无机材料学报 ›› 2015, Vol. 30 ›› Issue (2): 153-158.DOI: 10.15541/jim20140291

李 艳1,2, 崔 红2, 张华坤2, 嵇阿琳2, 介玉洁2

收稿日期:2014-06-04

修回日期:2014-07-30

出版日期:2015-02-20

网络出版日期:2015-01-27

作者简介:李 艳(1980–),女,博士研究生,高级工程师. E-mail:icering604@126.com

基金资助:LI Yan1,2, CUI Hong2, ZHANG Hua-Kun2, JI A-Lin2, JIE Yu-Jie2

Received:2014-06-04

Revised:2014-07-30

Published:2015-02-20

Online:2015-01-27

About author:LI Yan. E-mail:icering604@126.com

Supported by:摘要:

以整体毡为纤维增强体, 采用外壁恒温控温和内壁恒温控温两种方式, 通过热梯度化学气相渗透(TG-CVI)工艺研究了大尺寸C/C复合材料的致密化行为。结果表明, 外壁恒温控温方式制备的试样密度仅为0.64 g/cm3, 呈现出两边高中间低的特点, 热解碳结构为粗糙层与光滑层相结合。而内壁恒温控温方式制备的试样密度达到0.98 g/cm3, 致密效率相比提高了73.79%, 热解碳结构为具有优异性能的粗糙层结构, 试样内部密度分布均匀。通过与外壁恒温控温相比, 内壁恒温控温方式具有较高的温度和合适的温度梯度, 致密化行为符合理想致密化模型, 能够实现大尺寸C/C复合材料由内至外的正向密度增长, 致密均匀, 致密效率高, 且碳结构优异。

中图分类号:

李 艳, 崔 红, 张华坤, 嵇阿琳, 介玉洁. 热梯度CVI制备大尺寸C/C复合材料的致密化行为[J]. 无机材料学报, 2015, 30(2): 153-158.

LI Yan, CUI Hong, ZHANG Hua-Kun, JI A-Lin, JIE Yu-Jie. Densification Behavior of Thermal Gradient CVI of Large-scale C/C Composites[J]. Journal of Inorganic Materials, 2015, 30(2): 153-158.

图3 A、B试样不同位置温度随致密化时间变化关系图

Fig. 3 Temperature changes of samples prepared under out (A) and inner(B) wall temperature controlling at different densification time

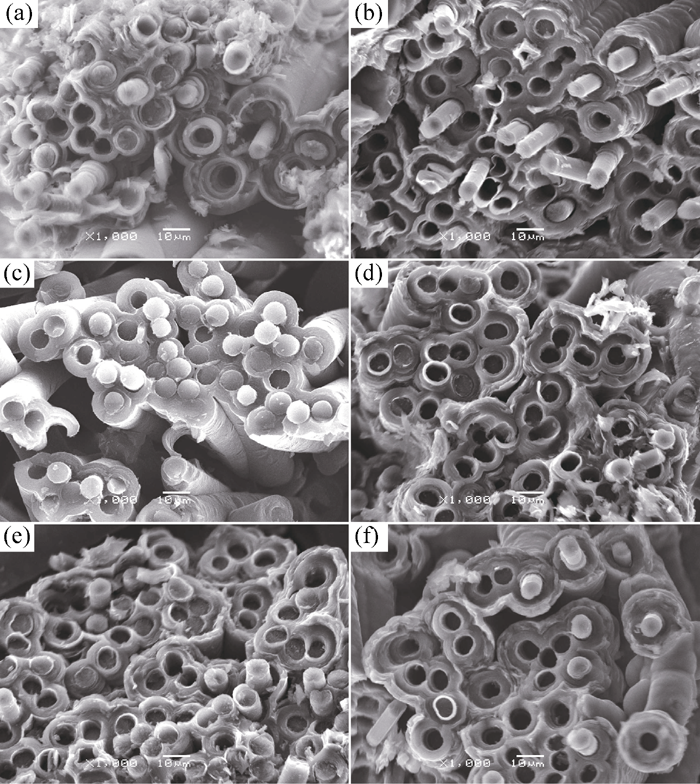

图4 恒温600 h后A、B试样不同位置SEM照片

Fig. 4 SEM images of sample A and B at different positions after densification for 600 h (a, c and e): Inner wall, central section and outer wall of sample A, respectively, under outer wall temperature controlling; (b, d and f): Inner wall, central section and outer wall of sample B under inner wall temperature controlling

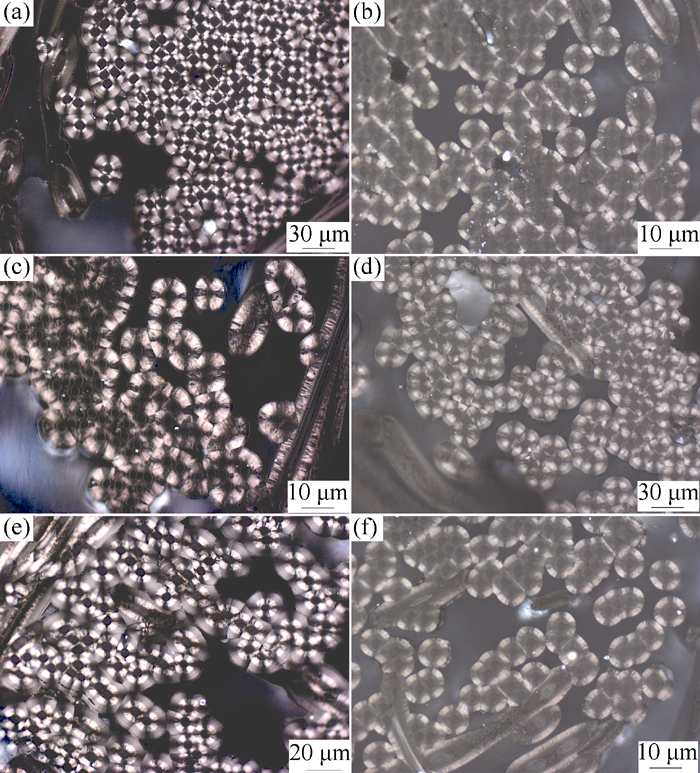

图5 A、B试样不同部位热解碳偏光显微照片

Fig. 5 PLM of pyrocarbon of samples A and B at different positions (a, c and e): Inner wall, central section and outer wall of sample A, respectively, under outer wall temperature controlling, and Ae values were 16°-18°; 16°-18° and 18°-20°, respectively. (b, d and f): Inner wall, central section and outer wall of sample B, respectively, under inner wall temperature controlling, and all Ae values were 18°-20°

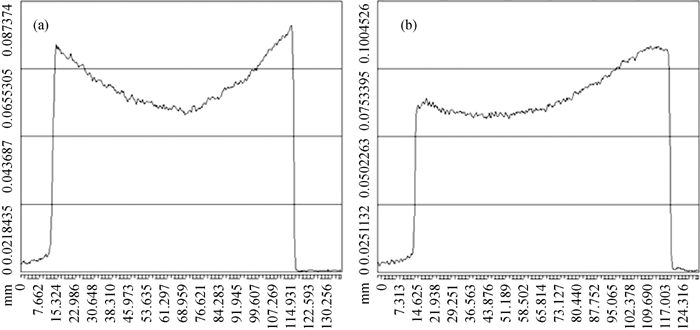

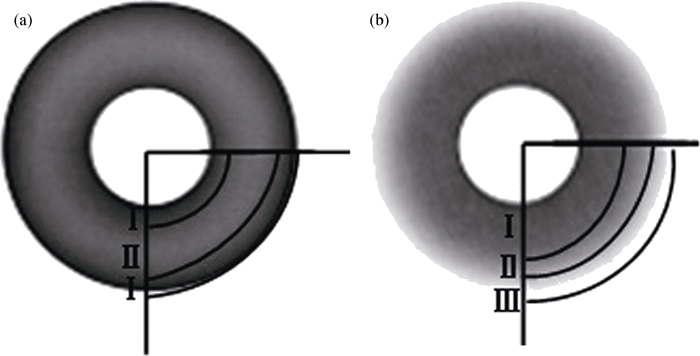

图6 不同致密时间后A试样在恒温致密化300 h(a)和600 h(b)时的CT曲线图

Fig. 6 CT curves of sample A under outer wall temperature controlling after densification for 300 h (a) and 600 h (b)

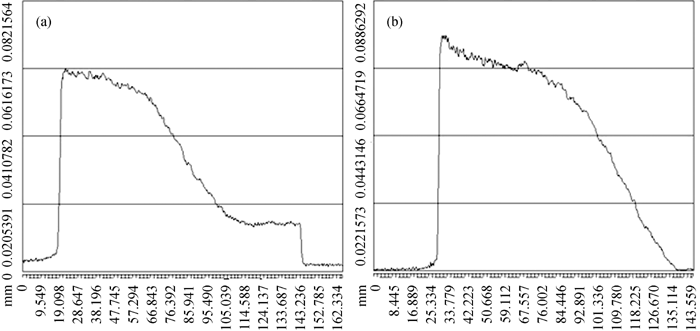

图7 不同致密时间后B试样在恒温致密化300 h(a)和600 h(b)的CT曲线图

Fig. 7 CT curves of sample B under inner wall temperature controlling after densification for 300 h (a) and 600 h (b)

图8 两种试样沉积600 h后CT剖面图

Fig. 8 CT images on cross section of samples under out wall (a) and inner wall (b) temperature controlling after densification for 600 h

| [1] | ZOU ZHI-QIANG, TANG ZHONG-HUA, XIONG JIE.The manufacturing of C/C composite brake disk by means of thermal gradient densification technique.New Carbon Materials, 2000, 15(2): 22-27. |

| [2] | DELHAES P.Chemical vapor deposition and infiltration processes of carbon materials. Carbon, 2002, 40: 641-657. |

| [3] | WANG JI-PING, QIAN JUN-MING, QIAO GUAN-JUN, et al.A rapid fabracation of composites by a thermal gradient chemical vapor infiltration method with vaporized kerosene as a precursor.Materials Chemistry and Physics, 2007, 101: 7-11. |

| [4] | LI HE-JUN.Carbon/carbon composites.New Carbon Materials, 2001, 16(2): 79-80. |

| [5] | ZHANG WEI-GANG, HU Z J, HÜTTINGRT K J. Chemical vapor infiltration of carbon fiber felt:optimization of densition and carbon microstruction.Carbon, 2002, 40: 2529-2545. |

| [6] | HU Z. J, ZHANG WEI-GANG, HÜTTINGRT K J, et al. Influence of pressure,temeperature and suface area/volume ratio on the texture of pyrolytic carbon deposited from methane.Carbon, 2003, 41: 749-758. |

| [7] | PAUW V D, COLLIN A, SEND W, et al.Deposition rates during the early stages of pyrolytic carbon deposition in a hot-wall reactor and the development of textrue.Carbon, 2006, 44: 3091-3101. |

| [8] | HU ZI-JUN, HÜTTINGR K J. Chemical vapor infiltration of carbon revised Part Ⅱ: Experimental results. Carbon, 2001, 39: 1023-1032. |

| [9] | ZHANG WEI-GANG, HÜTTINGR K J. Densification of a 2D carbon fiber perform by isothermal,isobaric CVI:Kinetics and carbon microstructurec CVI:Kinetics and carbon microstructure.Carbon, 2003, 41: 2325-2337. |

| [10] | WU XIAO-JUN, CHENG WEN, QIAO SHENG-RU, et al.Fast densification of thick-walled carbon/carbon composite tubes using electrically coupled chemical vapor infiltration. Carbon, 2013, 57: 371-379. |

| [11] | SUN GUO-LING, LI HE-JUN, QI LE-HUA, et al.Analysis of unstable temperature field for theraml gradient CVI densification process of C/C composite.Acta Metallurgica Sinica, 2006, 42(10): 1046-1050. |

| [12] | GUELLALI M, OBERACKER R, HOFFMANN M J, et al.Textures of pyrolytic carbon formed in the chemical vapor infiltration of capillaries.Carbon, 2003, 41: 97-104. |

| [13] | YIN JIAN, ZHANG HONG-BO, XIONG XIANG, et al.Influence of microstructure of pyrocarbon on ablation performances of C/C composites.Chinese Journal of Materials Research, 2007, 21(1): 10-14. |

| [14] | YAN GUI-SHEN, LI HE-JUN, ZHANG SHOU-YANG, et al.Densification mechanism of perform with thermal gradient CVI.Acta Materiae Compositae Silica, 2003, 20(2): 64-70. |

| [15] | DENG JING-YI,LIU WEN-CHUAN,DU HAI-FENG, et al. Control of the deposition temperature in thermal gradient CVI. Carbon Techniques, 1999(6): 22-24. |

| [16] | LI JIAN-LI,SU ZHE-AN,ZHANG MING-YU, et al.Mehanism of densification of C/C composites fabricated with high density perform.Journal of Inorganic Materials, 2011, 26(7): 711-714. |

| [1] | 王磊, 李建军, 宁军, 胡天玉, 王洪阳, 张占群, 武琳馨. CoFe2O4@Zeolite催化剂活化过一硫酸盐对甲基橙的强化降解: 性能与机理[J]. 无机材料学报, 2023, 38(4): 469-476. |

| [2] | 陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162. |

| [3] | 荆开开, 管皞阳, 朱思雨, 张超, 刘永胜, 王波, 王晶, 李玫, 张程煜. Cansas-II SiCf/SiC复合材料的高温拉伸蠕变行为[J]. 无机材料学报, 2023, 38(2): 177-183. |

| [4] | 陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646. |

| [5] | 吴西士, 朱云洲, 黄庆, 黄政仁. 树脂基多孔碳孔结构对Cf/SiC复合材料连接性能的影响[J]. 无机材料学报, 2022, 37(12): 1275-1280. |

| [6] | 张硕, 付前刚, 张佩, 费杰, 李伟. C/C多孔体的高温热处理对C/C-SiC复合材料摩擦磨损行为的影响[J]. 无机材料学报, 2023, 38(5): 561-568. |

| [7] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [8] | 郭隐犇, 陈子曦, 王宏志, 张青红. 基于无机填料复合薄膜的摩擦纳米发电机研究进展[J]. 无机材料学报, 2021, 36(9): 919-928. |

| [9] | 张维维, 陆晨, 应国兵, 张建峰, 江莞. AlN表面处理及级配填充对覆铜板绝缘层性能的影响规律与机制研究[J]. 无机材料学报, 2021, 36(8): 847-855. |

| [10] | 彭飞, 姜勇刚, 冯坚, 蔡华飞, 冯军宗, 李良军. 耐高温氧化铝气凝胶隔热复合材料研究进展[J]. 无机材料学报, 2021, 36(7): 673-684. |

| [11] | 郭猛, 张丰年, 苗洋, 刘宇峰, 郁军, 高峰. La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3钙钛矿高熵陶瓷粉体的制备及其电学性能[J]. 无机材料学报, 2021, 36(4): 431-435. |

| [12] | 张丰年, 郭猛, 苗洋, 高峰, 成楚飞, 程富豪, 刘宇峰. 高熵陶瓷(Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ的制备及烧结行为[J]. 无机材料学报, 2021, 36(4): 372-378. |

| [13] | 武志红, 邓悦, 蒙真真, 张国丽, 张路平, 王宇斌. 含SiC阵列改性涂层的新型SiC/Cf复合材料吸波性能研究[J]. 无机材料学报, 2021, 36(3): 306-312. |

| [14] | 郭小炜, 李玉妍, 陈南春, 王秀丽, 解庆林. 负载二甲酸钾缓释抗菌微球的构建[J]. 无机材料学报, 2021, 36(2): 181-187. |

| [15] | 马登浩, 侯振华, 李军平, 孙新, 金恩泽, 尹健. 界面相对3D-SiC/SiC复合材料静态力学性能及内耗特征的影响[J]. 无机材料学报, 2021, 36(1): 55-60. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||