Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (10): 1071-1087.DOI: 10.15541/jim20190622

Special Issue: 能源材料论文精选(一):锂离子电池(2020)

WANG Yanan1,2,3( ),LI Hua1,2,3,WANG Zhengkun1,LI Qingfeng1,LIAN Chen1,HE Xin1

),LI Hua1,2,3,WANG Zhengkun1,LI Qingfeng1,LIAN Chen1,HE Xin1

Received:2019-12-06

Revised:2020-02-27

Published:2020-10-20

Online:2020-03-05

About author:WANG Yanan(1981–), male, PhD, lecturer. E-mail: wyn@sdu.edu.cn

Supported by:CLC Number:

WANG Yanan, LI Hua, WANG Zhengkun, LI Qingfeng, LIAN Chen, HE Xin. Progress on Failure Mechanism of Lithium Ion Battery Caused by Diffusion Induced Stress[J]. Journal of Inorganic Materials, 2020, 35(10): 1071-1087.

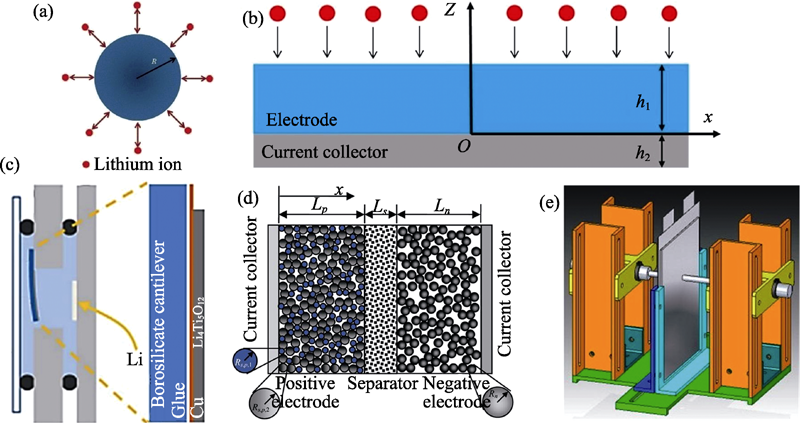

Fig. 1 Different scales of diffusion-induced stress in lithium-ion batteries (a) Active particle[4]; (b) Active electrode[5]; (c) Half cell[6]; (d) Cell unit[7]; (e) Cell[8]

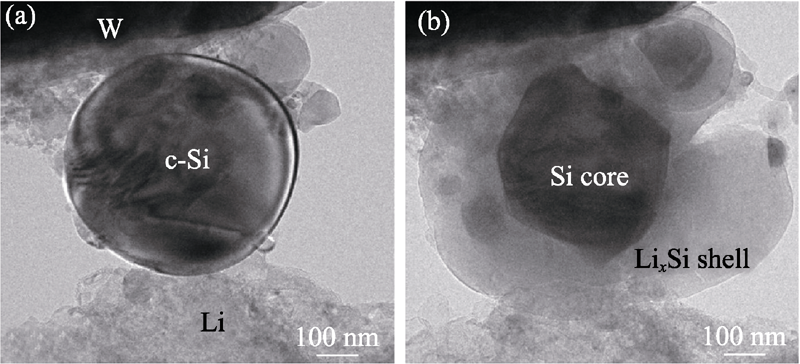

Fig. 4 Lithiation process of the spherical silicon particle[14] (a) Initial state; (b) Outer layer expansion and surface cracking of the particle during lithiation

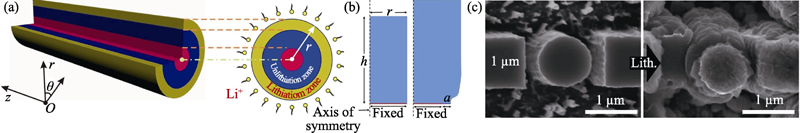

Fig. 5 (a) Nanowire particle and its lithiation process[23]; (b) Initial state and lithiation expansion state of nanowire particle with initial delamination defect[25]; (c) Initial state and lithiation expansion state of nanowire particle with mechanical clamping[26]

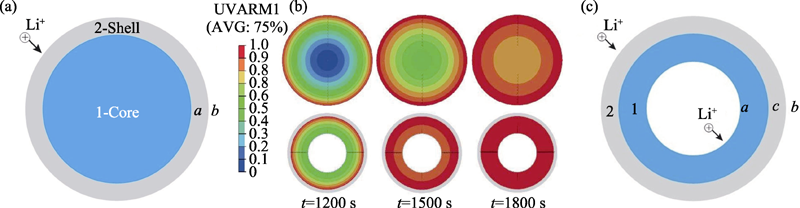

Fig. 6 (a) Solid sphere particle with carbon-coated shell[31]; (b) Lithium concentration distribution of carbon-coated solid sphere particle and hollow sphere particle during lithiation[32]; (c) Nanotube particle with carbon-coated shell[33]

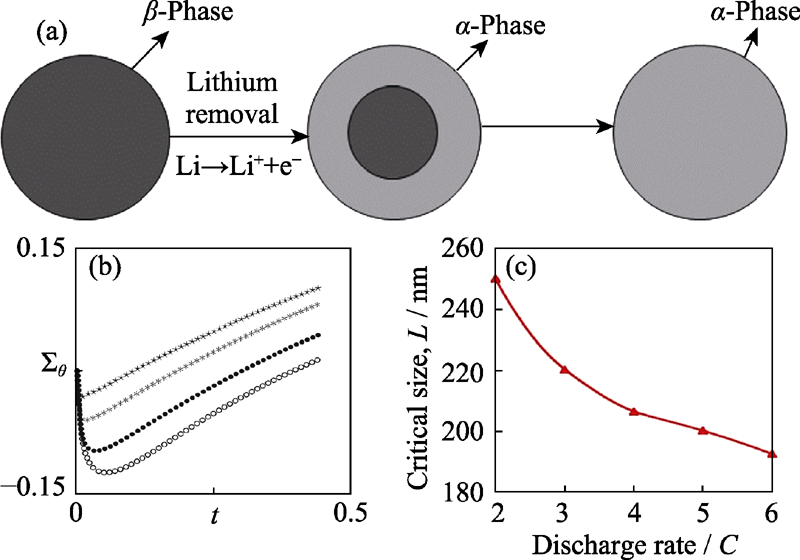

Fig. 7 (a) Delithiation process of spherical particle with two-phase deintercalation mechanism[35]; (b) Surface tangential stress of spherical particle during lithiation process with two-phase deintercalation mechanism[36], the hollow circle, solid circle, asterisk and star represent the initial dimensionless sizes of the particles as 0.01, 0.1, 1.0 and 10.0, respectively; (c) Relationship between critical dimension and discharge rate[42]

| Factor | Specific interpretation | Ref. |

|---|---|---|

| Particle shape | Solid sphere, hollow sphere, ellipsoid, cube, etc. | [ |

| Particle size | Radius/diameter, shell thickness, aspect ratio, edge length, etc. | [ |

| Material properties | Lithium expansion coefficient, elastic modulus, plastic deformation, strain rate, partial molar volume, medium expansion rate, lithium diffusion coefficient, etc. | [ [28-30] |

| Nanowires and nanotubes | Slender linear or tubular structures with small diameters | [ |

| Coating shell | Carbon coating, alumina coating, etc. | [ |

| Phase separation | Single- and two-phase deintercalation mechanism | [ |

| Dislocation effect | Microscopic defects in crystalline materials caused by local irregular arrangement of atoms | [ |

| Charging and discharging conditions | Ratio and strategy of charging and discharging, etc. | [ |

Table 1 Factors affecting diffusion-induced stress in a single particle model

| Factor | Specific interpretation | Ref. |

|---|---|---|

| Particle shape | Solid sphere, hollow sphere, ellipsoid, cube, etc. | [ |

| Particle size | Radius/diameter, shell thickness, aspect ratio, edge length, etc. | [ |

| Material properties | Lithium expansion coefficient, elastic modulus, plastic deformation, strain rate, partial molar volume, medium expansion rate, lithium diffusion coefficient, etc. | [ [28-30] |

| Nanowires and nanotubes | Slender linear or tubular structures with small diameters | [ |

| Coating shell | Carbon coating, alumina coating, etc. | [ |

| Phase separation | Single- and two-phase deintercalation mechanism | [ |

| Dislocation effect | Microscopic defects in crystalline materials caused by local irregular arrangement of atoms | [ |

| Charging and discharging conditions | Ratio and strategy of charging and discharging, etc. | [ |

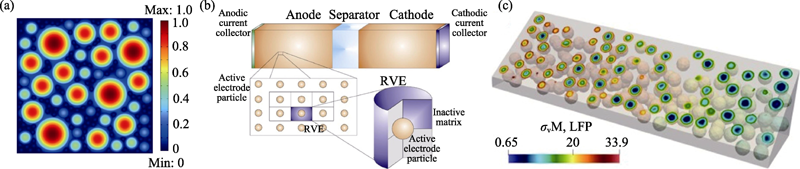

Fig. 8 (a) Lithium concentration distribution in the multi-particle model at 60% Depth of Discharge (DOD)[46,47]; (b) Multi-particle model considering homogeneous matrix and single-particle-matrix representative unit[48]; (c) Multi-particle-matrix electrode structure considering homogeneous matrix and diffusion-induced stress distribution of active particles during 1C discharge[50]

Fig. 9 (a) Multi-particle model established by X-ray scanning, (Black: The active particles and the binder; Blue: The electrolyte)[53]; (b) Diffusion-induced stress distribution of multi-particle model when fully charged at 1C rate[54]

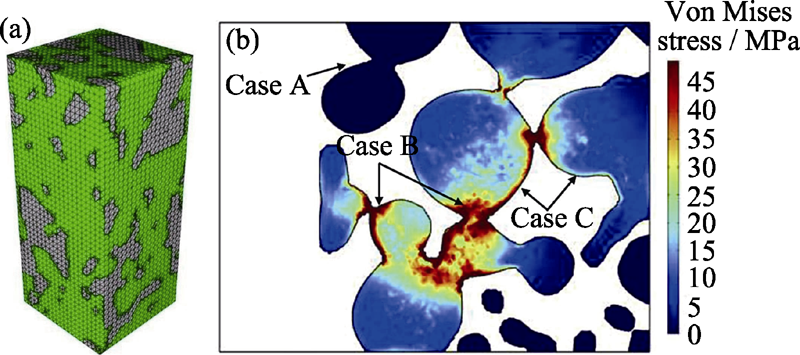

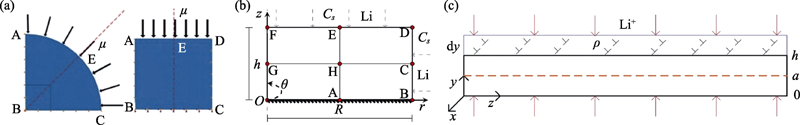

Fig. 10 Schematic diagrams of models (a) Cylindrical and plate electrode units[55]; (b) coin-shaped thin film silicon electrode[56]; (c) thin film silicon electrode considering dislocations[58]

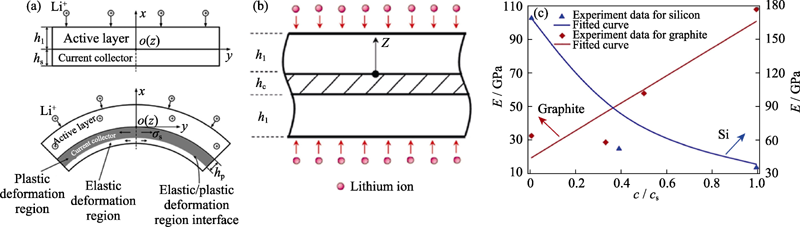

Fig. 11 (a) Initial state and lithiation deformation of the double-layer electrode considering plasticity of the current collector[62]; (b) Symmetrical electrode model composed of graphite active layers and copper current collector[63]; (c) Relationship between the elastic modulus of graphite and silicon and SOC[69]

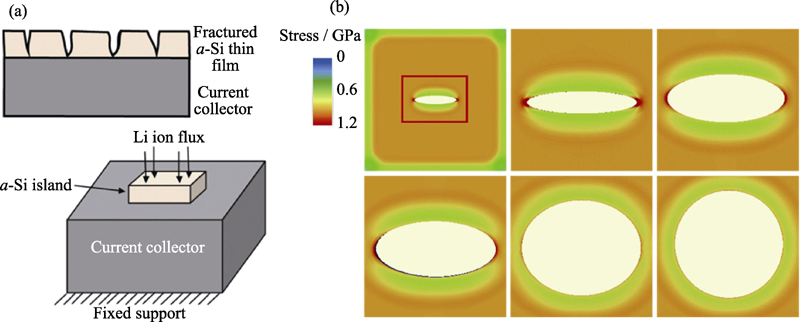

Fig. 12 (a) Double-layer silicon electrode cracks to form silicon islands (above), and double-layer electrode model of a silicon island constrained by a current collector (below)[73]; (b) Diffusion-induced stress distribution of the double-layer electrodes of silicon islands with initial defects after lithiation, the length ratios of the long and short axes of the initial defects are 0.2, 0.4, 0.6, 0.8 and 1, respectively[75]

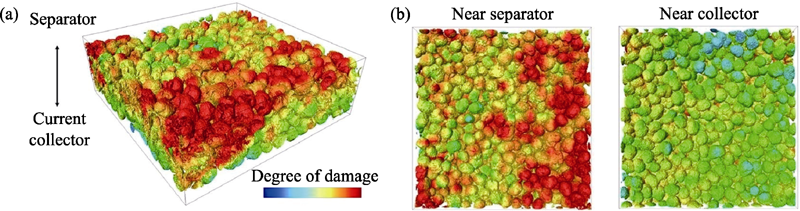

Fig. 13 Failure of particles in the NMC311 positive electrode[77] (a) Three-dimensional view of the electrode; (b) Views of the location near the separator and the current collector

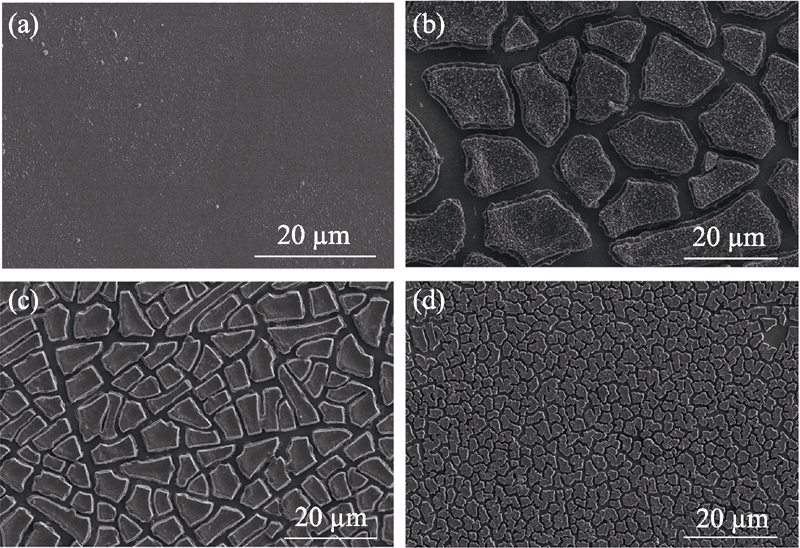

Fig. 15 Crack propagation of a silicon electrode[80] (a) Fresh electrode; (b) Electrode of 1000 nm thickness after 5 cycles; (c) Electrode of 500 nm thickness after 5 cycles; (d) Electrode of 200 nm thickness after 10 cycles

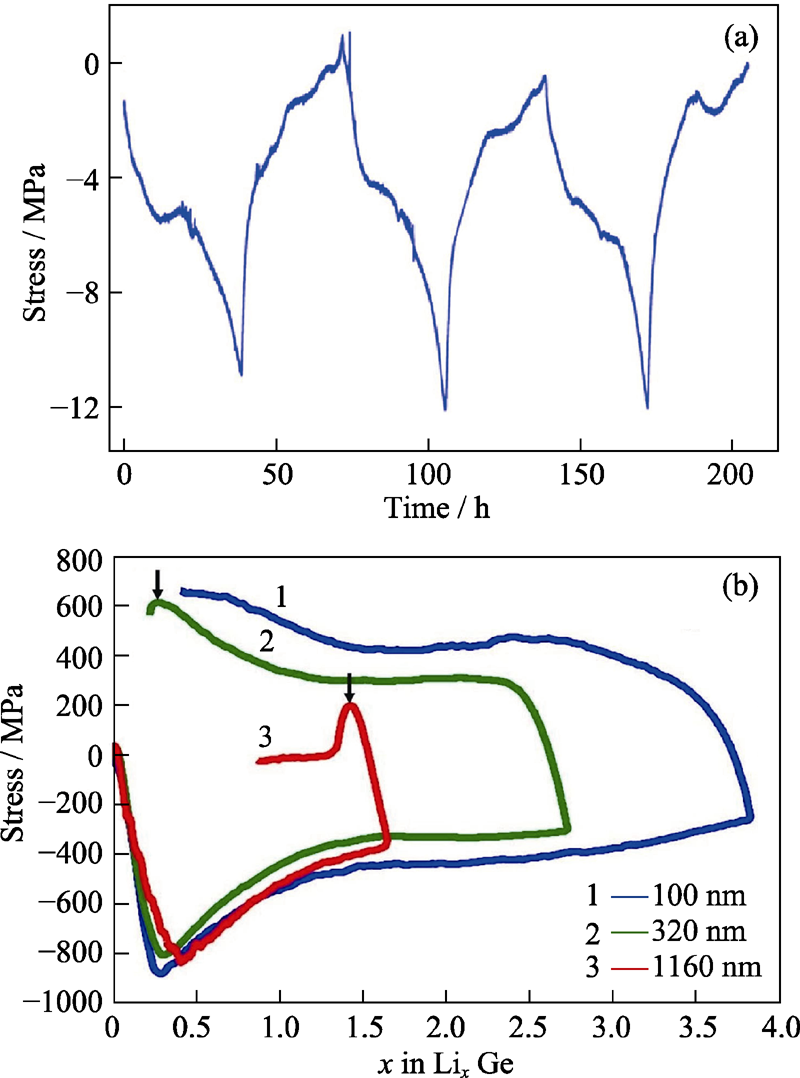

Fig. 16 (a) Diffusion-induced stress in the graphite anode during the first 3 cycles[85]; (b) Evolution of diffusion-induced stress in a Ge electrode during lithiation and delithiation, the arrows represent the moment when the electrode fractures[86]

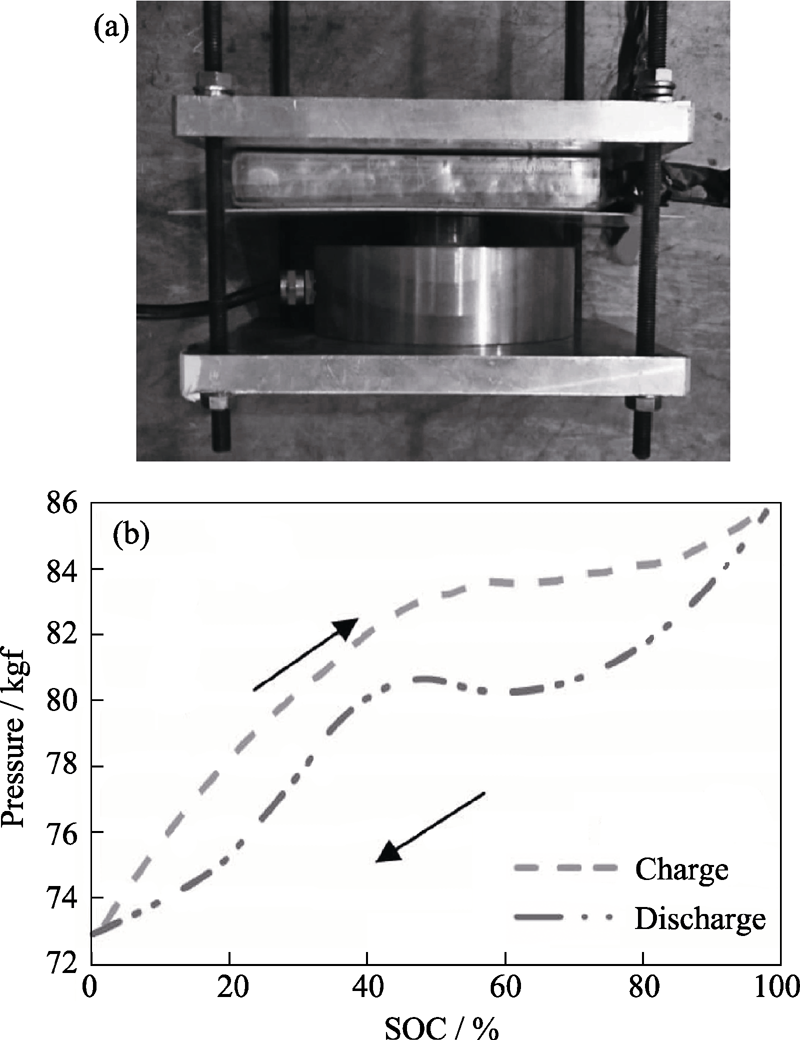

Fig. 18 Surface pressure during charge and discharge of a prismatic cell [93] (a) Experimental schematic diagram; (b) Change of surface pressure with SOC

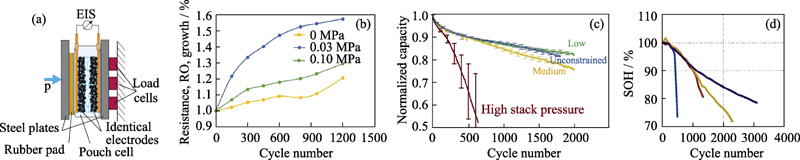

Fig. 19 (a) Experimental schematic diagram of the external constraint and EIS test[94]; (b) Impedance as a function of cycle times at different external pressures[95]; (c) Effect of external constraints on cycle lifetime of the cell, of which blue, green, yellow and red lines representing external constraints of 0, 0.05, 0.5 and 5 MPa, respectively[96]; (d) SOH as a function of cycle times, of which blue, red, yellow, and purple lines representing no external constraint, constant thickness constraint, elastic element constraint, and constant force spring constraint, respectively[97]

| Failure phenomenon | Corresponding mechanism | Ref. |

|---|---|---|

| Capacity decay/lifetime reduction | Side reaction of active particles and electrolyte results in regeneration of SEI film | [99] |

| Excessive stress causes fracture of electrode | [100] | |

| Uneven distribution of pressure inside cell brings about lithium precipitation on electrode | [100, 103] | |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] | |

| Impedance rise | Porosity decreasing and tortuosity increasing of positive and negative electrodes and separator | [94-95] |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] |

Table 2 Failure phenomenon of cell and their corresponding mechanism

| Failure phenomenon | Corresponding mechanism | Ref. |

|---|---|---|

| Capacity decay/lifetime reduction | Side reaction of active particles and electrolyte results in regeneration of SEI film | [99] |

| Excessive stress causes fracture of electrode | [100] | |

| Uneven distribution of pressure inside cell brings about lithium precipitation on electrode | [100, 103] | |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] | |

| Impedance rise | Porosity decreasing and tortuosity increasing of positive and negative electrodes and separator | [94-95] |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] |

| [1] | WANG Q Y, WANG S, ZHANG J N , et al. Overview of the failure analysis of lithium ion batteries. Energy Storage Sci. Technol., 2017,6(5):1008. |

| [2] | BELOVA I V, MURCH G E . Thermal and diffusion-induced stresses in crystalline solids. J. Appl. Phys., 1995,77(1):127-134. |

| [3] | ZHAO Y, STEIN P, BAI Y , et al. A review on modeling of electro- chemo-mechanics in lithium-ion batteries. J. Power Sources, 2019,413:259-283. |

| [4] | LI H L, SONG Y C, LU B , et al. Effects of stress dependent electrochemical reaction on voltage hysteresis of lithium ion batteries. Appl. Math. Mech-Engl., 2018,39(10):1453-1464. |

| [5] | LU Y J, CHE Q, SONG X , et al. Stress self-relaxation arising from diffusion-induced creep in bilayer lithium-ion battery electrode. Scr. Mater., 2018,150:164-167. |

| [6] | CHOI Z S, KRAMER D, MÖNIG R, et al. Correlation of stress and structural evolution in Li4Ti5O12-based electrodes for lithium ion batteries. J. Power Sources, 2013,240:245-251. |

| [7] | DAI Y L, CAI L, WHITE R E . Simulation and analysis of stress in a Li-ion battery with a blended LiMn2O4 and LiNi0.8Co0.15Al0.05O2 cathode. J. Power Sources, 2014,247:365-376. |

| [8] | FU R J, XIAO M, CHOE S Y . Modeling, validation and analysis of mechanical stress generation and dimension changes of a pouch type high power Li-ion battery. J. Power Sources, 2013,224:211-224. |

| [9] | MEI W X, DUAN Q L, QIN P , et al. A three-dimensional electrochemical-mechanical model at the particle level for lithium-ion battery. J. Electrochem. Soc., 2019,166(14):A3319-A3331. |

| [10] | ZHANG X Y, CHEN H S, FANG D N . Diffusion-induced stress of electrode particles with spherically isotropic elastic properties in lithium-ion batteries. J. Solid State Electrochem., 2016,20(10):2835-2845. |

| [11] | CHEN B B, ZHOU J Q, PANG X M , et al. Fracture damage of nanowire lithium-ion battery electrode affected by diffusion- induced stress and bending during lithiation. RSC Adv. , 2014,4(40):21072-21078. |

| [12] | CHRISTENSEN J, NEWMAN J . Stress generation and fracture in lithium insertion materials. J. Solid State Electrochem., 2006,10(5):293-319. |

| [13] | SUN H H, MANTHIRAM A . Impact of microcrack generation and surface degradation on a nickel-rich layered Li[Ni0.9Co0.05Mn0.05]O2 cathode for lithium-ion batteries. Chem. Mater., 2017,29(19):8486-8493. |

| [14] |

LIU X H, ZHONG L, HUANG S , et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano , 2012,6(2):1522-1531.

DOI URL PMID |

| [15] |

HU Y H, ZHAO X H, SUO Z G . Averting cracks caused by insertion reaction in lithium-ion batteries. J. Mater. Res., 2011,25(6):1007-1010.

DOI URL |

| [16] |

ZHU M, PARK J, SASTRY A M . Fracture analysis of the cathode in Li-ion batteries: a simulation study. J. Electrochem. Soc., 2012,159(4):A492-A498.

DOI URL |

| [17] |

PURKAYASTHA R, MCMEEKING R . Stress due to the intercalation of lithium in cubic-shaped particles: a parameter study. Meccanica, 2016,51(12):3081-3096.

DOI URL |

| [18] |

DELUCA C M, MAUTE K, DUNN M L . Effects of electrode particle morphology on stress generation in silicon during lithium insertion. J. Power Sources, 2011,196(22):9672-9681.

DOI URL |

| [19] | CHEN B B, ZHOU J Q, LIU Z . Effects of thermal diffusion in hollow lithium ion battery with spherical particle electrode. J. Nanjing Tech. U.: NAT. SCI. ED., 2016,38(3):1-7. |

| [20] |

LI J, FANG Q H, WU H , et al. Investigation into diffusion induced plastic deformation behavior in hollow lithium ion battery electrode revealed by analytical model and atomistic simulation. Electrochim. Acta , 2015,178:597-607.

DOI URL |

| [21] |

ZHAO K J, PHARR M, CAI S Q , et al. Large plastic deformation in high-capacity lithium-ion batteries caused by charge and discharge. J. Am. Ceram. Soc., 2011,94:s226-s235.

DOI URL |

| [22] |

LI Y, ZHANG K, ZHENG B , et al. Effect of local velocity on diffusion-induced stress in large-deformation electrodes of lithium-ion batteries. J. Power Sources, 2016,319:168-177.

DOI URL |

| [23] |

MA Z S, GAO X, WANG Y , et al. Effects of size and concentration on diffusion-induced stress in lithium-ion batteries. J. Appl. Phys., 2016,120(2):025302

DOI URL |

| [24] | RYU I, CHOI J W, CUI Y , et al. Size-dependent fracture of Si nanowire battery anodes. J. Mech. Phys. Solids , 2011,59(9):1717-1730. |

| [25] | HARDIN G R, ZHANG Y, FINCHER C D , et al. Interfacial fracture of nanowire electrodes of lithium-ion batteries. JOM, 2017,69(9):1-5. |

| [26] |

LEE S W, LEE H W, RYU I , et al. Kinetics and fracture resistance of lithiated silicon nanostructure pairs controlled by their mechanical interaction. Nat. Commun. , 2015,6:7533.

DOI URL PMID |

| [27] | CHANG S, MOON J, CHO K , et al. Multiscale analysis of prelithiated silicon nanowire for Li-ion battery. Comput. Mater. Sci., 2015,98:99-104. |

| [28] | PENG Y Z, ZHANG K, ZHENG B L . Stress analysis of a cylindrical composition-gradient electrode of lithium-ion battery in generalized plane strain condition. Acta Phys. Sin., 2016,65(10):1-8. |

| [29] | PENG Y Z, LI Y, ZHENG B L , et al. Influence of local velocity on diffusion-induced stress and axial reaction force in a hollow cylindrical electrode of lithium-ion batteries with considering expasion rate of medium. Acta Phys. Sin., 2018,67(7):27-35. |

| [30] | DESHPANDE R, QI Y, CHENG Y T , et al. Effects of concentration-dependent elastic modulus on diffusion-induced stresses for battery applications. J. Electrochem. Soc., 2010,157(8):A967-A971. |

| [31] | HAO F, FANG D . Diffusion-induced stresses of spherical core- shell electrodes in lithium-ion batteries: the effects of the shell and surface/interface stress. J. Electrochem. Soc., 2013,160(4):A595-A600. |

| [32] | SUN F N, FENG L, BU J H , et al. Effect of stress on electrochemical performance of hollow carbon-coated silicon snode in lithium ion batteries. Acta Phys. Sin. , 2019,68(12):42-51. |

| [33] | HAO F, FANG D . Tailoring diffusion-induced stresses of core-shell nanotube electrodes in lithium-ion batteries. J. Appl. Phys., 2013,113(1):013507 |

| [34] | ZHAO K J, PHARR M, HARTLE L , et al. Fracture and debonding in lithium-ion batteries with electrodes of hollow core-shell nanostructures. J. Power Sources , 2012,218:6-14. |

| [35] | DESHPANDE R, CHENG Y T, VERBRUGGE M W , et al. Diffusion induced stresses and strain energy in a phase-transforming spherical electrode particle. Electrochem. Soc., 2011,158(6):A718-A724. |

| [36] |

DROZDOV A D . A model for the mechanical response of electrode particles induced by lithium diffusion in Li-ion batteries. Acta Mech., 2014,225(11):2987-3005.

DOI URL |

| [37] |

HUANG S, FAN F, LI J , et al. Stress generation during lithiation of high-capacity electrode particles in lithium ion batteries. Acta Mater. , 2013,61(12):4354-4364.

DOI URL |

| [38] |

LIU Z J, ZHOU J Q, CHEN B B , et al. Interaction between dislocation mechanics on diffusion induced stress and electrochemical reaction in a spherical lithium ion battery electrode. RSC Adv. , 2015,5(91):74835-74843.

DOI URL |

| [39] | WEI P F, ZHOU J Q, DENG K J , et al. Effect of dislocation on spherical particle electrode for lithium ion battery. Chin. J. Power Sources , 2015, ( 4):719-722. |

| [40] | ZHU J W, ZHOU J Q, CHEN B B , et al. Dislocation effect on diffusion-induced stress for lithiation in hollow spherical electrode. J. Solid State Electrochem. , 2015,20(1):37-46. |

| [41] | LI J, FANG Q H, LIU F , et al. Analytical modeling of dislocation effect on diffusion induced stress in a cylindrical lithium ion battery electrode. J. Power Sources, 2014,272:121-127. |

| [42] | ZHAO K J, PHARR M, VLASSAK J J , et al. Fracture of electrodes in lithium-ion batteries caused by fast charging. J. Appl. Phys., 2010,108(7):073517. |

| [43] | LU B, SONG Y C, ZHANG J Q . Selection of charge methods for lithium ion batteries by considering diffusion induced stress and charge time. J. Power Sources, 2016,320:104-110. |

| [44] | ZHAO Y F, LÜ B . Stress evolution induced by charging shut-down in lithium-ion batteries. J. Mech. Strength, 2018,40(1):77-82. |

| [45] | KIM S, HUANG H Y S. Mechanical stresses at the cathode- electrolyte interface in lithium-ion batteries. J. Mater. Res., 2016,31(22):3506-3512. |

| [46] | JI L, GUO Z S . Analytical modeling and simulation of porous electrodes: Li-ion distribution and diffusion-induced stress. Acta Mech. Sin., 2018,34(1):187-198. |

| [47] | JI L, GUO Z S, WU Y J . Computational and experimental observation of Li-ion concentration distribution and diffusion-induced stress in porous battery electrodes. Energy Technol-Ger., 2017,5(9):1702-1711. |

| [48] | DIMITRIJEVIC B J, AIFANTIS K E, HACKL K . The influence of particle size and spacing on the fragmentation of nanocomposite anodes for Li batteries . J. Power Sources, 2012,206:343-348. |

| [49] | XU R, ZHAO K J . Mechanical interactions regulated kinetics and morphology of composite electrodes in Li-ion batteries. Extreme Mech. Lett., 2016,8:13-21. |

| [50] | MAI W J, YANG M, SOGHRATI S . A particle-resolved 3D finite element model to study the effect of cathode microstructure on the behavior of lithium ion batteries. Electrochim. Acta, 2019,294:192-209. |

| [51] | RENGANATHAN S, SIKHA G, SANTHANAGOPALAN S , et al. Theoretical analysis of stresses in a lithium ion cell. J. Electrochem. Soc., 2010,157(2):A155-A163. |

| [52] | RAHANI E K, SHENOY V B . Role of plastic deformation of binder on stress evolution during charging and discharging in lithium- ion battery negative electrodes. J. Electrochem. Soc., 2013 160(8):A1153-A1162. |

| [53] | MENDOZA H, ROBERTS S A, BRUNINI V E , et al. Mechanical and electrochemical response of a LiCoO2 cathode using reconstructed microstructures. Electrochim. Acta, 2016,190:1-15. |

| [54] | WU L M, XIAO X H, WEN Y H , et al. Three-dimensional finite element study on stress generation in synchrotron X-ray tomography reconstructed nickel-manganese-cobalt based half cell. J. Power Sources , 2016,336:8-18. |

| [55] | QI H R, FENG L, WANG S B , et al. Stress relaxation through electrochemical diffusion in electrodes. Scientia Sinica (Physica, Mechanica & Astronomica), 2016,46(8):1-15. |

| [56] | LIU M . Finite element analysis of lithium insertion-induced expansion of a silicon thin film on a rigid substrate under potentiostatic operation. J. Power Sources, 2015,275:760-768. |

| [57] | GAO Y F, ZHOU M . Coupled mechano-diffusional driving forces for fracture in electrode materials. J. Power Sources, 2013,230:176-193. |

| [58] | CHEN B B, ZHOU J Q, ZHU J W , et al. Diffusion induced stress and the distribution of dislocations in a nanostructured thin film electrode during lithiation. RSC Adv. , 2014,4(109):64216-64224. |

| [59] | WU B, LU W . A battery model that fully couples mechanics and electrochemistry at both particle and electrode levels by incorporation of particle interaction. J. Power Sources, 2017,360:360-372. |

| [60] | ZHANG J Q, LÜ B, SONG Y C . A review of fracture in lithium- ion battery electrodes. Chin. Quart. Mech., 2017,38(1):18-37. |

| [61] | JI L, GUO Z S, DU S Y , et al. Stress induced by diffusion, curvature, and reversible electrochemical reaction in bilayer lithium-ion battery electrode plates. Int. J. Mech. Sci., 2017,134:599-609. |

| [62] | SONG X, LU Y J, SHI M L , et al. Effects of plastic deformation in current collector on lithium diffusion and stress in bilayer lithium- ion battery electrode. Acta Phys. Sin. , 2018,67(14):1-9. |

| [63] | SONG Y C, LI Z Z, ZHANG J Q . Reducing diffusion induced stress in planar electrodes by plastic shakedown and cyclic plasticity of current collector. J. Power Sources, 2014,263:22-28. |

| [64] | LIU M, GAO C H, YANG F Q . Analysis of diffusion-induced delamination of an elastic-perfectly plastic film on a deformable substrate under potentiostatic operation. Modell. Simul. Mater. Sci. Eng., 2017,25(6):065019. |

| [65] | LIU D Y, CHEN W Q, SHEN X D . Diffusion-induced stresses in an imperfect bilayer electrode of coin-shaped lithium-ion batteries. Eur. J. Mech. A-Solid, 2016,55:167-180. |

| [66] | HAO F, FANG D N . Reducing diffusion-induced stresses of electrode- collector bilayer in lithium-ion battery by pre-strain. J. Power Sources, 2013,242:415-420. |

| [67] | SONG Y C, LI Z Z, SOH A K , et al. Diffusion of lithium ions and diffusion-induced stresses in a phase separating electrode under galvanostatic and potentiostatic operations: phase field simulations. Mech. Mater. , 2015,91:363-371. |

| [68] | LI Y, ZHANG J, ZHANG K , et al. A defect-based viscoplastic model for large-deformed thin film electrode of lithium-ion battery. Int. J. Plast., 2019,115:293-306. |

| [69] | HE Y L, HU H J, SONG Y C , et al. Effects of concentration- dependent elastic modulus on the diffusion of lithium ions and diffusion induced stress in layered battery electrodes. J. Power Sources , 2014,248:517-523. |

| [70] | LIU D Y, CHEN W Q, SHEN X D . Diffusion-induced stresses in graphene-based composite bilayer electrode of lithium-ion battery. Compos. Struct., 2017,165:91-98. |

| [71] | ZHANG X Y, HAO F, CHEN H S , et al. Diffusion-induced stress and delamination of layered electrode plates with composition- gradient. Mech. Mater. , 2015,91:351-362. |

| [72] | LU B, SONG Y C, GUO Z S , et al. Modeling of progressive delamination in a thin film driven by diffusion-induced stresses. Int. J. Solids Struct., 2013,50(14/15):2495-2507. |

| [73] | PAL S, DAMLE S S, KUMTA P N , et al. Modeling of lithium segregation induced delamination of a-Si thin film anode in Li-ion batteries. Comput. Mater. Sci., 2013,79:877-887. |

| [74] | HAFTBARADARAN H, XIAO X C, VERBRUGGE M W , et al. Method to deduce the critical size for interfacial delamination of patterned electrode structures and application to lithiation of thin-film silicon islands. J. Power Sources , 2012,206:357-366. |

| [75] | YANG L, CHEN H S, SONG W L , et al. In situ optical observations and simulations on defect induced failure of silicon island anodes. J. Power Sources, 2018,405:101-105. |

| [76] | CHEN D, KRAMER D, MÖNIG R. Chemomechanical fatigue of LiMn1.95Al0.05O4 electrodes for lithium-ion batteries. Electrochim. Acta, 2018,259:939-948. |

| [77] | XU R, YANG Y, YIN F , et al. Heterogeneous damage in Li-ion batteries: experimental analysis and theoretical modeling. J. Mech. Phys. Solids , 2019,129:160-183. |

| [78] | YIM T, CHOI S J, JO Y N , et al. Effect of binder properties on electrochemical performance for silicon-graphite anode: method and application of binder screening. Electrochim. Acta , 2014,136:112-120. |

| [79] | LI C L, SUN Q, JIANG J Y , et al. Electrochemistry and morphology evolution of carbon micro-net films for rechargeable lithium ion batteries. J. Phys. Chem. C , 2008,112:13782-13788. |

| [80] | LI J C, DOZIER A K, LI Y C , et al. Crack pattern formation in thin film lithium-ion battery electrodes. J. Electrochem. Soc., 2011,158(6):A689-A694. |

| [81] | ZHANG J Z, ZHANG J, WANG D , et al. Stress evolution in SiO electrodes for lithium-ion batteries during electrochemical cycling. Mater. Lett. , 2017,190:79-82. |

| [82] |

QU F, LI C L, WANG Z M , et al. Eutectic nano-droplet template injection into bulk silicon to construct porous frameworks with concomitant conformal coating as anodes for Li-ion batteries. Sci. Rep. , 2015,5:10381.

URL PMID |

| [83] |

QU F, LI C L, WANG Z M , et al. Metal-induced crystallization of highly corrugated silicon thick films as potential anodes for Li-ion batteries. ACS Appl. Mater. Interfaces , 2014,6:8782-8788.

DOI URL PMID |

| [84] | ZHANG Z A, ZENG T, LAI Y Q , et al. A comparative study of different binders and their effects on electrochemical properties of LiMn2O4 cathode in lithium ion batteries. J. Power Sources, 2014,247:1-8. |

| [85] | SETHURAMAN V A, WINKLE N V, ABRAHAM D P , et al. Real-time stress measurements in lithium-ion battery negative- electrodes. J. Power Sources , 2012,206:334-342. |

| [86] | PHARR M, CHOI Y S, LEE D W , et al. Measurements of stress and fracture in germanium electrodes of lithium-ion batteries during electrochemical lithiation and delithiation. J. Power Sources , 2016,304:164-169. |

| [87] | SUTHAR B, NORTHROP P W C, RIFE D, et al. Effect of porosity, thickness and tortuosity on capacity fade of anode. J. Electrochem. Soc., 2015,162(9):A1708-A1717. |

| [88] | YANG X G, BAUER C, WANG C Y . Sinusoidal current and stress evolutions in lithium-ion batteries. J. Power Sources, 2016,327:414-422. |

| [89] | WU W, XIAO X R, WANG M , et al. A microstructural resolved model for the stress analysis of lithium-ion batteries. J. Electrochem. Soc., 2014,161(5):A803-A813. |

| [90] | RIEGER B, ERHARD S V, KOSCH S , et al. Multi-dimensional modeling of the influence of cell design on temperature, displacement and stress inhomogeneity in large-format lithium-ion cells. J. Electrochem. Soc., 2016,163(14):A3099-A3110. |

| [91] | RIEGER B, SCHUSTER S F, ERHARD S V , et al. Multi-directional laser scanning as innovative method to detect local cell damage during fast charging of lithium-ion cells. J. Energy Storage , 2016,8:1-5. |

| [92] | ZHANG L J, CHENG H Z, MENG D J . Experiment study on ETSS coupling mechanism and identification of key parameter for lithium-ion batteries. J. Xi'an Jiaotong Univ., 2017,51(8):142-148. |

| [93] | YU C C, DAI H F. The stress measurement and analysis of the lithium-ion battery. Mechatronics, 2015, 21(8): 14-17+32. |

| [94] | SAUERTEIG D, HANSELMANN N, ARZBERGER A , et al. Electrochemical-mechanical coupled modeling and parameterization of swelling and ionic transport in lithium-ion batteries. J. Power Sources , 2018,378:235-247. |

| [95] | BARAI A, TANGIRALA R, UDDIN K , et al. The effect of external compressive loads on the cycle lifetime of lithium-ion pouch cells. J. Energy Storage, 2017,13:211-219. |

| [96] | CANNARELLA J, ARNOLD C B . Stress evolution and capacity fade in constrained lithium-ion pouch cells. J. Power Sources, 2014,245:745-751. |

| [97] | WÜNSCH M, KAUFMAN J, SAUER D U . Investigation of the influence of different bracing of automotive pouch cells on cyclic lifetime and impedance spectra. J. Energy Storage, 2019,21:149-155. |

| [98] | LI R H, REN D S, GUO D X , et al. Volume deformation of large-format lithium ion batteries under different degradation paths. J. Electrochem. Soc., 2019,166(16):A4106-A4114. |

| [99] | MUSSA A S, KLETT M, LINDBERGH G , et al. Effects of external pressure on the performance and ageing of single-layer lithium- ion pouch cells. J. Power Sources , 2018,385:18-26. |

| [100] | ZHANG J, HAN X, HU C J , , et al. An optimization of the pressing force applied onto the module structure of soft-package lithium-ion battery. Automot. Eng.., 2016, 38(6): 669-673+715. |

| [101] | PFRANG A, KERSYS A, KRISTON A , et al. Long-term cycling induced jelly roll deformation in commercial 18650 cells. J. Power Sources , 2018,392:168-175. |

| [102] | SCHUSTER S F, BACH T, FLEDER E , et al. Nonlinear aging characteristics of lithium-ion cells under different operational conditions. J. Energy Storage , 2015,1:44-53. |

| [103] | BACH T C, SCHUSTER S F, FLEDER E , et al. Nonlinear aging of cylindrical lithium-ion cells linked to heterogeneous compression. J. Energy Storage , 2016,5:212-223. |

| [1] | WEI Xiangxia, ZHANG Xiaofei, XU Kailong, CHEN Zhangwei. Current Status and Prospects of Additive Manufacturing of Flexible Piezoelectric Materials [J]. Journal of Inorganic Materials, 2024, 39(9): 965-978. |

| [2] | YANG Xin, HAN Chunqiu, CAO Yuehan, HE Zhen, ZHOU Ying. Recent Advances in Electrocatalytic Nitrate Reduction to Ammonia Using Metal Oxides [J]. Journal of Inorganic Materials, 2024, 39(9): 979-991. |

| [3] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [4] | HUANG Jie, WANG Liuying, WANG Bin, LIU Gu, WANG Weichao, GE Chaoqun. Research Progress on Modulation of Electromagnetic Performance through Micro-nanostructure Design [J]. Journal of Inorganic Materials, 2024, 39(8): 853-870. |

| [5] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [6] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [7] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [8] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [9] | ZHAO Rida, TANG Sufang. Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix [J]. Journal of Inorganic Materials, 2024, 39(6): 623-633. |

| [10] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [11] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [12] | ZHANG Hui, XU Zhipeng, ZHU Congtan, GUO Xueyi, YANG Ying. Progress on Large-area Organic-inorganic Hybrid Perovskite Films and Its Photovoltaic Application [J]. Journal of Inorganic Materials, 2024, 39(5): 457-466. |

| [13] | LI Zongxiao, HU Lingxiang, WANG Jingrui, ZHUGE Fei. Oxide Neuron Devices and Their Applications in Artificial Neural Networks [J]. Journal of Inorganic Materials, 2024, 39(4): 345-358. |

| [14] | BAO Ke, LI Xijun. Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications [J]. Journal of Inorganic Materials, 2024, 39(3): 233-258. |

| [15] | HU Mengfei, HUANG Liping, LI He, ZHANG Guojun, WU Houzheng. Research Progress on Hard Carbon Anode for Li/Na-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(1): 32-44. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||