无机材料学报 ›› 2017, Vol. 32 ›› Issue (6): 571-580.DOI: 10.15541/jim20160461

李大川1,2, 赵华玉1, 钟兴华1, 陶顺衍1

收稿日期:2016-08-08

修回日期:2016-09-26

出版日期:2017-06-20

网络出版日期:2017-05-27

作者简介:李大川(1987–), 男, 博士研究生. E-mail: dachuan_li@student.sic.ac.cn

基金资助:LI Da-Chuan1,2, ZHAO Hua-Yu1, ZHONG Xing-Hua1, TAO Shun-Yan1

Received:2016-08-08

Revised:2016-09-26

Published:2017-06-20

Online:2017-05-27

About author:LI Da-Chuan. E-mail: dachuan_li@student.sic.ac.cn

Supported by:摘要:

大气等离子体喷涂技术是一种常用的涂层制备工艺。作为所制备涂层的结构基元, 单片层的形貌特征及堆叠行为决定了涂层的微结构, 对涂层性能产生显著影响。本文较为系统地综述了与熔滴自身理化状态相关的主体因素、与沉积涂层的衬底相关的客体因素以及环境因素等对单片层形成过程的影响, 着重分析了粉体尺寸、衬底预热过程等产生的多种不同影响及其之间的关联性, 并通过对所述文献涉及实验方法各自特点的比较, 提出未来的实验和模拟研究或都将向着与真实生产条件更加接近的方向发展。

中图分类号:

李大川, 赵华玉, 钟兴华, 陶顺衍. 大气等离子体喷涂的单片层研究进展[J]. 无机材料学报, 2017, 32(6): 571-580.

LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat[J]. Journal of Inorganic Materials, 2017, 32(6): 571-580.

| Radial position /mm | Average particle diameter /μm | Average particle velocity/(m·s-1) | Average particle temperature /K |

|---|---|---|---|

| +50 | 25.7 | 236 | 3310 |

| +40 | 26.3 | 247 | 3342 |

| +30 | 27.8 | 254 | 3392 |

| +20 | 30.3 | 248 | 3430 |

| +10 | 32.3 | 233 | 3420 |

| 0 | 36.5 | 228 | 3400 |

| -10 | 37.0 | 215 | 3340 |

| -20 | 38.2 | 209 | 3310 |

| -30 | 42.3 | 199 | 3294 |

| -40 | 44.3 | 191 | 3270 |

| -50 | 45.6 | 188 | 3250 |

表1 不同轴向位置处颗粒的直径、速率及温度的平均值[12]

Table 1 Average values of the particle size, velocity and temperature at different radial positions from the plasma jet center line[12]

| Radial position /mm | Average particle diameter /μm | Average particle velocity/(m·s-1) | Average particle temperature /K |

|---|---|---|---|

| +50 | 25.7 | 236 | 3310 |

| +40 | 26.3 | 247 | 3342 |

| +30 | 27.8 | 254 | 3392 |

| +20 | 30.3 | 248 | 3430 |

| +10 | 32.3 | 233 | 3420 |

| 0 | 36.5 | 228 | 3400 |

| -10 | 37.0 | 215 | 3340 |

| -20 | 38.2 | 209 | 3310 |

| -30 | 42.3 | 199 | 3294 |

| -40 | 44.3 | 191 | 3270 |

| -50 | 45.6 | 188 | 3250 |

图4 测量钼液滴冷却时间的设备及其原理[26]

Fig. 4 Schematic of the experimental setup and typical signals collected during an impact of a molybdenum droplet on a smooth glass substrate[26]

图5 碰撞初期的激冷导致单片层呈溅射状的机理[34]

Fig. 5 Comparison of cooling and solidification processes inside the splat deposited onto substrates at a temperature above (left) and below (right) transition temperature[34]

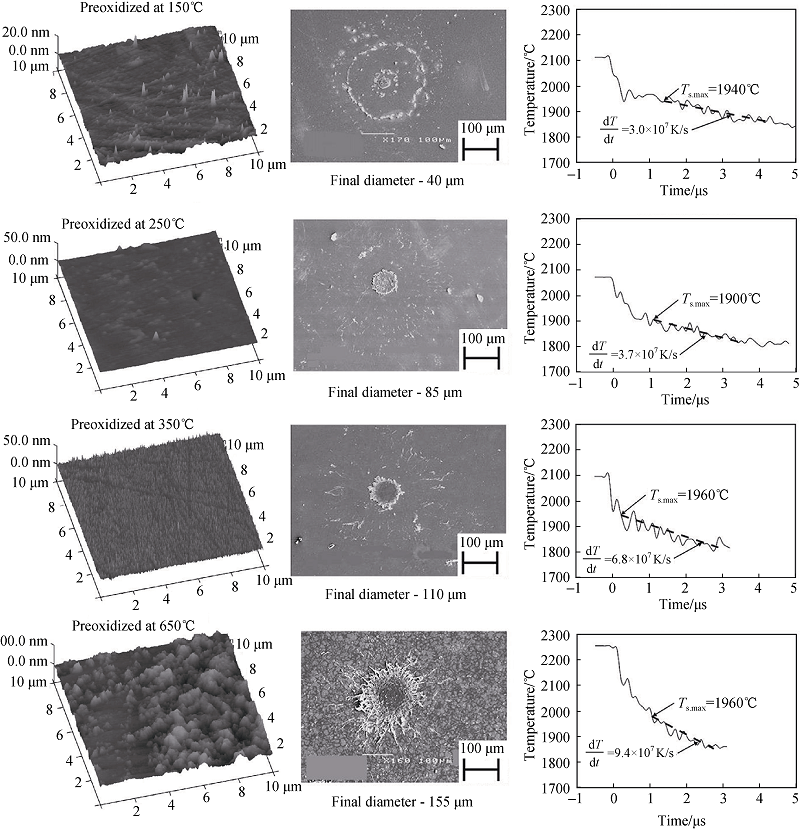

图7 经不同温度预氧化处理后的不锈钢表面形貌、所沉积镍单片层的形貌以及单片层形成过程中冷却速率的对比[39]

Fig. 7 Surface topologies of stainless steel surfaces either non-oxidized or preoxidized at different temperatures, images of nickel splats after solidification and cooling curves of splats[39]

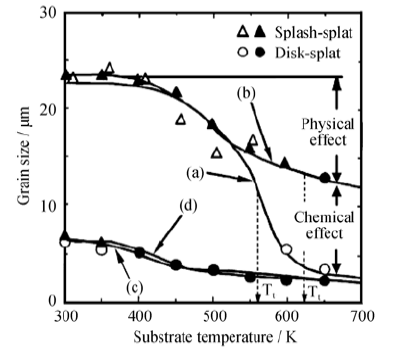

图8 温度、气压和基体表面成分对铜单片层外形及晶粒尺寸的影响[28]

Fig. 8 Grain size in a cross-section of the splat obtained in different ambient pressures[28](a) on stainless steel in atmospheric pressure; (b) on gold-coated stainless steel in atmospheric pressure; (c) on stainless steel under low pressure; and (d) on gold-coated stainless steel under low pressure

| [1] | 徐滨士, 李长久, 刘世参, 等. 表面工程与热喷涂技术及其发展. 中国表面工程, 1998, 38(1): 3-9. |

| [2] | 徐滨士, 马世宁, 时小军, 等. 中国表面工程的发展. 中国机械工程, 1996, 7(5): 3-5. |

| [3] | 曹学强. 热障涂层新材料和新结构. 北京: 科学出版社, 2016. |

| [4] | 黄小鸥, 吴朝军. 适应产业结构调整,开发新型涂层产品. 第十七届国际热喷涂研讨会(ITSS'2014)暨第十八届全国热喷涂年会(CNTSC'2014), 成都&自贡, 中国, 2014: 1-5. |

| [5] | 中国表面工程协会热喷涂专业委员会. 中国热喷涂年鉴: 2015年版. 北京: 科学技术文献出版社, 2016. |

| [6] | FAUCHAIS P, HEBERLEIN J, BOULOS M.Thermal Spray Fundamentals: from Powder to Part. New York: Springer Science+Business Media, 2014. |

| [7] | FAUCHAIS P.Understanding plasma spraying.J. Phys. D Appl. Phys., 2004, 37(9): 86-108. |

| [8] | VARDELLE M, VARDELLE A, DUSSOUBS B, et al.Influence of injector geometry on particle trajectories: analysis of particle dynamics in the injector and plasma jet.Thermal Spray, Vols 1 and 2, 1998: 887-894. |

| [9] | LI H P, CHEN X.Three-dimensional simulation of a plasma jet with transverse particle and carrier gas injection.Thin Solid Films, 2001, 390(1/2): 175-180. |

| [10] | XIONG H B, ZHENG L L, SAMPATH S, et al.Three-dimensional simulation of plasma spray: effects of carrier gas flow and particle injection on plasma jet and entrained particle behavior.Int. J. Heat Mass Tran., 2004, 47(24): 5189-5200. |

| [11] | YUGESWARAN S, KOBAYASHI A, SELVAN B, et al.In-flight behavior of lanthanum zirconate (La2Zr2O7) particles in gas tunnel type plasma jet and its coating properties.Vacuum, 2013, 88: 139-143. |

| [12] | ELSEBAEI A, HEBERLEIN J, ELSHAER M, et al.Comparison of in-flight particle properties, splat formation, and coating microstructure for regular and nano-ysz powders.J. Therm Spray Techn., 2010, 19(1/2): 2-10. |

| [13] | OERLIKON METCO.Thermal spray materials guide. , April 2015. |

| [14] | KUMAR A, GU S, TABBARA H, et al.Study of impingement of hollow ZrO2 droplets onto a substrate.Surf. Coat. Tech., 2013, 220: 164-169. |

| [15] | KANOUFF M P, NEISER R A, ROEMER T J.Surface roughness of thermal spray coatings made with off-normal spray angles.J. Therm. Spray Techn., 1998, 7(2): 219-228. |

| [16] | LEIGH S H, BERNDT C C.Evaluation of off-angle thermal spray.Surf. Coat. Tech., 1997, 89(3): 213-224. |

| [17] | ALAVI S, PASSANDIDEH-FARD M, MOSTAGHIMI J.Simulation of semi-molten particle impacts including heat transfer and phase change.J. Therm. Spray Techn., 2012, 21(6): 1278-1293. |

| [18] | ZHU Z H, KAMNIS S, GU S.Numerical study of molten and semi-molten ceramic impingement by using coupled Eulerian and Lagrangian method.Acta Mater., 2015, 90: 77-87. |

| [19] | GOUTIER S, VARDELLE M, FAUCHAIS P.Comparison between metallic and ceramic splats: influence of viscosity and kinetic energy on the particle flattening.Surf. Coat. Tech., 2013, 235: 657-668. |

| [20] | CHEN D, WANG Y, BAI Y, et al.Effect of reynolds number of molten particle on splat formation in plasma spraying.J. Inorg. Mater., 2015, 30(1): 65-70. |

| [21] | GOUTIER S, VARDELLE M, LABBE J C, et al.Flattening and cooling of millimeter- and micrometer-sized alumina drops.J. Therm. Spray Techn., 2011, 20(1/2): 59-67. |

| [22] | ESCURE C, VARDELLE M, FAUCHAIS P.Experimental and theoretical study of the impact of alumina droplets on cold and hot substrates.Plasma Chem. Plasma P., 2003, 23(2): 185-221. |

| [23] | LI L, VAIDYA A, SAMPATH S, et al.Particle characterization and splat formation of plasma sprayed zirconia.J. Therm. Spray Techn., 2006, 15(1): 97-105. |

| [24] | WANG Y Z, HUA J J, LIU Z W, et al.Melting index characterization and thermal conductivity model of plasma sprayed YSZ coatings.J. Eur. Ceram. Soc., 2012, 32(14): 3701-3707. |

| [25] | FUKUMOTO M, HUANG Y.Flattening mechanism in thermal sprayed nickel particle impinging on flat substrate surface.J. Therm. Spray Techn., 1999, 8(3): 427-432. |

| [26] | MOREAU C, GOUGEON P, LAMONTAGNE M.Influence of substrate preparation on the flattening and cooling of plasma- sprayed particles.J. Therm. Spray Techn., 1995, 4(1): 25-33. |

| [27] | FAUCHAIS P, VARDELLE M, VARDELLE A, et al.Parameters controlling the generation and properties of plasma sprayed zirconia coatings.Plasma Chem. Plasma P., 1996, 16(1): 99-125. |

| [28] | FUKUMOTO M, NISHIOKA E, MATSUBARA T.Effect of interface wetting on flattening of freely fallen metal droplet onto flat substrate surface.J. Therm. Spray Techn., 2002, 11(1): 69-74. |

| [29] | FAUCHAIS P, FUKUMOTO M, VARDELLE A, et al.Knowledge concerning splat formation: an invited review.J. Therm. Spray Techn., 2004, 13(3): 337-360. |

| [30] | MCDONALD A, MOREAU C, CHANDRA S.Thermal contact resistance between plasma-sprayed particles and flat surfaces.Int. J. Heat Mass Tran., 2007, 50(9/10): 1737-1749. |

| [31] | TRAN A T T, HYLAND M M. The role of substrate surface chemistry on splat formation during plasma spray deposition by experiments and simulations.J. Therm. Spray Techn., 2010, 19(1/2): 11-23. |

| [32] | ZHENG Y Z, LI Q, ZHENG Z H,et al.Modeling the impact, flattening and solidification of a molten droplet on a solid substrate during plasma spraying.Appl. Surf. Sci., 2014, 317: 526-533. |

| [33] | FUKUMOTO M, OHGITANI D, YASUI T.Effect of substrate surface change on flattening behaviour of thermal sprayed particles.Mater Trans., 2004, 45(6): 1869-1873. |

| [34] | FUKUMOTO M, NISHIOKA E, MATSUBARA T.Flattening and solidification behavior of a metal droplet on a flat substrate surface held at various temperatures.Surf. Coat. Tech., 1999, 120: 131-137. |

| [35] | JIANG X Y, WAN Y P, HERMAN H, et al.Role of condensates and adsorbates on substrate surface on fragmentation of impinging molten droplets during thermal spray.Thin Solid Films, 2001, 385(1/2): 132-141. |

| [36] | LI C J, LI J L.Evaporated-gas-induced splashing model for splat formation during plasma spraying.Surf. Coat. Tech., 2004, 184(1): 13-23. |

| [37] | LI H, COSTIL S, LIAO H L, et al.Effects of surface conditions on the flattening behavior of plasma sprayed Cu splats.Surf. Coat. Tech., 2006, 200(18/19): 5435-5446. |

| [38] | TRAN A T T, HYLAND M M, SHINODA K, et al. Influence of substrate surface conditions on the deposition and spreading of molten droplets.Thin Solid Films, 2011, 519(8): 2445-2456. |

| [39] | MCDONALD A, MOREAU C, CHANDRA S.Effect of substrate oxidation on spreading of plasma-sprayed nickel on stainless steel.Surf. Coat. Tech., 2007, 202(1): 23-33. |

| [40] | PARIZI H B, ROSENZWEIG L, MOSTAGHIMI J, et al.Numerical simulation of droplet impact on patterned surfaces.J. Therm. Spray Techn., 2007, 16(5/6): 713-721. |

| [41] | SHINODA K, RAESSI M, MOSTAGHIMI J, et al.Effect of substrate concave pattern on splat formation of yttria-stabilized zirconia in atmospheric plasma spraying.J. Therm. Spray Techn., 2009, 18(4): 609-618. |

| [42] | KHAN A N, LU J, LIAO H.Effect of residual stresses on air plasma sprayed thermal barrier coatings.Surf. Coat. Tech., 2003, 168(2-3): 291-299. |

| [43] | CHRISTOULIS D K, PANTELIS D I, DE DAVE-FABREGUE N, et al. Effect of substrate temperature and roughness on the solidification of copper plasma sprayed droplets.Mat. Sci. Eng. a-Struct., 2008, 485(1/2): 119-129. |

| [44] | LI D C, ZHAO H Y, ZHONG X H, et al.Effect of the bond coating surface morphology on ceramic splat construction.J. Therm. Spray Techn., 2015, 24(8): 1450-1458. |

| [45] | SYED A A, DENOIRJEAN A, HANNOYER B, et al.Influence of substrate surface conditions on the plasma sprayed ceramic and metallic particles flattening.Surf. Coat. Tech., 2005, 200(7): 2317-2331. |

| [46] | SALIMIJAZI H R, PERSHIN L, COYLE T W, et al.Effect of droplet characteristics and substrate surface topography on the final morphology of plasma-sprayed zirconia single splats.J. Therm. Spray Techn., 2007, 16(2): 291-299. |

| [47] | LI C J, LI C X, YANG G J, et al.Examination of substrate surface melting-induced splashing during splat formation in plasma spraying.J. Therm. Spray Techn., 2006, 15(4): 717-724. |

| [48] | BROSSARD S, MUNROE P R, TRAN A T T, et al. Study of the splat microstructure, splat-substrate interface, and the effects of substrate heating on the splat formation for ni-cr particles plasma sprayed on to aluminum substrates.J. Therm. Spray Techn., 2010, 19(5): 1115-1130. |

| [1] | 丁玲, 蒋瑞, 唐子龙, 杨运琼. MXene材料的纳米工程及其作为超级电容器电极材料的研究进展[J]. 无机材料学报, 2023, 38(6): 619-633. |

| [2] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [3] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [4] | 林俊良, 王占杰. 铁电超晶格的研究进展[J]. 无机材料学报, 2023, 38(6): 606-618. |

| [5] | 牛嘉雪, 孙思, 柳鹏飞, 张晓东, 穆晓宇. 铜基纳米酶的特性及其生物医学应用[J]. 无机材料学报, 2023, 38(5): 489-502. |

| [6] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [7] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [8] | 杨洋, 崔航源, 祝影, 万昌锦, 万青. 柔性神经形态晶体管研究进展[J]. 无机材料学报, 2023, 38(4): 367-377. |

| [9] | 游钧淇, 李策, 杨栋梁, 孙林锋. 氧化物双介质层忆阻器的设计及应用[J]. 无机材料学报, 2023, 38(4): 387-398. |

| [10] | 陈昆峰, 胡乾宇, 刘锋, 薛冬峰. 多尺度晶体材料的原位表征技术与计算模拟研究进展[J]. 无机材料学报, 2023, 38(3): 256-269. |

| [11] | 张超逸, 唐慧丽, 李宪珂, 王庆国, 罗平, 吴锋, 张晨波, 薛艳艳, 徐军, 韩建峰, 逯占文. 新型GaN与ZnO衬底ScAlMgO4晶体的研究进展[J]. 无机材料学报, 2023, 38(3): 228-242. |

| [12] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| [13] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [14] | 刘岩, 张珂颖, 李天宇, 周菠, 刘学建, 黄政仁. 陶瓷材料电场辅助连接技术研究现状及发展趋势[J]. 无机材料学报, 2023, 38(2): 113-124. |

| [15] | 谢兵, 蔡金峡, 王铜铜, 刘智勇, 姜胜林, 张海波. 高储能密度聚合物基多层复合电介质的研究进展[J]. 无机材料学报, 2023, 38(2): 137-147. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||