无机材料学报 ›› 2015, Vol. 30 ›› Issue (2): 159-164.DOI: 10.15541/jim20140376

袁文玉, 成来飞, 武 恒, 刘永胜

收稿日期:2014-07-21

修回日期:2014-09-23

出版日期:2015-02-20

网络出版日期:2015-01-27

作者简介:袁文玉(1992–), 男, 博士研究生. E-mail: ywy2014@mail.nwpu.edu.cn

基金资助:YUAN Wen-Yu, CHENG Lai-Fei , WU Heng, LIU Yong-Sheng

Received:2014-07-21

Revised:2014-09-23

Published:2015-02-20

Online:2015-01-27

About author:YUAN Wen-Yu. E-mail: ywy2014@mail.nwpu.edu.cn

Supported by:摘要:

将植物纤维转化为陶瓷是一种新型的、极具发展潜力的多孔陶瓷制备方法。本研究探索了将植物纤维转化为多孔SiC纤维的方法, 并分析了硅源对其反应产物的影响。结果表明, 由于密度效应, 气相硅陶瓷化相比液相而言, 具有更慢的反应速率, 表面所含的杂质也更少, 而且具有更可控的反应过程、更高的力学强度等优势。不同种类的硅源对反应速率、反应所需温度和产物的晶粒尺寸都有一定的影响, 研究发现SiO是一种较为理想的硅源物质。

中图分类号:

袁文玉, 成来飞, 武 恒, 刘永胜. 硅源对植物纤维制备SiC纤维的影响[J]. 无机材料学报, 2015, 30(2): 159-164.

YUAN Wen-Yu, CHENG Lai-Fei,WU Heng, LIU Yong-Sheng. Effect of Silicon Source on Biomorphic SiC Fibers Converted from Natural Fibers[J]. Journal of Inorganic Materials, 2015, 30(2): 159-164.

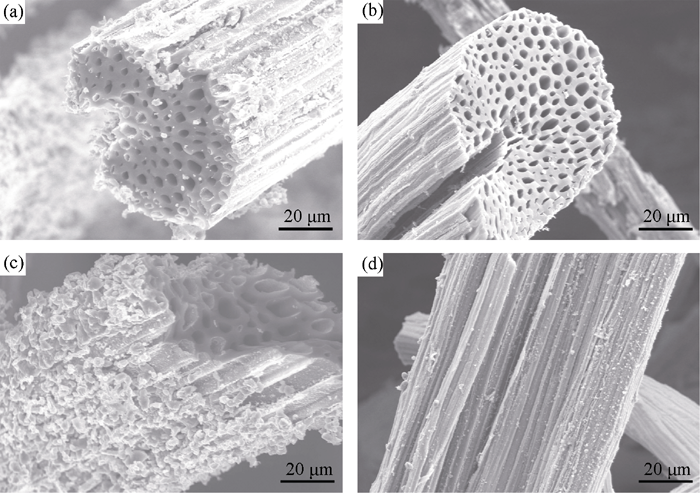

图3 剑麻纤维(碳化后)与液态(a, c)和气态(b, d)硅反应产物的SEM照片

Fig. 3 SEM images of the products produced by different states of silicon reaction with sisal fibers (carbide phases)

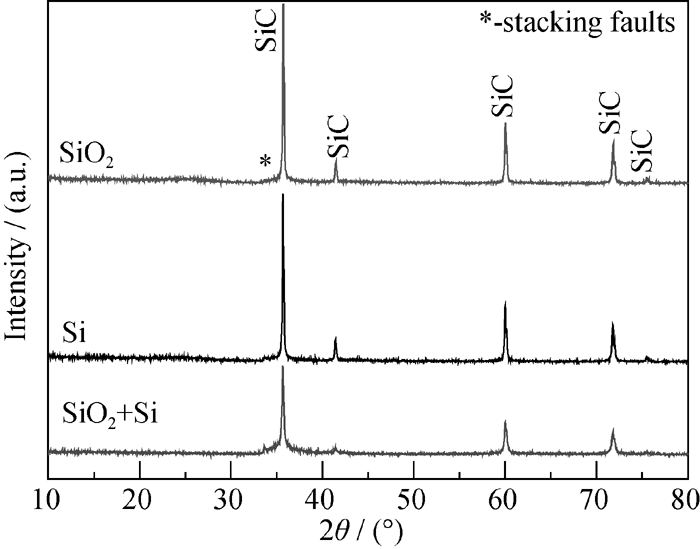

图4 不同硅源与黄麻纤维陶瓷化产物的XRD图谱

Fig. 4 XRD patterns of products that jute fibers vitrified with different silicon sources * Indicates stacking falts ([24, 32])

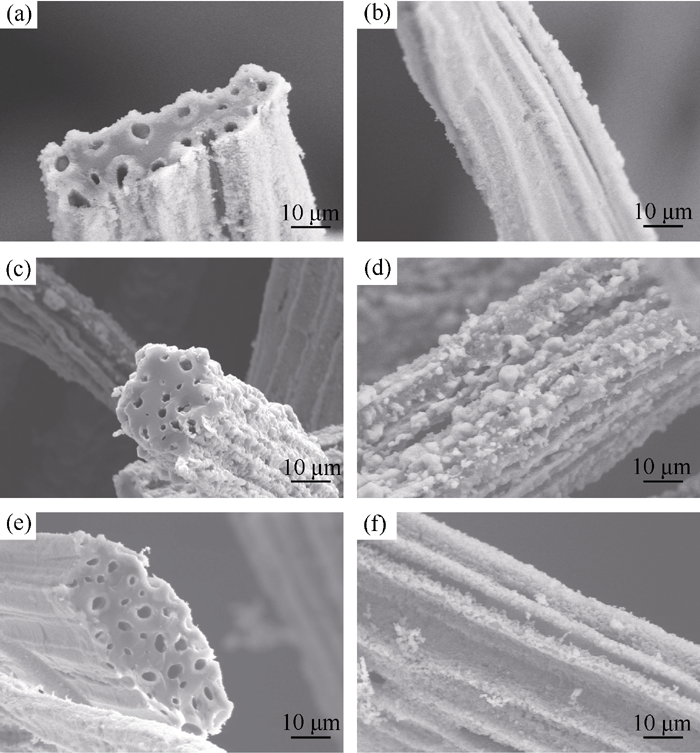

图5 不同硅源与黄麻纤维(碳化后)反应产物SiC纤维的截面和表面SEM照片

Fig. 5 SiC fibers’ cross-section and surface SEM images of the products prepared by Si (a, b), SiO2 (c, d) and Si+SiO2 (e, f) reaction with jute fibers (carbide phases)

| [1] | LI KAI, WANG LI-NA, GUAN LI, et al.Study on preparation and characterization of SiC composites reinforced with Nicanlon SiC fibers.Bulletin of the Chinese Ceramic Society, 2009, 28(z1): 164-167. |

| [2] | LIU HAITAO, CHENG HAIFENG, WANG JUN, et al.Study on the interphase of the continuous SiC fiber reinforced SiC composites.Materials Review, 2010, 24(01): 10-14, 30. |

| [3] | ZHU DAN, LI YUFENG, GAO MINGXIA, et al.Research development of fabrication techniques and proper ties of SiCf/SiC ceramic matrix composite. Materials Review, 2008, 22(3): 55-59. |

| [4] | 赵爽. SiCf/SiC复合材料的制备及其与LiPb熔液化学相容性初步研究. 湖南: 国防科学技术大学硕士学位论文, 2008. |

| [5] | KIM W J, KANG S M, PARK J Y, et al.Effect of a SiC whisker formation on the densification of Tyranno SA/SiC composites fabricated by the CVI process. Fusion Engineering and Design, 2006, 81(8-14): 931-936. |

| [6] | LIU QINGHUA.The industrial preparation of SiC fibers.The Light & Textile Industries of Fujian, 2006, 206(7): 7-12. |

| [7] | XUE JINGEN, LONG JIANFENG, SONG YONGCAI, et al.Research process in SiC fiber production technology.China Synthetic Fiber Industry, 2001, 24(3): 41-44. |

| [8] | LIU CUIXIA, YANG YANQING, XU TING, et al.Progress and prospect of CVD continuous SiC fibers. Materials Review, 2006, 20(8): 35-37, 40. |

| [9] | 杨大祥. PCS和PMCS的新合成方法及高耐温性SiC纤维的制备研究. 湖南: 国防科学技术大学博士学位论文, 2008. |

| [10] | CHEN JIANG-XI, HE GUO-MEI, HE XU-MIN, et al.Development of polymer precursors to SiC ceramic fiber.Journal of Functional Materials, 2004, 35(6): 679-682. |

| [11] | DONG ZHAN-NENG, LI CHUN-HUA, GUO YU-ZHONG.Mechanism of Wurtz-synthesis of polysilanes and preparation of β-SiC fiber. Journal of Kunming Uniersity of Science and Technology (Science and Technology), 2003, 28(2): 123-137. |

| [12] | 曹峰. 耐超高温碳化硅纤维新型先驱体研究及纤维制备. 湖南: 国防科学技术大学博士学位论文, 2002. |

| [13] | ZHAO DAFANG, LI XIAODONG, WANG HAIZHE, et al.ALuminm-containing silicon carbide fibers prepared from polyalumninocarbosilane and polycarbosilane blends.Acta Polymerica Sinica, 2008, 9(9): 831-839. |

| [14] | 赫荣安. 先驱体法制备SiC陶瓷多孔吸附纤维的研究. 湖南: 国防科学技术大学博士学位论文, 2008. |

| [15] | ZHAO DA-FANG, WANG HAI-ZHE, LI XIAO-DONG.Development of polymer-derived SiC fiber.Journal of Inorganic Materials, 2009, 24(6): 1097-1104. |

| [16] | YU XIAN-CHUN, SUN DE-LIN, SUN DE-BIN, et al.Basic properties of woodceramics made from bamboo powder and epoxy resin.Wood Science and Technology, 2012, 46(1/2/3): 23-31. |

| [17] | YAO CHUN-HUA, WU YI-QIANG, QING YAN, et al.Study on moulding process of eco-ceramics body with residual bamboo fiber.Bioinformatics and Biomedical Engineering, 3rd International Conference, 2009: 1-4. |

| [18] | KIYOTAKA SHIBATA, TOSHIHIRO OKABE, KOUJI SAITO, et al.Electromagnetic shielding properties of wood ceramics made from wastepaper.Journal of Porous Materials, 1997, 4(4): 269-275. |

| [19] | IIZUKA H, FUSHITANI M, OHTSUKA M, et al.Mechanical properties of porous carbon materials ie woodceramics.Journal of Materials Science Letters, 1996, 15(20): 1770-1772. |

| [20] | WU WENTAO, CHEN TIANHU, XU XIAOCHUN.Preparation and properties of palygorskite clay modified woodceramics from bagasse/wheat straw.Transactions of the CSAE, 2010, 26(1): 305-308. |

| [21] | SUN HAO-RAN.Study on preparation of woodceramics from corn stalk. Journal of Anhui Agri.Sci., 2012, 40(6): 3555-3556. |

| [22] | VOGLI E., SIEBER H., GREIL P., Biomorphic SiC-ceramic prepared by Si-vapor phase infiltration of wood.Journal of the European Ceramic Society, 2002, 22(14/15): 2663-2668. |

| [23] | DANIELA ALMEIDA STREITWIESER, NADJA POPOVSKA, HELMUT GERHARD, et al.Application of the chemical vapor infiltration and reaction (CVI-R) technique for the preparation of highly porous biomorphic SiC ceramics derived from paper.Journal of the European Ceramic Society, 2005, 25(6): 817-828. |

| [24] | WANG Q, ZHANG Y H.Biomorphic SiC prepared from carbonized millet by Sol-Gel and carbothermal reduction processing. Advanced Materials Research, 2010, 1683(152/153): 1683-1686. |

| [25] | 陈志林. 陶瓷化复合木材复合方法与性能的基础性研究. 北京: 北京工业大学博士学位论文, 2003. |

| [26] | HONGTAO ZHANG, JINSONG ZHANG, HONGYAN ZHANG.Electromagnetic properties of silicon carbide foams and their composites with silicon dioxide as matrix in X-band.Composites Part A: Applied Science and Manufacturing, 2007, 38(2): 602-608. |

| [27] | LIU QINGLEI, ZHANG DI, FAN TONGXIANGet al. Electromagnetic wave absorption properties of porous carbon/Co nanocomposites. Applied Physics Letters, 2008, 93(1): 013110-1-3. |

| [28] | JIN YANQIAO, ZHANG YIZHUAN, ZHAO XIAOXIAO, et al.Microstructure and properties of woodceramics prepared from lignin-modified phenol- formaldehyde resin.Journal of Wuhan University of Technology-Mater. Sci. Ed., 2012, 27(6): 1077-1080. |

| [29] | PETER GREIL.Biomorphous ceramics from lignocellulosics. Journal of the European Ceramic Society, 2001(21) : 105-118. |

| [30] | KINGERY W D, BOWEN H K, UHLMANN D R. 陶瓷导论, 2版. 北京: 高等教育出版社, 2010: 170-172. |

| [31] | VOGLI E, MUKERJI J, HOFFMANN C, et al.Conversion of oak to cellular silicon carbide by gas-phase reaction with silicon monoxide.J. Am. Ceram. Soc., 2001, 86(6): 1236-1240. |

| [32] | KUNIHITO KOUMOTO, SHUNJI TAKEDA, CHUL HOON PAI, et al.High-resolution electron microscopy observations of stacking faults in β-SiC.Journal of the American Ceramic Society, 1989, 72(10): 1985-1987. |

| [1] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [2] | 王袁杰, 裴学良, 李好义, 徐鑫, 何流, 黄政仁, 黄庆. 自由基引发活性聚碳硅烷交联及其在制备SiC纤维中的应用[J]. 无机材料学报, 2021, 36(9): 967-973. |

| [3] | 祝泉, 胡建宝, 杨金山, 周海军, 董绍明. 采用定向SiC纳米线烧结制备高强多孔SiC陶瓷[J]. 无机材料学报, 2021, 36(5): 547-551. |

| [4] | 张力, 杨现锋, 徐协文, 郭金玉, 周哲, 刘鹏, 谢志鹏. 熔融沉积法3D打印制备氧化锆陶瓷及其力学性能研究[J]. 无机材料学报, 2021, 36(4): 436-442. |

| [5] | 王西,王克杰,柏辉,宋卓林,王波,张程煜. 化学气相渗透2D-SiCf/SiC复合材料的蠕变性能及损伤机理[J]. 无机材料学报, 2020, 35(7): 817-821. |

| [6] | 董龙浩,张海军,张俊,吴文浩,贾全利. 碳纳米管改性海泡石多孔陶瓷及其高效油水分离性能研究[J]. 无机材料学报, 2020, 35(6): 689-696. |

| [7] | 王堋人, 苟燕子, 王浩. 第三代SiC纤维及其在核能领域的应用现状[J]. 无机材料学报, 2020, 35(5): 525-531. |

| [8] | 余汉青, 董志军, 袁观明, 丛野, 李轩科, 罗永明. B-C掺杂SiC纤维的制备及其性能研究[J]. 无机材料学报, 2019, 34(5): 493-501. |

| [9] | 王国栋, 宋永才. 熔融纺丝过程优化制备细直径碳化硅纤维及其对力学性能的影响[J]. 无机材料学报, 2018, 33(7): 721-727. |

| [10] | 穆阳, 邓佳欣, 李皓, 周万城. 两种连续SiC纤维的高温介电及吸波性能对比[J]. 无机材料学报, 2018, 33(4): 427-433. |

| [11] | 谢雨洲, 彭超群, 王小锋, 王日初, 罗 丰. HEMA-TBA凝胶体系制备多孔氧化铝陶瓷[J]. 无机材料学报, 2017, 32(7): 731-738. |

| [12] | 左亚卓, 李红, 王少雷, 杨敏, 任慕苏, 孙晋良. (C-SiC)f/C复合材料的烧蚀性能[J]. 无机材料学报, 2017, 32(11): 1141-1146. |

| [13] | 孙进兴, 陈 斌, 刘培生. 轻质多孔陶瓷的制备及吸声性能研究[J]. 无机材料学报, 2016, 31(8): 860-864. |

| [14] | 曹适意, 王 军, 王 浩, 王小宙. 自由碳的脱除对SiC纤维微观结构和性能的影响[J]. 无机材料学报, 2016, 31(5): 529-534. |

| [15] | 袁 钦, 宋永才. 连续SiC纤维和SiCf/SiC复合材料的研究进展[J]. 无机材料学报, 2016, 31(11): 1157-1165. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||