Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (5): 567-572.DOI: 10.15541/jim20180383

• RESEARCH LETTERS • Previous Articles

Zhi-Qiang SUN,Xiao-Bo YANG,Hua-Dong WANG,De-Li LI,Shu-Qin LI,Yi LÜ

Received:2018-08-31

Published:2019-05-20

Online:2019-05-14

Supported by:CLC Number:

Zhi-Qiang SUN, Xiao-Bo YANG, Hua-Dong WANG, De-Li LI, Shu-Qin LI, Yi LÜ. Ceramic/Resin Composite Powders with Uniform Resin Layer Synthesized from SiO2 Spheres for 3D Technology[J]. Journal of Inorganic Materials, 2019, 34(5): 567-572.

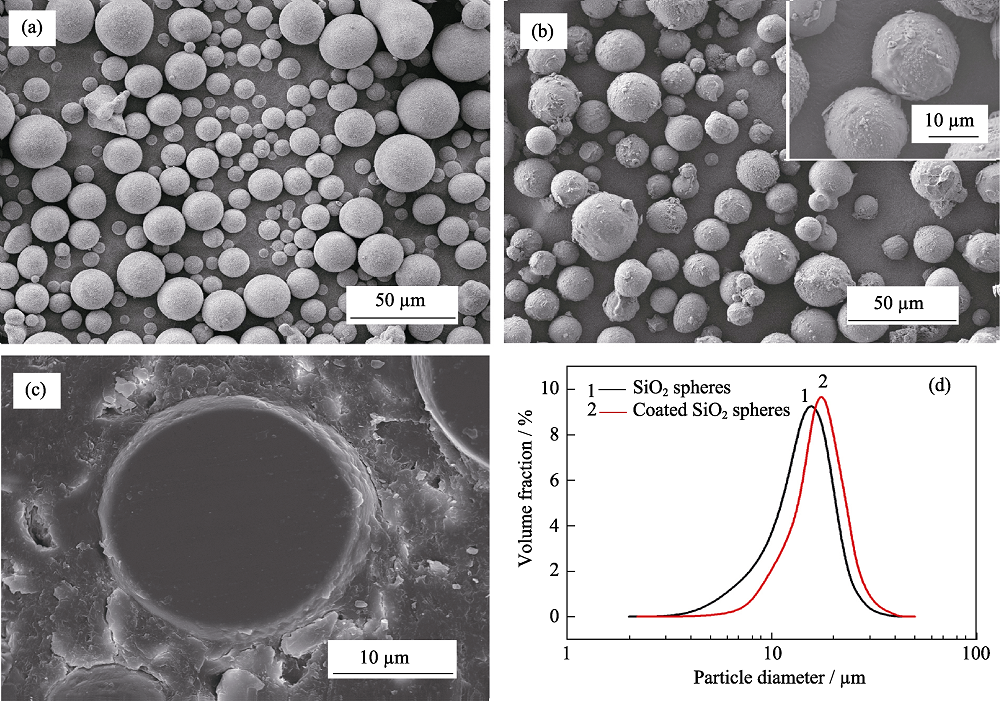

Fig. 3 SEM images of SiO2 spheres (a), coated spheres (b), the cross section of coating layer (c), and particle size distribution before/after coating (d)

Fig. 7 shows the characterization of SiO2 ceramics synthesized by the composite spheres with layer thickness of 2 μm after consolidated and sintered at 1250 ℃ for 2 h. Fig. 7(a) is the SEM image of the fracture surface of ceramic, exhibiting that the uniformly arranged particles are sintered together and the sintered necks among spheres can be easily observed. The pores are mostly composed of the cell walls of spheres and no blockages derived from uneven shrinkage can be found. The narrow pore size distribution shown in Fig. 7(b) also indicates the ceramics are well structured without structural defects.

| [1] | TIWARI S K, PANDE S . Material properties and selection for selective laser sintering process. Int.[J]. Adv. Manuf. Tech., 2013,27(4/5/6):198-217. |

| [2] |

LI X M, CAO M J, JIANG Y . Microstructure and mechanical properties of porous alumina ceramic prepared by a combination of 3-D printing and sintering. Ceram. Int., 2016,42(10):12531-12535.

DOI URL |

| [3] |

MAZZOLI A . Selective laser sintering in biomedical engineering. Med. Biol. Eng. Comput., 2013,51(3):245-256.

DOI URL PMID |

| [4] |

LYKOV P A, SAPOZHNIKOV S B, SHULEV I S , et al. Composite micropowders for selective laser sintering. Metallurgist, 2016,59(9/10):851-855.

DOI URL |

| [5] |

SHAHZAD K, DECKERS J, KRUTH J P , et al. Additive manufacturing of alumina parts by indirect selective laser sintering and post processing.[J]. Mater. Process. Tech., 2013,213(9):1484-1494.

DOI URL |

| [6] |

SLOCOMBE A, TAUFIK A, LI L . Diode laser ablation machining of 316L stainless steel powder/polymer composite material: effect of powder geometry. Appl. Surf. Sci., 2000,168(1-4):17-20.

DOI URL |

| [7] |

LORRISON J C, DALGARNO K W, WOOD D J . Processing of an apatite-mullite glass-ceramic and an hydroxyapatite/phosphate glass composite by selective laser sintering. J. Mater. Sci-Mater. M., 2005,16(8):775-781.

DOI URL PMID |

| [8] | WANG W, MA S, FUH J H , et al. Processing and characterization of laser-sintered Al2O3/ZrO2/SiO2. Int.[J]. Adv. Manuf. Tech., 2013,68(9/12):2565-2569. |

| [9] |

DENG Z Y, YANG J F, BEPPU Y , et al. Effect of agglomeration on mechanical properties of porous zirconia fabricated by partial sintering.[J]. Am. Ceram. Soc., 2002,85:1961-1965.

DOI URL |

| [10] |

SUN Z Q, LI B Q, HU P , et al. Alumina ceramics with uniform grains prepared from Al2O3 nanospheres.[J]. Alloy Compd., 2016,688:933-938.

DOI URL |

| [11] |

LI B Q, SUN Z Q, HOU G L , et al. The sintering behavior of quasispherical tungsten nanopowders. Int.[J]. Refract. Met. Hard Mater., 2016,56:44-50.

DOI URL |

| [12] | YANG S, GWAK J N, LIM T S , et al. Preparation of spherical titanium powders from polygonal titanium hydride powders by radio frequency plasma treatment. Mater. Trans., 2013,54(12):2313-2316. |

| [13] |

YAN M F, CANNON JR R M, BOWEN H K , et al. Effect of grain size distribution on sintered density. Mater. Sci. Eng., 1983,60(3):275-281.

DOI URL |

| [14] |

LU H M, WEN Z, JIANG Q , et al. Nucleus-liquid interfacial energy of elements. Colloid. Surface A, 2006,278(1):160-165.

DOI URL |

| [15] |

ZHAO J, LU L, ZHANG Z , et al. Continuum modeling of the cohesive energy for the interfaces between films, spheres, coats and substrates. Comp. Mater. Sci., 2015,96:432-438.

DOI URL |

| [16] | OZER I O, SUVACI E, KARADEMIR B , et al. Anisotropic sintering shrinkage in alumina ceramics containing oriented platelets.[J]. Am. Ceram. Soc., 2006,89(6):1972-1976. |

| [17] |

JAGOTA A, DAWSON P R . Simulation of the viscous sintering of two particles.[J]. Am. Ceram. Soc., 2010,73(1):173-177.

DOI URL |

| [18] |

WILSON P J, BLACKBURN S, GREENWOOD R W , et al. The role of zircon particle size distribution, surface area and contamination on the properties of silica-zircon ceramic materials.[J]. Eur. Ceram. Soc., 2011,31:1849-1855.

DOI URL |

| [1] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [2] | SHI Zhe, LIU Weiye, ZHAI Dong, XIE Jianjun, ZHU Yufang. Akermanite Scaffolds for Bone Tissue Engineering: 3D Printing Using Polymer Precursor and Scaffold Properties [J]. Journal of Inorganic Materials, 2023, 38(7): 763-770. |

| [3] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [4] | WANG Lukai, FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian. Direct-ink-writing 3D Printing of Ceramic-based Porous Structures: a Review [J]. Journal of Inorganic Materials, 2023, 38(10): 1133-1148. |

| [5] | SHI Jixiang, ZHAI Dong, ZHU Min, ZHU Yufang. Preparation and Characterization of Bioactive Glass-Manganese Dioxide Composite Scaffolds [J]. Journal of Inorganic Materials, 2022, 37(4): 427-435. |

| [6] | LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores [J]. Journal of Inorganic Materials, 2022, 37(3): 325-332. |

| [7] | ZHU Junyi, ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei. Influence of Debinding Process on the Properties of Photopolymerization 3D Printed Cordierite Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 317-324. |

| [8] | LI Qi, HUANG Yi, QIAN Bin, XU Beibei, CHEN Liying, XIAO Wenge, QIU Jianrong. Photo Curing and Pressureless Sintering of Orange-emitting Glass-ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 289-296. |

| [9] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [10] | WU Zhongcao, HUAN Zhiguang, ZHU Yufang, WU Chengtie. 3D Printing and Characterization of Microsphere Hydroxyapatite Scaffolds [J]. Journal of Inorganic Materials, 2021, 36(6): 601-607. |

| [11] | ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng. 3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties [J]. Journal of Inorganic Materials, 2021, 36(4): 436-442. |

| [12] | Xing-Peng LIU, Bin PENG, Wan-Li ZHANG, Jun ZHU. Al2O3 Coating Layer on the High Temperature Conductive Stability of Pt/ZnO/Al2O3 Film Electrode [J]. Journal of Inorganic Materials, 2019, 34(6): 605-610. |

| [13] | Sheng-Yang FU, Bin YU, Hui-Feng DING, Guo-Dong SHI, Yu-Fang ZHU. Zirconia Incorporation in 3D Printed β-Ca2SiO4 Scaffolds on Their Physicochemical and Biological Property [J]. Journal of Inorganic Materials, 2019, 34(4): 444-454. |

| [14] | XIN Chen, QI Xin, ZHU Min, ZHAO Shi-Chang, ZHU Yu-Fang. Hydroxyapatite Whisker-reinforced Composite Scaffolds Through 3D Printing for Bone Repair [J]. Journal of Inorganic Materials, 2017, 32(8): 837-844. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||