无机材料学报 ›› 2014, Vol. 29 ›› Issue (8): 827-834.DOI: 10.15541/jim20130577

汤营茂1, 缪清清2, 肖荔人1, 钱庆荣2, 陈庆华2

收稿日期:2013-11-05

修回日期:2013-12-09

出版日期:2014-08-20

网络出版日期:2014-07-15

作者简介:汤营茂(1990–), 男, 硕士研究生. E-mail: ymtang88@163.com

基金资助:TANG Ying-Mao1, MIAO Qing-Qing2, XIAO Li-Ren1, QIAN Qing-Rong2, CHEN Qing-Hua2

Received:2013-11-05

Revised:2013-12-09

Published:2014-08-20

Online:2014-07-15

About author:TANG Ying-Mao. E-mail: ymtang88@163.com

摘要:

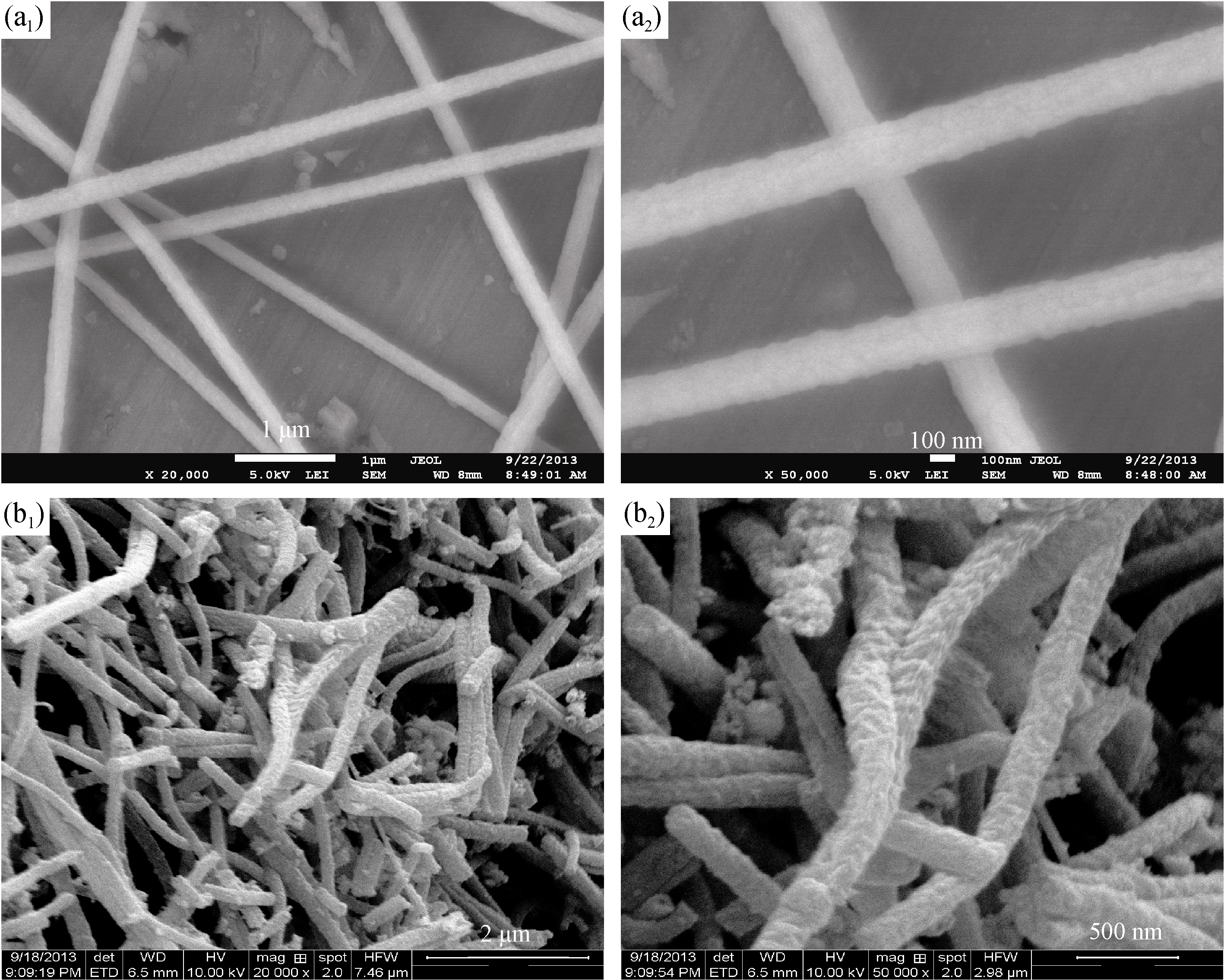

以聚丙烯腈(PAN)、乙酰丙酮铁(AAI)、N, N-二甲基甲酰胺(DMF)为原料, 采用静电纺丝-煅烧技术成功制备出磁性碳纳米复合纤维。通过TEM分析发现CF900的直径约为130~210 nm, 磁性纳米颗粒均匀地分散在碳纳米纤维中, 并探讨了碳化温度对碳纳米复合纤维磁性能的影响。结果显示: 饱和磁化强度(Ms)和剩余磁化强度(Mr)均随温度的升高而增大, 样品CF900的饱和磁化强度(Ms)高达27.55 A·m2/kg, 比表面积(SBET)和总孔容积(Vtotal)达354.0 m2/g和0.315 mL/g。

中图分类号:

汤营茂, 缪清清, 肖荔人, 钱庆荣, 陈庆华. 静电纺丝制备磁性碳纳米复合纤维及其表征[J]. 无机材料学报, 2014, 29(8): 827-834.

TANG Ying-Mao, MIAO Qing-Qing, XIAO Li-Ren, QIAN Qing-Rong, CHEN Qing-Hua. Preparation and Characterization of Electrospun Magnetic Carbon Composite Nanofibres[J]. Journal of Inorganic Materials, 2014, 29(8): 827-834.

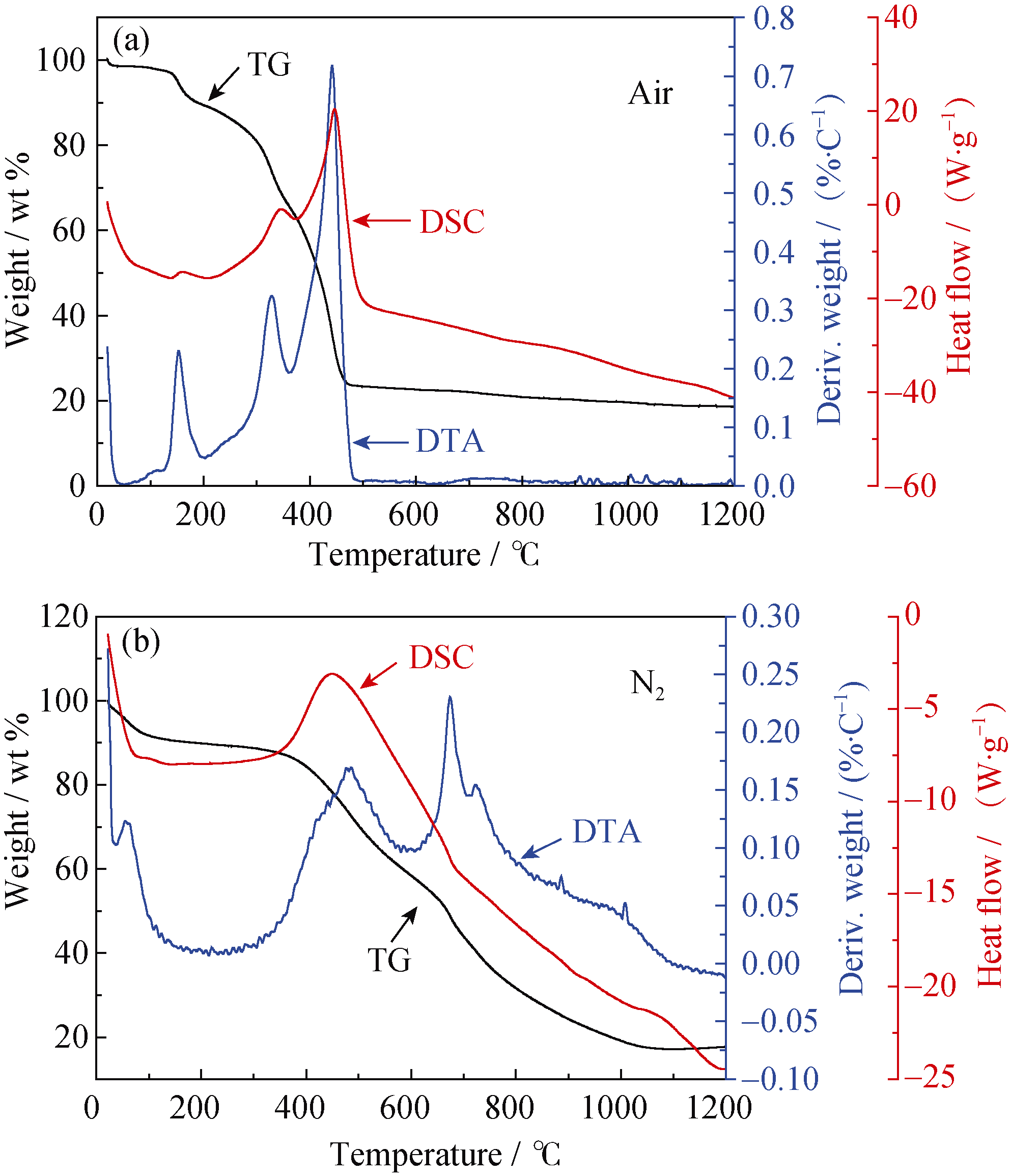

图1 PAN/AAI复合纳米纤维(空气氛围)(a)和预氧化后的碳纳米复合纤维(氮气氛围) (b)的DSC-TGA曲线

Fig. 1 DSC-TGA results for (a) PAN/AAI composite nanofiber in the air; (b) composite nanofiber after stabilizing treatment under the nitrogen

图2 PAN/AAI复合纳米纤维(a1, a2)和磁性碳纳米复合纤维CF900(b1, b2)的SEM照片

Fig. 2 SEM images of as spun PAN/AAI composite nanofiber (a1, a2) and magnetic carbon composite nanofiber of CF900 (b1, b2)

| Sample | R | La/nm |

|---|---|---|

| CF500 | 0.84 | 3.70 |

| CF600 | 0.92 | 4.05 |

| CF700 | 0.93 | 4.09 |

| CF800 | 1.02 | 4.49 |

| CF900 | 0.94 | 4.14 |

表1 各样品的石墨化程度R值的大小和石墨晶体晶面的La的大小

Table 1 The R values (R=IG/ID, degree of graphitization) of the carbon fibers and La values (La≈4.4×R) of various nanofibers

| Sample | R | La/nm |

|---|---|---|

| CF500 | 0.84 | 3.70 |

| CF600 | 0.92 | 4.05 |

| CF700 | 0.93 | 4.09 |

| CF800 | 1.02 | 4.49 |

| CF900 | 0.94 | 4.14 |

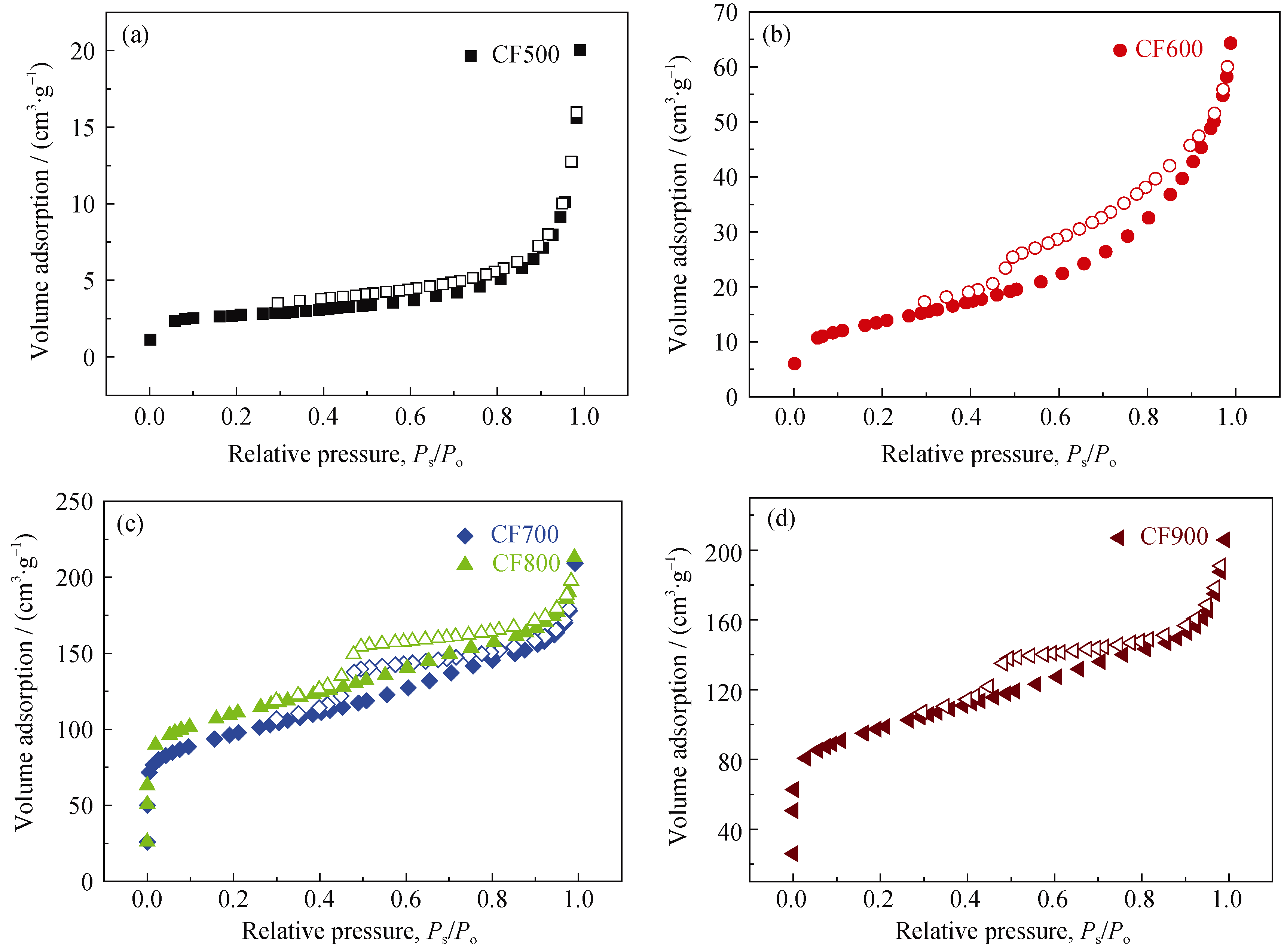

图7 各磁性碳纳米复合材料的氮气吸脱附曲线(实心符号: 吸附支, 空心符号: 脱附支)

Fig. 7 N2 adsorption-desorption isotherms of (a) CF500; (b) CF600; (c) CF700, CF800; (d) CF900 (Closed symbol: adsorption, open symbol: desorption

| Sample ID | SBET/(m2·g-1) | Vtotal/(mL·g-1) | DP/nm | NLDFT | ||

|---|---|---|---|---|---|---|

| Vt/(mL·g-1) | Vmic/(mL·g-1) | Vmes/(mL·g-1) | ||||

| CF500 | 10.0 | 0.031 | 12.2 | 0.030 | 0.002 | 0.028 |

| CF600 | 48.8 | 0.099 | 8.15 | 0.096 | 0.010 | 0.086 |

| CF700 | 351.1 | 0.317 | 3.61 | 0.302 | 0.110 | 0.192 |

| CF800 | 400.1 | 0.328 | 3.28 | 0.308 | 0.129 | 0.179 |

| CF900 | 354.0 | 0.315 | 3.56 | 0.296 | 0.120 | 0.176 |

表2 碳纳米复合纤维的表面积和孔容

Table 2 Surface areas and pore volumes of various magnetic carbon nanofibers

| Sample ID | SBET/(m2·g-1) | Vtotal/(mL·g-1) | DP/nm | NLDFT | ||

|---|---|---|---|---|---|---|

| Vt/(mL·g-1) | Vmic/(mL·g-1) | Vmes/(mL·g-1) | ||||

| CF500 | 10.0 | 0.031 | 12.2 | 0.030 | 0.002 | 0.028 |

| CF600 | 48.8 | 0.099 | 8.15 | 0.096 | 0.010 | 0.086 |

| CF700 | 351.1 | 0.317 | 3.61 | 0.302 | 0.110 | 0.192 |

| CF800 | 400.1 | 0.328 | 3.28 | 0.308 | 0.129 | 0.179 |

| CF900 | 354.0 | 0.315 | 3.56 | 0.296 | 0.120 | 0.176 |

| Sample | Ms/(A·m2·kg-1) | Mr/(A·m2·kg-1) | Hc/(kA·m-1) |

|---|---|---|---|

| CF500 | 1.02 | 0.05 | 7.96 |

| CF600 | 7.83 | 0.83 | 7.96 |

| CF700 | 16.57 | 3.53 | 16.00 |

| CF800 | 22.87 | 4.65 | 19.90 |

| CF900 | 27.55 | 5.10 | 19.90 |

表3 各磁性碳纳米复合纤维在298 K下的Ms、Mr和Hc值

Table 3 Ms, Mr and Hc of magnetic carbon composite nanofibres at 298 K

| Sample | Ms/(A·m2·kg-1) | Mr/(A·m2·kg-1) | Hc/(kA·m-1) |

|---|---|---|---|

| CF500 | 1.02 | 0.05 | 7.96 |

| CF600 | 7.83 | 0.83 | 7.96 |

| CF700 | 16.57 | 3.53 | 16.00 |

| CF800 | 22.87 | 4.65 | 19.90 |

| CF900 | 27.55 | 5.10 | 19.90 |

| [1] | BAYAT M, YANG H, KO F. Electromagnetic properties of electrospun Fe3O4/carbon composite nanofibers. Polymer, 2011, 52(7): 1645-1653. |

| [2] | JANG J, BAE J. Carbon nanofiber/polypyrrole nanocable as toxic gas sensor. Sensor. Actuat. B: Chem., 2007, 122(1): 7-13. |

| [3] | HONDA K, YOSHIMURA M, KAWAKITA K, et al. Electrochemical characterization of carbon nanotube/nanohoneycomb diamond composite electrodes for a hybrid anode of Li-ion battery and super capacitor. J. Electrochem. Soc., 2004, 151(4): A532-A541. |

| [4] | FUTABA D N, HATA K, YAMADA T, et al. Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes. Nat. Mater., 2006, 5(12): 987-994. |

| [5] | TEO K, CHHOWALLA M, AMARATUNGA G, et al. Field emission from dense, sparse, and patterned arrays of carbon nanofibers. Appl. Phys. Lett., 2002, 80(11): 2011-2013. |

| [6] | PARK C, BAKER R T K. Catalytic behavior of graphite nanofiber supported nickel particles. 2. The influence of the nanofiber structure. J. Phys. Chem. B, 1998, 102(26): 5168-5177. |

| [7] | STEIGERWALT E S, DELUGA G A, CLIFFEL D E, et al. A Pt-Ru/graphitic carbon nanofiber nanocomposite exhibiting high relative perfor-mance as a direct-methanol fuel cell anode catalyst. J. Phys. Chem. B, 2001, 105(34): 8097-8101. |

| [8] | WU M S, LEE J T,CHIANG P C J, et al. Carbon-nanofiber composite electrodes for thin and flexible lithium-ion batteries. J. Mater. Sci., 2007, 42(1): 259-265. |

| [9] | YOON S H, PARK C W, YANG H, et al. Novel carbon nanofibers of high graphitization as anodic materials for lithium ion secondary batteries. Carbon, 2004, 42(1): 21-32. |

| [10] | WANG X X, WANG J N, CHANG H, et al. Preparation of short carbon nanotubes and application as an electrode material in Li-ion batteries. Adv. Funct. Mater., 2007, 17(17): 3613-3618. |

| [11] | ALVAREZ W, KITIYANAN B, BORGNA A, et al. Synergism of Co and Mo in the catalytic production of single-wall carbon nanotubes by decomposition of CO. Carbon, 2001, 39(4): 547-558. |

| [12] | MAIYALAGAN T, VISWANATHAN B. Template synthesis and characteri-zation of well-aligned nitrogen containing carbon nanotubes. Mater. Chem. Phys., 2005, 93(2): 291-295. |

| [13] | KIM C, YANG K. Electrochemical properties of carbon nanofiber web as an electrode for supercapacitor prepared by electrospinning. Appl. Phys. Lett., 2003, 83(6): 1216-1218. |

| [14] | ZHANG D, KARKI A B, RUTMAN D, et al. Electrospun polyacrylonitrile nanocomposite fibers reinforced with Fe3O4 nanoparticles: Fabrication and property analysis. Polymer, 2009, 50(17): 4189-4198. |

| [15] | KEDEM S, SCHMIDT J, PAZ Y, et al. Composite polymer nanofibers with carbon nanotubes and titanium dioxide particles. Langmuir, 2005, 21(12): 5600-5604. |

| [16] | TAN S T, WENDORFF J H, PIETZONKA C, et al. Biocompatible and biodegradable polymer nanofibers displaying superparamagnetic properties. ChemPhysChem, 2005, 6(8): 1461-1465. |

| [17] | CHOI S W, JO S M, LEE W S, et al. An electrospun poly (vinylidene fluoride) nanofibrous membrane and its battery applications. Adv. Mater., 2003, 15(23): 2027-2032. |

| [18] | KATZ E, WILLNER I, KOTLYAR A B. A non-compartmentalized glucose∣O2 biofuel cell by bioengineered electrode surfaces. J. Electroanal. Chem., 1999, 479(1): 64-68. |

| [19] | PARDO-YISSAR V, KATZ E, WASSERMAN J, et al. Acetylcholine esterase- labeled CdS nanoparticles on electrodes: photoelectrochemical sensing of the enzyme inhibitors. J. Am. Chem. Soc., 2003, 125(3): 622-623. |

| [20] | OHLAN A, SINGH K, CHANDRA A, et al. Microwave absorption properties of conducting polymer composite with barium ferrite nanoparticles in 12.4-18. Appl. Phys. Lett. , 2008, 93(5): 053114-053114-3. |

| [21] | KAZANTSEVA N E, VILČÁKOVÁ J, KŘESÁLEK V, et al. Magnetic behaviour of composites containing polyaniline-coated manganese- zinc ferrite. J. Magn. Magn. Mater., 2004, 269(1): 30-37. |

| [22] | SINGH K, OHLAN A, SAINI P, et al. Poly (3, 4-ethylene-dioxythiophene) γ-Fe2O3 polymer composite-super paramagnetic behavior and variable range hopping 1D conduction mechanism- synthesis and characterization. Polym. Adv. Technol., 2008, 19(3): 229-236. |

| [23] | WILSON J, PODDAR P, FREY N, et al. Synthesis and magnetic properties of polymer nanocomposites with embedded iron nano-par-ticles. J. Appl. Phys., 2004, 95(3): 1439-1443. |

| [24] | KIM Y H, PARK S J. Roles of nanosized Fe3O4 on supercapacitive properties of carbon nanotubes. Curr. Appl. Phys., 2011, 11(3): 462-466. |

| [25] | YANG C, DU J, PENG Q, et al. Polyaniline/Fe3O4 nanoparticle composite: synthesis and reaction mechanism. J. Phys. Chem. B, 2009, 113(15): 5052-5058. |

| [26] | ZHANG H, ZHONG X, XU J J, et al. Fe3O4/polypyrrole/Au nanocomposites with core/shell/shell structure: synthesis, characterization, and their electrochemical properties. Langmuir, 2008, 24(23): 13748-13752. |

| [27] | ZHANG T, HUANG D, YANG Y, et al. Influence of iron (III) acetylacetonate on structure and electrical conductivity of Fe3O4/carbon composite nanofibers. Polymer, 2012, 53(26): 6000-6007. |

| [28] | LEE J, PARK K Y, KANG S Y, et al. Synthesis and characterization of magnetically active carbon nanofiber/iron oxide composites with hierarchical pore structures. Nanotechnology, 2008, 19(45): 455612. |

| [29] | WANG Y G, KORAI Y, MOCHIDA I, et al. Modification of synthetic mesophase pitch with iron oxide, Fe2O3. Carbon, 2001, 39(11): 1627-1634. |

| [30] | KABURAGI Y, HISHIYAMA Y, Oka H, et al. Growth of iron clusters and change of magnetic property with carbonization of aromatic polyimide film containing iron complex. Carbon, 2001, 39(4): 593-603. |

| [31] | ZHOU Z, LAI C, ZHANG L, et al. Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties. Polymer, 2009, 50(13): 2999-3006. |

| [32] | BABU V S, SEEHRA M. Modeling of disorder and X-ray diffraction in coal-based graphitic carbons. Carbon, 1996, 34(10): 1259-1265. |

| [33] | MICHELI D, APOLLO C, PASTORE R, et al. X-band microwave characterization of carbon-based nanocomposite material, absorption capability comparison and RAS design simulation. Compos. Sci. Technol., 2010, 70(2): 400-409. |

| [34] | KRAUPNER A, ANTONIETTI M, PALKOVITS R, et al. Mesoporous Fe3C sponges as magnetic supports and as heterogeneous catalyst. J. Mater. Chem., 2010, 20(29): 6019-6022. |

| [35] | BALTUŠNIKAS A, LEVINSKAS R. XRD analysis of carbide phase in heat resistant steels. Mater. Sci., 2006, 12(3): 192-198. |

| [36] | YANG Y, GUO Z, ZHANG H, et al. Electrospun magnetic carbon composite fibers: synthesis and electromagnetic wave absorption characteristics. J. Appl. Polym. Sci., 2013, 127(6): 4288-4295. |

| [37] | KNIGHT D S, WHITE W B. Characterization of diamond films by Raman spectroscopy. J. Mater. Res., 1989, 4(2): 385-393. |

| [38] | INAGAKI M, OKADA Y, Vignal V, et al. Graphite formation from a mixture of Fe3O4 and polyvinylehloride at 1000 ℃. Carbon, 1998, 36(11): 1706-1708. |

| [39] | GREGG S J,SING K S W. Adsorption, Surface Area and Porosity, 2nd edition, London: Academic Press, 1982: 195-288. |

| [40] | SCHNEEWEISS O, ZBORIL R, PIZUROVA N, et al. Novel solid-state synthesis of α-Fe and Fe3O4 nanoparticles embedded in a MgO matrix. Nanotechnology, 2006, 17(2): 607-616. |

| [41] | YANG H, OGAWA T, HASEGAWA D, et al. Shape-controlled synthesis of Fe nanoparticles with high-Ms via modest-temperature reduc-tion method. Phys. Status Solidi A, 2007, 204(12): 4013-4016. |

| [42] | HUANG Z, TANG F. Preparation, structure, and magnetic properties of mesoporous magnetite hollow spheres. J. Colloid Interf. Sci., 2005, 281(2): 432-436. |

| [43] | WANG J, CHEN Q, ZENG C, et al. Magnetic-field-induced growth of single-crystalline Fe3O4 nanowires. Adv. Mater., 2004, 16(2): 137-140. |

| [44] | FAN Y, YANG H, LIU X, et al. Preparation and study on radar absorbing materials of nickel-coated carbon fiber and flake graphite. J. Alloy. Compd., 2008, 461(1): 490-494. |

| [45] | ZHAO N, ZOU T, SHI C, et al. Microwave absorbing properties of activated carbon-fiber felt screens (vertical-arranged carbon fibers) /epoxy resin composites. Mater. Sci. Eng. B, 2006, 127(2): 207-211. |

| [46] | QING Y, ZHOU W, JIA S, et al. Electromagnetic and microwave absorption properties of carbonyl iron and carbon fiber filled epoxy/silicone resin coatings. Appl. Phys. A, 2010, 100(4): 1177-1181. |

| [47] | WANG L, YU Y, CHEN P, et al. Electrospinning synthesis of C/Fe3O4 composite nanofibers and their application for high performance lithium-ion batteries. J. Power Sources, 2008, 183(2): 717-723. |

| [1] | 盛丽丽, 常江. 光/磁热Fe2SiO4/Fe3O4双相生物陶瓷及其复合电纺丝膜制备及抗菌性能研究[J]. 无机材料学报, 2022, 37(9): 983-990. |

| [2] | 刘城, 赵倩, 牟志伟, 雷洁红, 段涛. 新型铋基SiOCNF复合膜对放射性气态碘的吸附性能[J]. 无机材料学报, 2022, 37(10): 1043-1050. |

| [3] | 张晓山, 王兵, 吴楠, 韩成, 刘海燕, 王应德. 高红外遮蔽SiZrOC纳米纤维膜的制备及其性能研究[J]. 无机材料学报, 2022, 37(1): 93-100. |

| [4] | 马玲玲, 常江. Nd掺杂硅酸钙及其复合电纺丝膜的制备及性能研究[J]. 无机材料学报, 2021, 36(9): 974-980. |

| [5] | 王袁杰, 裴学良, 李好义, 徐鑫, 何流, 黄政仁, 黄庆. 自由基引发活性聚碳硅烷交联及其在制备SiC纤维中的应用[J]. 无机材料学报, 2021, 36(9): 967-973. |

| [6] | 李婷婷, 张志明, 韩正波. 基于静电纺丝技术的聚合物基MOFs纳米纤维膜的研究进展[J]. 无机材料学报, 2021, 36(6): 592-600. |

| [7] | 包峰, 常江. 硅酸钙纳米线复合电纺丝支架的制备及离子释放研究[J]. 无机材料学报, 2021, 36(11): 1199-1207. |

| [8] | 朱正旺,冯锐,柳扬,张扬,谢文翰,董丽杰. 类鱼骨结构CoFe2O4纳米纤维的制备与性能[J]. 无机材料学报, 2020, 35(9): 1011-1016. |

| [9] | 赵占奎, 李涛, 鲁书含, 王明罡, 张京京, 程道文, 吴臣, 迟悦, 王虹力. SPS界面反应增强机制调控的软磁复合材料磁性能和电阻率[J]. 无机材料学报, 2020, 35(11): 1223-1226. |

| [10] | 孙晓璐,宋肖飞,刘艳华,吴越,蔡以兵,赵宏梅. 电纺FeMnO3纳米纤维毛毡的制备及电化学性能研究[J]. 无机材料学报, 2019, 34(7): 709-714. |

| [11] | 赵海雷, 孙振川, 陈馈, 王宏志, 杨延栋, 周建军, 李凤远, 张兵, 宋法亮. Ca0.68Si9Al3(ON)16 : Eu2+带状荧光纳米纤维的制备、性能及盾构盘型滚刀的磨损检测[J]. 无机材料学报, 2018, 33(8): 866-872. |

| [12] | 周鑫, 马垒, 刘涛, 郭永斌, 王岛, 董培林. Si3N4/FePd/Si3N4薄膜的晶体结构和磁性能研究[J]. 无机材料学报, 2018, 33(8): 909-913. |

| [13] | 崔博, 贾巍, 陈振华, 李耀刚, 张青红, 王宏志. CaSi2O2N2:Ce/Tb、Eu叠层纤维膜的制备及其荧光性能研究[J]. 无机材料学报, 2018, 33(4): 403-408. |

| [14] | 杜海英, 姚朋军, 王兢, 孙炎辉, 于乃森, 张涛, 董良. 异质复合结构纳米纤维SnO2/ZnO的制备及其气敏特性研究[J]. 无机材料学报, 2018, 33(4): 453-461. |

| [15] | 蔡建信, 李志鹏, 李巍, 赵鹏飞, 杨震宇, 吁霁. Fe2O3纳米纤维锂离子电池负极材料的制备及其电化学性能研究[J]. 无机材料学报, 2018, 33(3): 301-306. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||