无机材料学报 ›› 2015, Vol. 30 ›› Issue (2): 113-121.DOI: 10.15541/jim20140300

• • 下一篇

罗凌虹, 余 辉, 黄祖志

收稿日期:2014-06-09

修回日期:2014-08-01

出版日期:2015-02-20

网络出版日期:2015-01-27

基金资助:LUO Ling-Hong, YU Hui, HUANG Zu-Zhi

Received:2014-06-09

Revised:2014-08-01

Published:2015-02-20

Online:2015-01-27

Supported by:摘要:

封接玻璃是中温固体氧化物燃料电池(IT-SOFC)的主要组成部分, 封接玻璃应同时具有适宜的热性能、化学性能、力学性能及与电池元件有良好的粘合能力, 防止SOFC在运行过程中气体的泄漏, 并保证玻璃在IT-SOFC工作温度及氧化气氛或燃料气氛下长期运行的热稳定性和封接玻璃与其它电池元件之间的界面稳定性。本文综述了关于IT-SOFC封接玻璃近十年的研究进展。从玻璃特性和封接玻璃与元件之间的界面反应的角度, 讨论封接玻璃的组分-结构-性能三者之间的关系, 提出了当前IT-SOFC封接玻璃研究的主要问题。

中图分类号:

罗凌虹, 余 辉, 黄祖志. 中温固体氧化物燃料电池封接玻璃的研究进展[J]. 无机材料学报, 2015, 30(2): 113-121.

LUO Ling-Hong, YU Hui, HUANG Zu-Zhi. Research Progress of the Sealing Glass for Intermediate Temperature Solid Oxide Fuel Cell[J]. Journal of Inorganic Materials, 2015, 30(2): 113-121.

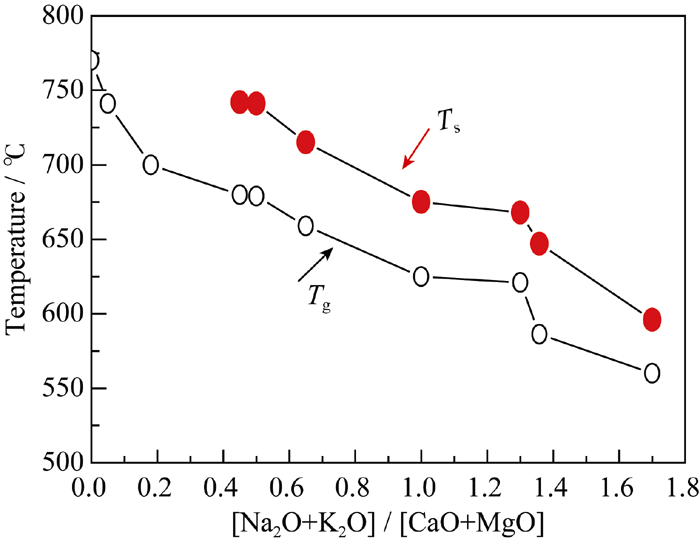

图2 (Na2O +K2O)/(CaO +MgO)摩尔比值对硅酸盐封接玻璃的Tg和Ts的影响[20]

Fig. 2 Variation of Tg and Ts with (Na2O+K2O)/(CaO+MgO) molar ratio in silicate glass composition[20]

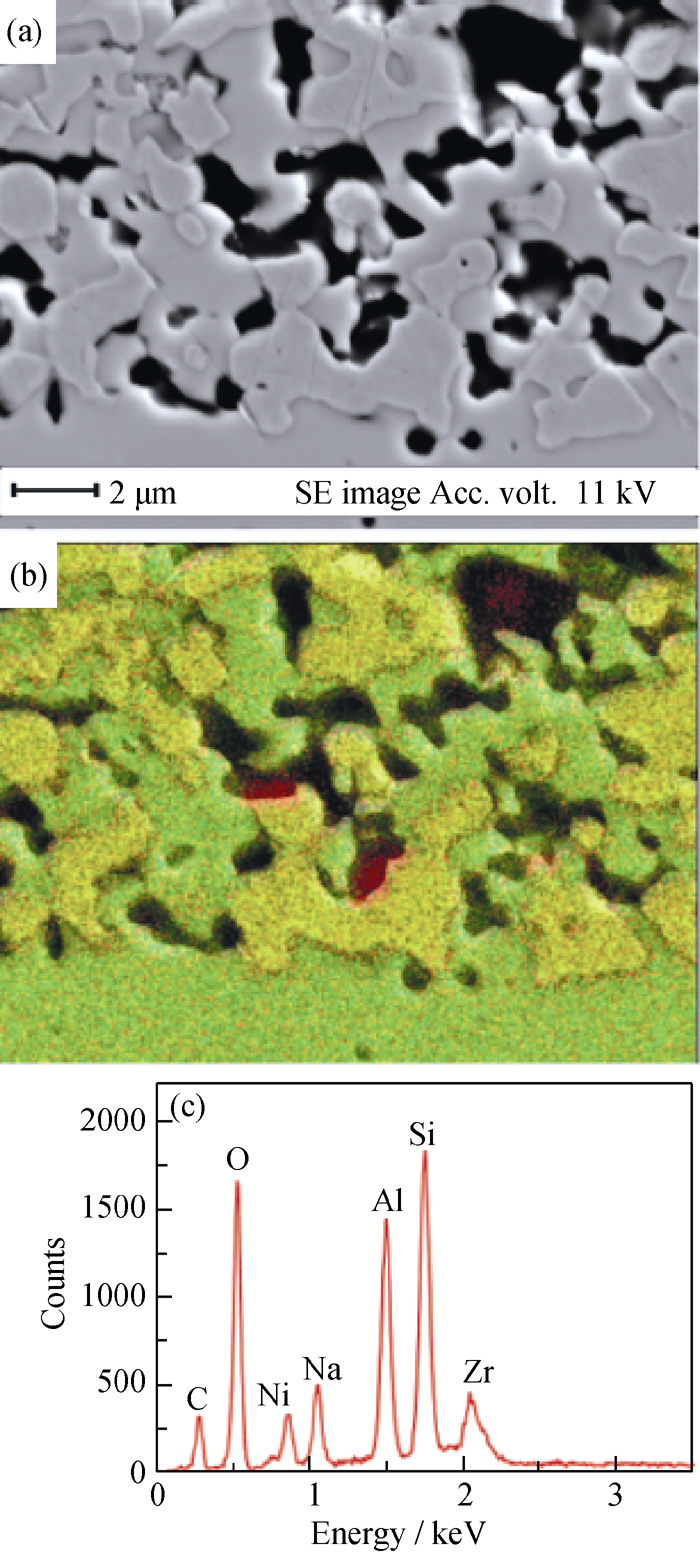

图5 阳极的 (a)微观结构, (b) a区的EDS(绿色点Zr, 黄色为Ni, 红色为Si和(c)靠近电解质侧的EDS元素分析[49]

Fig. 5 (a) SEM image of the anode, (b)EDS pattern of the same region as in (a) (Zr is green, Ni is yellow, and Si is red). For clarity the element pattern for Al and Na have not been overlaid) and (c) EDS point analysis of the Na and Al containing silicate impurity closest to the electrolyte in (b) [49]

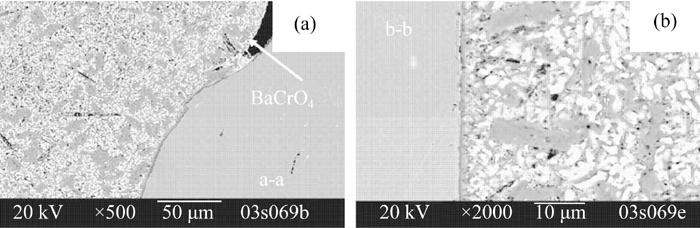

图6 G18玻璃与Crofer22 APU在850℃ 热处理1 h, 后在750℃ 处理24 h后的界面反应[57]

Fig. 6 Interfacial reactions between G18 sealing glass and stainless steel Crofer22 APU were joined with G18 through heat treatment at 850℃ for 1 h, followed by 750℃ for 24 h[57]

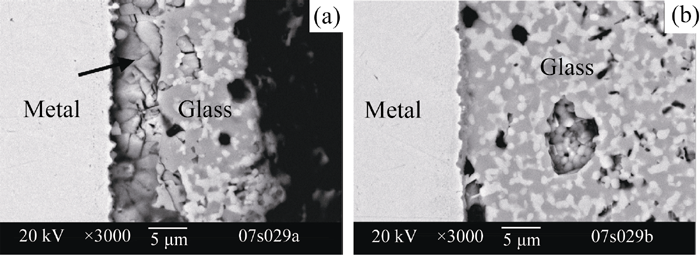

图7 玻璃/金属连接板的粘合界面形貌照片[60]

Fig. 7 Cross-section view of the glass/metal interface[60] (a) Without treatment, and (b) Crofer22 APU surface coated with MnCo2O4

| [1] | HUANG Y H, DASS R I, XING Z L, et al.Good enough, double perovskites as anode materials for solid-oxide fuel cells.Science, 2006, 312: 254-257. |

| [2] | SINGH A, KRISHNAN V V.Anode characterization and SOFC performance using Ni-YSZ anodes formed by Ni impregnation methods.ECS Transactions, 2008, 6(21): 25-32. |

| [3] | DING J, LIU J, YIN G Q.Fabrication and characterization of low-temperature SOFC stack based on GDC electrolyte membrane.J. Membr. Sci., 2011, 3719(1/2): 219-225. |

| [4] | TOMKIEWICZ A C, MELONI M, MCINTOSH S.On the link between bulk structure and surface activity of double perovskite based SOFC cathodes.Solid State Ionics, 2014, 260(1): 55-59. |

| [5] | SEO H S, YUN D W, KIM K Y.Oxidation behavior of ferritic stainless steel containing Nb, Nb-Si and Nb-Ti for SOFC interconnect. Int. J. Hydrogen Energy, 2013, 38(5):2432-2442. |

| [6] | SMEACETTO F, SALVO M, SANTARELLI M, et al.Performance of a glass-ceramic sealant in a SOFC short stack. Int. J. Hydrogen Energy, 2013, 38(11):588-596. |

| [7] | HAANAPPEL V A C, SHEMET V, GROSS S M, et al. Behaviour of various glass-ceramic sealants with ferritic steels under simulated SOFC stack conditions.J. Power Sources, 2005, 150(1):86-100. |

| [8] | NORBERT H MENZLER, SEBOLD D, MOHSINE Z, et al.Interaction of metallic SOFC interconnect materials with glass-ceramic sealant in various atmospheres.J. Power Sources, 2005, 152(1):156-167. |

| [9] | SMEACETTO F, SALVO M, LEONE P, et al.Performance and testing of joined Crofer22APU-glass-ceramic sealant-anode supported cell in SOFC relevant conditions.Mater. Lett., 2011, 65(6): 1048-1052. |

| [10] | PARK J L, LIM T H, LEE S B, et al.Fabrication and operation of a 6 kW class interconnector-type anode-supported tubular solid oxide fuel cell stack.Int. J. Hydrogen Energy, 2014, 35(24): 12884-12893. |

| [11] | LU K, LI W L.Study of an intermediate temperature solid oxide fuel cell sealing glass system.J. Power Sources, 2014, 245(1): 752-757. |

| [12] | MAHAPATRA M K, LU K.Glass-based seals for solid oxide fuel and electrolyzer cells-a review.Mater. Sci. Eng. R, 2010 , 67(5/6):65-85. |

| [13] | CHEN K, AI N, ZHAO L, et al.Effect of volatile boron species on the electrocatalytic activity of cathodes of solid oxide fuel cells I. (La, Sr) MnO3 based electrodes.J. Electrochem. Soc., 2013, 160(9): 183-190. |

| [14] | ANANTHANARAYANAN A, KOTHIYAL G P L, Montagne, et al. The effect of P2O5 on the structure, sintering and sealing properties of barium calcium aluminum boro-silicate (BCABS) glasses.Mater. Chem. Phys., 2011, 130(3):880-889. |

| [15] | MAHAPATRA M K, LU K.Seal glass for solid oxide fuel cells.J. Power Sources, 2010, 95(21):7129-7139. |

| [16] | SCOTT WEIL K.The state-of-the-art in sealing technology for solid oxide fuel cells.J. Miner, Metal & Mater Soc., 2006, 58(8):37-44. |

| [17] | JEFFREY W FERGUS.Sealants for solid oxide fuel cells.J. Power Sources, 2005, 147(1/2):46-57. |

| [18] | MAHAPATRA M K, LU K, BODNAR R J.Network structure and thermal property of a novel high temperature seal glass,Appl. Phys. A, 2009, 95(2):493-500. |

| [19] | SCHOLZE H. GlassNature, Structure, and Properties, Springer Verlag, New York, 1991. |

| [20] | LEE S, MYSEN B, CODY G.Oxygen-17 nuclear magnetic resonance study of the structure of mixed cation calcium-sodium silicate glasses at high pressure: implications for a molecular link to element partioning between silicate liquids and crystals.J. Phys. Chem. B., 2008, 112: 11756-11761. |

| [21] | LARA C, PASCUAL M J, PRADO M O.Sintering of glasses in the system RO-Al2O3-BaO-SiO2 (R=Ca, Mg, Zn) studied by hot-stage microscopy.Solid State Ionics, 2004, 170:201-208. |

| [22] | BROCHU M, GAUNTT B D, SHAH R G, et al.Loehman. Comparison between barium and strontium-glass composites for sealing SOFCs.J. Euro. Ceram. Soc., 2006, 26(15): 3307-3313. |

| [23] | OJHA P K, RATH S K, CHONGDAR T K.Physical and thermal behaviour of Sr-La-Al-B-Si based SOFC glass sealants as function of SrO content and B2O3/SiO2 ratio in the matrix.J. Power Sources, 2011, 196:4594-4598. |

| [24] | KIM H, YANG J F, HAN C H, et al.Barium-free glass-ceramic sealants from the system CaO-MgO-B2O3-Al2O3-SiO2 for application in the SOFC.Materi Sci Forum, 2011, 695:1-4. |

| [25] | SOHN S B, CHOI S Y, KIM G H, et al.Suitable glass-ceramic sealant for planar solid-oxide fuel cells.J. Am. Ceram. Soc., 2004, 87(2): 254-260. |

| [26] | LARA C, PASCUAL M J, KEDING R, et al.Electrical behaviour of glass-ceramics in the systems RO-BaO-SiO2 (R = Mg, Zn) for sealing SOFCs.J. Power Sources, 2006, 157(1): 377-384. |

| [27] | ZHENG R, WANG S R, NIE H W, et al.SiO2-CaO-B2O3-Al2O3 ceramic glaze as sealant for planar IT-SOFC.J. Power Sources, 2004, 128(2):165. |

| [28] | CHOU Y S, STEVENSON J W, Xia G G, et al.Electrical stability of a novel sealing glass with (Mn, Co)-spinel coated Crofer22APU in a simulated SOFC dual environment. J. Power Sources, 2010, 195(17):5666-5673. |

| [29] | LAOSIRIPOJANA N, WIYARATN W.Reviews on solid oxide fuel cell technology.Engine J., 2009, 13(1):65-83. |

| [30] | DONALD I W, METCALFE B L, LEE A.Interfacial reactions in glass-ceramic-to-metal seals.J. Am. Ceram. Soc., 2008, 91: 715-720. |

| [31] | MAHAPATRA M K, LU K.Network structure and thermal property of a novel high temperature seal glass.Appl. Phys. A, 2009, 95(2): 493-500. |

| [32] | OJHA P K, RATH S K, CHONGDAR T K, et al.Physical and thermal behaviour of Sr-La-Al-B-Si based SOFC glass sealants as function of SrO content and B2O3/SiO2 ratio in the matrix.J. Power Sources, 2011, 196(10):4594-4598. |

| [33] | LIM E S, KIM B S, LEE J H, et al.Effect of BaO content on the sintering and physical properties of BaO-B2O3-SiO2 glasses.J. Non-Cryst Solids, 2006, 352(8): 821-826. |

| [34] | LEY K L, KRUMPELT M, KUMAR R, et al.glass-ceramic sealants for solid oxide fuel cells: part I. physical properties.J. Mater. Res., 1996, 11:1489-1493. |

| [35] | LARA C, PASCUAL M J, DURAN A.Glass-forming ability, sinterability and thermal properties in the systems RO-BaO-SiO2 (R = Mg, Zn). J. Non-Cryst. Solids, 2004, 348:149-155. |

| [36] | SOHN S B, CHOI S Y, KIM G H, et al.Suitable glass-ceramic sealant for planar solid-oxide fuel cells.J. Am. Ceram. Soc, 2004, 87(2): 254-260. |

| [37] | REDDY A A, TULYAGANOV D U, GOEL A, et al.Diopside-Mg orthosilicate and diopside-Ba disilicate glass-ceramics for sealing applications in SOFC: sintering and chemical interactions studies. Int. J. Hydrogen Energy, 2012, 37(17):588-596. |

| [38] | MAHAPATRA M K, LU K.Effects of nickel on network structure and thermal properties of a new solid oxide cell seal glass.J. Power Sources, 2008, 185(2):993-1000. |

| [39] | TAYLOR P, CAMPBELL A B, OWEN D G.Liquid immiscibility in the systems X2O-MO-B2O3-SiO2 (X=Na, K; M=Mg, Ca, Ba) and Na2O-MgO-BaO-B2O3-SiO2. J. Am. Ceram. Soc., 1983, 66(2): 347-351. |

| [40] | LARA C, PASCUAL M J, KEDING R, et al.Electrical behaviour of glass-ceramics in the systems RO-BaO-SiO2 (R = Mg, Zn) for sealing SOFCs.Journal of Power Sources, 2006, 157: 377-384. |

| [41] | LAHL N, SINGH K, SINGHEISER L, et al.Crystallisation kinetics in AO-Al2O3-SiO2-B2O3 glasses (A = Ba, Ca, Mg).J. Mater. Sci., 2006, 35(12): 3089-3096. |

| [42] | CHOU Y S, STEVENSON J W, Singh P.Effect of aluminizing of Cr-containing ferritic alloys on the seal strength of a novel high-temperature solid oxide fuel cell sealing glass.Solid State Ionics, 2008, 185(2):1001-1008. |

| [43] | LARA C, PASCUAL M J, PRADO M O, et al.Sintering of glasses in the system RO-Al2O3-BaO-SiO2 (R=Ca, Mg, Zn) studied by hot-stage microscopy.Solid State Ionics, 2004, 170(3/4): 201-208. |

| [44] | PASCUAL M J, GUILLET A, DURAN A.Optimization of glass-ceramic sealant compositions in the system MgO-BaO-SiO2 for solid oxide fuel cells (SOFC) J.Power Sources, 2007, 169:40-46. |

| [45] | PENG L, ZHU Q.The development of thermally stable sealing glass in the BaO-B2O3-SiO2 system for planar sOFC applications.J. Fuel Cell Sci. Technol, 2008, 5(3):3121. |

| [46] | ZHANG T, FAHRENHOLTZ W G, Reis S T, et al.Borate volatility from SOFC sealing glasses.J. Am. Ceram. Soc. 2008, 91(8):2564. |

| [47] | CHENG C T, LANAGAN M, JONES B, et al.Crystallization kinetics and phase development of PbO-BaO-SrO-Nb2O5-B2O3-SiO2-Based glass- ceramics. J. Am. Ceram. Soc., 2005: 3037-3042. |

| [48] | TOMOZAWA M, ITO S, MOLINELLI J.Hygroscopicity of glasses with high water content. J. Non-Cryst Solids, 1984, 64(1/2): 269-278. |

| [49] | HAUCH A, EBBESEN S D, JENSEN S H, et al.Solid oxide electrolysis cells: microstructure and degradation of the Ni/yttria-stabilized zirconia electrode.J. Electrochem. Soc., 2008, 155(9):B1184-B1193. |

| [50] | WINCEWICZ K C, COOPER J S.Taxonomies of SOFC material and manufacturing alternatives. J. Power Sources, 2005, 140(2):280-296. |

| [51] | OGASAWARA K, KAMEDA H, SAKURAI M T.Chemical stability of ferritic alloy interconnect for SOFCs.J. Electrochem. Soc., 2007, 154(7): B657-B663. |

| [52] | WU J W, LIU XINGBO.Recent development of SOFC metallic interconnect.J. Mater. Sci & Tech., 2010, 26(4):293-305. |

| [53] | GHOSH S, SHARMA A D, KUNDU P, et al.Glass-Ceramic Sealants for planar IT-SOFC: a bilayered approach for joining electrolyte and metallic interconnect.J. Electrochem. Soc., 2008, 155(5):B473-B478. |

| [54] | SMEACETTO F, SALVO M, FERRARIS M, et al.Characterization and performance of glass-ceramic sealant to join metallic interconnects to YSZ and anode-supported-electrolyte in planar SOFCs,J. Eur. Ceram. Soc., 2008, 28(13):2521-2527. |

| [55] | YANG Z, XIA G, MEINHARDT K D, et al.Chemical stability of glass seal interfaces in intermediate temperature solid oxide fuel cells.J. Mater. Eng. Perform, 2004, 13(3):327-334. |

| [56] | MAHAPATRA M K, LU K.Interfacial study of Crofer 22 APU interconnects SABS seal glass for solid oxide fuel/electrolyzer cells.J. Mater. Sci., 2009, 44(20): 5569-5578. |

| [57] | YANG Z, MEINHARDT K D, STEVENSON J W.Chemical compatibility of barium-calcium-aluminosilicate-based sealing glasses with the ferritic stainless steel interconnect in SOFCs.J. Electrochem. Soc., 2003, 150(10):A1095-A1101. |

| [58] | CHOU Y S, STEVENSON J W, SINGH P.Effect of aluminizing of Cr-containing ferritic alloys on the seal strength of a novel high-temperature solid oxide fuel cell sealing glass. J. Power Sources, 2008, 185(2):1001-1008. |

| [59] | SMEACETTO F, SALVO M, FERRARIS M.et al.Glass-ceramic seal to join Crofer 22 APU alloy to YSZ ceramic in planar SOFCs.J. Eur. Ceram. Soc., 2008, 28(1):61-68. |

| [60] | CHOU Y S, STEVENSON J W, SINGH P.Effect of pre-oxidation and environmental aging on the seal strength of a novel high-temperature solid oxide fuel cell (SOFC) sealing glass with metallic interconnect.J. Power Sources, 2008, 184(1):238-244. |

| [61] | STEPHENS E V, VETRANO J S, KOEPPEL B J, et al.Experimental characterization of glass-ceramic seal properties and their constitutive implementation in solid oxide fuel cell stack models.J. Power Sources, 2009, 193(2):625-631. |

| [62] | MALZBENDER J, STEINBRECH R W.Symmetric shear test of glass-ceramic sealants at SOFC operation temperature.J. Mater. sci., 2007, 42(15):6297-6301. |

| [63] | CHIU Y T, LIN C K.Thermo-mechanical fatigue properties of a ferritic stainless steel for solid oxide fuel cell interconnect.J. Power Sources, 2012, 219(1/2):112-119. |

| [64] | ZHANG T, ZHU Q S, XIE Z H.Modeling of cracking of the glass-based seals for solid oxide fuel cell.J. Power Sources, 2009 188(1):177-183. |

| [65] | SINGH R N.Sealing technology for solid oxide fuel cells (SOFC).Int. J. Appl. Ceram. Tech., 2007, 4(2):134-144. |

| [66] | MÜLLER A, GOSWAMI S, BECKER W, et al. Assessement of the Sealing Joints within SOFC Stacks by numerical Simulation.Fuel Cells, 2006, 6(2):107-112. |

| [67] | PENG L, ZHU Q S.Thermal cycle stability of BaO-B2O3-SiO2 sealing glass.J. Power Sources, 2009, 194(2):880-885. |

| [1] | 赵占奎, 李涛, 鲁书含, 王明罡, 张京京, 程道文, 吴臣, 迟悦, 王虹力. SPS界面反应增强机制调控的软磁复合材料磁性能和电阻率[J]. 无机材料学报, 2020, 35(11): 1223-1226. |

| [2] | 张 浩, 高鹏越, 陈光耀, 李明阳, 鲁雄刚, 李重河. Al2O3/BaZrO3双陶瓷界面微观组织演化及机理[J]. 无机材料学报, 2017, 32(8): 819-824. |

| [3] | 李斯琳, 屠恒勇, 于立军. 中温固体氧化物燃料电池Nd2NiO4+δ-Ce0.8Gd0.2O2-δ复合阴极性能研究[J]. 无机材料学报, 2017, 32(5): 469-475. |

| [4] | 张莉莉, 李 可, 于称称, 张玉文, 吴成章, 丁伟中. Ag-Cu钎料与双相陶瓷透氧膜的润湿和界面反应研究[J]. 无机材料学报, 2016, 31(6): 607-612. |

| [5] | 鲁 元, 李京龙, 杨建锋, 李 鹏. 热处理温度对双连续β-氮化硅增强铝基复合材料性能的影响[J]. 无机材料学报, 2015, 30(3): 277-281. |

| [6] | 王贺云, 刘 茜, 周 遥, 周真真,刘光辉. 碳纤维复合Si3N4陶瓷材料的制备及性能研究[J]. 无机材料学报, 2014, 29(9): 1003-1008. |

| [7] | 路金蓉, 周 洋, 李海燕, 郑 涌, 李世波, 黄振莺. Cu/Ti3SiC2体系润湿性及润湿过程的研究[J]. 无机材料学报, 2014, 29(12): 1313-1319. |

| [8] | 熊明文, 尹屹梅, 原鲜霞, 马紫峰. 中温固体氧化物燃料电池阴极材料SrCo1-xGaxO3-δ的制备及性能研究[J]. 无机材料学报, 2013, 28(7): 713-719. |

| [9] | 张 强, 姜龙涛, 武高辉. 无压浸渗法制备氧化态SiC颗粒增强铝基复合材料[J]. 无机材料学报, 2012, 27(4): 353-357. |

| [10] | 赵德森, 洪建和, 高金飞, 何明中, 何 岗. SnO-CaO-P2O5体系无铅封接玻璃的形成与性能优化研究[J]. 无机材料学报, 2010, 25(10): 1053-1057. |

| [11] | 郝红霞,刘瑞泉. 天然气中温SOFCs阳极材料钴掺杂氧化铈的制备与性能研究[J]. 无机材料学报, 2009, 24(3): 539-544. |

| [12] | 李家科,刘 磊,刘意春,张文龙,胡文彬. Ti-Si共晶钎料的制备及其对SiC陶瓷可焊性[J]. 无机材料学报, 2009, 24(1): 204-208. |

| [13] | 彭练,朱庆山,谢朝晖,黄文来. 中温SOFC密封玻璃热稳定性研究[J]. 无机材料学报, 2006, 21(4): 867-872. |

| [14] | 郑锐,聂怀文,王大千,吕之奕,温廷琏. SiO2-CaO-B2O3-Al2O3微晶玻璃在平板式ITSOFC中密封性能的研究[J]. 无机材料学报, 2004, 19(1): 37-42. |

| [15] | 汤文明,郑治祥,丁厚福,金志浩. SiC/Fe-Cr合金界面反应的研究[J]. 无机材料学报, 2001, 16(5): 921-927. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||