无机材料学报 ›› 2017, Vol. 32 ›› Issue (7): 731-738.DOI: 10.15541/jim20160550

谢雨洲1, 彭超群1, 王小锋1, 王日初1, 罗 丰2

收稿日期:2016-10-08

修回日期:2016-12-23

出版日期:2017-07-20

网络出版日期:2017-06-23

作者简介:谢雨洲(1991–), 男, 硕士研究生. E-mail: 447109919@qq.com

基金资助:XIE Yu-Zhou1, PENG Chao-Qun1, WANG Xiao-Feng1, WANG Ri-Chu1, LUO Feng2

Received:2016-10-08

Revised:2016-12-23

Published:2017-07-20

Online:2017-06-23

About author:XIE Yu-Zhou. E-mail: 447109919@qq.com

Supported by:摘要:

采用HEMA-TBA凝胶体系制备具有高气孔率, 高强度的多孔氧化铝陶瓷, 研究多孔氧化铝陶瓷的浆料和坯体制备工艺, 并系统研究了分散剂含量和固相体积分数对浆料粘度和悬浮稳定性的影响、干燥和单体含量对生坯性能的影响以及固相体积分数和烧结温度对烧结体微观结构的影响。结果表明: 加入柠檬酸可以使浆料粘度降低, 稳定性提高, 柠檬酸加入量达到2wt%后浆料粘度和稳定性趋于稳定; 固相体积分数的增加会导致浆料粘度和稳定性的增加; 生坯在干燥过程中的收缩比水基体系小很多, 干燥时间也相对更短; 单体含量对生坯强度影响较大, 当单体含量为25wt%时, 生坯强度较高; 通过选择不同的固相体积分数和烧结温度, 可以有效地控制烧结体的微观结构, 气孔率的变化范围在40%~65%, 同时烧结体强度也会随之发生变化, 变化范围在5.7~91.2 MPa。

中图分类号:

谢雨洲, 彭超群, 王小锋, 王日初, 罗 丰. HEMA-TBA凝胶体系制备多孔氧化铝陶瓷[J]. 无机材料学报, 2017, 32(7): 731-738.

XIE Yu-Zhou, PENG Chao-Qun, WANG Xiao-Feng, WANG Ri-Chu, LUO Feng. Porous Alumina Ceramic Prepared by HEMA-TBA Gelcasting System[J]. Journal of Inorganic Materials, 2017, 32(7): 731-738.

| Name | Abbreviation | Purity | Manufacture |

|---|---|---|---|

| Tert-butanol | TBA | AR | Shanghai Chemical Reagent Co. |

| 2-hydroxyethyl methacrylate | HEMA | AR | Shanghai Chemical Reagent Co. |

| Methylene-bis-acrylamide | MBAM | AR | Shanghai Chemical Reagent Co. |

| Benzoyl peroxide | BPO | AR | Shanghai Chemical Reagent Co. |

| N, N-dimethylaniline | DMA | AR | Shanghai Chemical Reagent Co. |

| Citric acid | C6H6O7 | AR | Shanghai Chemical Reagent Co. |

| Acetic acid | C2H4O2 | AR | Shanghai Chemical Reagent Co. |

| Alumina | α-Al2O3 | 99.8% | Henan Jiyuan Brother Material Co. |

表1 实验原料的来源和纯度

Table 1 Manufacture and purity of the raw materials

| Name | Abbreviation | Purity | Manufacture |

|---|---|---|---|

| Tert-butanol | TBA | AR | Shanghai Chemical Reagent Co. |

| 2-hydroxyethyl methacrylate | HEMA | AR | Shanghai Chemical Reagent Co. |

| Methylene-bis-acrylamide | MBAM | AR | Shanghai Chemical Reagent Co. |

| Benzoyl peroxide | BPO | AR | Shanghai Chemical Reagent Co. |

| N, N-dimethylaniline | DMA | AR | Shanghai Chemical Reagent Co. |

| Citric acid | C6H6O7 | AR | Shanghai Chemical Reagent Co. |

| Acetic acid | C2H4O2 | AR | Shanghai Chemical Reagent Co. |

| Alumina | α-Al2O3 | 99.8% | Henan Jiyuan Brother Material Co. |

| Solid loading | Shrinkage |

|---|---|

| 5% | 9.2%-10.1% |

| 10% | 5.1%-6.3% |

| 15% | 0.9%-1.2% |

| 20% | 0.8%-1.0% |

表2 不同固相体积分数的坯体干燥后的收缩率

Table 2 Shrinkage in green body with different solid loadings after drying

| Solid loading | Shrinkage |

|---|---|

| 5% | 9.2%-10.1% |

| 10% | 5.1%-6.3% |

| 15% | 0.9%-1.2% |

| 20% | 0.8%-1.0% |

| Monomer amount | Flexural strength/MPa |

|---|---|

| 15% | 3.2±0.2 |

| 25% | 6.1±0.2 |

| 35% | 4.2±0.2 |

表3 不同单体含量的坯体干燥后的抗弯强度

Table 3 Flexural strength of green body after drying with different monomer amounts

| Monomer amount | Flexural strength/MPa |

|---|---|

| 15% | 3.2±0.2 |

| 25% | 6.1±0.2 |

| 35% | 4.2±0.2 |

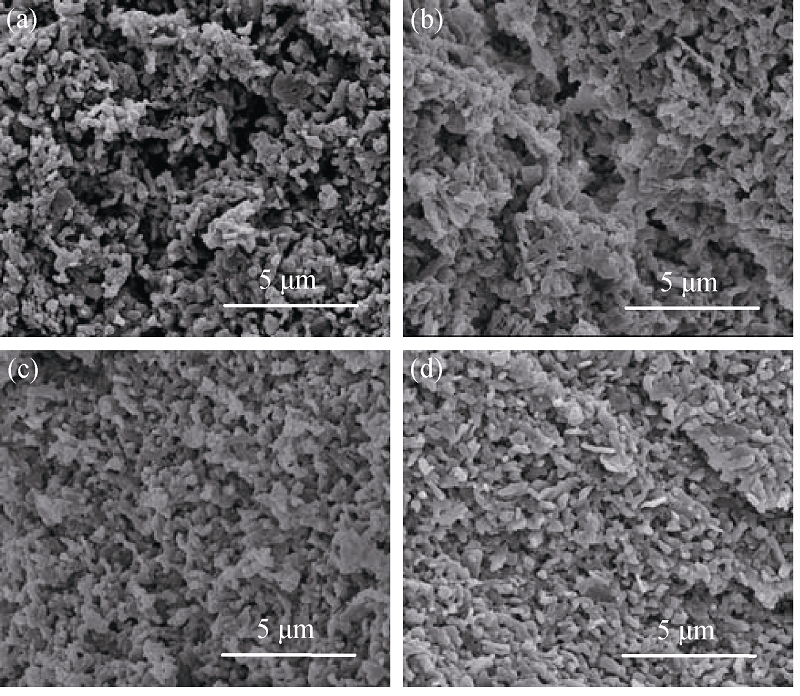

图8 1500℃烧结的不同固相体积分数的多孔氧化铝陶瓷的显微形貌

Fig. 8 Microstructures of porous alumina ceramic with different solid loadings sintered at 1500℃(a) 5% ; (b) 10%; (c) 15%; (d) 20%

| Solid loading | Porosity | Flexural strength/MPa |

|---|---|---|

| 5% | 61-65% | 5.7±0.2 |

| 10% | 55-58% | 8.3±0.2 |

| 15% | 47-49% | 27.6±1.5 |

| 20% | 43-46% | 48.5±2.1 |

表4 1500℃烧结的不同固相体积分数的多孔氧化铝陶瓷的气孔率与抗弯强度

Table 4 Porosity and flexural strength of porous alumina ceramic with different solid loadings sintered at 1500℃

| Solid loading | Porosity | Flexural strength/MPa |

|---|---|---|

| 5% | 61-65% | 5.7±0.2 |

| 10% | 55-58% | 8.3±0.2 |

| 15% | 47-49% | 27.6±1.5 |

| 20% | 43-46% | 48.5±2.1 |

| Sintering temperature/℃ | Porosity | Flexural strength/MPa |

|---|---|---|

| 1400 | 49%-50% | 23.7±1.3 |

| 1500 | 43%-46% | 48.5±2.1 |

| 1600 | 40%-42% | 91.2±4.5 |

表5 不同烧结温度下多孔氧化铝陶瓷的气孔率和抗弯强度

Table 5 Porosity and flexural strength of porous alumina ceramic sintered at different temperatures

| Sintering temperature/℃ | Porosity | Flexural strength/MPa |

|---|---|---|

| 1400 | 49%-50% | 23.7±1.3 |

| 1500 | 43%-46% | 48.5±2.1 |

| 1600 | 40%-42% | 91.2±4.5 |

| [1] | OHJI T, FUKUSHIMA M.Macro-porous ceramic: processing and properties.International Materials Reviews, 2012, 57(2): 115-131. |

| [2] | SU C H, XU Y Q, ZHANG W, et al.Porous ceramic membrane with superhydrophobic and superoleophilic surface for reclaiming oil from oily water.Applied Surface Science, 2012, 258(7): 2319-2323. |

| [3] | HAUGEN H J, MONJO M, RUBERT M, et al.Porous ceramic titanium dioxide scaffolds promote bone formation in rabbit peri-implant cortical defect model.Acta Biomaterialia, 2013, 9(2): 5390-5399. |

| [4] | YOUNG A C, OMATETE O O, JANNEY M A, et al.Gelcasting of alumina.Journal of the American Ceramic Society, 1991, 74(3): 612-618. |

| [5] | WANG X F, WANG R C, PENG C Q, et al.Research and development of gelcasting.The Chinese Journal of Nonferrous Metal, 2010, 20(3): 496-509. |

| [6] | WU J M, ZHANG X Y, YANG J L.Novel porous Si3N4 ceramic prepared by aqueous gelcasting using Si3N4 poly-hollow microspheres as pore-forming agent.Journal of the European Ceramic Society, 2014, 34(5): 1089-1096. |

| [7] | LIU Y F, LIU X Q, WEI H, et al.Porous mullite ceramic from national clay produced by gelcasting.Ceramic International, 2001, 27(1): 1-7. |

| [8] | ZHANG F Z, KATO T, FUJI M, et al.Gelcasting fabrication of porous ceramics using a continuous process.Journal of the European Ceramic Society, 2006, 26(4): 667-671. |

| [9] | CHEN R F, HUANG Y, WANG C A, et al.Ceramics with ultra- low density fabricated by gelcasting: An unconventional view.Journal of the American Ceramic Society, 2007, 90(11): 3424-3429. |

| [10] | 彭俊. 醇水基浆料凝胶注模成型氧化铝多孔陶瓷. 长沙: 中南大学硕士学位论文, 2013. |

| [11] | 刘伟渊. 高气孔率、高强度多孔氧化铝陶瓷的制备及表征. 北京: 清华大学硕士学位论文, 2009. |

| [12] | 高濂, 孙静, 刘阳桥. 纳米粉体的分散及表面改性. 北京: 化学工业出版社, 2003. |

| [13] | LEWIS J A.Colloidal processing of ceramic.Journal of the American Ceramic Society, 2000, 83(10): 2341-2359. |

| [14] | HOU Z G, DU H Y, LIU J C, et al.Fabrication and properties of mullite fiber matrix porous ceramics by a TBA-based gelcasting process.Journal of the European Ceramic Society, 2013, 33(4): 717-725. |

| [15] | WANG X F, WANG R C, PENG C Q, et al.Reology of aqueous BeO suspension with NH4PAA as a dispersant.Progress in Natural Science, 2012, 22(4): 347-353. |

| [16] | YANG J L, XIE Z P, TANG Q, et al.Studies on rheological behavior and gelcasting of α-Al2O3 suspension.Journal of the Chinese Ceramic Society, 1998, 26(1): 41-46. |

| [17] | MENON M, DECOURCELLE S, RAMOUSSE S, et al.Stabilization of ethanol-based alumina suspensions. Journal of the American Ceramic Society, 2006, 89(2): 457-464. |

| [18] | HIIDBER P C, GRAULE T J, GAUCKLER L J.Citric acid-a dispersant for aqueous alumina suspensions.Journal of the American Ceramic Society, 1996, 79(7): 1857-1867. |

| [19] | LIU B, PENG C Q, WANG R C, et al.Influence factors for stability behavior of Al2O3 suspension.The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2833-2838. |

| [20] | YANG J L, YU J L, HUANG Y.Recent developments in gelcasting of ceramics.Journal of the European Ceramic Society, 2011, 31(14): 2569-2591. |

| [21] | WANG X F, PENG C Q, WANG R C, et al.Liquid drying of BeO gelcast green bodies using ethanol as liquid desiccant.Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2466-2472. |

| [22] | WANG X F, WANG R C, PENG C Q, et al.Rheological property and drying mechanism of thermoresponsive gelcasting of ZnO.Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2789-2796. |

| [23] | WANG X F, WANG R C, PENG C Q, et al.Thermoresponsive gelcasting: improved drying of gelcast bodies.Journal of the American Ceramic Society, 2011, 94(6): 1679-1682. |

| [24] | XU K H, SUN Y, HUANG Y, et al.Preparation of porous alumina ceramics by TBA gelcasting process.Refractories, 2011, 45(2): 93-95. |

| [25] | LI Y G, WANG Z Y.Influences of different drying methods on the dehydration process of alumina green body fabricated by gelcasting.Shandong Ceramics, 2011, 34(6): 26-28. |

| [26] | 潘祖仁. 高分子化学(增强版). 北京: 化学工业出版社, 2007. |

| [27] | WANG X F, WANG R C, PENG C Q, et al.Gelation kinetics uniformity of gelcasting.Journal of Central South University (Science and Technology), 2012, 43(4): 1281-1289. |

| [28] | WANG X F, WANG R C, PENG C Q, et al.Effect of process conditions on strength of BeO green body prepared by gelcasting.Journal of Functional Materials, 2011, 42(7): 1197-1202. |

| [29] | JIN X, CAI K, LIU W, et al.Effects of monomer content on internal stresses during solidification process and properties of green bodies by gelcasting.Journal of the Chinese Ceramic Society, 2011, 39(5): 794-798. |

| [30] | ZHOU L Z, WANG C A, LIU W Y, et al.Fabrication of low density high strength porous mullite ceramics by tert-buty alcohol- based gelcasting process.Journal of Inorganic Materials, 2009, 24(6): 1173-1177. |

| [1] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [2] | 王士维. 基于疏水作用的陶瓷浆料自发凝固成型研究进展[J]. 无机材料学报, 2022, 37(8): 809-820. |

| [3] | 周红莉, 蔡志勇, 王小锋, 曾婧, 冯艳, 彭超群, 王日初. 石膏的直写成型:可打印石膏浆料的研制[J]. 无机材料学报, 2022, 37(3): 338-346. |

| [4] | 周港怀, 刘耀, 石原, 刘绍军. 活性氧化铝催化剂载体的光固化浆料制备与成型[J]. 无机材料学报, 2022, 37(3): 297-302. |

| [5] | 祝泉, 胡建宝, 杨金山, 周海军, 董绍明. 采用定向SiC纳米线烧结制备高强多孔SiC陶瓷[J]. 无机材料学报, 2021, 36(5): 547-551. |

| [6] | 张力, 杨现锋, 徐协文, 郭金玉, 周哲, 刘鹏, 谢志鹏. 熔融沉积法3D打印制备氧化锆陶瓷及其力学性能研究[J]. 无机材料学报, 2021, 36(4): 436-442. |

| [7] | 董龙浩,张海军,张俊,吴文浩,贾全利. 碳纳米管改性海泡石多孔陶瓷及其高效油水分离性能研究[J]. 无机材料学报, 2020, 35(6): 689-696. |

| [8] | 李兴邦,仲鹤,张景贤,段于森,江东亮. 粉体性质对树脂基氧化锆光固化浆料流变行为的影响[J]. 无机材料学报, 2020, 35(2): 231-235. |

| [9] | 张金诚, 王皓, 徐鹏宇, 涂兵田, 王为民, 傅正义. ZnO·2.56Al2O3透明陶瓷凝胶注模成型与烧结制备[J]. 无机材料学报, 2019, 34(10): 1072-1076. |

| [10] | 付云飞, 朱伯铨, 李享成, 陈平安. 含镁铝尖晶石的铝酸钙水泥的合成与流变特性[J]. 无机材料学报, 2017, 32(8): 884-890. |

| [11] | 宋盛星, 殷 杰, 朱云洲, 黄毅华, 刘学建, 黄政仁. 水基浆料涂覆结合原位反应制备Cf/SiC复合材料表面光学涂层[J]. 无机材料学报, 2017, 32(2): 210-214. |

| [12] | 孙进兴, 陈 斌, 刘培生. 轻质多孔陶瓷的制备及吸声性能研究[J]. 无机材料学报, 2016, 31(8): 860-864. |

| [13] | 孙 阳, 薛伟江, 孙加林, 周国治, 黄 勇. 海藻酸钠离子凝胶法制备直通孔氧化铝多孔陶瓷[J]. 无机材料学报, 2015, 30(8): 877-881. |

| [14] | 袁文玉, 成来飞, 武 恒, 刘永胜. 硅源对植物纤维制备SiC纤维的影响[J]. 无机材料学报, 2015, 30(2): 159-164. |

| [15] | 刘 岗, 严 岩. 冷冻干燥法制备多孔陶瓷研究进展[J]. 无机材料学报, 2014, 29(6): 571-583. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||