Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (9): 961-966.DOI: 10.15541/jim20160638

• Orginal Article • Previous Articles Next Articles

Received:2016-11-25

Revised:2017-02-05

Published:2017-09-30

Online:2017-08-29

About author:LIU Xiao-Yan. E-mail: liuxy108110@163.com

Supported by:CLC Number:

LIU Xiao-Yan, WEI Chun-Cheng, NIU Jin-Ye, YANG Zan-Zhong, YU Chang-Xin. Oxidation Resistance and Residual Strength of Laminated ZrB2-SiC-G

Ceramics at 1300[J]. Journal of Inorganic Materials, 2017, 32(9): 961-966.

| Sample | Matrix layer | Interface layer |

|---|---|---|

| LZS-1 | ZrB2-20vol%SiC | Graphite-20vol%ZrB2- 10vol% SiC |

| LZS-2 | ZrB2-20vol%SiC | Graphite-30vol%ZrB2- 10vol% SiC |

| LZS-3 | ZrB2-20vol%SiC | Graphite-40vol%ZrB2- 10vol% SiC |

Table1 Composition ratio of each layer in laminated ZrB2-SiC-G ceramics

| Sample | Matrix layer | Interface layer |

|---|---|---|

| LZS-1 | ZrB2-20vol%SiC | Graphite-20vol%ZrB2- 10vol% SiC |

| LZS-2 | ZrB2-20vol%SiC | Graphite-30vol%ZrB2- 10vol% SiC |

| LZS-3 | ZrB2-20vol%SiC | Graphite-40vol%ZrB2- 10vol% SiC |

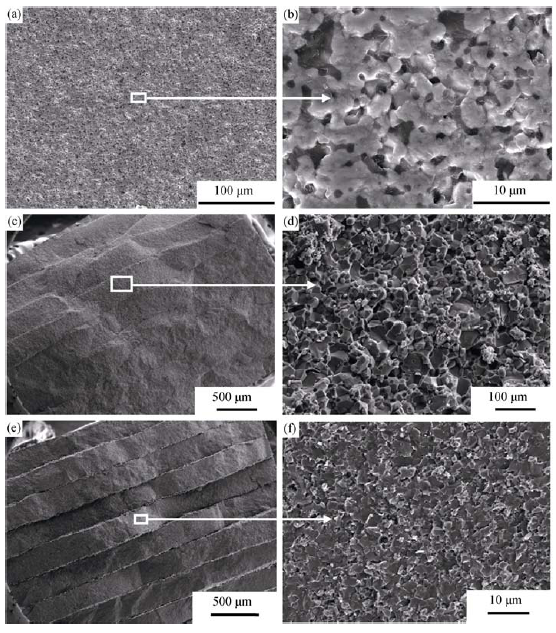

Fig. 1 SEM images of laminated ceramics (a, b) Surface of laminated LZS-3 ceramic; (c, d) Fracture surface of laminated LZS-3 ceramic; (e, f) Fracture surface of laminated LZS-1 ceramic

| Sample | LZS-1 | LZS-2 | LZS-3 |

|---|---|---|---|

| k / [(mg·cm-2)2﹒h-1] | 0.85 | 0.54 | 0.42 |

Table2 k values of the laminated ZrB2-SiC-G ceramic after oxidation for 10 h

| Sample | LZS-1 | LZS-2 | LZS-3 |

|---|---|---|---|

| k / [(mg·cm-2)2﹒h-1] | 0.85 | 0.54 | 0.42 |

| [1] | ZAMHARIR M J, ASL M S, VAFA N P,et al.Significance of hot pressing parameters and reinforcement size on densification behavior of ZrB2-25vol% SiC UHTC. Ceramics International, 2015, 41(5): 6439-6447. |

| [2] | ZHANG GUO-JUN, ZOU JI, NI DE-WEI,et al. Boride ceramics: densification, microstructure tailoring and properties improvemen. Journal of Inorganic Materials, 2012, 27(3): 225-233. |

| [3] | YAN YONG-JIE, ZHANG HUI, HUANG ZHENG-REN,et al.Oxidation behaviors of the pressureless sintered ZrB2-SiC composite. Journal of Inorganic Materials, 2009, 24(3): 631-635. |

| [4] | ASL M S, KAKROUDI M G.Characterization of hot-pressed graphene reinforced ZrB2-SiC composit. Materials Science & Engineering A, 2015, 625: 385-392. |

| [5] | GUO S, MIZUGUCHI T, IKEGAMI M,et al.Oxidation behavior of ZrB2-MoSi2-SiC composites in air at 1500. Ceramics International, 2011, 37(2): 585-591. |

| [6] | HE J, WANG Y, LUO L, et al. Oxidation behaviour of ZrB2-SiC (Al/Y) ceramics at 1700℃ at 1700. Journal of the European Ceramic Society, 2016, 36(15): 3769-3774. |

| [7] | ZIELONKA W.Effect of oxidation at 1100℃ on the strength of ZrB2-SiC-graphite ceramic.Journal of Alloys & Compounds, 2011, 509(24): 6871-6875. |

| [8] | HWANG S S, VASILIEV A L, PADTURE N P.Improved processing and oxidation-resistance of ZrB2 ultra-high temperature ceramics containing SiC nanodispersoid.Materials Science and Engineering: A, 2007, 464(1): 216-224. |

| [9] | GUO W M, ZHANG G J.Oxidation resistance and strength retention of ZrB2-SiC ceramic.Journal of the European Ceramic Society, 2010, 30(11): 2387-2395. |

| [10] | SCITI D, BRACH M, BELLOSI A.Long-term oxidation behavior and mechanical strength degradation of a pressurelessly sintered ZrB2-MoSi2 cerami.Scripta Materialia, 2005, 53(11): 1297-1302. |

| [11] | LI N, ZHOU S, JIN X,et al.Effect of surface oxidation on the flexural strength of ZrB2-SiC composite. Journal of Alloys and Compounds, 2015, 620: 142-148. |

| [12] | ZHOU P, FAN Y, WANG P,et al.The indentation thermal shock behavior of laminated ZrB2-SiC ceramics with strong interface. Ceramics International, 2016, 42(15): 17489-17496. |

| [13] | WEI C, ZHANG X, HU P,et al.Microstructure and mechanical properties of laminated ZrB2-SiC ceramics with ZrO2 interface layer. International Journal of Refractory Metals & Hard Materials, 2012, 30(1): 173-176. |

| [14] | LI Y, LI Q, WANG Z,et al.Oxidation behavior of laminated ZrB2-SiC composites and monolithic ZrB2-SiC composites. Ceramics International, 2016, 42(1): 2063-2069. |

| [15] | PADOVANO E, BADINI C, CWLASCO E,et al.Oxidation behavior of ZrB2/SiC laminates: Effect of composition on microstructure and mechanical strengt. Journal of the European Ceramic Society, 2015, 35(6): 1699-1714. |

| [16] | GUO W M, ZHANG G J.Oxidation resistance and strength retention of ZrB2-SiC ceramic.Journal of the European Ceramic Society, 2010, 30(11): 2387-2390. |

| [1] | ZHANG Xiangsong, LIU Yetong, WANG Yongying, WU Zirui, LIU Zhenzhong, LI Yi, YANG Juan. Self-assembled Platinum-iridium Alloy Aerogels and Their Efficient Electrocatalytic Ammonia Oxidation Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 511-520. |

| [2] | WANG Lei, LI Jianjun, NING Jun, HU Tianyu, WANG Hongyang, ZHANG Zhanqun, WU Linxin. Enhanced Degradation of Methyl Orange with CoFe2O4@Zeolite Catalyst as Peroxymonosulfate Activator: Performance and Mechanism [J]. Journal of Inorganic Materials, 2023, 38(4): 469-476. |

| [3] | YU Yefan, XU Ling, NI Zhongbing, SHI Dongjian, CHEN Mingqing. Prussian Blue Modified Biochar: Preparation and Adsorption of Ammonia Nitrogen from Sewage [J]. Journal of Inorganic Materials, 2023, 38(2): 205-212. |

| [4] | LUO Yi, XIA Shuhai, NIU Bo, ZHANG Yayun, LONG Donghui. Preparation and High Temperature Inorganic Transformation of Flexible Silicone Aerogels [J]. Journal of Inorganic Materials, 2022, 37(12): 1281-1288. |

| [5] | SHU Chaoqin, ZHU Min, ZHU Yufang. Cobalt-incorporated Chlorapatite: Preparation by Molten Salt Method, Anti-oxidation and Cytocompatibility [J]. Journal of Inorganic Materials, 2022, 37(11): 1225-1235. |

| [6] | WANG Haoxuan, LIU Qiaomu, WANG Yiguang. Research Progress of High Entropy Transition Metal Carbide Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 355-364. |

| [7] | ZHANG Wenjin, SHEN Qianqian, XUE Jinbo, LI Qi, LIU Xuguang, JIA Husheng. Preparation and Photoelectrochemical Water Oxidation of Hematite Nanobelts Containing Highly Ordered Oxygen Vacancies [J]. Journal of Inorganic Materials, 2021, 36(12): 1290-1296. |

| [8] | ZHANG Yachen, MENG Jia, CAI Kun, SHENG Xiaochen, LE Jun, SONG Lixin. Bending Failure Mechanism Study of Si-Cr-Ti High Temperature Oxidation Resistance Coating via Acoustic Emission Technique [J]. Journal of Inorganic Materials, 2021, 36(11): 1185-1192. |

| [9] | LEI Yiming, ZHANG Jie, BAI Guanghai, ZHANG Yanwei, WANG Xiaohui, WANG Jingyang. Influence of Al Content on Oxidation Resistance of Phase-pure Ti2AlC under Simulated Loss-of-coolant Accident Conditions [J]. Journal of Inorganic Materials, 2021, 36(10): 1097-1102. |

| [10] | WANG Zhihu,ZHANG Jumei,BAI Lijing,ZHANG Guojun. Mg(OH)2 Film on Micro-arc Oxidation Ceramic Coating of AZ31 Magnesium Alloy: Preparation and Corrosion Resistance [J]. Journal of Inorganic Materials, 2020, 35(6): 709-716. |

| [11] | HUANG Xieyi,WANG Peng,YIN Guoheng,ZHANG Shaoning,ZHAO Wei,WANG Dong,BI Qingyuan,HUANG Fuqiang. Removal of Volatile Organic Compounds Driven by Platinum Supported on Amorphous Phosphated Titanium Oxide [J]. Journal of Inorganic Materials, 2020, 35(4): 482-490. |

| [12] | YANG Shaohui, YAN Shufang, LI Shijiang, CHEN Weidong, DU Pei, MA Wen. Effect of Phase Duty Cycle on the Properties of ZrH1.8 Surface Micro-arc Oxidized Ceramic Layer [J]. Journal of Inorganic Materials, 2020, 35(10): 1112-1116. |

| [13] | LYU Ziye, TANG Yiping, CAO Huazhen, ZHENG Guoqu, HOU Guangya. Effect of V Doping on Electrocatalytic Performance of Ni-Co-S on Bacterial Cellulose-derived Carbon Aerogel [J]. Journal of Inorganic Materials, 2020, 35(10): 1142-1148. |

| [14] | LI Zhao, SUN Qiangqiang, CHEN Suoqian, ZHOU Chunsheng, CAO Jing, WANG Yongfeng, WANG Yanan. Hydrothermal Synthesized Nickel Copper Composite Phosphides as Bifunctional Electrocatalysts for Hydrogen Evolution and Hydrazine Oxidation [J]. Journal of Inorganic Materials, 2020, 35(10): 1149-1156. |

| [15] | GUO Yang, ZHANG Wei, ZHOU Xing, DENG Lei. Oxidation Characteristics of Magnesium Diboride [J]. Journal of Inorganic Materials, 2019, 34(8): 873-878. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||