Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (7): 773-778.DOI: 10.15541/jim20150644

• Orginal Article • Previous Articles Next Articles

LI Jian1,2,3, CHEN Bao-Rong1, ZHOU Hong-Ming1,2,3

Received:2015-12-22

Published:2016-07-20

Online:2016-06-22

About author:LI Jian(1969–), PhD, associate professor. E-mail: ziliao2000@126.com

Supported by:CLC Number:

LI Jian, CHEN Bao-Rong, ZHOU Hong-Ming. Effects of Washing and Heat-treatment on Structure and Electrochemical Charge/Discharge Property of LiNi0.8Co0.15Al0.05O2 Powder[J]. Journal of Inorganic Materials, 2016, 31(7): 773-778.

| Samples | M1 | N1 | N2 | N3 |

|---|---|---|---|---|

| Water content/(×10-6) | 500.16 | 1552.45 | 257.95 | 207.74 |

Table 1 Water content of primitive LiNi0.8Co0.15Al0.05O2 powder (M1) and treated samples (N1, N2, N3)

| Samples | M1 | N1 | N2 | N3 |

|---|---|---|---|---|

| Water content/(×10-6) | 500.16 | 1552.45 | 257.95 | 207.74 |

| Samples | a/nm | c/nm | c/a | I(003)/I(104) | R | V/(×10-5, nm3) |

|---|---|---|---|---|---|---|

| M1 | 0.2868 | 1.4183 | 4.945 | 1.18 | 0.40 | 1.0101 |

| N1 | 0.2867 | 1.4177 | 4.945 | 1.16 | 0.42 | 1.0091 |

| N2 | 0.2867 | 1.4180 | 4.946 | 1.18 | 0.42 | 1.0092 |

| N3 | 0.2867 | 1.4178 | 4.945 | 1.11 | 0.44 | 1.0090 |

Table 2 Lattice constant, c/a ratio, I(003)/I(104), R, and V of primitive LiNi0.8Co0.15Al0.05O2 powder (M1) and treated samples (N1, N2, N3)

| Samples | a/nm | c/nm | c/a | I(003)/I(104) | R | V/(×10-5, nm3) |

|---|---|---|---|---|---|---|

| M1 | 0.2868 | 1.4183 | 4.945 | 1.18 | 0.40 | 1.0101 |

| N1 | 0.2867 | 1.4177 | 4.945 | 1.16 | 0.42 | 1.0091 |

| N2 | 0.2867 | 1.4180 | 4.946 | 1.18 | 0.42 | 1.0092 |

| N3 | 0.2867 | 1.4178 | 4.945 | 1.11 | 0.44 | 1.0090 |

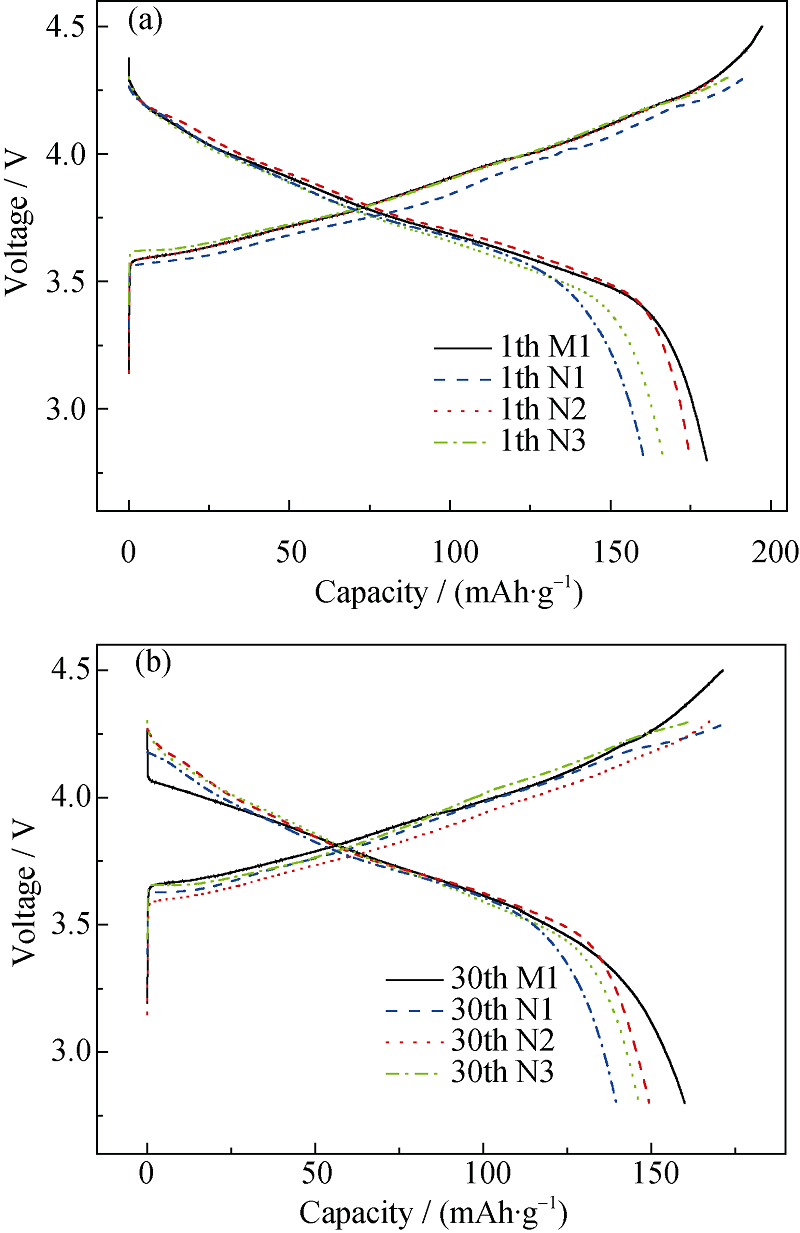

Fig. 5 Initial (a) and the 30th cycle (b) charge and discharge curves at 0.2C of primitive LiNi0.8Co0.15Al0.05O2 powder (M1) and treated samples (N1, N2, N3)

| [1] | CAO H, XIA B J, XU N X, et al.Structural and electrochemical characteristics of Co and Al co-doped lithium nickelate cathode materials for lithium-ion batteries.Journal of Alloys and Compounds, 2004, 376(2): 282-286. |

| [2] | TARASCON J M, ARMAND M.Issues and challenges facing rechargeable lithium batteries.Nature, 2001, 414: 359-367. |

| [3] | ITOU Y, UKYO Y.Performance of LiNiCoO2 materials for advanced lithium-ion batteries.Journal of Power Sources, 2005, 146(2): 39-44. |

| [4] | OHZUKU T, UEDA A, NAGAYAMA M, et al.Comparative study of LiCoO2, LiNi1/2Co1/2O2 and LiNiO2 for 4 volt secondary lithium cells.Electrochimica Acta, 1993, 38(9): 1159-1167. |

| [5] | MORALES J, VICENTE C P, TIRADO J L.Cation distribution and chemical deintercalation of Li1-xNi1+xO2.Materials Research Bulletin, 1990, 25(5): 623-630. |

| [6] | OHZUKU T, UEDA A, NAGAYAMA M.Electrochemistry and structural chemistry of LiNiO2 (R3-m) for 4 volt secondary lithium cells.Journal of the Electrochemical Society, 1993, 140(7): 1862-1870. |

| [7] | XIONG X H, WANG Z X, YUE P, et al.Washing effects on electrochemical performance and storage characteristics of LiNi0.8Co0.1Mn0.1O2 as cathode material for lithium-ion batteries.Journal of Power Sources, 2013, 222: 318-325. |

| [8] | MAJUMDER S B, NIETO S, KATIYAR R S.Synthesis and electrochemical properties of LiNi0.80(Co0.20-xAlx)O2 (x = 0.0 and 0.05) cathodes for Li ion rechargeable batteries.Journal of Power Sources, 2006, 154(1): 262-267. |

| [9] | ZHUANG G V, CHEN G Y, SHIM J, et al.Li2CO3 in LiNi0.8Co0.15Al0.05O2 cathodes and its effects on capacity and power. Journal ofPower Sources, 2004, 134(2): 293-297. |

| [10] | HWANG I, LEE C W, KIM J C, et al.Particle size effect of Ni-rich cathode materials on lithium ion battery performance.Materials Research Bulletin, 2012, 47(1): 73-78. |

| [11] | HUANG B, LI X H, WANG Z X, et al.Enhanced electrochemical performance in LiNi0.8Co0.15Al0.05O2 cathode material: resulting from Mn-surface-modification using a facile oxidizing-coating method.Materials Letters, 2014, 115(15): 49-52. |

| [12] | LIU W M, HU G R, PENG Z D, et al.Synthesis of spherical LiNi0.8Co0.15Al0.05O2 cathode materials for lithium-ion batteries by a co-oxidation-controlled crystallization method.Chinese Chemical Letters, 2011, 22(9): 1099-1102. |

| [13] | DU K, HUANG J L, CAO Y B, et al.Study of effects on LiNi0.8Co0.15Al0.05O2 cathode by LiNi1/3Co1/3Mn1/3O2 coating for lithium ion batteries.Journal of Alloys and Compounds, 2013, 574: 377-382. |

| [14] | HU G R, LIU W M, PENG Z D, et al.Synthesis and electrochemical properties of LiNi0.8Co0.15Al0.05O2 prepared from the precursor Ni0.8Co0.15Al0.05OOH.Journal of Power Sources, 2012, 198: 258-263. |

| [15] | GUILMARD M, POUILLERIE C, CROGUENNEC L, et al.Structural and electrochemical properties of LiNi0.70Co0.15Al0.15O2.Solid State Ionics, 2003, 160(2): 39-50. |

| [16] | CHO Y, CHO J.Significant improvement of LiNi0.8Co0.15Al0.05 O2 cathodes at 60℃ by SiO2 dry coating for Li-ion batteries.Journal of Electrochemical Society, 2010, 157(6): A625-A629. |

| [17] | SONG Q, TANG Z Y, GUO H T, et al.Structural characteristics of nickel hydroxide synthesized by a chemical precipitation route under different pH values.Journal of Power Sources, 2002, 112(2): 428-434. |

| [18] | FREITAS M B J G. Nickel hydroxide powder for NiO·OH/ Ni (OH)2 electrodes of the alkaline batteries.Journal of Power Sources, 2001, 93(2): 163-173. |

| [19] | REIMERS J N, ROSSEN E, JONES C D, et al.Structure and electrochemistry of LixFeyNi1-yO2.Solid State Ionics, 1993, 61(4): 335-344. |

| [20] | OLIVA P, LEONARDI J, LAURENT J F, et al.Review of the structure and the electrochemistry of nickel hydroxides and oxy-hydroxides.Journal of Power Sources, 1982, 8(2): 229-255. |

| [21] | ŠURCA A, OREL B, PIHLAR B, et al.Optical, spectroelectrochemical and structural properties of Sol-Gel derived Ni-oxide electrochromic film.Journal of Electroanalytical Chemistry, 1996, 408(2): 83-100. |

| [22] | LIU B, WANG X Y, YUAN H T, et al.Physical and electrochemical characteristics of aluminium-substituted nickel hydroxide.Journal of Applied Electrochemistry, 1999, 29(7): 855-860. |

| [23] | HORÀNYI T S. Investigation of the effects of heat treatment on the β-Ni(OH)2-β-NiOOH system using IR spectroscopy.Thermochimica Acta, 1989, 142(1): 143-150. |

| [24] | YOON W S, CHUNG K Y, MCBREEN J, et al.Electronic structural changes of the electrochemically Li-ion deintercalated LiNi0.8Co0.15Al0.05O2 cathode material investigated by X-ray absorption spectroscopy.Journal of Power Sources, 2007, 174: 1015-1020. |

| [25] | EIN-ELI Y, MARKOVSKY B, AURBACH D, et al.The dependence of the performance of Li-C intercalation anodes for Li-ion secondary batteries on the electrolyte solution composition.Electrochimica Acta, 1994, 39(17): 2559-2569. |

| [1] | YU Xiangkun, LIU Kun, LI Zhipeng, ZHAO Yulu, SHEN Jinyou, MAO Ping, SUN Aiwu, JIANG Jinlong. Efficient Adsorption of Radioactive Iodide by Copper/Palygorskite Composite [J]. Journal of Inorganic Materials, 2021, 36(8): 856-864. |

| [2] | GUO Meng, ZHANG Fengnian, MIAO Yang, LIU Yufeng, YU Jun, GAO Feng. Preparation and Electrical Properties of High Entropy La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 Perovskite Ceramics Powder [J]. Journal of Inorganic Materials, 2021, 36(4): 431-435. |

| [3] | LIU Yong, BAI Haijun, ZHAO Qizhi, YANG Jinge, LI Yujie, ZHENG Chunman, XIE Kai. Storage Aging Mechanism of LiNi0.8Co0.15Al0.05O2/Graphite Li-ion Batteries at High State of Charge [J]. Journal of Inorganic Materials, 2021, 36(2): 175-180. |

| [4] | LI Teng-Fei, HUANG Lu-Jun, YAN Xu-Dong, LIU Qing-Lei, GU Jia-Jun. Ti3C2Tx/Wood Carbon as High-areal-capacity Electrodes for Supercapacitors [J]. Journal of Inorganic Materials, 2020, 35(1): 126-130. |

| [5] | LU Chang-Jian, ZHU Fa-Quan, Yin Ji-Guang, ZHANG Jian-Bo, YU Ya-Wei, HU Xiu-Lan. Synthesis of α-MnO2 Nanowires via Facile Hydrothermal Method and Their Application in Li-O2 Battery [J]. Journal of Inorganic Materials, 2018, 33(9): 1029-1034. |

| [6] | GUO Rui-hua, MO Yi-Jie, AN Sheng-Li, ZHANG Jie-Yu, ZHOU Guo-Zhi. Cerium Oxide Hollow Sphere: Controllable Synthesis and Its Effect on Electrocatalytic Performance of Pt-based Catalysts [J]. Journal of Inorganic Materials, 2018, 33(7): 779-786. |

| [7] | MENG Xiang-Lu, HUO Han-Yu, GUO Xiang-Xin, DONG Shao-Ming. Influence of Film Thickness on the Electrochemical Performance of α-SiOx Thin-film Anodes [J]. Journal of Inorganic Materials, 2018, 33(10): 1141-1146. |

| [8] | WEI Zhi-Guo, LU Xin, TONG Jian-Bo, PAN Yu, WANG Guo-Qing, QU Xuan-Hui. Preparation and Discharge Performance of Porous VB2 Anodes for High Capacity VB2-air Battery [J]. Journal of Inorganic Materials, 2017, 32(2): 122-126. |

| [9] | MENG Fang-Li, ZHANG Dong-Yun, CHANG Cheng-Kang, XU Jia-Yue, KAMZIN A S. Synthesis and Electrochemical Performance of LiFePO4/C Cathode Materials Using Fe Powder [J]. Journal of Inorganic Materials, 2016, 31(8): 802-806. |

| [10] | HE Yue-De, JIAN Zhi-Min, LIU Hong-Bo, XIAO Hai-He. Preparation and Electrochemical Performance of Flake Graphite Anode Materials with Slightly Expanded Interlayer [J]. Journal of Inorganic Materials, 2013, 28(9): 931-936. |

| [11] | LIU Ling, YUAN Zhong-Zhi, QIU Cai-Xia, Cheng Si-Jie, LIU Jin-Cheng. Synthesis and Electrochemical Characteristics of the Novel FeS2/VGCF Material for Lithium-Ion Batteries [J]. Journal of Inorganic Materials, 2013, 28(12): 1291-1295. |

| [12] | GAO Jian, MU Xin, LI Jian-Jun, HE Xiang-Ming, JIANG Chang-Yin. Preparation and Characterization of Porous Spherical Li4Ti5O12/C Anode Material for Lithium Ion Batteries [J]. Journal of Inorganic Materials, 2012, 27(3): 253-257. |

| [13] | JIAO Yi, TANG Shi-Yun, WANG Jian-Li, ZHU Qing-Chao, CHEN Yao-Qiang, GONG Mao-Chu. Effects of Different Preparation Methods on the Properties of CeO2-ZrO2-Al2O3 [J]. Journal of Inorganic Materials, 2011, 26(8): 813-818. |

| [14] | WANG Wei-Qing,FENG Qi-Ming,DONG Fa-Qin,LI Hu-Jie,ZHAO Xiao-Dong. Preparation and Properties of Fe3O4/Clinoptilolite Magnetic Composite [J]. Journal of Inorganic Materials, 2010, 25(4): 401-405. |

| [15] |

WANG Jin,CHENG Xue-Lian,WANG Zi-Gang,YANG Hui.

Synthesis and Electrochemical Properties of Highly Dispersed Li4Ti5O12 Nanocrystalline as Anode Material for Lithium Secondary Batteries [J]. Journal of Inorganic Materials, 2010, 25(3): 235-241. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||