Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (7): 711-720.DOI: 10.15541/jim20170421

Special Issue: 陶瓷基复合材料

• Orginal Article • Previous Articles Next Articles

LIU Hai-Tao1, YANG Ling-Wei2, HAN Shuang1

Received:2017-08-30

Revised:2017-10-26

Published:2018-07-10

Online:2018-06-19

Supported by:CLC Number:

LIU Hai-Tao, YANG Ling-Wei, HAN Shuang. Research Progress on Micro-mechanical Property of Continuous Fiber-reinforced Ceramic Matrix Composites[J]. Journal of Inorganic Materials, 2018, 33(7): 711-720.

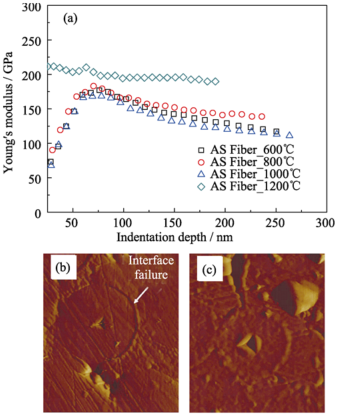

Fig. 1 (a) Young's modulus of the AS fiber in ASf/SiO2 composites prepared at different temperatures as a function of penetration depth; SPM images of the nanoindentation imprints of ASf/SiO2 composites fabricated at 600℃ (b) and 1200℃ (c)[10]

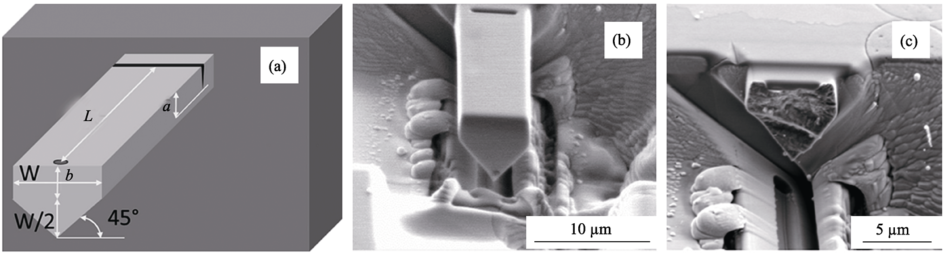

Fig. 4 (a) Schematic representation of the micro-cantilever bending geometry; SEM images of a micro-cantilever prepared from SiC matrix in SiCf/SiC composites before (a) and after (b) testing[11,18]

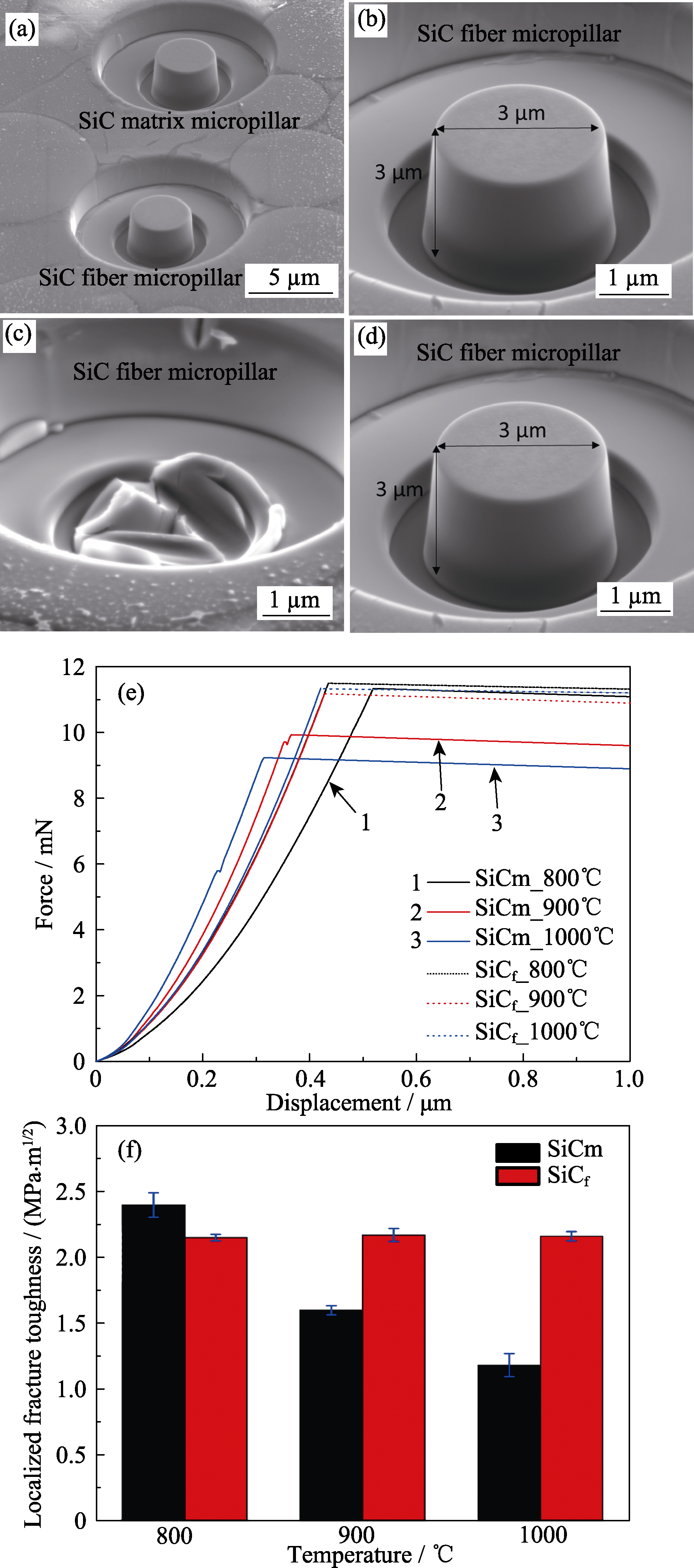

Fig. 6 Morphologies of the micropillars on individual SiC matrix and SiC fiber (a, b); Micropillar morphologies of SiC fiber and SiC matrix after pillar splitting tests(c, d); Representive force-displacement curves of SiC matrix and SiC fiber by the micropillar splitting tests (e); Evolution of localized fracture toughness of the SiC matrix and SiC fiber as a function of composite fabrication temperature(f)[28]

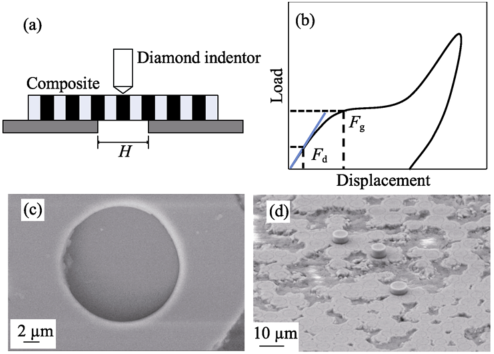

Fig. 8 (a) Schematic drawing of fiber push-out measurement; (b) Typical load-displacement push-out test curve; SEM images of the frontside surface (c) and backside surface (d) of SiCf/SiC minicomposite after fiber push-out test using a flat punch indenter[43]

| Composites | Interphase | τ/MPa | Flexural strength/MPa | Fracture mode | Ref. |

|---|---|---|---|---|---|

| PIP 3D Cf/SiC | None | 105 | 23 | Brittle | [19] |

| PyC | 30 | 378 | Toughened | ||

| PIP 3D Nextel440 ASf/SiC | None | 293 | 45 | Brittle | [34] |

| PyC | 42 | 163 | Toughened | ||

| Sol-Gel 3D SiCf/Mullite | None | 537 | 230 | Brittle | [46] |

| PyC | 155 | 35 | Toughened | ||

| PIP 3D SiCf/SiC | None | 450 | 90 | Brittle | [28] |

| BN | 50 | 200 | Toughened | ||

| Sol-Gel 3D ALF ASf/SiO2(600℃) | None | 50 | 105 | Toughened | [10] |

| Sol-Gel 3D ALF ASf/SiO2(1200℃) | None | 260 | 45 | Brittle |

Table 1 Interfacial bonding strength of typical CFRCMCs investigated in our research group

| Composites | Interphase | τ/MPa | Flexural strength/MPa | Fracture mode | Ref. |

|---|---|---|---|---|---|

| PIP 3D Cf/SiC | None | 105 | 23 | Brittle | [19] |

| PyC | 30 | 378 | Toughened | ||

| PIP 3D Nextel440 ASf/SiC | None | 293 | 45 | Brittle | [34] |

| PyC | 42 | 163 | Toughened | ||

| Sol-Gel 3D SiCf/Mullite | None | 537 | 230 | Brittle | [46] |

| PyC | 155 | 35 | Toughened | ||

| PIP 3D SiCf/SiC | None | 450 | 90 | Brittle | [28] |

| BN | 50 | 200 | Toughened | ||

| Sol-Gel 3D ALF ASf/SiO2(600℃) | None | 50 | 105 | Toughened | [10] |

| Sol-Gel 3D ALF ASf/SiO2(1200℃) | None | 260 | 45 | Brittle |

| Composites | Em/GPa | Ef/GPa | Γm/(J·m-2) | Γf/(J·m-2) | EBN interphase/GPa | ΓBN interphase/(J·m-2) |

|---|---|---|---|---|---|---|

| SiCf/SiC (800℃) | 118 | 160 | 49 | 29 | - | - |

| SiCf/SiC (900℃) | 170 | 160 | 15 | 29 | - | - |

| SiCf/SiC (1000℃) | 256 | 160 | 5 | 29 | - | - |

| SiCf/BN/SiC | - | 160 | - | 29 | 70 | 4 |

Table 2 Micro-mechanical parameters of SiCf/SiC and SiCf/BN/SiC composites investigated in Liu’s group[28]

| Composites | Em/GPa | Ef/GPa | Γm/(J·m-2) | Γf/(J·m-2) | EBN interphase/GPa | ΓBN interphase/(J·m-2) |

|---|---|---|---|---|---|---|

| SiCf/SiC (800℃) | 118 | 160 | 49 | 29 | - | - |

| SiCf/SiC (900℃) | 170 | 160 | 15 | 29 | - | - |

| SiCf/SiC (1000℃) | 256 | 160 | 5 | 29 | - | - |

| SiCf/BN/SiC | - | 160 | - | 29 | 70 | 4 |

| [1] | 陈朝辉, 李伟, 王松, 等. 先驱体转化陶瓷基复合材料, 北京: 科学出版社, 2012. |

| [2] | 张立同. 纤维增韧碳化硅陶瓷复合材料—模拟、表征与设计.北京: 化学工业出版社, 2009. |

| [3] | KRENKEL WALTER. Ceramic Matrix Composites.Weinheim: WILEY-VCH Verlag GmbH & Co.KGaA, 2008. |

| [4] | WANG YI, LIU HAI-TAO, CHENG HAI-FENG.Research progress on oxide/oxide ceramic matrix composites.Journal of Inorganic Materials, 2014, 29(7): 673-680. |

| [5] | MA QING-SONG, LIU HAI-TAO, PAN YU,et al.Research progress on the application of C/SiC composites in scramjet.Journal of Inorganic Materials, 2013, 28(3): 247-255. |

| [6] | MEYER P, WAAS A M.FEM predictions of damage in continuous fiber ceramic matrix composites under transverse tension using the crack band method.Acta Materialia, 2016, 102: 292-303. |

| [7] | Li L B, SONG Y D, SUN Y C.Modeling the tensile behavior of unidirectional C/SiC ceramic-matrix composites.Mechanics of Composite Materials, 2014, 49(6): 659-672. |

| [8] | WANG L, WANG Z, DONG S M,et al.Finite element simulation of stress distribution and development of Cf/SiC ceramice-matrix composite coated with single layer SiC coating during thermal shock.Composites: Part B, 2013, 51: 204-214. |

| [9] | EVANS A G, ZOK F W.The physics and mechanics of fibre-reinforced brittle matrix composites.Journal of Materials Science, 1994, 29: 3857-3896. |

| [10] | YANG L W, WANG J Y, LIU H T,et al.Sol-Gel temperature dependent ductile-to-brittle transition of aluminosilicate fiber reinforced silica matrix composite.Composites: Part B, 2017, 119: 79-89. |

| [11] | FRAZER D, ABAD M D, KRUMWIEDE D,et al.Localized mechanical property assessment of SiC/SiC composite materials.Composites: Part A, 2015, 70: 93-101. |

| [12] | BLAESE D, GARCIA D E, GUGLIELMI P,et al.ZrO2 fiber- matrix interfaces in alumina fiber-reinforced model composites.Journal of European Ceramic Society, 2015, 35: 1593-1598. |

| [13] | UDAYAKUMAR A, SRI GANESH A, RAJA S,et al.Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI.Journal of the European Ceramic Society, 2011, 31: 1145-1153. |

| [14] | YAN W, PUN C L, WU Z,et al.Some issues on nanoindentation method to measure the elastic modulus of particles in composites.Composites: Part B, 2011, 42: 2093-2097. |

| [15] | ZHANG L, REN C, ZHOU C,et al.Single fiber push-out characterization of interfacial mechanical properties in unidirectional CVI-C/SiC composites by the nano-indentation technique.Applied Surface Science, 2015, 357: 1427-1433. |

| [16] | HINOKI T, ZHANG W, KOHYAMA A, ,et al. . Effect of fiber coating on interfacial shear strength of SiC/SiC by nano-indentation technique. Journal of Nuclear Materials, 1998, 258-263: 1567-1571. |

| [17] | SEBASTIANI M, JOHANNS K E, HERBERT E G,et al.A novel pillar indentation splitting test for measuring fracture toughness of thin ceramic coatings.Philosophical Magazine, 2015, 95: 1928-1944. |

| [18] | SEBASTIANI M, JOHANNS K E, HERBERT E G,et al.Measurement of fracture toughness by nanoindentation methods: recent advances and future challenges.Current Opinion in Solid State and Materials Science, 2015, 19: 324-333. |

| [19] | LIU H T, YANG L W, SUN X,et al.Enhancing the fracture resistance of carbon fiber reinforced SiC matrix composites by interface modification through a simple fiber heat-treatment process.Carbon, 2016, 109: 435-443. |

| [20] | LEATHERBARROW A, WU H Z.Mechanical behaviour of the constituents inside carbon-fibre/carbon-silicon carbide composites characterised by nano-indentation.Journal of the European Ceramic Society, 2012, 32: 579-588. |

| [21] | MARX D T, RIESTER L.Mechanical properties of carbon-carbon composite components determined using nanoindentation.Carbon, 1999, 37: 1679-1684. |

| [22] | DISS P, LAMON J, CARPENTIER L,et al.Sharp indentation behavior of carbon/carbon composites and varieties of carbon.Carbon, 2002, 40: 2567-2579. |

| [23] | MULLER W M, MOOSBURGER-WILL J, SAUSE M G R,et al.Quantification of crack area in ceramic matrix composites at single- fiber push-out testing and influence of pyrocarbon fiber coating thickness on interfacial fracture toughness.Journal of the European Ceramic Society, 2015, 35: 2981-2989. |

| [24] | OLIVER W C, PHARR G M.An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments.Journal of Materials Research, 1992, 7(6): 1564-1583. |

| [25] | VANLANDINGHAM M R.Review of instrumented indentation.Journal of Research of the National Institute of Standards and Technology, 2003, 108(4): 249-265. |

| [26] | OLIVER W C, PHARR G M.Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. Journal of Materials Research, 2004, 19(1): 3-20. |

| [27] | FISCHER-CRIPPS A C. Critical review analysis and interpretation of nanoindentation test data.Surface& Coatings Technology, 2006, 200: 4153-4165. |

| [28] | YANG L W, LIU H T, CHENG H F.Processing-temperature dependent micro- and macro-mechanical properties of SiC fiber reinforced SiC matrix composites.Composites: Part B, 2017, 129: 152-161. |

| [29] | HONJO K.Fracture toughness of PAN-based carbon fibers estimated from strength-mirror size relation.Carbon, 2003, 41: 979-984. |

| [30] | MORISHITA K, OCHIAI S, OKUDA H,et al.Fracture toughness of a crystalline silicon carbide fiber (tyranno-SA3®).Journal of the American Ceramic Society, 2006, 89(8): 2571-2576. |

| [31] | OCHIAI S, KUBOSHIMA S, MORISHITA K,et al.Fracture toughness of Al2O3 fibers with an artificial notch introduced by a focused-ion-beam.Journal of the European Ceramic Society, 2010, 30: 1659-1667. |

| [32] | CASELLAS D, CARO J, MOLAS S,et al.Fracture toughness of carbides in tool steels evaluated by nanoindentation.Acta Materialia, 2007, 55: 4277-4286. |

| [33] | MUELLER M G, PEJCHAL V, ŽAGAR G,et al.Fracture toughness testing of nanocrystalline alumina and fused quartz using chevron-notched microbeams.Acta Materialia, 2015, 86: 385-395. |

| [34] | LIU H T, YANG L W, HAN S,et al.Interface controlled micro- and macro-mechanical properties of aluminosilicate fiber reinforced SiC matrix composites.Journal of the European Ceramic Society, 2017, 37: 883-890. |

| [35] | CAO S Y, WANG J, WANG H.High-temperature behavior and degradation mechanism of SiC fibers annealed in Ar and N2 atmospheres.Journal of Materials Science, 2016, 51: 4650-4659. |

| [36] | DAVIES I J, ISHIKAWA T, SHIBUYA M,et al.Fibre and interfacial properties measured in situ for a 3D woven SiC/SiC-based composite with glass sealant.Composites: Part A, 1999, 30: 587-591. |

| [37] | DAVIES I J, OGASAWARA T, ISHIKAWA T.Distribution of fibre pullout length and interface shear strength within a single fibre bundle for an orthogonal 3-D woven Si-Ti-C-O fibre/Si-Ti-C-O matrix composite tested at 1100℃ in air.Journal of the European Ceramic Society, 2005, 25: 599-604. |

| [38] | BRANDSTETTER J, PETERLIK H, KROMP K,et al.A new fibre- bundle pull-out test to determine interface properties of a 2D- woven carbon/carbon composite.Composites Science Technology, 2003, 63: 653-660. |

| [39] | BERTRAND S, FORIO P, PAILLER R,et al.Hi-Nicalon/SiC minicomposites with (pyrocarbon/SiC)n nanoscale multilayered interphases.Journal of the American Ceramic Society, 1999, 82(9): 2465-2473. |

| [40] | SAUDER C, BRUSSON A, LAMON J.Influence of interface characteristics on the mechanical properties of Hi-Nicalon type-S or Tyranno-SA3 fiber-reinforced SiC/SiC minicomposites.International Journal of Applied Ceramic Technology, 2010, 7(3): 291-303. |

| [41] | MORSCHER G N, MARTINEZ-FERNANDEZ J.Fiber effects on minicomposite mechanical properties for several silicon carbide fiber-chemically vapor-infiltrated silicon carbide matrix systems.Journal of the American Ceramic Society, 1999, 82(1): 145-155. |

| [42] | REBILLAT F, LAMON J, GUETTE A.The concept of a strong interface applied to SiC/SiC composites with a BN interphase.Acta Materialia, 2000, 48: 4609-4618. |

| [43] | BUET E, SAUDER C, SORNIN D,et al.Influence of surface fibre properties and textural organization of a pyrocarbon interphase on the interfacial shear stress of SiC/SiC minicomposites reinforced with Hi-Nicalon S and Tyranno SA3 fibres.Journal of the European Ceramic Society, 2014, 34: 179-188. |

| [44] | MUELLER W M, MOOSBURGER-WILL J, SAUSE M G R,et al.Microscopic analysis of single-fiber push-out tests on ceramic matrix composites performed with Berkovich and flat-end indenter and evaluation of interfacial fracture toughness.Journal of the European Ceramic Society, 2013, 33: 441-451. |

| [45] | RODRÍGUEZ M, MOLINA-ALDAREGUÍA J M, GONZÁLEZ C,et al.A methodology to measure the interface shear strength by means of the fiber push-in test.Composites Science and Technology, 2012, 72: 1924-1932. |

| [46] | HAN S, YANG L W, LIU H T,et al.Micro-mechanical properties and interfacial engineering of SiC fiber reinforced Sol-Gel fabricated mullite matrix composites.Materials and Design, 2017, 131: 265-272. |

| [47] | HE M Y, HUTCHINSON J W.Crack deflection at the interface between dissimilar materials.International Journal of Solids and Structures, 1989, 25(9): 1053-1067. |

| [48] | HE M Y, EVANS A G, HUTCHINSON J W.Crack deflection at an interface between dissimilar elastic materials: role of residual stresses.International Journal of Solids and Structures, 1994, 31(24): 3443-3455. |

| [49] | FUJITA H, JEFFERSON G, MCMEEKING R M,et al.Mullite/alumina mixtures for use as porous matrices in oxide fiber composites.Journal of the American Ceramic Society, 2004, 87(2): 261-267. |

| [1] | WEI Xiangxia, ZHANG Xiaofei, XU Kailong, CHEN Zhangwei. Current Status and Prospects of Additive Manufacturing of Flexible Piezoelectric Materials [J]. Journal of Inorganic Materials, 2024, 39(9): 965-978. |

| [2] | YANG Xin, HAN Chunqiu, CAO Yuehan, HE Zhen, ZHOU Ying. Recent Advances in Electrocatalytic Nitrate Reduction to Ammonia Using Metal Oxides [J]. Journal of Inorganic Materials, 2024, 39(9): 979-991. |

| [3] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [4] | HUANG Jie, WANG Liuying, WANG Bin, LIU Gu, WANG Weichao, GE Chaoqun. Research Progress on Modulation of Electromagnetic Performance through Micro-nanostructure Design [J]. Journal of Inorganic Materials, 2024, 39(8): 853-870. |

| [5] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [6] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [7] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [8] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [9] | ZHAO Rida, TANG Sufang. Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix [J]. Journal of Inorganic Materials, 2024, 39(6): 623-633. |

| [10] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [11] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [12] | ZHANG Hui, XU Zhipeng, ZHU Congtan, GUO Xueyi, YANG Ying. Progress on Large-area Organic-inorganic Hybrid Perovskite Films and Its Photovoltaic Application [J]. Journal of Inorganic Materials, 2024, 39(5): 457-466. |

| [13] | LI Zongxiao, HU Lingxiang, WANG Jingrui, ZHUGE Fei. Oxide Neuron Devices and Their Applications in Artificial Neural Networks [J]. Journal of Inorganic Materials, 2024, 39(4): 345-358. |

| [14] | BAO Ke, LI Xijun. Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications [J]. Journal of Inorganic Materials, 2024, 39(3): 233-258. |

| [15] | WU Jun, XU Peifei, JING Rui, ZHANG Dahai, FEI Qingguo. Experimental Study on Low-velocity Impact and Residual Strength of SiC/SiC Composite Laminates [J]. Journal of Inorganic Materials, 2024, 39(1): 51-60. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||