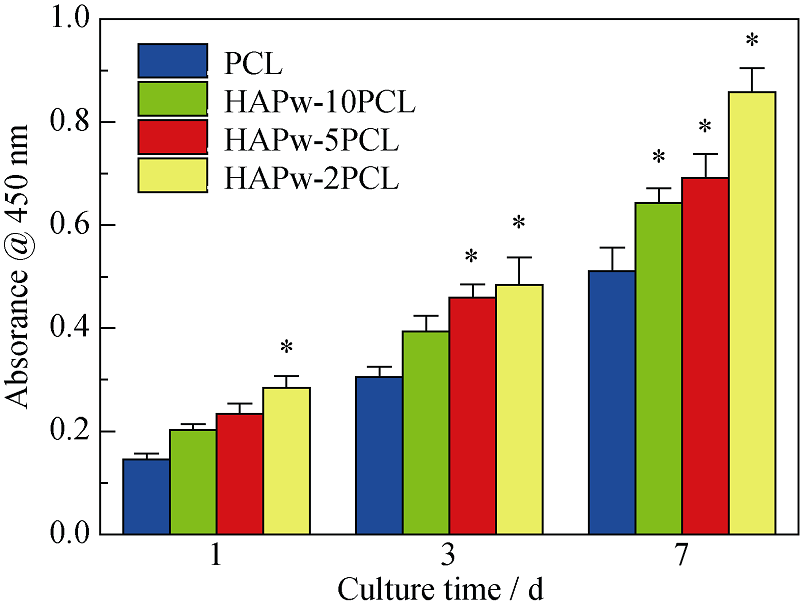

图7 hBMSCs在PCL 和HAPw-PCL 复合支架上培养1、3、7 d后的细胞增殖情况

Fig. 7 Proliferation of hBMSCs on the PCL and HAPw-PCL scaffolds for 1, 3 and 7 d (*p<0.05 if compared with the PCL scaffold control)

图8 hBMSCs在PCL 和HAPw-PCL 复合支架上培养7、14 d后的碱性磷酸酶活性结果

Fig. 8 ALP activity of hBMSCs cultured on PCL and HAPw-PCL scaffolds for 7 and 14 d (*p<0.05 if compared with the PCL scaffold control)

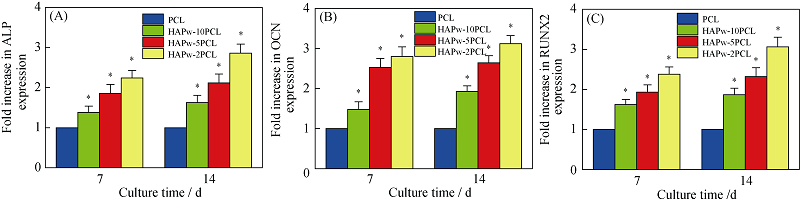

图9 hBMSCs在HAPw-PCL复合支架上培养7 d和14 d后的相关成骨基因表达(ALP(A), RUNX2(B), OCN(C))

Fig. 9 Osteogenic expression of ALP (A), OCN (B), RUNX2 (C) for hBMSCs cultured on the PCL and HAPw-PCL scaffolds by qRT-PCR analysis after 7 d and 14 d (*p < 0.05 if compared with the PCL scaffold control)

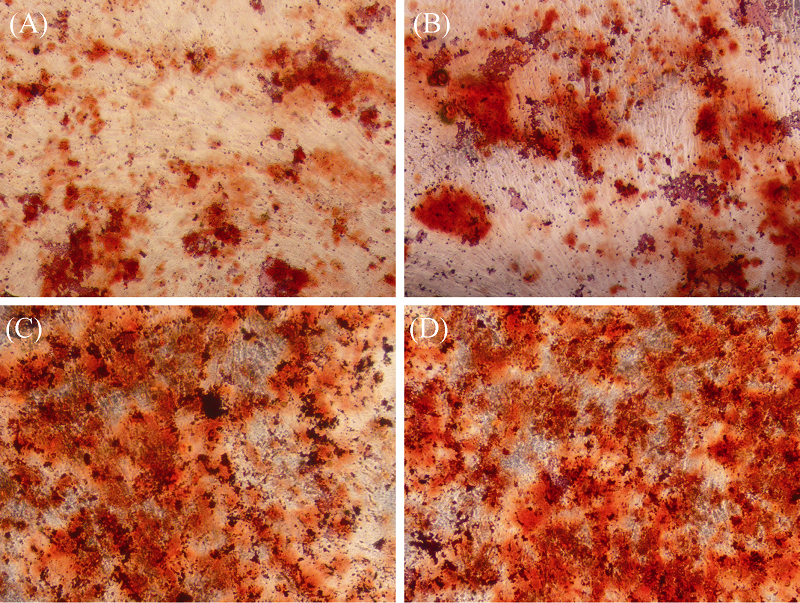

图10 hBMSCs 在PCL(A)、HAPw-10PCL (B)、HAPw-5PCL (C) 和 HAPw-2PCL (D)支架上培养21d后的ECM矿化情况

Fig. 10 ECM mineralization of hBMSCs on the PCL(A), HAPw-10PCL (B), HAPw-5PCL (C) and HAPw-2PCL (D) scaffolds after culturing for 21 d

| [1] | CRANE G M, LSHAUG S L, MIKOS A G, et al.Bone Tissue Engineering.Nature Medicine, 1995, 1(12): 1322-1324. |

| [2] | NAIR L S, LAURENCIN C T.Biodegradable polymers as biomaterials.Progress in Polymer Science, 2007, 32(8): 762-798. |

| [3] | YUN H S, KIM S E, PARK E K.Bioactive glass-poly (ε-caprolactone) composite scaffolds with 3 dimensionally hierarchical pore networks.Materials Science and Engineering C, 2011, 31(2): 198-205. |

| [4] | ZHU N, LI M G, COOPER D, et al.Development of novel hybrid poly (L-lactide)/chitosan scaffolds using the rapid freeze prototyping technique.Biofabrication, 2011, 3(3): 390-395. |

| [5] | ZHANG J H, ZHAO S C, ZHU Y F, et al.Three dimensional printing of strontium-containing mesoporous bioactive glass scaffolds for bone regeneration.Acta Biomaterialia, 2014, 10(5): 2269-2281. |

| [6] | DOROZHKIN S V.Bioceramics of calcium orthophosphates.Biomaterials, 2010, 31(7): 1465-1485. |

| [7] | SANTOS C, LUKLINSKA Z B, CLARKE R L, et al.Hydroxyapatite as a filler for dental composite materials: mechanical properties and in vitro bioactivity of composites.Journal of Materials Science: Materials in Medicine, 2001, 12(7): 565-573. |

| [8] | ZHANG H, DARVELL B W.Mechanical properties of hydroxyapatite whisker-reinforced bis-GMA-based resin composites.Dental Materials Official Publication of the Academy of Dental Materials, 2012, 28(8): 824-830. |

| [9] | GAO W M, RUAN C X, CHEN Y F.Effects of hydroxyapatite morphology on the mechanical strength of hydroxyapatite- polyanhydride composites. Journal of Materials Science & Engineering, 2006, 24(5): 636-646. |

| [10] | KANE R J, CONVERSE G L, ROEDER R K.Effects of the reinforcement morphology on the fatigue properties of hydroxyapatite reinforced polymers.Journal of the Mechanical Behavior of Biomedical Materials, 2008, 1(3): 261-268. |

| [11] | ZHANG H Q, DARVELL B W.Failure and behavior in water of hydroxyapatite whisker-reinforced bis-GMA-based resin composites.Journal of the Mechanical Behavior of Biomedical Materials, 2012, 10(6): 39-47. |

| [12] | CONVERSE G L, YUE W, ROEDER R K.Processing and tensile properties of hydroxyapatite whisker reinforced polyetheretherketone.Biomaterials, 2007, 28(6): 927-935. |

| [13] | HU H, XU G, ZAN Q, et al.In situ formation of nano hydroxyapatite whisker reinforced porous β-TCP scaffolds.Microelectronic Engineering, 2012, 98: 566-569. |

| [14] | JANSEN E J, SLADEK R E, BAHAR H, et al.Hydrophobicity as a design criterion for polymer scaffolds in bone tissue engineering.Biomaterials, 2005, 26(21): 4423-4431. |

| [15] | WHANG K, GOLDSTICK T K, HEALY K E.A biodegradable polymer scaffold for delivery of osteotropic factors.Biomaterials, 2000, 21(24): 2545-2551. |

| [16] | WU C, ZHOU Y, XU M, et al.Copper-containing mesoporous bioactive glass scaffolds with multifunctional properties of angiogenesis capacity, osteostimulation and antibacterial activity.Biomaterials, 2013, 34(2): 422-433. |

| [17] | PARK S A, LEE S H, KIM W D.Fabrication of porous polycaprolactone/hydroxyapatite (PCL/HA) blend scaffolds using a 3D plotting system for bone tissue engineering.Bioprocess and Biosystems Engineering, 2011, 34(4): 505-513. |

| [18] | SHI G Q.Individualized artificial knee joint design and manufacturing based on CAD software.Journal of University of Shanghai for Science and Technology, 2013, 35(1): 82-86. |

| [19] | CIOCCA L, DE CF, FANTINI M, et al.CAD/CAM and rapid prototyped scaffold construction for bone regenerative medicine and surgical transfer of virtual planning: a pilot study.Computerized Medical Imaging & Graphics, 2009, 33(1): 58-62. |

| [20] | MATSUBARA T, SUARDITA K, ISHII M, et al.Alveolar bone marrow as a cell source for regenerative medicine: differences between alveolar and iliac bone marrow stromal cells.Journal of Bone and Mineral Research, 2005, 20(3): 399-409. |

| [21] | ASSA S, LARON Z.Preparation and characterization of dense nanohydroxyapatite/PLLA composites.Materials Science and Engineering C, 2009, 29(1): 172-177. |

| [22] | HAYATI A N, HOSSEINALIPOUR S M, REZAIE H R, et al.Characterization of poly(3-hydroxybutyrate)/nano-hydroxyapatite composite scaffolds fabricated without the use of organic solvents for bone tissue engineering applications.Materials Science & Engineering C, 2012, 32(3): 416-422. |

| [23] | ZHANG R Y, MA P X.Poly(α-hydroxyl acids)/hydroxyapatite porous composites for bone-tissue engineering. I. Preparation and morphology.Journal of Biomedical Materials Research Part A, 1999, 44(4): 446-455. |

| [24] | FLEISCHER S, SHAPIRA A, REGEV O, et al.Albumin Fiber Scaffolds for Engineering Functional Cardiac Tissues.Biotechnology and Bioengineering, 2014, 11(6): 1246-1257. |

| [25] | HUTMACHER D W.Scaffolds in tissue engineering bone and cartilage.Biomaterials, 2001, 21(24): 2529-2543. |

| [26] | BOMBONATO-PRADO K, BELLESINI L C, MARQUES M, et al.Microarray-based gene expression analysis of human osteoblasts in response to different biomaterials.Journal of Biomedical Materials Research Part A, 2009, 88(2): 401-408. |

| [27] | SOHN S H, JUN H K, KIM C S, et al.Biological responses in osteoblast-like cell line according to thin layer hydroxyapatite coatings on anodized titanium.Journal of Oral Rehabilitation, 2006, 33(12): 898-911. |

| [28] | HUANG Y C, HSIAO P C, CHAI H J.Hydroxyapatite extracted from fish scale: effects on MG63 osteo6last-like cells.Ceramics International, 2011, 37(6): 1825-1831. |

| [29] | LIU Y K, WANG G C, CAI Y R, et al.In vitro effects of nanophase hydroxyapatite particles on proliferation and osteogenic differentiation of bone marrow-derived mesenchymal stem cells.Journal of Biomedical Materials Research Part A. 2009, 90(4): 1083-1091. |

| [30] | BABISTER J C, HAILS L A, OREFFO R O, et al.The effect of pre-coating human bone marrow stromal cells with hydroxyapatite/ amino acid nanoconjugates on osteogenesis.Biomaterials, 2009, 30(18): 3174-3182. |

| [31] | LUO E, LIU X, WEI S C, et al.Osteoblast adhesion to clodronate- hydroxyapatite composite.Applied Surface Science, 2008, 255(2): 308-311. |

| [32] | DIMITRIEVSKA S, BUREAU MN, ANTONIOU J, et al.Titanic- hydroxyapatite nanocomposite coatings support human mesenchymal stem cells osteogenic differentiation.Journal of Biomedical Materials Research Part A, 2011, 98(4): 576-588. |

| [33] | ZHAO H, DONG W, ZHENG Y, et al.The structural and biological properties of hydroxyapatite-modified titanate nanowire scaffolds.Biomaterials, 2011, 32(25): 5837-5846. |

| [34] | HU Q H, TAN Z, LIU Y K, et al.Effect of crystallinity of calcium phosphate nanoparticles on adhesion proliferation, and differentiation of bone marrow mesenchymal stem cells.Journal of Materials Chemistry, 2007, 17(44): 4690-4698. |

| [35] | LI Y, MA T, YANG S T, et al.Thermal compression and characterization of three-dimensional nonwoven PET matrices as tissue engineering scaffolds.Biomaterials, 2001, 22(6): 609-618. |

| [36] | MURPHY C M, HAUGH M G, O’BRIEN F J. The effect of mean pore size on cell attachment, proliferation and migration in collagen glycosaminoglycan scaffolds for bone tissue engineering.Biomaterials, 2010, 31(3): 461-466. |

| [37] | HU H T, XU G H, ZAN Q F.In situ formation of nano-hydroxyapatite whisker reinfoced porous b-TCP scaffolds.Microelectronic Engineering, 2012, 98: 566-569. |

| [1] | 施吉翔, 翟东, 朱敏, 朱钰方. 生物活性玻璃-二氧化锰复合支架的制备与表征[J]. 无机材料学报, 2022, 37(4): 427-435. |

| [2] | 张航, 韩坤原, 董兰兰, 李祥. DLP打印β-磷酸三钙/纳米黏土复合支架的制备与表征[J]. 无机材料学报, 2022, 37(10): 1116-1122. |

| [3] | 吴重草, 郇志广, 朱钰方, 吴成铁. 3D打印HA微球支架的制备与表征[J]. 无机材料学报, 2021, 36(6): 601-607. |

| [4] | 董少杰,王旭东,沈国芳,王晓虹,林开利. 生物陶瓷支架的功能改性及应用研究进展[J]. 无机材料学报, 2020, 35(8): 867-881. |

| [5] | 傅声扬, 俞斌, 丁惠锋, 石国栋, 朱钰方. 二氧化锆掺入对三维打印的硅酸二钙支架物理化学和生物学性能的影响[J]. 无机材料学报, 2019, 34(4): 444-454. |

| [6] | 陈希亮, 陈庆华, 庄颖, 颜廷亭. KGM/明胶/nano HAP椎间盘纤维环组织工程支架的制备与研究[J]. 无机材料学报, 2018, 33(1): 60-66. |

| [7] | 肖 雯, 刘玉梅, 任凯歌, 匙 峰, 李 焰, 智 伟, 翁 杰, 屈树新. 利用鸡胚模型半体内评价多孔磷酸钙骨修复材料血管化的研究[J]. 无机材料学报, 2017, 32(6): 649-654. |

| [8] | 李 根, 李炯炯, 李丽梅, 蒋佳兴, 李玉宝, 李吉东. 原位自发泡制备磷酸钙/聚氨酯复合骨修复支架[J]. 无机材料学报, 2016, 31(7): 719-725. |

| [9] | 王泉翔, 邬迎阳, 董谢平, 马旭辉, 魏 杰. 磷酸镁/PBS/小麦蛋白复合骨修复材料[J]. 无机材料学报, 2015, 30(9): 957-962. |

| [10] | 黄 萍, 李 鹏, 赵军胜, 屈树新, 冯 波, 翁 杰. 机械活化增强多孔磷酸钙骨水泥支架的研究[J]. 无机材料学报, 2015, 30(4): 432-438. |

| [11] | 罗品风, 智 伟, 张静微, 匙 峰, 段 可, 汪建新, 鲁 雄, 翁 杰. 基于Micro-CT不同多孔结构陶瓷支架的建模及其贯通性与液流分布分析[J]. 无机材料学报, 2015, 30(1): 71-76. |

| [12] | 巩梦安, 饶群力, 王鸿烈. 造孔剂和发泡剂结合法制备氟化羟基磷灰石多孔支架研究[J]. 无机材料学报, 2014, 29(3): 289-293. |

| [13] | 李 波, 徐文峰, 廖晓玲. 磷酸钙微球骨修复材料研究进展[J]. 无机材料学报, 2014, 29(10): 1009-1017. |

| [14] | 李丽梅, 左 奕, 杜晶晶, 李吉东, 孙 斌, 李玉宝. 醇化改性蓖麻油基聚氨酯/n-HA复合支架材料的结构及力学性能[J]. 无机材料学报, 2013, 28(8): 811-817. |

| [15] | 吴成铁, 常 江. 硅酸盐生物活性陶瓷用于骨组织修复及再生的研究[J]. 无机材料学报, 2013, 28(1): 29-39. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||