Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (12): 1337-1343.DOI: 10.15541/jim20220208

Special Issue: 【能源环境】超级电容器,锂金属电池,钠离子电池和水系电池(202409)

• RESEARCH ARTICLE • Previous Articles Next Articles

CAI Jia( ), HUANG Gaoxu, JIN Xiaopan, WEI Chi, MAO Jiayi, LI Yongsheng(

), HUANG Gaoxu, JIN Xiaopan, WEI Chi, MAO Jiayi, LI Yongsheng( )

)

Received:2022-04-12

Revised:2022-07-13

Published:2022-12-20

Online:2022-10-19

Contact:

LI Yongsheng, professor. E-mail: ysli@ecust.edu.cnAbout author:CAI Jia (1996-), female, Master candidate. E-mail: caijia0902@163.com

Supported by:CLC Number:

CAI Jia, HUANG Gaoxu, JIN Xiaopan, WEI Chi, MAO Jiayi, LI Yongsheng. In-situ Modification of Carbon Nanotubes with Metallic Bismuth Nanoparticles for Uniform Lithium Deposition[J]. Journal of Inorganic Materials, 2022, 37(12): 1337-1343.

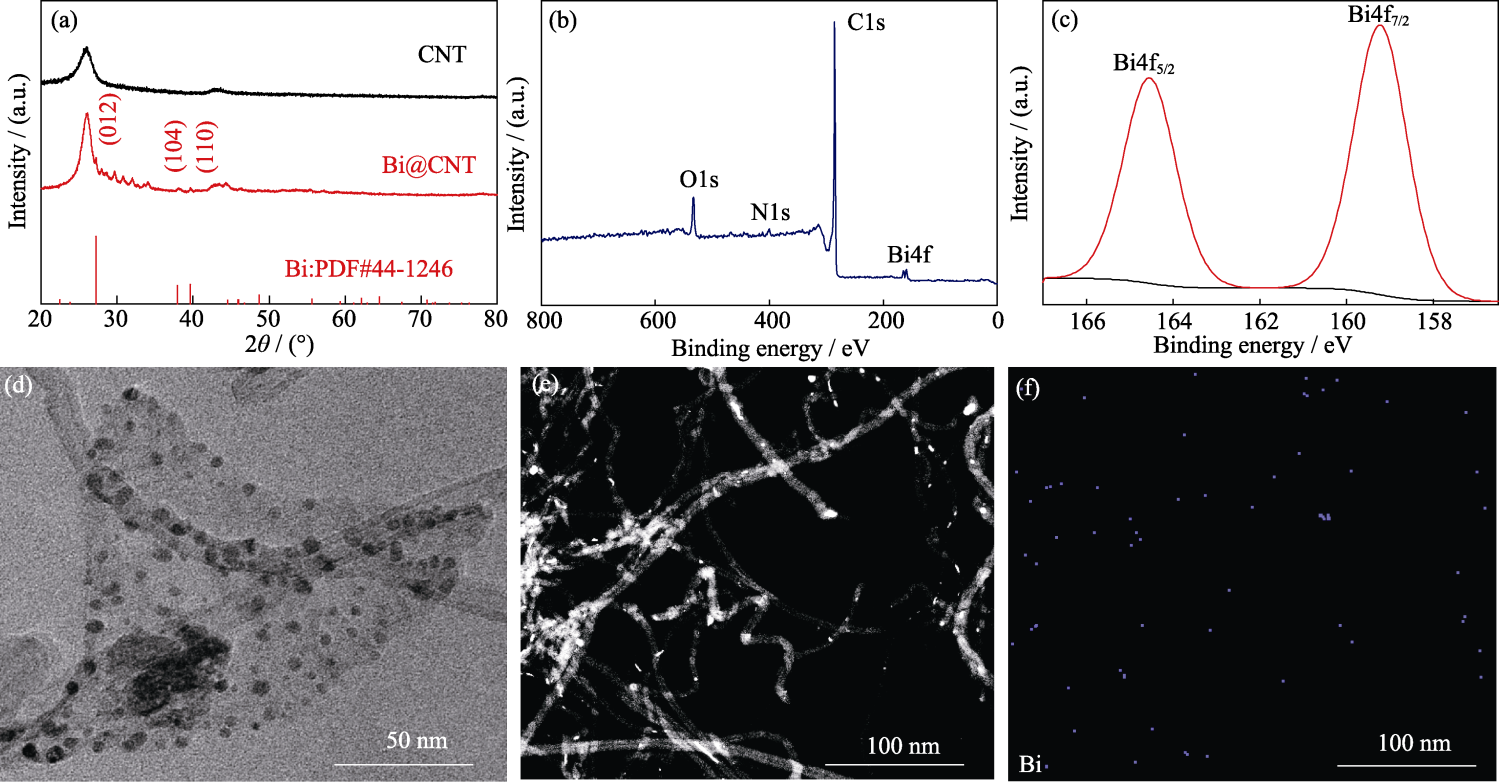

Fig. 2 Microstructure characterization of samples (a) XRD patterns of CNT and Bi@CNT; (b) Total survey and (c) high-resolution Bi4f XPS spectra of Bi@CNT; (d, e) TEM images and (f) EDS elemental mapping of Bi@CNT

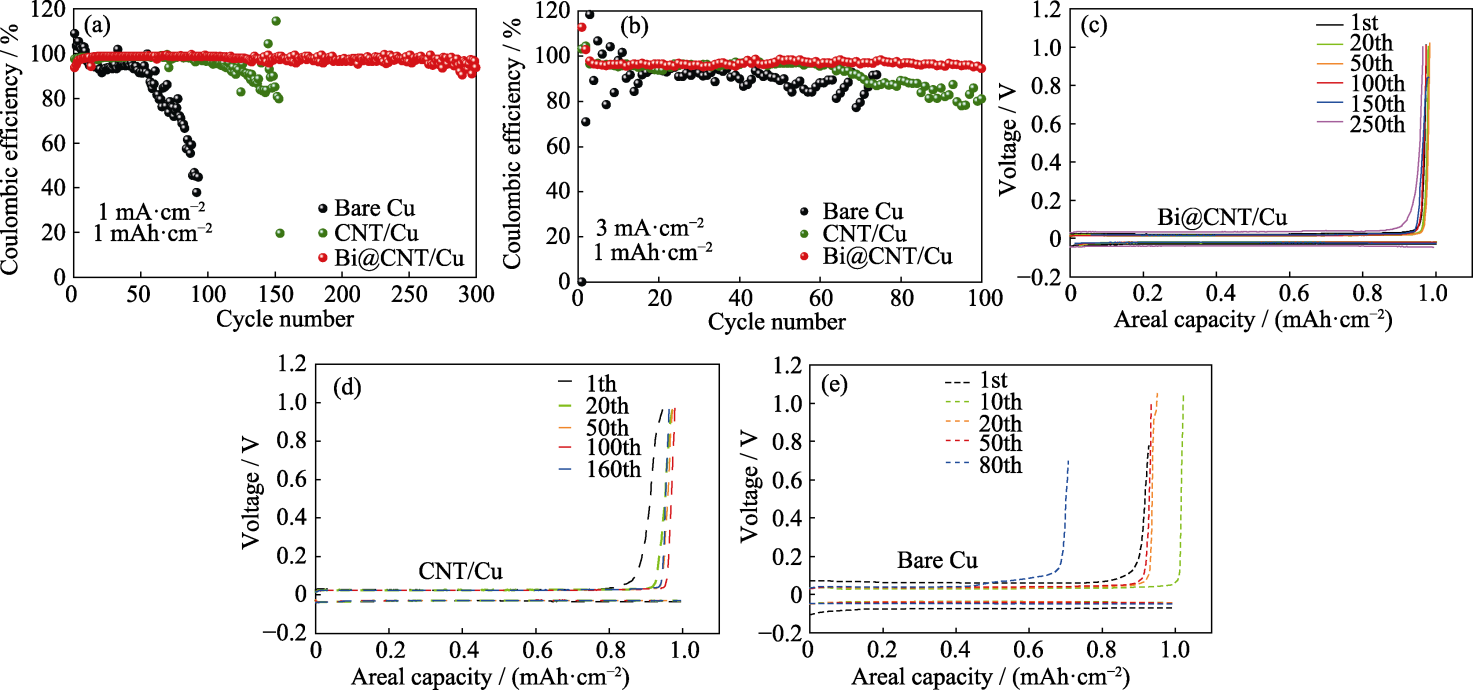

Fig. 3 Coulombic efficiencies of Li|Cu cells based on Bi@CNT/Cu, CNT/Cu and Cu current collectors at (a) 1 mA·cm-2, 1 mAh·cm-2 and (b) 3 mA·cm-2, 1 mAh·cm-2; Capacity-voltage curves of Li|Cu cells based on (c) Bi@CNT/Cu, (d) CNT/Cu, and (e) Cu current collectors at 1 mA·cm-2, 1 mAh·cm-2Colorful figures are available on website

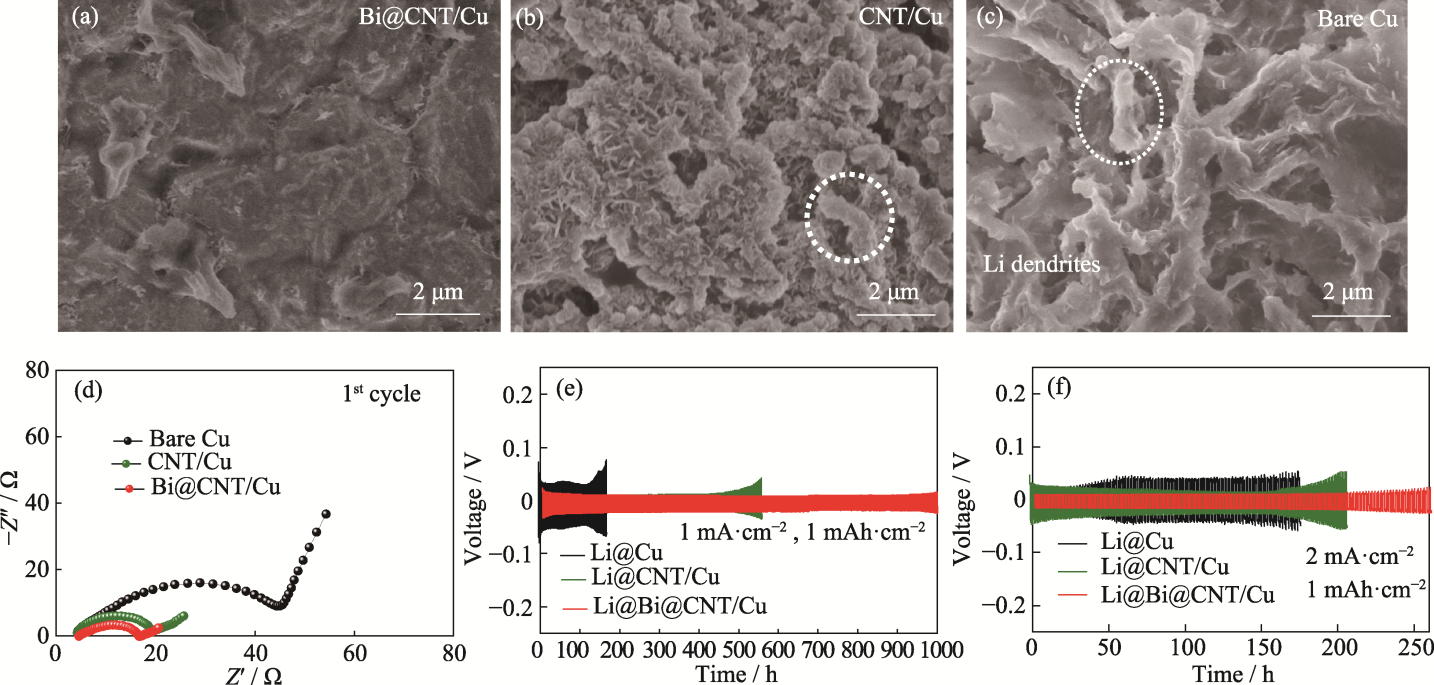

Fig. 4 SEM images of (a) Bi@CNT/Cu, (b) CNT/Cu, and (c) Cu current collectors in Li|Cu cells after 50 cycles; (d) First cyclic EIS plots of Li|Cu cells based on Bi@CNT/Cu, CNT/Cu and Cu current collectors, and voltage-time curves of symmetric cells based on Li@Bi@CNT/Cu, Li@CNT/Cu and Li@Cu anodes at (e) 1 mA·cm-2, 1 mAh·cm-2 and (f) 2 mA·cm-2, 1 mAh·cm-2 Colorful figures are available on website

| Symmetric cell | Li|Cu cell | |||||||

|---|---|---|---|---|---|---|---|---|

| Current collector | Current density/ (mA·cm-2) | Planting/ strippingcapacity/ (mAh·cm-2) | Cycling time/h | Current density/ (mA·cm-2) | Planting capacity/ (mAh·cm-2) | Cycle number, n | Coulombic efficiency/% | Ref. |

| Bi@CNT | 1 | 1 | 1000 | 1 | 1 | 300 | 98 | This work |

| 2 | 1 | 260 | 3 | 1 | 100 | 96 | ||

| SMC-2 | 1 | 1 | 220 | 0.5 | 1 | 210 | 97 | [21] |

| PDA | 0.1 | 0.2 | 800 | 1 | 1 | 100 | 96 | [22] |

| 3D-CuZn | 1 | 1 | 450 | 1 | 1 | 150 | 95 | [23] |

| Li-MMT | 3 | 1 | 70 | 2 | 0.25 | 100 | 97.9 | [24] |

| LHCE | 1 | 1 | 700 | 1 | 1 | 200 | 99.1 | [25] |

| NMPC | 0.5 | 0.5 | 400 | 1 | 1 | 200 | 98 | [26] |

| Duplex Cu | 1 | 1 | 880 | 1 | 1 | 300 | 97.3 | [27] |

| Ti3C2Tx | 1 | 1 | 500 | 1 | 1 | 250 | 98.4 | [28] |

| q-PET | 3 | 1 | 100 | 1 | 1 | 100 | 98 | [29] |

| SF | 3 | 3 | 350 | 1 | 1 | 200 | 96 | [30] |

Table 1 Comparison of electrochemical properties of copper foils modified by different materials

| Symmetric cell | Li|Cu cell | |||||||

|---|---|---|---|---|---|---|---|---|

| Current collector | Current density/ (mA·cm-2) | Planting/ strippingcapacity/ (mAh·cm-2) | Cycling time/h | Current density/ (mA·cm-2) | Planting capacity/ (mAh·cm-2) | Cycle number, n | Coulombic efficiency/% | Ref. |

| Bi@CNT | 1 | 1 | 1000 | 1 | 1 | 300 | 98 | This work |

| 2 | 1 | 260 | 3 | 1 | 100 | 96 | ||

| SMC-2 | 1 | 1 | 220 | 0.5 | 1 | 210 | 97 | [21] |

| PDA | 0.1 | 0.2 | 800 | 1 | 1 | 100 | 96 | [22] |

| 3D-CuZn | 1 | 1 | 450 | 1 | 1 | 150 | 95 | [23] |

| Li-MMT | 3 | 1 | 70 | 2 | 0.25 | 100 | 97.9 | [24] |

| LHCE | 1 | 1 | 700 | 1 | 1 | 200 | 99.1 | [25] |

| NMPC | 0.5 | 0.5 | 400 | 1 | 1 | 200 | 98 | [26] |

| Duplex Cu | 1 | 1 | 880 | 1 | 1 | 300 | 97.3 | [27] |

| Ti3C2Tx | 1 | 1 | 500 | 1 | 1 | 250 | 98.4 | [28] |

| q-PET | 3 | 1 | 100 | 1 | 1 | 100 | 98 | [29] |

| SF | 3 | 3 | 350 | 1 | 1 | 200 | 96 | [30] |

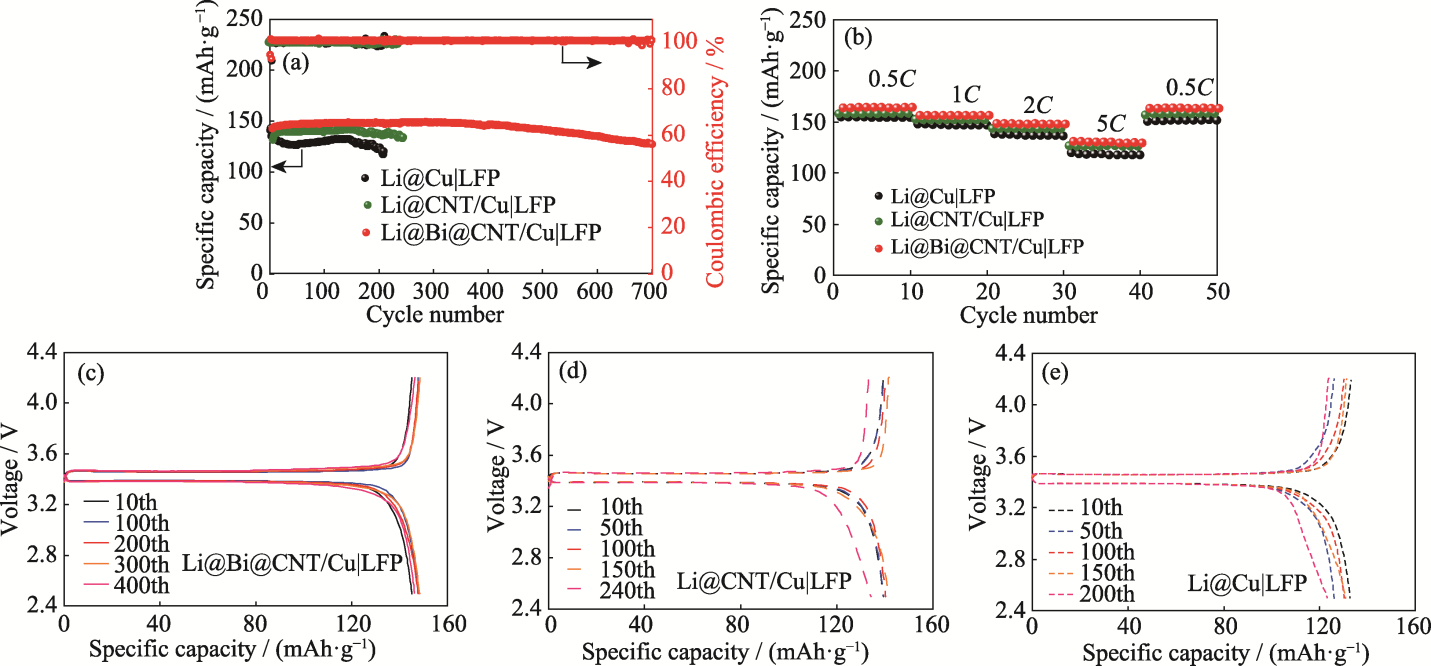

Fig.5 (a) Cycling performances and (b) rate performances of LFP full cells based on Li@Bi@CNT/Cu, Li@CNT/Cu, and Li@Cu anodes, and (c-e) capacity-voltage profiles of LFP full cells based on (c) Li@Bi@CNT/Cu, (d) Li@CNT/Cu, and (e) Li@Cu anodes at 1C Colorful figures are available on website

| [1] |

DUNN B, KAMATH H, TARASCON J M. Electrical energy storage for the grid: a battery of choices. Science, 2011, 334(6058): 928-935.

DOI PMID |

| [2] |

QIAN J, HENDERSON W A, XU W, et al. High rate and stable cycling of lithium metal anode. Nature Communications, 2015, 6: 6362.

DOI PMID |

| [3] |

HE B, RAO Z, CHENG Z, et al. Rationally design a sulfur cathode with solid-phase conversion mechanism for high cycle-stable Li-S batteries. Advanced Energy Materials, 2021, 11(14): 2003690.

DOI URL |

| [4] |

JUNG W B, PARK H, JANG J S, et al. Polyelemental nanoparticles as catalysts for a Li-O2 battery. ACS nano, 2021, 15(3): 4235-4244.

DOI URL |

| [5] |

WOOD K N, KAZYAK E, CHADWICK A F, et al. Dendrites and pits: untangling the complex behavior of lithium metal anodes through operando video microscopy. ACS Central Science, 2016, 2(11): 790-801.

PMID |

| [6] |

SANCHEZ A J, KAZYAK E, CHEN Y, et al. Plan-view operando video microscopy of Li metal anodes: identifying the coupled relationships among nucleation, morphology, and reversibility. ACS Energy Letters, 2020, 5(3): 994-1004.

DOI URL |

| [7] |

AURBACH D. Review of selected electrode-solution interactions which determine the performance of Li and Li ion batteries. Journal of Power Sources, 2000, 89(2): 206-218.

DOI URL |

| [8] |

CHENG X B, ZHANG R, ZHAO C Z, et al. A review of solid electrolyte interphases on lithium metal anode. Advanced Science, 2016, 3(3): 1500213.

DOI URL |

| [9] |

SHEN X, LI Y, QIAN T, et al. Lithium anode stable in air for low-cost fabrication of a dendrite-free lithium battery. Nature Communications, 2019, 10: 900.

DOI PMID |

| [10] |

XU R, ZHANG X Q, CHENG X B, et al. Artificial soft-rigid protective layer for dendrite-free lithium metal anode. Advanced Functional Materials, 2018, 28(8): 1705838.

DOI URL |

| [11] |

LIU Y, LIU Q, XIN L, et al. Making Li-metal electrodes rechargeable by controlling the dendrite growth direction. Nature Energy, 2017, 2: 17083.

DOI URL |

| [12] |

XU K. Electrolytes and interphases in Li-ion batteries and beyond. Chemical Reviews, 2014, 114(23): 11503-11618.

DOI PMID |

| [13] |

HUANG S, ZHANG W, MING H, et al. Chemical energy release driven lithiophilic layer on 1 m2 commercial brass mesh toward highly stable lithium metal batteries. Nano Letters, 2019, 19(3): 1832-1837.

DOI URL |

| [14] |

PEI F, FU A, YE W, et al. Robust lithium metal anodes realized by lithiophilic 3D porous current collectors for constructing high-energy lithium-sulfur batteries. ACS Nano, 2019, 13(7): 8337-8346.

DOI PMID |

| [15] |

YAN K, LU Z, LEE H W, et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nature Energy, 2016, 1: 16010.

DOI URL |

| [16] |

PEI A, ZHENG G, SHI F, et al. Nanoscale nucleation and growth of electrodeposited lithium metal. Nano Letters, 2017, 17(2): 1132-1139.

DOI PMID |

| [17] |

ZHANG Y, LUO W, WANG C, et al. High-capacity, low-tortuosity, and channel-guided lithium metal anode. Proceedings of the National Academy of Sciences, 2017, 114(14): 3584-3589.

DOI URL |

| [18] |

QIU H, TANG T, ASIF M, et al. 3D porous Cu current collectors derived by hydrogen bubble dynamic template for enhanced Li metal anode performance. Advanced Functional Materials, 2019, 29(19): 1808468.

DOI URL |

| [19] |

HU Z, LI Z, XIA Z, et al. PECVD-derived graphene nanowall/ lithium composite anodes towards highly stable lithium metal batteries. Energy Storage Materials, 2019, 22: 29-39.

DOI URL |

| [20] |

HOU G, SUN Q, AI Q, et al. Growth direction control of lithium dendrites in a heterogeneous lithiophilic host for ultra-safe lithium metal batteries. Journal of Power Sources, 2019, 416: 141-147.

DOI URL |

| [21] |

ZHANG F, LIU X, YANG M, et al. Novel S-doped ordered mesoporous carbon nanospheres toward advanced lithium metal anodes. Nano Energy, 2020, 69: 104443.

DOI URL |

| [22] |

HE Y, XU H, SHI J, et al. Polydopamine coating layer modified current collector for dendrite-free Li metal anode. Energy Storage Materials, 2019, 23: 418-426.

DOI URL |

| [23] |

ZHANG D, DAI A, WU M, et al. Lithiophilic 3D porous CuZn current collector for stable lithium metal batteries. ACS Energy Letters, 2019, 5(1): 180-186.

DOI URL |

| [24] |

NAN Y, LI S, HAN C, et al. Interlamellar lithium-ion conductor reformed interface for high performance lithium metal anode. Advanced Functional Materials, 2021, 31(25): 2102336.

DOI URL |

| [25] | LIU Y, WU X, NIU C, et al. Systematic evaluation of carbon hosts for high-energy rechargeable lithium-metal batteries. ACS Energy Letters, 2021, 6(4): 1550-1559. |

| [26] |

LIU H, WANG E, ZHANG Q, et al. Unique 3D nanoporous/ macroporous structure Cu current collector for dendrite-free lithium deposition. Energy Storage Materials, 2019, 17: 253-259.

DOI URL |

| [27] |

LIN K, LI T, CHIANG S W, et al. Facile synthesis of ant-nest-like porous duplex copper as deeply cycling host for lithium metal anodes. Small, 2020, 16(37): 2001784.

DOI URL |

| [28] |

YANG D, ZHAO C, LIAN R, et al. Mechanisms of the planar growth of lithium metal enabled by the 2D lattice confinement from a Ti3C2Tx MXene intermediate layer. Advanced Functional Materials, 2021, 31(24): 2010987.

DOI URL |

| [29] |

ZHANG W, ZHUANG H L, FAN L, et al. A “cation-anion regulation” synergistic anode host for dendrite-free lithium metal batteries. Science Advances, 2018, 4(2): eaar4410.

DOI URL |

| [30] |

FU A, WANG C, PENG J, et al. Lithiophilic and antioxidative copper current collectors for highly stable lithium metal batteries. Advanced Functional Materials, 2021, 31(15): 2009805.

DOI URL |

| [1] | LI Rui,WANG Hao,FU Qiang,TIAN Ziyu,WANG Jianxu,MA Xiaojian,YANG Jian,QIAN Yitai. Stable Li-metal Depositon on Lithiophilic 3D CuO Nanosheet-decorated Cu Mesh [J]. Journal of Inorganic Materials, 2020, 35(8): 882-888. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||