Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (10): 1103-1110.DOI: 10.15541/jim20210091

• RESEARCH LETTER • Previous Articles Next Articles

ZHANG Junmin1,2,3( ), CHEN Xiaowu1,2(

), CHEN Xiaowu1,2( ), LIAO Chunjin1,2, GUO Feiyu1,2,3, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2(

), LIAO Chunjin1,2, GUO Feiyu1,2,3, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2( )

)

Received:2021-02-09

Revised:2021-03-24

Published:2021-10-20

Online:2021-04-05

Contact:

CHEN Xiaowu, lecturer. E-mail: xwchen@mail.sic.ac.cn; DONG Shaoming, professor. E-mail: smdong@mail.sic.ac.cn

About author:ZHANG Junmin(1996–), male, PhD candidate. E-mail: zhangjm2@shanghaitech.edu.cn

Supported by:CLC Number:

ZHANG Junmin, CHEN Xiaowu, LIAO Chunjin, GUO Feiyu, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Optimizing Microstructure and Properties of SiCf/SiC Composites Prepared by Reactive Melt Infiltration[J]. Journal of Inorganic Materials, 2021, 36(10): 1103-1110.

| Preform | Preparing process | Further impregnation | Composites |

|---|---|---|---|

| Pre-1 | Slurry impregnation | None | Com-1 |

| Pre-2 | Slurry impregnation | Pure PF | Com-2 |

| Pre-3 | Slurry impregnation | Polymer blend | Com-3 |

| Preform | Preparing process | Further impregnation | Composites |

|---|---|---|---|

| Pre-1 | Slurry impregnation | None | Com-1 |

| Pre-2 | Slurry impregnation | Pure PF | Com-2 |

| Pre-3 | Slurry impregnation | Polymer blend | Com-3 |

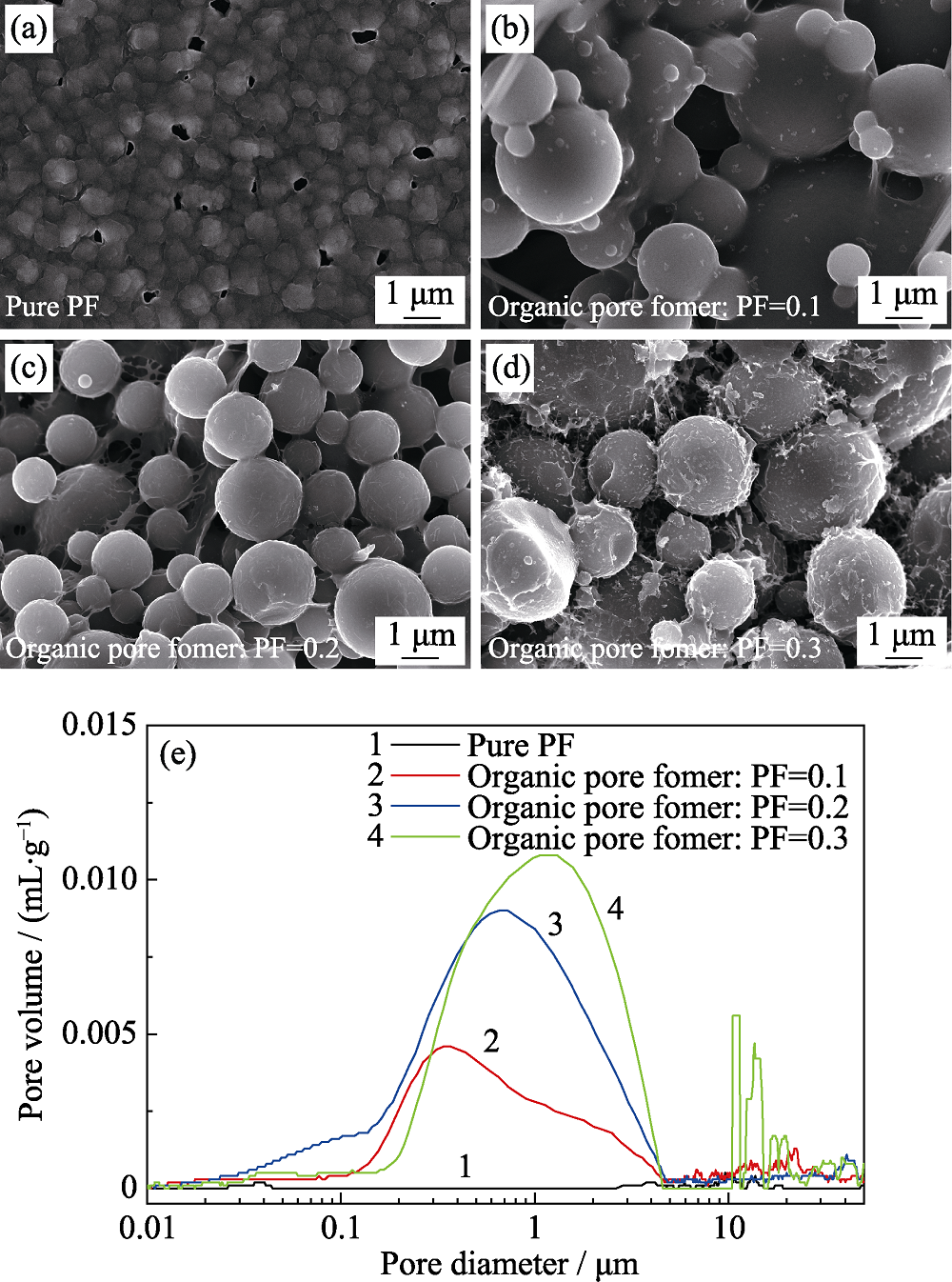

Fig. 2 SEM images of pyrolytic carbon prepared with different organic pore former contents ((a) Pure PF; (b) Organic pore former: PF=0.1; (c) Organic pore former: PF=0.2, (d) Organic pore former: PF=0.3); (e) Pore size distribution of pyrolytic carbon

| Composites | Density/(g·cm-3) | Open porosity/% | Flexural strength/MPa | Elastic modulus/GPa |

|---|---|---|---|---|

| Com-1 | (2.41±0.08) | (10.08±0.50) | (96.04±9.50) | (42.53±0.73) |

| Com-2 | (2.57±0.08) | (8.39±0.58) | (176.76±3.78) | (67.55±0.46) |

| Com-3 | (2.61±0.05) | (7.92±0.61) | (200.50±7.33) | (79.19±0.65) |

| Composites | Density/(g·cm-3) | Open porosity/% | Flexural strength/MPa | Elastic modulus/GPa |

|---|---|---|---|---|

| Com-1 | (2.41±0.08) | (10.08±0.50) | (96.04±9.50) | (42.53±0.73) |

| Com-2 | (2.57±0.08) | (8.39±0.58) | (176.76±3.78) | (67.55±0.46) |

| Com-3 | (2.61±0.05) | (7.92±0.61) | (200.50±7.33) | (79.19±0.65) |

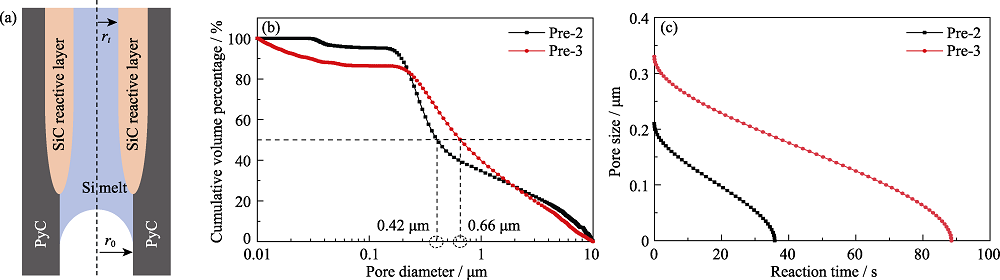

Fig. 8 (a) Schematic of reaction layer generated during the RMI, (b) curves of cumulative volume percentage vs pore diameter of preforms, and (c) variation of pore radius with infiltration time for preforms

| [1] |

ZHU Y, WANG S, LI W, et al. Preparation of carbon fiber-reinforced zirconium carbide matrix composites by reactive melt infiltration at relative low temperature. Scripta Materialia, 2012, 67(10):822-825.

DOI URL |

| [2] |

WANG J, LIN M, XU Z, et al. Microstructure and mechanical properties of C/C-SiC composites fabricated by a rapid processing method. J. Eur. Ceram. Soc., 2009, 29(14):3091-3097.

DOI URL |

| [3] |

TIAN J T, SHOBU K. Fabrication of silicon carbide-mullite composite by melt infiltration. J. Am. Ceram. Soc., 2003, 86(1):39-42.

DOI URL |

| [4] | SINGH M, ALMAN D E, HAWK J A. Microstructure and Wear Behavior of SiC-based Composites Fabricated by Melt Infiltration, in: Alman D E, HAWK J A., SIMMONS J W (Eds.). Roll of Characterization in Understanding Environmental Degradation of Materials, ASM International, 1998: 169-175. |

| [5] |

WANG Y X, TAN S H, JIANG D L. The effect of porous carbon preform and the infiltration process on the properties of reaction- formed SiC. Carbon, 2004, 42(8/9):1833-1839.

DOI URL |

| [6] |

JIANG S Z, XIONG X, CHEN Z K, et al. Influence factors of C/C-SiC dual matrix composites prepared by reactive melt infiltration. Materials & Design, 2009, 30(9):3738-3742.

DOI URL |

| [7] |

WANG D, DONG S M, ZHOU H J, et al. Fabrication and microstructure of 3D Cf/ZrC-SiC composites: through RMI method with ZrO2 powders as pore-making agent. Ceram. Int., 2016, 42(6):6720-6727.

DOI URL |

| [8] |

ROGER J, CHOLLON G. Mechanisms and kinetics during reactive infiltration of molten silicon in porous graphite. Ceram. Int., 2019, 45(7):8690-8699.

DOI URL |

| [9] |

PILLLEE S, KIYOON H, SOOPARK J, et al. Processing and properties of SiC and SiC/SiC composite materials by melt infiltration process. International Journal of Modern Physics B, 2003, 17(8):1833-1838.

DOI URL |

| [10] |

WASHBURN E W. The dynamics of capillary flow. Physical Review, 1921, 17(3):273-283.

DOI URL |

| [11] |

BOUGIOURI V, VOYTOVYCH R, ROJO-CALDERON N, et al. The role of the chemical reaction in the infiltration of porous carbon by NiSi alloys. Scripta Materialia, 2006, 54(11):1875-1878.

DOI URL |

| [12] |

KUMAR S, KUMAR A, SHUKLA A, et al. Capillary infiltration studies of liquids into 3D-stitched C-C preforms Part A: Internal pore characterization by solvent infiltration, mercury porosimetry, and permeability studies. J. Eur. Ceram. Soc., 2009, 29(12):2643-2650.

DOI URL |

| [13] |

KUMAR S, KUMAR A, DEVI R, et al. Capillary infiltration studies of liquids into 3D-stitched C-C preforms Part B: Kinetics of silicon infiltration. J. Eur. Ceram. Soc., 2009, 29(12):2651-2657.

DOI URL |

| [14] |

WANG Y, ZHU X, ZHANG L, et al. C/C-SiC-ZrC composites fabricated by reactive melt infiltration with Si0.87Zr0.13 alloy. Ceram. Int., 2012, 38(5):4337-4343.

DOI URL |

| [15] |

CHEN X W, NI D W, KAN Y M, et al. Reaction mechanism and microstructure development of ZrSi2 melt-infiltrated Cf/SiC-ZrC- ZrB2 composites: the influence of preform pore structures. Journal of Materiomics, 2018, 4(3):266-275.

DOI URL |

| [16] |

CHEN X W, FENG Q, KAN Y M, et al. Effects of preform pore structure on infiltration kinetics and microstructure evolution of RMI-derived Cf/SiC-ZrC-ZrB2 composite. J. Eur. Ceram. Soc., 2020, 40(7):2683-2690.

DOI URL |

| [17] |

ZHONG Q, ZHANG X Y, DONG S M, et al. Reactive melt infiltrated Cf/SiC composites with robust matrix derived from novel engineered pyrolytic carbon structure. Ceram. Int., 2017, 43(7):5832-5836.

DOI URL |

| [18] | LEE S P, PARK J S, KATOH Y, et al. Process, microstructure and flexural properties of reaction sintered Tyranno SA/SiC composites. Journal of Nuclear Materials, 2002, 307:1191-1195. |

| [19] |

ZHAO Y Y, XIA H Y, TANG R, et al. A low cost preparation of C/SiC composites by infiltrating molten Si into gelcasted pure porous carbon preform. Ceram. Int., 2015, 41(5):6478-6487.

DOI URL |

| [20] |

SINGH M, FARMER S C. Morphological characterization of microporous carbon materials. Journal of Materials Science Letters, 1997, 16(11):946-949.

DOI URL |

| [21] | LEVENSPIEL O. Ingenieria de las Reacciones. 2nd ed. Wiley (ed.). Barcelona: Revertre, 1978. |

| [22] |

HON M H, DAVIS R F. Self-diffusion of C-14 in polycrystalline beta-sic. J. Mater. Sci., 1979, 14(10):2411-2421.

DOI URL |

| [1] | GUO Ziyu, ZHU Yunzhou, WANG Li, CHEN Jian, LI Hong, HUANG Zhengren. Effect of Zn2+ Catalyst on Microporous Structure of Porous Carbon Prepared from Phenolic Resin/Ethylene Glycol [J]. Journal of Inorganic Materials, 2025, 40(5): 466-472. |

| [2] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [3] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [4] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [5] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [6] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [7] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [8] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [9] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [10] | SHI Weigang, ZHANG Chao, LI Mei, WANG Jing, ZHANG Chengyu. 2D-SiCf/SiC Interlaminar Mode I Fracture Testing and Characterization [J]. Journal of Inorganic Materials, 2024, 39(1): 45-50. |

| [11] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [12] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [13] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [14] | LING Jie, ZHOU Anning, WANG Wenzhen, JIA Xinyu, MA Mengdan. Effect of Cu/Mg Ratio on CO2 Adsorption Performance of Cu/Mg-MOF-74 [J]. Journal of Inorganic Materials, 2023, 38(12): 1379-1386. |

| [15] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||