Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (12): 1295-1301.DOI: 10.15541/jim20220238

• RESEARCH ARTICLE • Previous Articles Next Articles

HAO Hongjian1( ), LI Haiyan1,2, WAN Detian1,2,3(

), LI Haiyan1,2, WAN Detian1,2,3( ), BAO Yiwang1,2,3(

), BAO Yiwang1,2,3( ), LI Yueming3

), LI Yueming3

Received:2022-04-22

Revised:2022-07-14

Published:2022-12-20

Online:2022-08-04

Contact:

WAN Detian, professor. E-mail: dtwan@ctc.ac.cn;About author:HAO Hongjian (1996-), male, Master candidate. E-mail: haohongjian1996@qq.com

Supported by:CLC Number:

HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating[J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301.

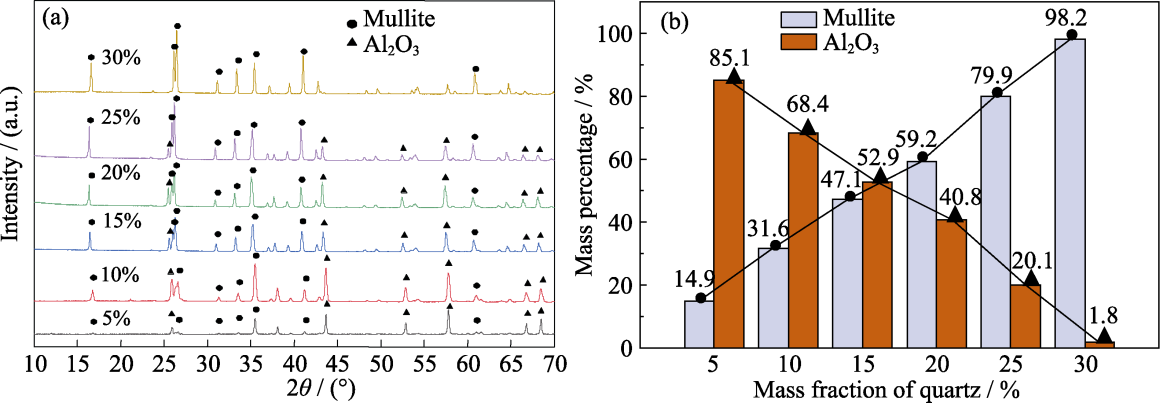

Fig. 2 Phase analyses of mullite-alumina coating materials fabricated with different mass fractions of quartz (a) XRD patterns after sintered at 1550 ℃; (b) Quantitative analysis by Rietveld method

| Sample | Ec/GPa | Es/GPa | αc/(×10-6, K-1) | αs/(×10-6, K-1) | hc/μm | hs/μm | ΔT | σc/MPa | σs/MPa |

|---|---|---|---|---|---|---|---|---|---|

| C5-A | 91.36 | 380.11 | 6.69 | 7.58 | 50 | 1450 | 1000 ℃ | -119.66 | 4.80 |

| C10-A | 80.18 | 380.11 | 6.06 | 7.58 | 50 | 1450 | 1000 ℃ | -151.94 | 6.09 |

| C15-A | 73.33 | 380.11 | 5.33 | 7.58 | 50 | 1450 | 1000 ℃ | -181.86 | 7.29 |

| C20-A | 67.71 | 380.11 | 5.04 | 7.58 | 50 | 1450 | 1000 ℃ | -189.74 | 7.60 |

| C25-A | 62.14 | 380.11 | 4.72 | 7.58 | 50 | 1450 | 1000 ℃ | -196.17 | 7.86 |

| C30-A | 58.31 | 380.11 | 4.41 | 7.58 | 50 | 1450 | 1000 ℃ | -197.69 | 7.91 |

Table 1 Calculation of residual stresses of coatings and substrates in pre-stressed Al2O3 fabricated with different mass fractions of quartz

| Sample | Ec/GPa | Es/GPa | αc/(×10-6, K-1) | αs/(×10-6, K-1) | hc/μm | hs/μm | ΔT | σc/MPa | σs/MPa |

|---|---|---|---|---|---|---|---|---|---|

| C5-A | 91.36 | 380.11 | 6.69 | 7.58 | 50 | 1450 | 1000 ℃ | -119.66 | 4.80 |

| C10-A | 80.18 | 380.11 | 6.06 | 7.58 | 50 | 1450 | 1000 ℃ | -151.94 | 6.09 |

| C15-A | 73.33 | 380.11 | 5.33 | 7.58 | 50 | 1450 | 1000 ℃ | -181.86 | 7.29 |

| C20-A | 67.71 | 380.11 | 5.04 | 7.58 | 50 | 1450 | 1000 ℃ | -189.74 | 7.60 |

| C25-A | 62.14 | 380.11 | 4.72 | 7.58 | 50 | 1450 | 1000 ℃ | -196.17 | 7.86 |

| C30-A | 58.31 | 380.11 | 4.41 | 7.58 | 50 | 1450 | 1000 ℃ | -197.69 | 7.91 |

| [1] |

NIELSEN J H, THIELE K, SCHNEIDER J, et al. Compressive zone depth of thermally tempered glass. Construction and Building Materials, 2021, 310: 125238.

DOI URL |

| [2] |

GREEN D J. Crack arrest and multiple cracking in glass through the use of designed residual stress profiles. Science, 1999, 283(5406): 1295-1297.

PMID |

| [3] |

BERMEJO R, TORRES Y, SÁNCHEZ-HERENCIA A J, et al. Residual stresses, strength and toughness of laminates with different layer thickness ratios. Acta Materialia, 2006, 54(18): 4745-4757.

DOI URL |

| [4] |

BERMEJO R, PASCUAL J, LUBE T, et al. Optimal strength and toughness of Al2O3-ZrO2 laminates designed with external or internal compressive layers. Journal of the European Ceramic Society, 2008, 28(8): 1575-1583.

DOI URL |

| [5] |

LAKSHMINARAYANAN R, SHETTY D, CUTLER R A. Toughening of layered ceramic composites with residual surface compression. Journal of the American Ceramic Society, 1996, 79(1): 79-87.

DOI URL |

| [6] |

BAO Y W, KUANG F H, SUN Y, et al. A simple way to make pre-stressed ceramics with high strength. Journal of Materiomics, 2019, 5(4): 657-662.

DOI |

| [7] |

LI H Y, HAO H J, TIAN Y, et al. Effects of residual stresses on strength and crack resistance in ZrO2 ceramics with alumina coating. Journal of Inorganic Materials, 2022, 37(4): 467-472.

DOI URL |

| [8] |

BAO Y W, SUN Y, KUANG F H, et al. Development and prospects of high strength pre-stressed ceramics. Journal of Inorganic Materials, 2020, 35(4): 399-408.

DOI |

| [9] |

LI N, ZHANG X Y, QU Y N, et al. A simple and efficient way to prepare porous mullite matrix ceramics via directly sintering SiO2- Al2O3 microspheres. Journal of the European Ceramic Society, 2016, 36(11): 2807-2812.

DOI URL |

| [10] |

LI H, LIU Y S, LIU Y S, et al. Silica strengthened alumina ceramic cores prepared by 3D printing. Journal of the European Ceramic Society, 2021, 41(4): 2938-2947.

DOI URL |

| [11] |

LIN Y M, LI C W, WANG C A. Effects of mullite content on the properties and microstructure of porous anorthite/mullite composite ceramics. Journal of Inorganic Materials, 2011, 26(10): 1095-1100.

DOI |

| [12] |

JIANG Y, CHANG L F, RU H Q, et al. Microstructure and oxidation behaviors of dense mullite-silicon carbide-silicon coating for graphite fabricated by dipping-pyrolysis and reactive infiltration. Surface and Coatings Technology, 2018, 350: 410-418.

DOI URL |

| [13] | 包亦望. 先进陶瓷力学性能评价方法与技术. 北京: 中国建材工业出版社, 2017: 3. |

| [14] |

ZHOU X, LIU D, BU H L, et al. XRD-based quantitative analysis of clay minerals using reference intensity ratios, mineral intensity factors, Rietveld, and full pattern summation methods: a critical review. Solid Earth Sciences, 2018, 3(1): 16-29.

DOI URL |

| [15] |

BAO Y W, SU S B, HUANG J L. An uneven strain model for analysis of residual stress and interface stress in laminate composites. Journal of Composite Materials, 2002, 36(14): 1769-1778.

DOI URL |

| [16] | CAI P Z, GREEN D J, MESSING G L. Constrained densification of alumina/zirconia hybrid laminates, II: viscoelastic stress computation. Journal of the American Ceramic Society, 1997, 80(8): 1948-1949. |

| [17] |

JIANG R, SUN X, LIU H T, et al. Microstructure and mechanical properties improvement of the Nextel™ 610 fiber reinforced alumina composite. Journal of the European Ceramic Society, 2021, 41(10): 5394-5399.

DOI URL |

| [18] |

PABST W, GREGOROVÁ E, ČERNÝ M. Isothermal and adiabatic Young's modulus of alumina and zirconia ceramics at elevated temperatures. Journal of the European Ceramic Society, 2013, 33(15): 3085-3093.

DOI URL |

| [19] |

WANG W, SHI Z, WANG Z, et al. Phase transformation and properties of high-quality mullite ceramics synthesized using desert drift sands as raw materials. Materials Letters, 2018, 221: 271-274.

DOI URL |

| [20] |

WEI C G, LIU Z, BAO Y W, et al. Evaluating thermal expansion coefficient and density of ceramic coatings by relative method. Materials Letters, 2015, 161: 542-544.

DOI URL |

| [21] |

BAO Y W, ZHOU Y C, BU X X, et al. Evaluating elastic modulus and strength of hard coatings by relative method. Materials Science and Engineering: A, 2007, 458(1): 268-274.

DOI URL |

| [22] |

CAI P Z, GREEN D J, MESSING G L. Constrained densification of alumina/zirconia hybrid laminates, I: experimental observations of processing defects. Journal of the American Ceramic Society, 1997, 80(8): 1929-1939.

DOI URL |

| [1] | ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei. Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method [J]. Journal of Inorganic Materials, 2024, 39(6): 733-740. |

| [2] | WANG Bo, CAI Delong, ZHU Qishuai, LI Daxin, YANG Zhihua, DUAN Xiaoming, LI Yanan, WANG Xuan, JIA Dechang, ZHOU Yu. Mechanical Properties and Thermal Shock Resistance of SrAl2Si2O8 Reinforced BN Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(10): 1182-1188. |

| [3] | LI Haiyan, KUANG Fenghua, WU Haolong, LIU Xiaogen, BAO Yiwang, WAN Detian. Temperature Dependence of Residual Tensile Stresses and Its Influences on Crack Propagation Behaviour [J]. Journal of Inorganic Materials, 2023, 38(11): 1265-1270. |

| [4] | LI Haiyan, HAO Hongjian, TIAN Yuan, WANG Changan, BAO Yiwang, WAN Detian. Effects of Residual Stresses on Strength and Crack Resistance in ZrO2 Ceramics with Alumina Coating [J]. Journal of Inorganic Materials, 2022, 37(4): 467-472. |

| [5] | LI Meng, HUANG Hailu, WU Jiamin, LIU Chunlei, WU Yaru, ZHANG Jingxian, SHI Yusheng. Effect of Solid Loading of Slurry on Properties of Si3N4 Ceramics Formed by Digital Light Processing [J]. Journal of Inorganic Materials, 2022, 37(3): 310-316. |

| [6] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| [7] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [8] | JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2020, 35(6): 669-674. |

| [9] | XING Yuan-Yuan, WU Hai-Bo, LIU Xue-Jian, HUANG Zheng-Ren. Grain Composition on Solid-state-sintered SiC Ceramics [J]. Journal of Inorganic Materials, 2018, 33(11): 1167-1172. |

| [10] | YUAN Kang, LIAO Qi-Long, WANG Fu, DAI Yun-Ya, HUANG Jin-Shan. Effects of Sintering Aids (Y3+, La3+ and Mg2+) on the Optical Transmittance of Translucent Alumina Ceramic [J]. Journal of Inorganic Materials, 2017, 32(9): 1004-1008. |

| [11] | SUN Yang, XUE Wei-Jiang, SUN Jia-Lin, ZHOU Guo-Zhi, HUANG Yong. Porous Alumina Ceramics with Unidirectional Oriented Pores Fabricated by Ionotropic Process of Sodium Alginate [J]. Journal of Inorganic Materials, 2015, 30(8): 877-881. |

| [12] | LEI Zhuo-Yan, WANG Zhi, FAN Heng-Bing, MA Wen-Bin, CHEN Jian, WANG Xu. Effect of B2O3 Doping and Phosphate Impregnation on Oxidation Resistance and Mechanical Properties of Mesocarbon Microbead Composites [J]. Journal of Inorganic Materials, 2015, 30(7): 769-773. |

| [13] | ZHANG Xiao-Qiang, SUN Yi, SHIMAI Shun-Zo, WANG Shi-Wei. Effect of Water-soluble Epoxy Resin on Microstructure and Properties of Porous Alumina Ceramics by Gel-casting [J]. Journal of Inorganic Materials, 2015, 30(10): 1085-1088. |

| [14] | HU Hai-Long, ZENG Yu-Ping, ZUO Kai-Hui, XIA Yong-Feng, YAO Dong-Xu. Effect of Sintering Additive Composition on the Mechanical and Tribological Properties of Si3N4/SiC Ceramics [J]. Journal of Inorganic Materials, 2014, 29(8): 885-890. |

| [15] | TIAN Zhuo, DUAN Xiao-Ming, YANG Zhi-Hua, JIA De-Chang, ZHOU Yu. Effects of AlN Content on the Thermal Properties and Thermal Shock Resistance of BN Matrix Composite Ceramic [J]. Journal of Inorganic Materials, 2014, 29(5): 503-508. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||