无机材料学报 ›› 2015, Vol. 30 ›› Issue (1): 1-8.DOI: 10.15541/jim20140313

• • 下一篇

李戈扬

收稿日期:2014-06-18

修回日期:2014-09-08

出版日期:2015-01-20

网络出版日期:2014-12-29

基金资助:LI Ge-Yang

Received:2014-06-18

Revised:2014-09-08

Published:2015-01-20

Online:2014-12-29

Supported by:摘要:

由于报道获得了超过金刚石的硬度, TiN/Si3N4纳米复合薄膜成为十多年来超硬材料和薄膜材料的重要热点。本文从实验基础方面对这类薄膜的Veprek模型和“超高硬度”进行了评述。在微结构方面, Veprek提出的非晶Si3N4包裹TiN纳米晶的结构模型(即nc-TiN/a-Si3N4)缺乏足够的实验依据, 直接观察表明: 高硬度薄膜中的TiN晶粒并非等轴晶,而是纳米直径的柱状晶。就Si3N4界面相来说也并非以1个单分子层(~0.3 nm)的非晶态存在, 而是厚度约3个分子层(~0.7 nm)的晶体态, 更重要的是Si3N4界面相与相邻的TiN晶体形成了共格结构。在制备技术方面, 十余年来始终没有人在这类材料中重复出Veprek超过金刚石硬度的结果, Veprek不仅将其归咎于缺乏足够高的沉积温度和氮分压, 甚至归咎于薄膜中存在不可避免的微量氧, 但也缺乏足够的直接证据。在超高硬度的样品方面, Veprek所报道超过金刚石硬度(最高达138.9 GPa)的样品不但未经任何他人检测确认, 而且现在这些样品已经不存在了。

中图分类号:

李戈扬. 评Veprek的nc-TiN/a-Si3N4模型和其“超过金刚石硬度”的实验基础[J]. 无机材料学报, 2015, 30(1): 1-8.

LI Ge-Yang. Comment on Experiment Fundament of Veprek’s nc-TiN/a-Si3N4 Model and Its “Exceed Diamond Hardness”[J]. Journal of Inorganic Materials, 2015, 30(1): 1-8.

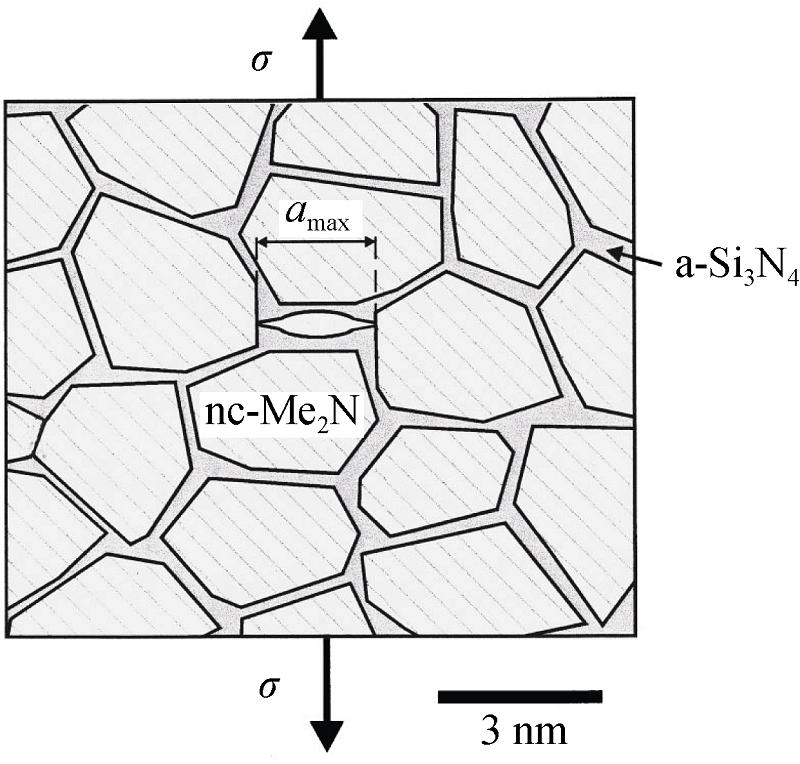

图1 纳米复合薄膜非晶包裹纳米晶结构及微裂纹受阻的示意图[21]

Fig. 1 Illustration of nanostructure and limited growth of a nanocrack in nanocrystalline/amorphous composite films[21]

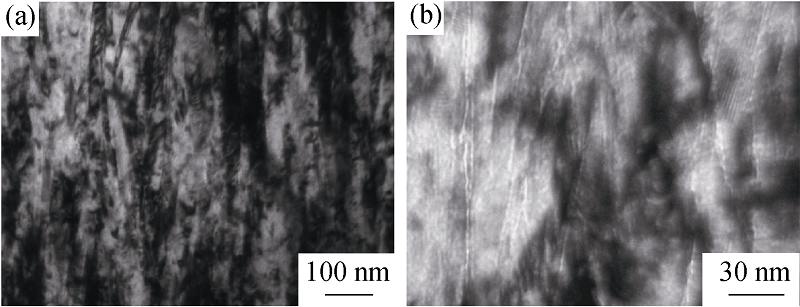

图2 ~5at% Si的TiN/Si3N4复合膜截面的低倍(a)和高倍(b)TEM照片[26]

Fig. 2 Low magnification (a) and high magnification (b) cross- sectional TEM images of ~5at% Si nanocomposite film[26]

图3 TiN/Si3N4纳米多层膜的截面HRTEM照片(a)和硬度随Si3N4层厚的变化(b)[29]

Fig. 3 Cross-sectional HRTEM image of TiN/Si3N4 multilayers (a) and hardness of TiN/Si3N4 vs thickness of Si3N4 (b)[29]

图4 纳米复合膜的微结构的Hultman模型[33]

Fig. 4 Hultman microstructural model of nanocomposite films[33],Si3N4 tissue is amorphous (lSi3N4>0.7 nm)(a) and part of tissue forms epitaxial pseudo-crystal (lSi3N4≤0.5-0.7 nm)(b)

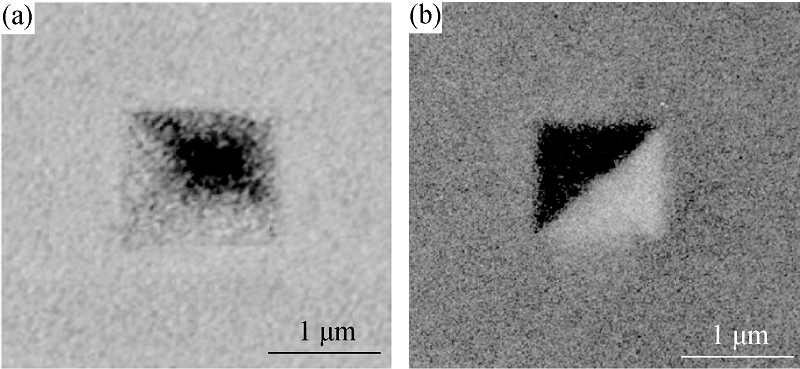

图7 Veprek两次提供的超高硬度纳米复合薄膜压痕

Fig. 7 Two indentation SEM images of ultra-hardness composite films provided by Veprek. The hardness is only 51 GPa[58] compares with the claimed 138.4 GPa[8] (a) and the hardness is over 100 GPa[27] (b) computed by the scale on the SEM images

| [1] | LIU A Y, COHEN M L.Prediction of new low compressibility solids.Science, 1989, 245(4920): 841-842. |

| [2] | NIEDERHOFER A, NESLÁDEK P, MÄNNLING H D, et al. Structural properties, internal stress and thermal stability of nc-TiN/a-Si3N4, nc-TiN/TiSix and nc-(Ti1-yAlySix)N superhard nanocomposite coatings reaching the hardness of diamond. Surface and Coatings Technology, 1999, 120-121: 173-178. |

| [3] | VEPŘEK S. The search for novel, superhard materials.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 1999, 17(5): 2401-2420. |

| [4] | NIEDERHOFER A, MOTO K, NESLADEK P, et al.Diamond is not the Hardest Material Anymore: Ultrahard Nanocomposites nc-TiN/a-Si3N4, Presented at 4th Int. in Symp. presented at 4th Int. Symp. Plasma Chemistry, Prague, Czech Republic, 2-6 August 1999. |

| [5] | VEPREK S, NIEDERHOFER A, MOTO K, et al.Nanocomposites nc-TiN/a-Si3N4/a- and nc-TiSi2 with hardness exceeding 100 GPa and high fracture toughness.Materials Research Society Symposium - Proceedings, 2000, 581: 321-326. |

| [6] | MÄNNLING H D, PATIL D S, MOTO K, et al. Thermal stability of superhard nanocomposite coatings consisting of immiscible nitrides. Surface and Coatings Technology, 2001, 146-147: 263-267. |

| [7] | VEPREK S, ARGON A S. Mechanical properties of superhard nanocomposites. Surface and Coatings Technology, 2001, 146-147: 175-182. |

| [8] | VEPREK S, ARGON A S.Towards the understanding of mechanical properties of super- and ultrahard nanocomposites.Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, 2002, 20(2): 650-664. |

| [9] | VEPREK S, MUKHERJEE S, KARVANKOVA P, et al.Limits to the strength of super- and ultrahard nanocomposite coatings.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2003, 21(3): 532-544. |

| [10] | VEPREK S, MUKHERJEE S, KARVANKOVA P, et al.Hertzian analysis of the self-consistency and reliability of the indentation hardness measurements on superhard nanocomposite coatings.Thin Solid Films, 2003, 436(2): 220-231. |

| [11] | NESLÁDEK P, VEPŘEK S. Superhard nanocrystalline composites with hardness of diamond.Physica Status Solidi (A) Applied Research, 2000, 177(1): 53-62. |

| [12] | VEPREK S, NIEDERHOFER A, MOTO K, et al. Composition, nanostructure and origin of the ultrahardness in nc-TiN/a- Si3N4/a- and nc-TiSi2 nanocomposites with Hv=80 to ≥105 GPa. Surface and Coatings Technology, 2000, 133-134: 152-159. |

| [13] | MENG W J, ZHANG X D, SHI B, et al.Microstructure and mechanical properties of Ti-Si-N coatings.Journal of Materials Research, 2002, 17(10): 2628-2632. |

| [14] | KIM S H, KIM J K, KIM K H.Influence of deposition conditions on the microstructure and mechanical properties of Ti-Si-N films by DC reactive magnetron sputtering.Thin Solid Films, 2002, 420: 360-365. |

| [15] | HU X P, HAN Z H, LI G Y, et al.Microstructure and properties of Ti-Si-N nanocomposite films.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2002, 20(6): 1921-1926. |

| [16] | PATSCHEIDER J, ZEHNDER T, DISERENS M.Structure- performance relations in nanocomposite coatings.Surface and Coatings Technology, 2001, 146: 201-208. |

| [17] | ZHANG C H, LUO J B, LI W Z, et al.The study of the microstructure of TiN and Ti1-xSixNy coatings.Acta Physica Sinica, 2004, 53(1): 182-188. |

| [18] | ZHAO H Y, FAN Q L, SONG L X, et al.Research status and development of superhard nanocomposite films.Journal of Inorganic Materials, 2004, 19(1): 9-16. |

| [19] | VEPŘEK S, REIPRICH S, LI S Z. Superhard nanocrystalline composite materials: The TiN/Si3N4 system.Applied Physics Letters, 1995, 66: 2640. |

| [20] | VEPŘEK S, REIPRICH S. A concept for the design of novel superhard coatings.Thin Solid Films, 1995, 268(1/2): 64-71. |

| [21] | VEPŘEK S, HAUSSMANN M, REIPRICH S, et al. Novel thermodynamically stable and oxidation resistant superhard coating materials. Surface and Coatings Technology, 1996, 86-87(1): 394-401. |

| [22] | CHRISTIANSEN S, ALBRECHT M, STRUNK H P, et al.Microstructure of novel superhard nanocrystalline-amorphous composites as analyzed by high resolution transmission electron microscopy.Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, 1998, 16(1): 19-22. |

| [23] | PROCHÁZKA J, KARVÁNKOVÁ P, VEPŘEK-HEIJMAN M G J, et al. Conditions required for achieving superhardness of ≥45 GPa in nc-TiN/a-Si3N4 nanocomposites.Materials Science and Engineering A, 2004, 384(1/2): 102-116. |

| [24] | VEPREK S, VEPREK-HEIJMAN M G J, KARVANKOVA P, et al. Different approaches to superhard coatings and nanocomposites.Thin Solid Films, 2005, 476(1): 1-29. |

| [25] | KARVANKOVA P, VEPREK-HEIJMAN M G J, AZINOVIC D, et al. Properties of superhard nc-TiN/a-BN and nc-TiN/a-BN/a- TiB2 nanocomposite coatings prepared by plasma induced chemical vapor deposition.Surface and Coatings Technology, 2006, 200(9): 2978-2989. |

| [26] | KONG M, ZHAO W J, WEI L, et al.Investigations on the microstructure and hardening mechanism of TiN/Si3N4 nanocomposite coatings.Journal of Physics D: Applied Physics, 2007, 40(9): 2858-2863. |

| [27] | VEPREK S, VEPREK-HEIJMAN M G J. Limits to the preparation of superhard nanocomposites: Impurities, deposition and annealing temperature.Thin Solid Films, 2012, 522: 274-282. |

| [28] | VEPREK S, MÄNNLING H D, KARVANKOVA P, et al. The issue of the reproducibility of deposition of superhard nanocomposites with hardness of ≥50 GPa.Surface and Coatings Technology, 2006, 200(12/13): 3876-3885. |

| [29] | HU X P, ZHANG H J, DAI J W, et al.Study on the superhardness mechanism of Ti-Si-N nanocomposite films: Influence of the thickness of the Si3N4 interfacial phase.Journal of Vacuum Science and Technology A: Vacuum, Surfaces and Films, 2005, 23(1): 114-117. |

| [30] | SÖDERBERG H, ODÉN M, MOLINA-ALDAREGUIA J M, et al. Nanostructure formation during deposition of TiN/SiN nanomultilayer films by reactive dual magnetron sputtering.Journal of Applied Physics, 2005, 97: 114327. |

| [31] | SÖDERBERG H, ODÉN M, LARSSON T, et al. Epitaxial stabilization of cubic-SiN in TiN/SiN multilayers.Applied Physics Letters, 2006, 88: 191902. |

| [32] | SÖDERBERG H, ODÉN M, FLINK A, et al. Growth and characterization of TiN/SiN (001) superlattice films.Journal of Materials Research, 2007, 22(11): 3255-3264. |

| [33] | HULTMAN L, BAREÑO J, FLINK A, et al. Interface structure in superhard TiN-SiN nanolaminates and nanocomposites: film growth experiments and ab initio calculations.Physical Review B, 2007, 75(15): 155437. |

| [34] | MEI F H, SHAO N, HU X P, et al.Microstructure and mechanical properties of reactively sputtered Ti-Si-N nanocomosite films.Materials Letters, 2005, 59(19/20): 2442-2445. |

| [35] | KIM I W, LI Q, MARKS L D, et al.Critical thickness for transformation of epitaxially stabilized cubic AlN in superlattices.Applied Physics Letters, 2001, 78(7): 892-894. |

| [36] | MADAN A, KIM I, CHENG S, et al.Stabilization of cubic AlN in epitaxial AlN/TiN superlattices.Physical Review Letters, 1997, 78(9): 1743. |

| [37] | 冯端, 师昌绪, 刘治国. 材料科学导论. 北京: 化学工业出版社, 2002: 588. |

| [38] | DONG Y S, ZHAO W J, YUE J L, et al.Crystallization of Si3N4 layers and its influences on the microstructure and mechanical properties of ZrN/Si3N4 nanomultilayers.Applied Physics Letters, 2006, 89(12): 121916. |

| [39] | LI G Q, LI Y G.Crystallization of amorphous Si3N4 and superhardness effect in HfC/Si3N4 nanomultilayers.Applied Surface Science, 2011, 257(13): 5799-5802. |

| [40] | WEN M, MENG Q N, HU C Q, et al.Structure and mechanical properties of δ-NbN/SiNx and δ′-NbN/SiNx nano-multilayer films deposited by reactive magnetron sputtering.Surface and Coatings Technology, 2009, 203(12): 1702-1708. |

| [41] | LAO J J, SHAO N, MEI F H, et al. Mutual promotion effect of crystal growth in TiN/SiC nanomultilayers. Applied Physics Letters, 2005, 86(1): 011902-1-3. |

| [42] | WEI L, MEI F H, SHAO N, et al. Template-induced crystallization of amorphous SiO2 and its effects on the mechanical properties of TiN/SiO2 nanomultilayers. Applied Physics Letters, 2005, 86(2): 021919-1-3. |

| [43] | WEI L, KONG M, DONG Y S, et al. Crystallization of Al2O3 and its effects on the mechanical properties in TiN/Al2O3 nanomultilayers. Journal of Applied Physics, 2005, 98(7): 074302-1-4. |

| [44] | YUE J L, LIU Y, ZHAO W J, et al.Crystallization of AlON and its effects on the growth and hardness of reactively synthesized VN/AlON nanomultilayer.Scripta Materialia, 2006, 55(10): 895-898. |

| [45] | ZHAO W J, KONG M, WU Y, et al.Pseudocrystallization of SiO2 and superhardness effects of AlN/SiO2 nanomultilayers.Journal of Applied Physics, 2008, 103(4): 043506. |

| [46] | YU L H, DONG S T, DONG S R, et al.Epitaxial growth and mechanical properties of AlN/Si3N4 nanostructured multilayerscta Physica Sinica, 2008, 57(8): 5151-5158. |

| [47] | LI G Q, LI Y G.Coherent growth and superhardness effect of heterostructure h-TiB2/c-VC nanomultilayers.Vacuum, 2011, 86(4): 476-479. |

| [48] | ZHANG R F, ARGON A S, VEPREK S.Electronic structure, stability, and mechanism of the decohesion and shear of interfaces in superhard nanocomposites and heterostructures.Physical Review B - Condensed Matter and Materials Physics, 2009, 79(24): 245426. |

| [49] | ZHANG R F, ARGON A S, VEPREK S.Friedel oscillations are limiting the strength of superhard nanocomposites and heterostructures.Physical Review Letters, 2009, 102(1): 015503. |

| [50] | VEPREK S, KARVANKOVA P, VEPREK-HEIJMAN M G J. Possible role of oxygen impurities in degradation of nc-TiN/a- Si3N4 nanocomposites.Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, 2005, 23(6): L17-L21. |

| [51] | VEPREK S, VEPREK-HEIJMAN M G. Concept for the Design of Superhard Nanocomposites with High Thermal Stability: Their Preparation, Properties, and Industrial Applications. Nanostructured Coatings, Springer Press, 2006: 347-406. |

| [52] | ZHANG R F, VEPREK S.Phase stabilities of self-organized nc-TiN/a-Si3N4 nanocomposites and of Ti1-xSixNy solid solutions studied by abinitio calculation and thermodynamic modeling.Thin Solid Films, 2008, 516(8): 2264-2275. |

| [53] | MA D Y, MA S L, XU K W, et al.Hardness degradation of Ti-Si- N coatings induced by oxygen impurity and its mechanisms.Materials Letters, 2005, 59(7): 838-841. |

| [54] | MA D Y, MA S L, XU K W, et al.Impact of residual oxygen on hardness of nano structured TiN+Si3N4 film.Acta Metallurgica Sinica, 2004, 40(10): 1037-1040. |

| [55] | LI S, SHI Y, PENG H. Plasma Chem.Plasma Process, 1992, 22: 287-297. |

| [56] | ZHANG R F, LEGUT D, LIN Z J, et al.Stability and strength of transition-metal tetraborides and triborides.Physical Review Letters, 2012, 108(25): 255502. |

| [57] | HAO S Q, DELLEY B, VEPREK S, et al.Superhard nitride- based nanocomposites: role of interfaces and effect of impurities.Physical Review Letters, 2006, 97(8): 086102. |

| [58] | FISCHER-CRIPPS A, BULL S, SCHWARZER N.Critical review of claims for ultra-hardness in nanocomposite coatings.Philosophical Magazine, 2012, 92(13): 1601-1630. |

| [59] | PAN L, BAI Y Z, ZHANG D, et al.Ti-Si-N films prepared by magnetron sputtering.Rare Metals, 2012, 31(2): 183-188. |

| [60] | PATSCHEIDER J, HELLGREN N, HAASCH R T, et al.Electronic structure of the SiNx/TiN interface: a model system for superhard nanocomposites.Physical Review B, 2011, 83(12): 125124. |

| [1] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [2] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [3] | 徐谱昊, 张相召, 刘桂武, 张明芬, 桂新易, 乔冠军. Al-Ti合金钎焊SiC陶瓷接头界面微观结构与力学性能[J]. 无机材料学报, 2022, 37(6): 683-690. |

| [4] | 黄龙之, 殷杰, 陈晓, 王新广, 刘学建, 黄政仁. 低黏结剂含量SiC素坯的选区激光烧结[J]. 无机材料学报, 2022, 37(3): 347-352. |

| [5] | 孙鲁超, 周翠, 杜铁锋, 吴贞, 雷一明, 李家麟, 苏海军, 王京阳. 光悬浮区熔定向凝固Al2O3/Er3Al5O12和Al2O3/Yb3Al5O12共晶陶瓷的制备与性能研究[J]. 无机材料学报, 2021, 36(6): 652-658. |

| [6] | 杨以娜, 王冉冉, 孙静. MXenes在柔性力敏传感器中的应用研究进展[J]. 无机材料学报, 2020, 35(1): 8-18. |

| [7] | 邢媛媛, 吴海波, 刘学建, 黄政仁. 颗粒级配对固相烧结碳化硅陶瓷的影响[J]. 无机材料学报, 2018, 33(11): 1167-1172. |

| [8] | 魏菁, 李汉超, 柯培玲, 汪爱英. 不同厚度四面体非晶碳薄膜的高通量制备及表征[J]. 无机材料学报, 2018, 33(11): 1173-1178. |

| [9] | 郑遗凡, 张露露, 王锴, 潘再法. 混合尖晶石型Zn6Ga8TiO20:Cr3+荧光粉的合成、结构表征与发光性能[J]. 无机材料学报, 2018, 33(1): 9-13. |

| [10] | 梁汉琴, 姚秀敏, 黄政仁, 曾宇平. 液相烧结碳化硅陶瓷的原位研究[J]. 无机材料学报, 2016, 31(4): 443-448. |

| [11] | 何绍阳, 曾建邦, 蒋方明. 锂离子电池石墨负极微结构数值重建及特征化分析[J]. 无机材料学报, 2015, 30(9): 906-912. |

| [12] | 刘 才, 温兆银, 芮 琨. 高电导率F掺杂Li7La3Zr2O12石榴石结构固体电解质[J]. 无机材料学报, 2015, 30(9): 995-1001. |

| [13] | 刘 婧, 刘 军, 李 江, 林 丽, 潘裕柏, 程晓农, 郭景坤. 球磨转速对Nd:YAG透明陶瓷的显微结构及光学性能的影响[J]. 无机材料学报, 2015, 30(6): 581-587. |

| [14] | 李 磊, 梁笠智, 吴 恒, 梁 爽, 朱瑛莺, 朱信华. 钙钛矿锰氧化物低维纳米结构研究进展[J]. 无机材料学报, 2015, 30(4): 337-344. |

| [15] | 吴志立, 李玉阁, 吴 彼, 雷明凯. 高功率调制脉冲磁控溅射沉积TiAlSiN纳米复合涂层结构调控与性能研究[J]. 无机材料学报, 2015, 30(12): 1254-1260. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||