无机材料学报 ›› 2017, Vol. 32 ›› Issue (5): 509-516.DOI: 10.15541/jim20160425

张昌松, 刘 强, 陈 威

收稿日期:2016-07-18

修回日期:2016-10-03

出版日期:2017-05-20

网络出版日期:2017-05-02

基金资助:ZHANG Chang-Song, LIU Qiang, CHEN Wei

Received:2016-07-18

Revised:2016-10-03

Published:2017-05-20

Online:2017-05-02

Supported by:摘要:

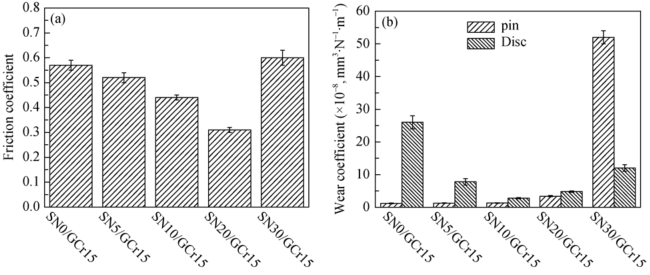

利用纳米级粉体经热压烧结制备了Si3N4-hBN复相陶瓷, 研究了hBN含量对Si3N4-hBN复相陶瓷致密度、力学性能、摩擦学性能、微观结构的影响。用阿基米德排水法、三点弯曲法和维氏压痕法测量材料的致密度、力学性能; 用摩擦磨损试验机测试材料的摩擦学性能; 用XRD、EDAX和SEM、LSCM分析观察材料的物相组成和微观结构。研究结果表明, 随着hBN含量的增加, 复相陶瓷的密度将会持续下降, 气孔率先是急剧上升, 然后趋于平缓, 力学性能持续下降, 干摩擦条件下复相陶瓷与GCr15配副的摩擦学性能呈现先提高后降低的趋势, 当hBN含量低于20wt%时, 随着hBN含量的增加, 摩擦系数和磨损率逐渐减小; 当hBN含量大于20wt%时, 摩擦系数和磨损率急剧增大; hBN含量为20wt%时, 获得最低的摩擦系数为0.31。hBN的引入直接影响Si3N4-hBN复相陶瓷的微观组织结构, 进而影响复合陶瓷的力学性能和摩擦学性能。

中图分类号:

张昌松, 刘 强, 陈 威. hBN含量对Si3N4-hBN复相陶瓷性能和微观结构的影响[J]. 无机材料学报, 2017, 32(5): 509-516.

ZHANG Chang-Song, LIU Qiang, CHEN Wei. Effect of hBN Content on Property and Microstructure of Si3N4-hBN Composite Ceramics[J]. Journal of Inorganic Materials, 2017, 32(5): 509-516.

| Number | HBN/ wt% | Density /(g·cm-3) | Relative density /% | Porosity /% | Bending strength /MPa | Vickers hardness /GPa | Fracture toughness /(MPa·m1/2) |

|---|---|---|---|---|---|---|---|

| SN0 | 0 | 3.20 | 97.0 | 0.24 | 818 | 14.9 | 7.36 |

| SN5 | 5 | 3.12 | 96.7 | 0.55 | 764 | 13.3 | 6.67 |

| SN10 | 10 | 3.04 | 96.4 | 0.80 | 717 | 12.4 | 6.58 |

| SN20 | 20 | 2.89 | 96.0 | 1.02 | 695 | 8.9 | 6. 39 |

| SN30 | 30 | 2.79 | 91.2 | 1.08 | 577 | 6.6 | 5.98 |

表1 热压烧结Si3N4-hBN复相陶瓷的致密度和力学性能

Table 1 Physical and mechanical properties of Si3N4-hBN composite ceramics by hot-pressed sintering

| Number | HBN/ wt% | Density /(g·cm-3) | Relative density /% | Porosity /% | Bending strength /MPa | Vickers hardness /GPa | Fracture toughness /(MPa·m1/2) |

|---|---|---|---|---|---|---|---|

| SN0 | 0 | 3.20 | 97.0 | 0.24 | 818 | 14.9 | 7.36 |

| SN5 | 5 | 3.12 | 96.7 | 0.55 | 764 | 13.3 | 6.67 |

| SN10 | 10 | 3.04 | 96.4 | 0.80 | 717 | 12.4 | 6.58 |

| SN20 | 20 | 2.89 | 96.0 | 1.02 | 695 | 8.9 | 6. 39 |

| SN30 | 30 | 2.79 | 91.2 | 1.08 | 577 | 6.6 | 5.98 |

| Analysis area | Elements /at% | ||||

|---|---|---|---|---|---|

| Si | N | O | Al | Y | |

| “1” area | 39.72 | 52.91 | 5.36 | 1.57 | 0.42 |

表2 纯Si3N4陶瓷微区成分分析(EDAX)

Table 2 Microareas elements of EDAX analysis of pure Si3N4 ceramics

| Analysis area | Elements /at% | ||||

|---|---|---|---|---|---|

| Si | N | O | Al | Y | |

| “1” area | 39.72 | 52.91 | 5.36 | 1.57 | 0.42 |

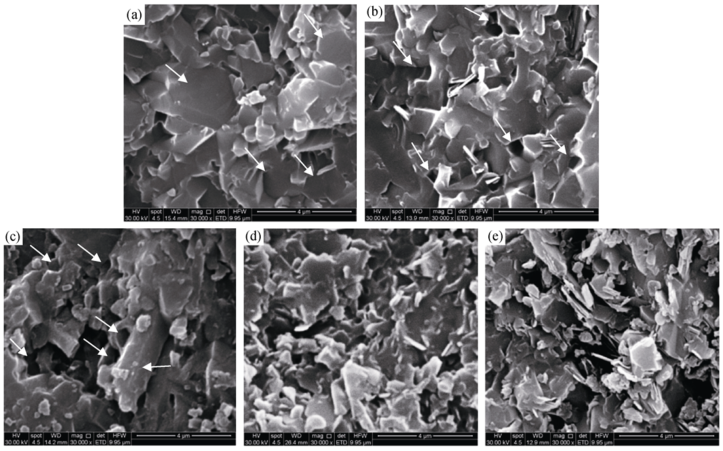

图3 Si3N4-hBN陶瓷复合材料断口形貌

Fig. 3 Fracture morphologies of Si3N4-hBN ceramic composites(SEM) (a) pure Si3N4; (b) Si3N4-5wt%hBN; (c) Si3N4-10wt%hBN; (d) Si3N4-20wt%hBN; (e) Si3N4-30wt%hBN

图4 SN0-SN30与GCr15配副摩擦面的摩擦因数(a)和磨损率(b)变化图

Fig. 4 Change of friction coefficient (a) and wear coefficient (b) of SN0-SN30 and GCr15 with a pair of friction surface

| [1] | RILEY F L.Silicon nitride and related materials.Journal of the American Ceramic Society, 2000, 83(2): 245-265. |

| [2] | ZIEGLER A, IDROBO J C, CINIBYLK M K, et al.Interface structure and atomic bonding characteristics in sicon nitride ceramics.Science, 2004, 306(3): 1768-1770. |

| [3] | ZHU C J, JIANG J, GAO L, et al.The fabrication and progress of silicon nitride ceramics.Jiangsu Ceramics, 2001, 34(3): 10-12. |

| [4] | ZHANG W R.Current status and progress of Si3N4-SiCp multiphase ceramic.Hebei Ceramic, 1995, 23(03): 21-24. |

| [5] | PETZOW G, HERRMANN M.Silicon Nitride Ceramics: Structure & Bonding. Berlin Heidelberg: Springer-Verlag, 2002, 102: 47-167. |

| [6] | 周玉. 陶瓷材料学. 北京: 科学出版社, 2004. |

| [7] | 李世普. 特种陶瓷工艺学. 武汉: 武汉理工大学, 2008. |

| [8] | ZHANG G J, ZOU J, NI D W, et al.Boride ceramics: densification, microstructure tailoring and properties improvement.Journal of Inorganic Materials, 2012, 27(3): 225-233. |

| [9] | DUAN X M, YANG Z, CHEN L, et al.Review on the properties of hexagonal boron nitride matrix composite ceramics.Journal of the European Ceramic Society, 2016, 36(15): 3725-3737. |

| [10] | SUN Y, MENG Q C, JIA D C, et al.Effect of hexagonal BN on the microstructure and mechanical properties of Si3N4 ceramics.Journal of Materials Processing Technology, 2007, 182(1): 134-138. |

| CHO M W, KIM D W, CHO W S.Analysis of micromachining characteristics of Si3N4-hBN composites.Journal of the Europ- ean Ceramic Society, 2007, 27(2): 1259-1265. | |

| [11] | WEI D Q, MENG Q C, JIA D C.Microstructure of hot pressed hBN-Si3N4 ceramic composites with Y2O3-Al2O3 sintering additive.Ceramics International, 2007, 33(2): 221-226. |

| [12] | WANG R G, PAN W, JIANG M N, et al.Investigation of the physical and mechanical properties of hot-pressed machinable Si3N4-hBN composites and FGM.Materials Science and Engineering: B, 2002, 90(3): 261-268. |

| [13] | ZOU J, ZHANG G J, SHEN Z J, et al.Ultra-low temperature reactive spark plasma sintering of ZrB2-hBN ceramics.Journal of the European Ceramic Society, 2016, 36(15): 3637-3645. |

| [14] | ZOU J, LIU J, ZHANG G J, et al.Hexagonal BN-encapsulated ZrB2 particle by nitride boronizing.Acta Materialia, 2014, 72(15): 167-177. |

| [15] | GAO L, JIN X, LI J, et al.BN/Si3N4 nanocomposite with high strength and good machinability.Materials Science and Engineering: A, 2006, 415(1): 145-148. |

| [16] | SKOPP A, WOYDT M.Ceramic and ceramic composite materials with improved friction and wear properties.Tribology transactions, 1995, 38(2): 233-242. |

| [17] | CARRAPICHANO J M, GOMES J R, SILVA R F.Tribological behaviour of Si3N4-BN ceramic materials for dry sliding applications.Wear, 2002, 253(9): 1070-1076. |

| [18] | CHEN W, GAO Y M, CHEN C.Tribological behavior of Si3N4-hBN ceramic materials against stainless steel under dry friction condition.Tribology, 2010, 30(3): 243. |

| [19] | LIZUKA T, KITA H, HIRAI T, et al.Tribological behavior of W2C nano-particle reinforced Si3N4 matrix composite.Wear, 2004, 257(9): 953-961. |

| [20] | YUAN L J, YAN D S, MAO Z Q.Mechanism and knetics of sintering of hot-pressed silicon nitride at lower temperatures.Journal of the Chinese Ceramic Society, 1989, 17(6): 530-536. |

| [1] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [2] | 安文然, 黄晶琪, 卢祥荣, 蒋佳宁, 邓龙辉, 曹学强. 热处理温度对LaMgAl11O19涂层热/力学性能的影响[J]. 无机材料学报, 2022, 37(9): 925-932. |

| [3] | 张叶, 曾宇平. 自蔓延高温合成氮化硅多孔陶瓷的研究进展[J]. 无机材料学报, 2022, 37(8): 853-864. |

| [4] | 夏乾, 孙是昊, 赵义亮, 张翠萍, 茹红强, 王伟, 岳新艳. 碳化硼颗粒级配对硅反应结合碳化硼复合材料结构与性能的影响[J]. 无机材料学报, 2022, 37(6): 636-642. |

| [5] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [6] | 徐谱昊, 张相召, 刘桂武, 张明芬, 桂新易, 乔冠军. Al-Ti合金钎焊SiC陶瓷接头界面微观结构与力学性能[J]. 无机材料学报, 2022, 37(6): 683-690. |

| [7] | 丁健翔, 张凯歌, 柳东明, 郑伟, 张培根, 孙正明. Ti3AlC2陶瓷及其衍生物Ti3C2Tx增强的Ag基电接触材料[J]. 无机材料学报, 2022, 37(5): 567-573. |

| [8] | 李榅凯, 赵宁, 毕志杰, 郭向欣. 钠离子电池Na3Zr2Si2PO12陶瓷电解质的喷雾干燥法制备及性能优化[J]. 无机材料学报, 2022, 37(2): 189-196. |

| [9] | 蔚海浪, 曹学强, 邓龙辉, 蒋佳宁. LaMeAl11O19/YSZ热障涂层热力学性能和热循环寿命[J]. 无机材料学报, 2022, 37(12): 1259-1266. |

| [10] | 孙扬善, 杨治华, 蔡德龙, 张正义, 柳琪, 房树清, 冯良, 石丽芬, 王友乐, 贾德昌. 粉末烧结法制备α-堇青石基玻璃陶瓷的析晶动力学和性能[J]. 无机材料学报, 2022, 37(12): 1351-1357. |

| [11] | 吴西士, 朱云洲, 黄庆, 黄政仁. 树脂基多孔碳孔结构对Cf/SiC复合材料连接性能的影响[J]. 无机材料学报, 2022, 37(12): 1275-1280. |

| [12] | 孙鲁超, 周翠, 杜铁锋, 吴贞, 雷一明, 李家麟, 苏海军, 王京阳. 光悬浮区熔定向凝固Al2O3/Er3Al5O12和Al2O3/Yb3Al5O12共晶陶瓷的制备与性能研究[J]. 无机材料学报, 2021, 36(6): 652-658. |

| [13] | 吴永豪, 李向锋, 朱向东, 张兴栋. 高强度羟基磷灰石纳米陶瓷的构建及其促成骨细胞活性研究[J]. 无机材料学报, 2021, 36(5): 552-560. |

| [14] | 吕莎莎, 祖宇飞, 陈国清, 赵伯俊, 付雪松, 周文龙. 陶瓷颗粒增强Cr0.5MoNbWTi难熔高熵合金复合材料的制备及其力学性能[J]. 无机材料学报, 2021, 36(4): 386-392. |

| [15] | 王皓轩, 刘巧沐, 王一光. 高熵过渡金属碳化物陶瓷的研究进展[J]. 无机材料学报, 2021, 36(4): 355-364. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||