Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (12): 1247-1255.DOI: 10.15541/jim20210126

Special Issue: MXene材料专辑(2020~2021)

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Xiao1,2,3( ), LI Youbing2,3, CHEN Ke2,3, DING Haoming2,3, CHEN Lu2,3, LI Mian2,3, SHI Rongrong1(

), LI Youbing2,3, CHEN Ke2,3, DING Haoming2,3, CHEN Lu2,3, LI Mian2,3, SHI Rongrong1( ), CHAI Zhifang2,3, HUANG Qing2,3(

), CHAI Zhifang2,3, HUANG Qing2,3( )

)

Received:2021-03-03

Revised:2021-03-24

Published:2021-12-20

Online:2021-06-01

Contact:

SHI Rongrong, associate professor. E-mail: shirr@lzu.edu.cn;HUANG Qing, professor. E-mail: huangqing@nimte.ac.cn

About author:ZHANG Xiao(1996-), male, Master candidate. E-mail: zhangxiao18@lzu.edu.cn

Supported by:CLC Number:

ZHANG Xiao, LI Youbing, CHEN Ke, DING Haoming, CHEN Lu, LI Mian, SHI Rongrong, CHAI Zhifang, HUANG Qing. Tailoring MAX Phase Magnetic Property Based on M-site and A-site Double Solid Solution[J]. Journal of Inorganic Materials, 2021, 36(12): 1247-1255.

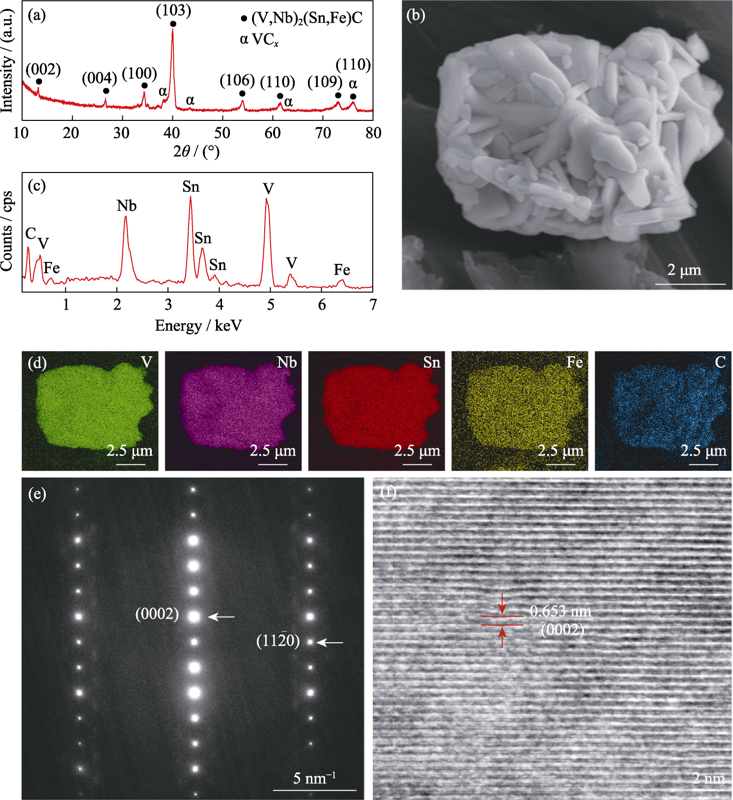

Fig. 1 Characterization results of (V, Nb)2(Sn, Fe)C after acid treatment (a) XRD pattern; (b) SEM image; (c) Corresponding energy-dispersive spectroscopy analysis; (d) Elemental mapping scanning on one particle; (e) Selected area electron diffraction pattern, showing the electron beam being paralleled to the [1$\bar{1}$00] direction; (f) HR-TEM image

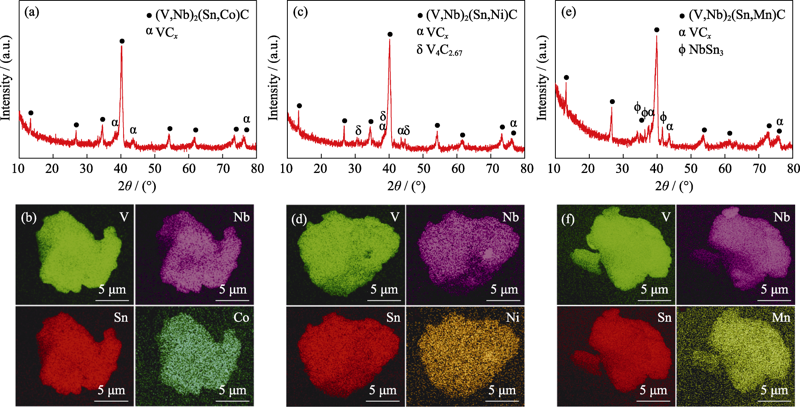

Fig. 2 XRD patterns of (a) (V, Nb)2(Sn, Co)C, (c) (V, Nb)2(Sn, Ni)C, and (e) (V, Nb)2(Sn, Mn)C after acid treatment; SEM-EDS elemental mappings of (b) (V, Nb)2(Sn, Co)C, (d) (V, Nb)2(Sn, Ni)C, and (f) (V, Nb)2(Sn, Mn)C after acid treatment

| MAX phase | Lattice parameter | Element percentage/% | Nb element in M site/% | Magnetic element in A site/% | |||||

|---|---|---|---|---|---|---|---|---|---|

| a/nm | c/nm | c/a | V | Nb | Sn | A | |||

| V2(Sn, Fe)C[ | 0.2984 | 1.3345 | 4.4718 | 66.84 | - | 22.05 | 11.11 | - | 33.50 |

| (V, Nb)2(Sn, Fe)C | 0.3014 | 1.3447 | 4.4622 | 54.32 | 13.38 | 25.03 | 7.27 | 19.76 | 22.51 |

| V2(Sn, Co)C[ | 0.2989 | 1.3409 | 4.4864 | 66.36 | - | 22.44 | 11.19 | - | 33.28 |

| (V, Nb)2(Sn, Co)C | 0.3016 | 1.3419 | 4.4493 | 56.41 | 11.23 | 24.60 | 7.76 | 16.60 | 23.98 |

| V2(Sn, Ni)C[ | 0.2985 | 1.3357 | 4.4751 | 67.47 | - | 24.36 | 8.16 | - | 25.10 |

| (V, Nb)2(Sn, Ni)C | 0.3021 | 1.3413 | 4.4402 | 56.87 | 13.00 | 21.66 | 8.47 | 18.61 | 28.10 |

| V2(Sn, Mn)C[ | 0.2982 | 1.3403 | 4.4941 | 66.19 | - | 23.07 | 10.74 | - | 31.76 |

| (V, Nb)2(Sn, Mn)C | 0.3026 | 1.3509 | 4.4646 | 57.10 | 10.84 | 23.50 | 8.56 | 15.96 | 26.70 |

Table 1 Lattice parameters and atomic percentage of element in MAX phases

| MAX phase | Lattice parameter | Element percentage/% | Nb element in M site/% | Magnetic element in A site/% | |||||

|---|---|---|---|---|---|---|---|---|---|

| a/nm | c/nm | c/a | V | Nb | Sn | A | |||

| V2(Sn, Fe)C[ | 0.2984 | 1.3345 | 4.4718 | 66.84 | - | 22.05 | 11.11 | - | 33.50 |

| (V, Nb)2(Sn, Fe)C | 0.3014 | 1.3447 | 4.4622 | 54.32 | 13.38 | 25.03 | 7.27 | 19.76 | 22.51 |

| V2(Sn, Co)C[ | 0.2989 | 1.3409 | 4.4864 | 66.36 | - | 22.44 | 11.19 | - | 33.28 |

| (V, Nb)2(Sn, Co)C | 0.3016 | 1.3419 | 4.4493 | 56.41 | 11.23 | 24.60 | 7.76 | 16.60 | 23.98 |

| V2(Sn, Ni)C[ | 0.2985 | 1.3357 | 4.4751 | 67.47 | - | 24.36 | 8.16 | - | 25.10 |

| (V, Nb)2(Sn, Ni)C | 0.3021 | 1.3413 | 4.4402 | 56.87 | 13.00 | 21.66 | 8.47 | 18.61 | 28.10 |

| V2(Sn, Mn)C[ | 0.2982 | 1.3403 | 4.4941 | 66.19 | - | 23.07 | 10.74 | - | 31.76 |

| (V, Nb)2(Sn, Mn)C | 0.3026 | 1.3509 | 4.4646 | 57.10 | 10.84 | 23.50 | 8.56 | 15.96 | 26.70 |

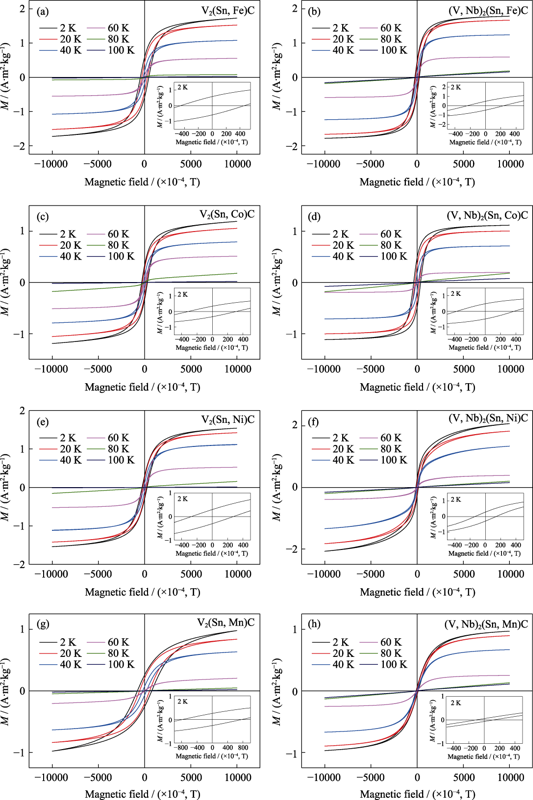

Fig. 4 Magnetic hysteresis loops of V2(Sn, A)C and V2(Sn, A)C (A=Fe, Co, Ni and Mn) at different temperatures in the range from -1 to 1 T, respectively Colourful figures are available on website

| MAX phase | TC | 2 K | 20 K | 40 K | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hc | Mr | Ms | Hc | Mr | Ms | Hc | Mr | Ms | ||

| V2(Sn, Fe)C | 63 | 458 | 0.59 | 1.73 | 305 | 0.42 | 1.53 | 152 | 0.18 | 1.08 |

| (V, Nb)2(Sn, Fe)C | 63 | 238 | 0.48 | 1.79 | 174 | 0.37 | 1.67 | 73 | 0.14 | 1.24 |

| V2(Sn, Co)C | 66 | 314 | 0.34 | 1.19 | 224 | 0.26 | 1.05 | 113 | 0.12 | 0.79 |

| (V, Nb)2(Sn, Co)C | 53 | 378 | 0.49 | 1.11 | 240 | 0.33 | 1.00 | 134 | 0.17 | 0.71 |

| V2(Sn, Ni)C | 60 | 276 | 0.30 | 1.54 | 191 | 0.23 | 1.42 | 94 | 0.10 | 1.12 |

| (V, Nb)2(Sn, Ni)C | 53 | 140 | 0.29 | 2.07 | 96 | 0.19 | 1.83 | 45 | 0.07 | 1.34 |

| V2(Sn, Mn)C | 56 | 780 | 0.26 | 0.98 | 545 | 0.21 | 0.84 | 206 | 0.07 | 0.63 |

| (V, Nb)2(Sn, Mn)C | 57 | 117 | 0.06 | 0.97 | 75 | 0.04 | 0.90 | 32 | 0.01 | 0.67 |

Table 2 Magnetic parameters of V2(Sn, A)C and (V, Nb)2(Sn, A)C (A = Fe, Co, Ni and Mn)

| MAX phase | TC | 2 K | 20 K | 40 K | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hc | Mr | Ms | Hc | Mr | Ms | Hc | Mr | Ms | ||

| V2(Sn, Fe)C | 63 | 458 | 0.59 | 1.73 | 305 | 0.42 | 1.53 | 152 | 0.18 | 1.08 |

| (V, Nb)2(Sn, Fe)C | 63 | 238 | 0.48 | 1.79 | 174 | 0.37 | 1.67 | 73 | 0.14 | 1.24 |

| V2(Sn, Co)C | 66 | 314 | 0.34 | 1.19 | 224 | 0.26 | 1.05 | 113 | 0.12 | 0.79 |

| (V, Nb)2(Sn, Co)C | 53 | 378 | 0.49 | 1.11 | 240 | 0.33 | 1.00 | 134 | 0.17 | 0.71 |

| V2(Sn, Ni)C | 60 | 276 | 0.30 | 1.54 | 191 | 0.23 | 1.42 | 94 | 0.10 | 1.12 |

| (V, Nb)2(Sn, Ni)C | 53 | 140 | 0.29 | 2.07 | 96 | 0.19 | 1.83 | 45 | 0.07 | 1.34 |

| V2(Sn, Mn)C | 56 | 780 | 0.26 | 0.98 | 545 | 0.21 | 0.84 | 206 | 0.07 | 0.63 |

| (V, Nb)2(Sn, Mn)C | 57 | 117 | 0.06 | 0.97 | 75 | 0.04 | 0.90 | 32 | 0.01 | 0.67 |

| [1] |

JEITSCHKO W, NOWOTNY H, BENESOVSKY F. Kohlenstoffhaltige ternäre Verbindungen (H-Phase). Monatshefte für Chemie und verwandte Teile anderer Wissenschaften, 1963, 94(4): 672-676.

DOI URL |

| [2] |

JEITSCHKO W, NOWOTNY H, BENESOVSKY F. Die H-phasen Ti2TlC, Ti2PbC, Nb2InC, Nb2SnC und Ta2GaC. Monatshefte für Chemie und verwandte Teile anderer Wissenschaften, 1964, 95(2): 431-435.

DOI URL |

| [3] |

BARSOUM M W. The MN+1AXN phases: a new class of solids; Thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000, 28(1-4): 201-281.

DOI URL |

| [4] |

BARSOUM M W, RADOVIC M. Elastic and mechanical properties of the MAX phases. Annual Review of Materials Research, 2011, 41(1): 195-227.

DOI URL |

| [5] |

SUN Z M. Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2013, 56(3): 143-166.

DOI URL |

| [6] | RADOVIC M, BARSOUM M W. MAX phases: bridging the gap between metals and ceramics. American Ceramics Society Bulletin, 2013, 92(3): 20-27. |

| [7] |

SHI S, ZHANG L, LI J. Ti3SiC2 material: an application for electromagnetic interference shielding. Applied Physics Letters, 2008, 93(17): 172903.

DOI URL |

| [8] |

NG W H K, GNANAKUMAR E S, BATYREV E, et al. The Ti3AlC2 MAX phase as an efficient catalyst for oxidative dehydrogenation of n-butane. Angewandte Chemie International Edition, 2018, 57(6): 1485-1490.

DOI URL |

| [9] |

ZHAO S, DALL’AGNESE Y, CHU, et al. Electrochemical interaction of Sn-containing MAX phase (Nb2SnC) with Li-ions. ACS Energy Letters, 2019, 4(10): 2452-2457.

DOI URL |

| [10] |

INGASON A S, MOCKUTE A, DAHLQVIST M, et al. Magnetic self-organized atomic laminate from first principles and thin film synthesis. Physical Review Letters, 2013, 110(19): 195502.

DOI URL |

| [11] |

INGASON A S, PETRUHINS A, DAHLQVIST M, et al. A nanolaminated magnetic phase: Mn2GaC. Materials Research Letters, 2013, 2(2): 89-93.

DOI URL |

| [12] |

LIN S, TONG P, WANG B S, et al. Magnetic and electrical/ thermal transport properties of Mn-doped Mn+1AXn phase compounds Cr2-xMnxGaC (0≤x≤1). Journal of Applied Physics, 2013, 113(5): 053502.

DOI URL |

| [13] |

THORE A, DAHLQVIST M, ALLING B, et al. Magnetic exchange interactions and critical temperature of the nanolaminate Mn2GaC from first-principles supercell methods. Physical Review B, 2016, 93(5): 054432.

DOI URL |

| [14] |

INGASON A S, DAHLQVIST M, ROSÉN J. Magnetic MAX phases from theory and experiments; a review. Journal of Physics: Condensed Matter, 2016, 28(43): 433003.

DOI URL |

| [15] |

BEI G, PEDIMONTE B J, FEY T, et al. Oxidation behavior of MAX phase Ti2Al1-xSnxC solid solution. Journal of the American Ceramic Society, 2013, 96(5): 1359-1362.

DOI URL |

| [16] |

NECHICHE M, GAUTHIER-BRUNET V, MAUCHAMP V, et al. Synthesis and characterization of a new (Ti1-ε, Cuε)3(Al, Cu)C2 MAX phase solid solution. Journal of the European Ceramic Society, 2017, 37(2): 459-466.

DOI URL |

| [17] |

ZAPATA-SOLVAS E, HADI M A, HORLAIT D, et al. Synthesis and physical properties of (Zr1-x, Tix)3AlC2 MAX phases. Journal of the American Ceramic Society, 2017, 100(8): 3393-3401.

DOI URL |

| [18] |

QU L, BEI G, STELZER B, et al. Synthesis, crystal structure, microstructure and mechanical properties of (Ti1-xZrx)3SiC2 MAX phase solid solutions. Ceramics International, 2019, 45(1): 1400-1408.

DOI URL |

| [19] |

MENG F L, ZHOU Y C, WANG J Y. Strengthening of Ti2AlC by substituting Ti with V. Scripta Materialia, 2005, 53(12): 1369-1372.

DOI URL |

| [20] |

LI Y, LI M, LU J, et al. Single-atom-thick active layers realized in nanolaminated Ti3(AlxCu1-x)C2 and its artificial enzyme behavior. ACS Nano, 2019, 13(8): 9198-9205.

DOI URL |

| [21] |

HAMM C M, BOCARSLY J D, SEWARD G, et al. Non-conventional synthesis and magnetic properties of MAX phases (Cr/Mn)2AlC and (Cr/Fe)2AlC. Journal of Materials Chemistry C, 2017, 5(23): 5700-5708.

DOI URL |

| [22] |

FATHEEMA J, FATIMA M, MONIR N B, et al. A comprehensive computational and experimental analysis of stable ferromagnetism in layered 2D Nb-doped Ti3C2 MXene. Physica E: Low-dimensional Systems and Nanostructures, 2020, 124: 114253.

DOI URL |

| [23] |

LI Y, LU J, LI M, et al. Multielemental single-atom-thick A layers in nanolaminated V2(Sn, A) C (A = Fe, Co, Ni, Mn) for tailoring magnetic properties. Proceedings of the National Academy of Sciences, 2020, 117(2): 820-825.

DOI URL |

| [24] |

XU Q, ZHOU Y, ZHANG H, et al. Theoretical prediction, synthesis, and crystal structure determination of new MAX phase compound V2SnC. Journal of Advanced Ceramics, 2020, 9(4): 481-492.

DOI URL |

| [25] |

BARSOUM M W, YAROSCHUK G, TYAGI S. Fabrication and characterization of M2SnC (M=Ti, Zr, Hf and Nb). Scripta Materialia, 1997, 37(10): 1583-1591.

DOI URL |

| [26] |

TIAN W B, WANG P L, KAN Y M, et al. Cr2AlC powders prepared by molten salt method. Journal of Alloys and Compounds, 2008, 461(1/2): L5-L10.

DOI URL |

| [27] |

GUO X, WANG J, YANG S, et al. Preparation of Ti3SiC2 powders by the molten. salt method. Materials Letters, 2013, 111: 211-213.

DOI URL |

| [28] |

WANG B, ZHOU A, HU Q, et al. Synthesis and oxidation resistance of V2AlC powders by molten salt method. International Journal of Applied Ceramic Technology, 2017, 14(5): 873-879.

DOI URL |

| [29] |

MANOUN B, SAXENA S K, HUG G, et al. Synthesis and compressibility of Ti3(Al,Sn0.2)C2 and Ti3Al(C0.5,N0.5)2. Journal of Applied Physics, 2007, 101(11): 113523.

DOI URL |

| [30] |

SALIKHOV R, MESHKIAN R, WELLER D, et al. Magnetic properties of nanolaminated (Mo0.5Mn0.5)2GaC MAX phase. Journal of Applied Physics, 2017, 121(16): 163904.

DOI URL |

| [31] |

BEGG B D, VANCE E R, NOWOTNY J. Effect of particle size on the room-temperature crystal structure of barium titanate. Journal of the American Ceramic Society, 1994, 77(12): 3186-3192.

DOI URL |

| [32] |

GRIFFITHS R B. Nonanalytic behavior above the critical point in a random ising ferromagnet. Physical Review Letters, 1969, 23(1): 17-19.

DOI URL |

| [33] |

SHOEMAKER D P, RODRIGUEZ E E, SESHADRI R, et al. Intrinsic exchange bias in ZnxMn3-xO4 (x≤1) solid solutions. Physical Review B, 2009, 80(14): 144422.

DOI URL |

| [34] |

MEHDAOUI B, PENA O, BAHOUT M, et al. Magnetic properties of the spinel system MgxMn3-xO4(0≤x≤2). Boletín de la Sociedad Española de Cerámica y Vidrio, 2008, 47: 143-147.

DOI URL |

| [35] |

UCHINO K, SADANAGA E, HIROSE T, et al. Dependence of the crystal structure on particle size in barium titanate. Journal of the American Ceramic Society, 1989, 72(8): 1555-1558.

DOI URL |

| [36] |

ALI M A, HOSSAIN M M, HOSSAIN M A, et al. Recently synthesized (Zr1-xTix)2AlC (0 ≤x≤ 1) solid solutions: theoretical study of the effects of M mixing on physical properties. Journal of Alloys and Compounds, 2018, 743: 146-154.

DOI URL |

| [37] |

KRONIK L, JAIN M, CHELIKOWSKY J R. Electronic structure and spin polarization of MnxGa1-xN. Physical Review B, 2002, 66(4): 041203.

DOI URL |

| [38] |

KUMAR S, OJHA A K. Room temperature ferromagnetism in undoped and Mn doped t-ZrO2 nanostructures originated due to oxygen vacancy and effect of Mn doping on its optical properties. Materials Chemistry and Physics, 2016, 169: 13-20.

DOI URL |

| [39] |

KUMAR S, LAYEK S, YASHPAL M, et al. Room temperature ferromagnetism in undoped and Mn doped CdO nanostructures. Journal of Magnetism and Magnetic Materials, 2015, 393: 555-561.

DOI URL |

| [40] |

MERINO I L C, FIGUEIREDO L C, PASSAMANI E C, et al. Study of the influence of Nb buffer layer on the exchange coupling induced at the Co/IrMn interface. Journal of Magnetism and Magnetic Materials, 2017, 432: 494-500.

DOI URL |

| [41] |

DOSPIAL M, PLUSA D, ŚLUSAREK B. Study of the magnetic interaction in nanocrystalline Pr-Fe-Co-Nb-B permanent magnets. Journal of Magnetism and Magnetic Materials, 2012, 324(5): 843-848.

DOI URL |

| [42] |

STAMOPOULOS D, ARISTOMENOPOULOU E, LAGOGIANNIS A. Co/Nb/Co trilayers as efficient cryogenic spin valves and supercurrent switches: the relevance to the standard giant and tunnel magnetoresistance effects. Superconductor Science and Technology, 2014, 27(9): 095008.

DOI URL |

| [1] | ZHANG Yuchen, LU Zhiyao, HE Xiaodong, SONG Guangping, ZHU Chuncheng, ZHENG Yongting, BAI Yuelei. Predictions of Phase Stability and Properties of S-group Elements Containing MAX Borides [J]. Journal of Inorganic Materials, 2024, 39(2): 225-232. |

| [2] | LIU Yanyan, XIE Xi, LIU Zengqian, ZHANG Zhefeng. Metal Matrix Composites Reinforced by MAX Phase Ceramics: Fabrication, Properties and Bioinspired Designs [J]. Journal of Inorganic Materials, 2024, 39(2): 145-152. |

| [3] | DING Haoming, LI Mian, LI Youbing, CHEN Ke, XIAO Yukun, ZHOU Jie, TAO Quanzheng, Johanna Rosen, YIN Hang, BAI Yuelei, ZHANG Bikun, SUN Zhimei, WANG Junjie, ZHANG Yiming, HUANG Zhenying, ZHANG Peigen, SUN Zhengming, HAN Meikang, ZHAO Shuang, WANG Chenxu, HUANG Qing. Progress in Structural Tailoring and Properties of Ternary Layered Ceramics [J]. Journal of Inorganic Materials, 2023, 38(8): 845-884. |

| [4] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [5] | LI Youbing, QIN Yanqing, CHEN Ke, CHEN Lu, ZHANG Xiao, DING Haoming, LI Mian, ZHANG Yiming, DU Shiyu, CHAI Zhifang, HUANG Qing. Molten Salt Synthesis of Nanolaminated Sc2SnC MAX Phase [J]. Journal of Inorganic Materials, 2021, 36(7): 773-778. |

| [6] | BAI Jiawei, YANG Jing, LÜ Zhenfei, TANG Xiaodong. Magnetic and Dielectric Properties of Ti 4+-doped M-type Hexaferrite BaFe12-xTixO19 Ceramics [J]. Journal of Inorganic Materials, 2021, 36(1): 43-48. |

| [7] | CHEN Lei-Lei, DENG Zi-Xuan, LI Mian, LI Peng, CHANG Ke-Ke, HUANG Feng, DU Shi-Yu, HUANG Qing. Phase Diagrams of Novel MAX Phases [J]. Journal of Inorganic Materials, 2020, 35(1): 35-40. |

| [8] | JIN Sen, WANG Zuo-Tong, DU Ya-Qiong, HU Qian-Ku, YU Jian-Gong, ZHOU Ai-Guo. Hot-pressing Sintering of Double-A-layer MAX Phase Mo2Ga2C [J]. Journal of Inorganic Materials, 2020, 35(1): 41-45. |

| [9] | DANG Xiao-Lin, FAN Xiao-Meng, YIN Xiao-Wei, MA Yu-Zhao, MA Xiao-Kang. Research Progress on Multi-functional Integration MAX Phases Modified Continuous Fiber-reinforced Ceramic Matrix Composites [J]. Journal of Inorganic Materials, 2020, 35(1): 29-34. |

| [10] | LI Mian, HUANG Qing. Recent Progress and Prospects of Ternary Layered Carbides/Nitrides MAX Phases and Their Derived Two-dimensional Nanolaminates MXenes [J]. Journal of Inorganic Materials, 2020, 35(1): 1-7. |

| [11] | LI Mian, LI You-Bing, LUO Kan, LU Jun, EKLUND Per, PERSSON Per, ROSEN Johanna, HULTMAN Lars, DU Shi-Yu, HUANG Zheng-Ren, HUANG Qing. Synthesis of Novel MAX Phase Ti3ZnC2 via A-site-element-substitution Approach [J]. Journal of Inorganic Materials, 2019, 34(1): 60-64. |

| [12] | CHEN Chun-Xia, LI Hao-Ran, ZHENG Ren-Kui. Properties of Multiferroic PrBi4Fe0.5Co0.5Ti3O15 Ceramics [J]. Journal of Inorganic Materials, 2015, 30(5): 511-515. |

| [13] | TANG Ying-Mao, MIAO Qing-Qing, XIAO Li-Ren, QIAN Qing-Rong, CHEN Qing-Hua. Preparation and Characterization of Electrospun Magnetic Carbon Composite Nanofibres [J]. Journal of Inorganic Materials, 2014, 29(8): 827-834. |

| [14] | LIU Xue-Zhen, BAO Shan-Yong, ZHANG Huan-Huan, MA Chun-Yu, XU Xiao-Ming, ZHANG Qing-Yu . Study on the Magnetism of Epitaxial ZnCoO Films Deposited by Pulsed Laser Deposition [J]. Journal of Inorganic Materials, 2012, 27(4): 369-374. |

| [15] | LI Hai-Feng, GONG Rong-Zhou, LU Xiu-Fang, YU Wei, WANG Xian, FAN Li-Ren1, He Gang. Molten Salt Synthesis and Magnetic Properties of BaFe12O19 Hexaferrite [J]. Journal of Inorganic Materials, 2011, 26(8): 792-796. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||