无机材料学报 ›› 2015, Vol. 30 ›› Issue (11): 1139-1147.DOI: 10.15541/jim20150158

王小锋1, 孙月花1, 彭超群1, 王日初1, 张 斗2, 马 超2

收稿日期:2015-04-03

修回日期:2015-05-27

出版日期:2015-11-20

网络出版日期:2015-10-20

作者简介:王小锋(1980–), 男, 博士. E-mail: wangxiaofeng@csu.edu.cn

基金资助:WANG Xiao-Feng1, SUN Yue-Hua1, PENG Chao-Qun1, WANG Ri-Chu1, ZHANG Dou2, MA Chao2

Received:2015-04-03

Revised:2015-05-27

Published:2015-11-20

Online:2015-10-20

About author:WANG Xiao-Feng. E-mail: wangxiaofeng@csu.edu.cn

Supported by:摘要:

直写成型技术是一种新型的三维复杂结构的制备方法。本文综述了直写成型用悬浮液的研究进展: 根据直写成型悬浮液的固化特点, 将之划分为自固化悬浮液和外固化悬浮液; 分析了自固化悬浮液的流变性能要求与设计准则, 综述了典型的自固化悬浮液; 分析了外固化悬浮液的要求与固化方式, 并总结了典型的外固化悬浮液与固化方式; 探讨了直写成型用悬浮液的发展方向。

中图分类号:

王小锋, 孙月花, 彭超群, 王日初, 张 斗, 马 超. 直写成型用悬浮液的设计[J]. 无机材料学报, 2015, 30(11): 1139-1147.

WANG Xiao-Feng, SUN Yue-Hua, PENG Chao-Qun, WANG Ri-Chu, ZHANG Dou, MA Chao. Suspensions Designed for Direct Ink Writing[J]. Journal of Inorganic Materials, 2015, 30(11): 1139-1147.

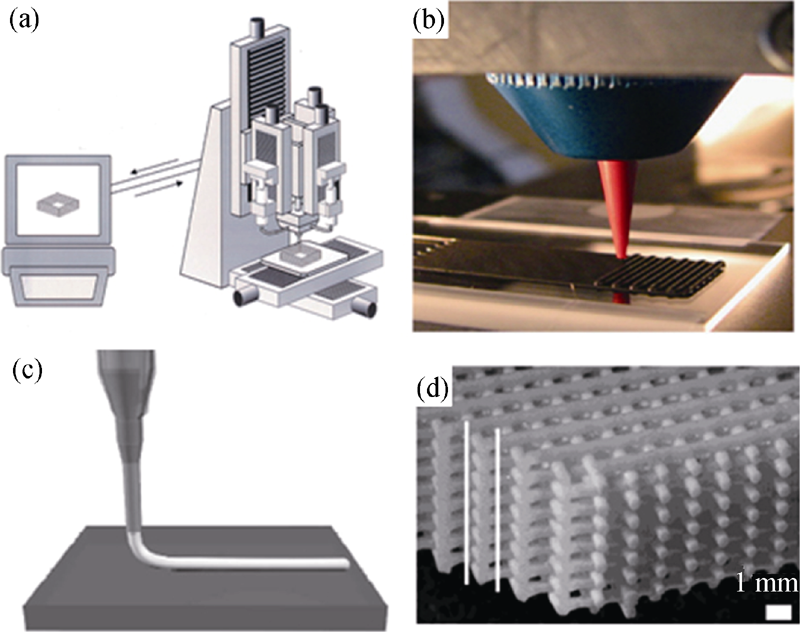

图1 直写成型(自动注浆成型)示意图

Fig. 1 Direct ink writing (robocasting) (a) Schematic view[1] and (b) optical image of direct ink writing[26]; (c) schematic view of filament fluid[1]; (d) optical image of a 3-D periodic structure[25]

| Self-solidification suspensions | Tailoring routes for rheological properties of suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Colloidal gel suspensions | Changing pH values | 100 μm | [25, 35-36] |

| Tailoring ionic concentrations | 30 μm | [37] | |

| Adding oppositive polyelectrolyte | 200 μm | [13, 38] | |

| Biphasic suspensions | Changing inter environment of suspensions with homopolymer and copolymer, e.g. ionic concentrations | < 100 μm | [39] |

| Controlling the hydrophilicity/hydrophobicity between particles and solvent | - | [39] | |

| Using powder with different isoelectric points (IEP) | - | [39] |

表1 直写成型的自固化悬浮液[13, 25, 35-39]

Table 1 Self-solidification suspensions designed for direct ink writing[13, 25, 35-39]

| Self-solidification suspensions | Tailoring routes for rheological properties of suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Colloidal gel suspensions | Changing pH values | 100 μm | [25, 35-36] |

| Tailoring ionic concentrations | 30 μm | [37] | |

| Adding oppositive polyelectrolyte | 200 μm | [13, 38] | |

| Biphasic suspensions | Changing inter environment of suspensions with homopolymer and copolymer, e.g. ionic concentrations | < 100 μm | [39] |

| Controlling the hydrophilicity/hydrophobicity between particles and solvent | - | [39] | |

| Using powder with different isoelectric points (IEP) | - | [39] |

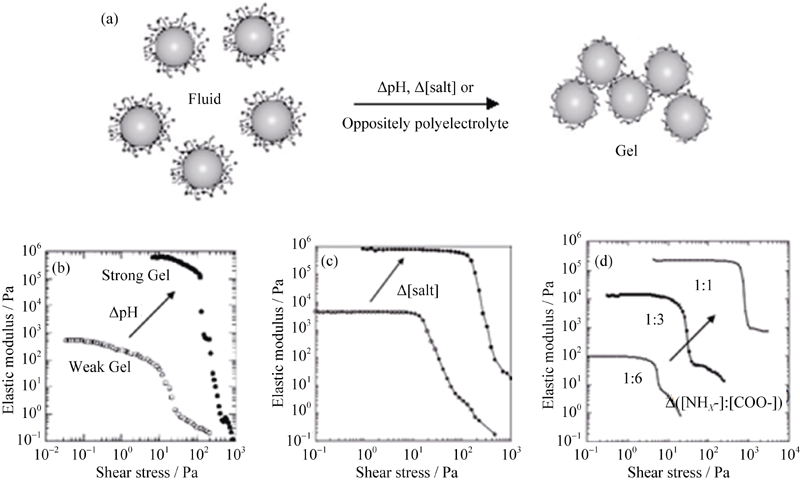

图3 改变酸碱度、离子强度或者加入反电离聚电解质改变时悬浮液从流体到凝胶的转变

Fig. 3 Fluid-to-gel transition of colloidal inks that occur upon changing pH, ionic strength or adding oppositely charged polyelectrolyte (a) Schematic view[25, 36]; (b) Shear elastic modulus versus shear stress for concentrated silica gels of varying strength through changing pH [25]; (c) Equilibrium elastic modulus of BaTiO3 nanoparticle inks with different salt additions[37]; (d) Ink elasticity varying [NHx+]: [COO-] ratios[38]

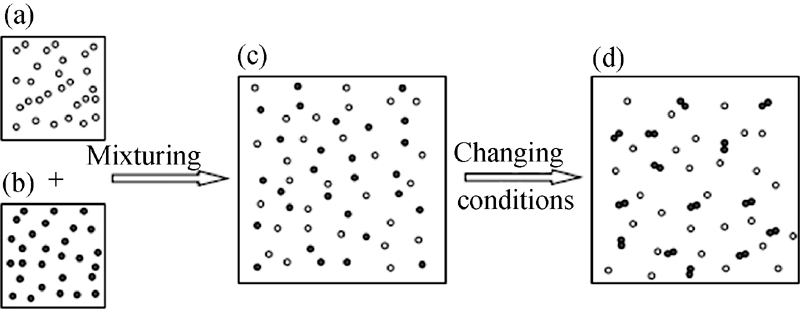

图4 双相悬浮液的示意图

Fig. 4 Schematic image of biphasic suspensions Two stably dispersed suspensions (a, b) are mixed (c), and then conditions are changed to trigger the flocculation of one suspension but still another suspensions flowing (d)

| External conditions for solidification of suspensions | Assistant-solidification suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Fast evaporation of solvent in suspensions | Colloidal suspensions with shear thinning behavior | 500 μm | [17] |

| Suspensions composited of nanoparticles and organic solvent | 1 μm | [42-43] | |

| Solubility divergence between solvent in suspensions and liquid in deposition reservoir | polyelectrolyte complexes (PECs) | 500 μm 30 μm 1 μm | [30, 43-44] |

| Polymerization of organic monomer under ultraviolet irradiation | Silk fibroin solution | 5 μm | [45] |

| Sol-Gel suspension | 0.3 μm | [46] | |

| Organic monomer solution | 5 μm | [31] | |

| Suspensions containing organic monomer | — | [47] |

表2 直写成型的外固化悬浮液[17, 30-31, 42-47]

Table 2 Assistant-solidification suspensions designed for direct ink writing[17, 30-31, 42-47]

| External conditions for solidification of suspensions | Assistant-solidification suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Fast evaporation of solvent in suspensions | Colloidal suspensions with shear thinning behavior | 500 μm | [17] |

| Suspensions composited of nanoparticles and organic solvent | 1 μm | [42-43] | |

| Solubility divergence between solvent in suspensions and liquid in deposition reservoir | polyelectrolyte complexes (PECs) | 500 μm 30 μm 1 μm | [30, 43-44] |

| Polymerization of organic monomer under ultraviolet irradiation | Silk fibroin solution | 5 μm | [45] |

| Sol-Gel suspension | 0.3 μm | [46] | |

| Organic monomer solution | 5 μm | [31] | |

| Suspensions containing organic monomer | — | [47] |

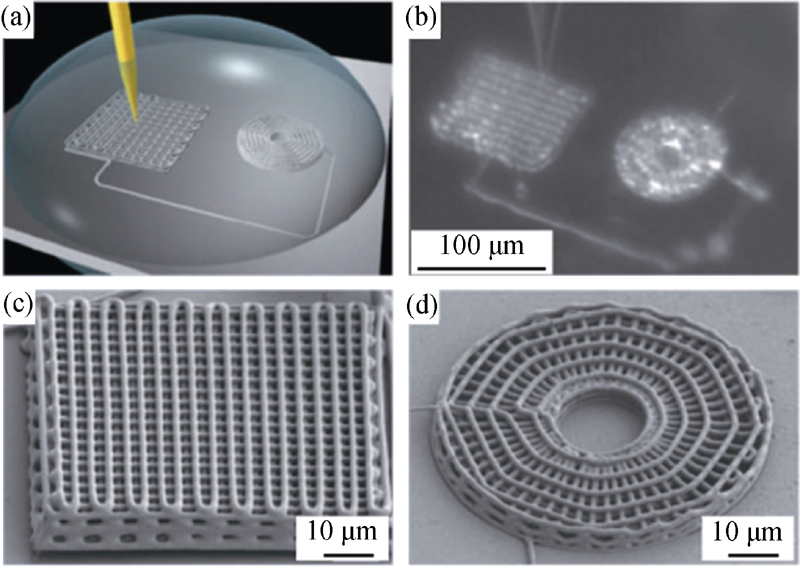

图5 采用聚电解质混合物制备的三维周期结构

Fig. 5 Direct ink writing of three-dimensional microperiodic structures (a) Schematic diagram of direct ink writing with deposition reservoir; (b) Optical image acquired in situ during deposition; (c) Three-dimensional periodic structure with a face-centred tetragonal geometry; (d) Three- dimensional radial array[30]

| [1] | LEWIS J A.Colloidal processing of ceramics.Journal of the American Ceramic Society, 2000, 83(10): 2341-2359. |

| [2] | LEWIS J A, GRATSON G M.Direct writing in three dimensions.Materials Today, 2004, 7(7): 32-39. |

| [3] | LEWIS J A, SMAY J E, STUECKER J, et al.Direct ink writing of three-dimensional ceramic structures. Journal of the American Ceramic Society, 2006, 89(12): 3599-3609. |

| [4] | ALLAHVERDI M, DANFORTH S C, JAFARI M, et al.Processing of advanced electroceramic components by fused deposition technique.Journal of the European Ceramic Society, 2001, 21(10): 1485-1490. |

| [5] | SAFARI A, AKDOGAN E K.Rapid prototyping of novel piezoelectric composites.Ferroelectrics, 2006, 331(1): 153-179. |

| [6] | TRESSLER J F, ALKOY S, DOGAN A, et al.Functional composites for sensors, actuators and transducers.Composites. Part A: Applied Science and Manufacturing, 1999, 30(4): 477-482. |

| [7] | LI Y, LI L, LI B.Direct ink writing of 3-3 piezoelectric composite.Journal of Alloys and Compounds, 2015, 620(25): 125-128. |

| [8] | SAN MARCHI C, KOUZELI M, RAO R, et al.Alumina-aluminum interpenetrating-phase composites with three-dimensional periodic architecture.Scripta Materialia, 2003, 49(9): 861-866. |

| [9] | RAO M P, SANCHEZ-HERENCIA A J, BELTZ G E, et al. Laminar ceramics that exhibit a threshold strength.Science, 1999, 286(5437): 102-105. |

| [10] | SOUNDARARAJAN R, KUHN G, ATISIVAN R, et al.Processing of mullite-aluminum composites.Journal of the American Ceramic Society, 2001, 84(3): 509-513. |

| [11] | EQTESADI S, MOTEALLEH A, MIRANDA P, et al.Robocasting of 45S5 bioactive glass scaffolds for bone tissue engineering.Journal of the European Ceramic Society, 2014, 34(1): 107-118. |

| [12] | MAAZOUZ Y, MONTUFAR E B, GUILLEM-MARTI J, et al.Robocasting of biomimetic hydroxyapatite scaffolds using self-setting inks.Journal of Materials Chemistry B, 2014, 2(33): 5378-5386. |

| [13] | MICHNA S, WU W, LEWIS J A.Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds.Biomaterials, 2005, 26(28): 5632-5639. |

| [14] | JOANNOPOULOS J D, VILLENEUVE P R, FAN S.Photonic crystals: putting a new twist on light. Nature, 1997, 386(6621): 143-149. |

| [15] | SHEN W, LI M, YE C, et al.Direct-writing colloidal photonic crystal microfluidic chips by inkjet printing for label-free protein detection.Lab on a Chip, 2012, 12(17): 3089-3095. |

| [16] | VLASOV Y A, BO X Z, STURM J C, et al.On-chip natural assembly of silicon photonic bandgap crystals.Nature, 2001, 414(6861): 289-293. |

| [17] | CESARANO III J.A review of robocasting technology.Materials Research Symposium Proceedings, 1999, 542: 133-139. |

| [18] | CESARANO III J, BAER T A, CALVERT P. Recent Developments in Freeform Fabrication of Dense Ceramics from Slurry Deposition. Albuquerque, NM: Sandia National Labs., 1997, SAND97-2857C. |

| [19] | ZEIN I, HUTMACHER D W, TAN K C, et al.Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials, 2002, 23(4): 1169-1185. |

| [20] | AGARWALA M K, BANDYOPADHYAY A, WEEREN R, et al.FDC, rapid fabrication of structural components.American Ceramic Society Bulletin, 1996, 75(11): 60-65. |

| [21] | RANGARAJAN S, QI G, VENKATARAMAN N, et al.Powder processing, rheology, and mechanical properties of feedstock for fused deposition of Si3N4 ceramics.Journal of the American Ceramic Society, 2000, 83(7): 1663-1669. |

| [22] | SACHS E, CIMA M, WILLIAMS P, et al.Three dimensional printing: rapid tooling and prototypes directly from a CAD model.Journal of Manufacturing Science and Engineering, 1992, 114(4): 481-488. |

| [23] | LEE K W, WANG S, LU L, et al.Fabrication and characterization of poly (propylene fumarate) scaffolds with controlled pore structures using 3-dimensional printing and injection molding. Tissue Engineering, 2006, 12(10): 2801-2811. |

| [24] | SACHS E, CIMA M, BREDT J, et al.CAD-casting: direct fabrication of ceramic shells and cores by three-dimensional printing.Manufacturing Review (USA), 1992, 5(2): 117-126. |

| [25] | SMAY J E, CESARANO J, LEWIS J A.Colloidal inks for directed assembly of 3-D periodic structures.Langmuir, 2002, 18(14): 5429-5437. |

| [26] | AHN B Y, SHOJI D, HANSEN C J, et al.Printed origami structures.Advanced Materials, 2010, 22(20): 2251-2254. |

| [27] | LI QI, LI BO, ZHOU JI, et al.Robocasting: a novel avenue for engineering complex 3D structures.Journal of Inorganic Materials, 2005, 20(1): 13-20. |

| [28] | CESARANO J, SEGALMAN R, CALVERT P.Robocasting provides moldless fabrication from slurry deposition.Ceramic Industry, 1998, 148(4): 94-102. |

| [29] | STUECKER J N, CESARANO J, HIRSCHFELD D A.Control of the viscous behavior of highly concentrated mullite suspensions for robocasting. Journal of Materials Processing Technology, 2003, 142(2): 318-325. |

| [30] | GRATSON G M, XU M, LEWIS J A.Microperiodic structures: direct writing of three-dimensional webs.Nature, 2004, 428(6981): 386. |

| [31] | BARRY R A, SHEPHERD R F, HANSON J N, et al.Direct-write assembly of 3D hydrogel scaffolds for guided cell growth.Advanced Materials, 2009, 21(23): 2407-2410. |

| [32] | HERSCHEL W H, BULKLEY R.Konsistenzmessungen von gummi-benzollösungen.Kolloid-Zeitschrift, 1926, 39(4): 291-300. |

| [33] | CHANNELL G M, ZUKOSKI C F.Shear and compressive rheology of aggregated alumina suspensions. AIChE Journal, 1997, 43(7): 1700-1708. |

| [34] | TRAPPE V, PRASAD V, CIPELLETTI L, et al.Jamming phase diagram for attractive particles.Nature, 2001, 411(6839): 772-775. |

| [35] | SMAY J E, CESARANO J, TUTTLE B A, et al.Directed colloidal assembly of linear and annular lead zirconate titanate arrays.Journal of the American Ceramic Society, 2004, 87(2): 293-295. |

| [36] | SMAY J E, CESARANO III J, TUTTLE B A, et al.Piezoelectric properties of 3-X periodic Pb(ZrxTi1-x)O3-polymer composites.Journal of Applied Physics, 2002, 92(10): 6119-6127. |

| [37] | LI Q, LEWIS J A.Nanoparticle inks for directed assembly of three-dimensional periodic structures.Advanced Materials, 2003, 15(19): 1639-1643. |

| [38] | RAO R B, KRAFCIK K L, MORALES A M, et al.Microfabricated deposition nozzles for direct-write assembly of three-dimensional periodic structures.Advanced Materials, 2005, 17(3): 289-293. |

| [39] | LEWIS J A, LI Q, RAO R. Biphasic Inks. U.S. Patent 8187500.2012-5-29. |

| [40] | GRAULE T J, GAUCKLER L J, BAADER F H.Direct coagulation casting-a new green shaping technique PT. 1. processing principles.Industrial Ceramics, 1996, 16(1): 31-34. |

| [41] | RHODES S K, LAMBETH R H, GONZALES J, et al.Cationic comb polymer superdispersants for colloidal silica suspensions. Langmuir, 2009, 25(12): 6787-6792. |

| [42] | AHN B Y, DUOSS E B, MOTALA M J, et al.Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes.Science, 2009, 323(5921): 1590-1593. |

| [43] | GRATSON G M, LEWIS J A.Phase behavior and rheological properties of polyelectrolyte inks for direct-write assembly.Langmuir, 2005, 21(1): 457-464. |

| [44] | XU M, LEWIS J A.Phase behavior and rheological properties of polyamine-rich complexes for direct-write assembly.Langmuir, 2007, 23(25): 12752-12759. |

| [45] | GHOSH S, PARKER S T, WWANG X, et al.Direct-write assembly of microperiodic silk fibroin scaffolds for tissue engineering applications.Advanced Functional Materials, 2008, 18(13): 1883-1889. |

| [46] | DUOSS E B, TWARDOWSKI M, LEWIS J A.Sol-Gel inks for direct-write assembly of functional oxides.Advanced Materials, 2007, 19(21): 3485-3489. |

| [47] | SHEPHERD R F, PANDA P, BAO Z, et al.Stop-flow lithography of colloidal, glass, and silicon microcomponents.Advanced Materials, 2008, 20(24): 4734-4739. |

| [48] | CESARANO III J, KING B H, DENHAM H B. Recent Developments in Robocasting of Ceramics and Multimaterial Deposition. Albuquerque, NM: Sandia National Labs., 1998, SAND98-2195C. |

| [49] | 高濂, 孙静, 刘阳桥. 纳米粉体的分散及表面改性. 北京: 化学工业出版社, 2003: 65-90. |

| [50] | PHILIPP B, DAUTZENBERG H, LINOW K J, et al.Polyelectrolyte complexes-recent developments and open problems.Progress in Polymer Science, 1989, 14(1): 91-172. |

| [51] | AHN B Y, LORANG D J, DUOSS E B, et al.Direct-write assembly of microperiodic planar and spanning ITO microelectrodes.Chemical Communications, 2010, 46(38): 7118-7120. |

| [52] | SUN JING-BO, LI BO, HUANG XUE-GUANG, et al.Direct-write assembly of ceramic three-dimensional structures based on photosensitive inks.Journal of Inorganic Materials, 2009, 24(6): 1147-1150. |

| [53] | SUN JING-BO, LI BO, CAI KUN-PENG, et al.TiO2 photolysis device fabricated by direct ink write assembly.Journal of Inorganic Materials, 2011, 26(3): 300-304. |

| [54] | CAI KUN-PENG, LI YA-YUN, SUN ZHEN-XIN, et al.Preparation of 3D ceramic meshes by direct-write method and modulation of its photocatalytic properties by structure design.Journal of Inorganic Materials, 2012, 27(1): 1-5. |

| [1] | 丁玲, 蒋瑞, 唐子龙, 杨运琼. MXene材料的纳米工程及其作为超级电容器电极材料的研究进展[J]. 无机材料学报, 2023, 38(6): 619-633. |

| [2] | 靳赛, 刘小根, 齐爽, 赵润昌, 李志军. 激光诱导损伤对熔石英玻璃弯曲强度弱化影响及安全设计[J]. 无机材料学报, 2023, 38(6): 671-677. |

| [3] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [4] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [5] | 林俊良, 王占杰. 铁电超晶格的研究进展[J]. 无机材料学报, 2023, 38(6): 606-618. |

| [6] | 牛嘉雪, 孙思, 柳鹏飞, 张晓东, 穆晓宇. 铜基纳米酶的特性及其生物医学应用[J]. 无机材料学报, 2023, 38(5): 489-502. |

| [7] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [8] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [9] | 杨洋, 崔航源, 祝影, 万昌锦, 万青. 柔性神经形态晶体管研究进展[J]. 无机材料学报, 2023, 38(4): 367-377. |

| [10] | 游钧淇, 李策, 杨栋梁, 孙林锋. 氧化物双介质层忆阻器的设计及应用[J]. 无机材料学报, 2023, 38(4): 387-398. |

| [11] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [12] | 陈昆峰, 胡乾宇, 刘锋, 薛冬峰. 多尺度晶体材料的原位表征技术与计算模拟研究进展[J]. 无机材料学报, 2023, 38(3): 256-269. |

| [13] | 张超逸, 唐慧丽, 李宪珂, 王庆国, 罗平, 吴锋, 张晨波, 薛艳艳, 徐军, 韩建峰, 逯占文. 新型GaN与ZnO衬底ScAlMgO4晶体的研究进展[J]. 无机材料学报, 2023, 38(3): 228-242. |

| [14] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| [15] | 谢兵, 蔡金峡, 王铜铜, 刘智勇, 姜胜林, 张海波. 高储能密度聚合物基多层复合电介质的研究进展[J]. 无机材料学报, 2023, 38(2): 137-147. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||