Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (4): 363-372.DOI: 10.15541/jim20170278

• Orginal Article • Next Articles

ZHU Dong-Bin1,2, SONG Yan-Jun2, LIANG Jin-Sheng2, ZHANG Xiao-Xu1, CHU Rui-Qing1, WU Min-Qiang1

Received:2017-06-05

Revised:2017-09-11

Published:2018-04-30

Online:2018-03-27

About author:ZHU Dong-Bin. E-mail: zhudongbin@hebut.edu.cn

Supported by:CLC Number:

ZHU Dong-Bin, SONG Yan-Jun, LIANG Jin-Sheng, ZHANG Xiao-Xu, CHU Rui-Qing, WU Min-Qiang. Progress of Toughness in Dental Zirconia Ceramics[J]. Journal of Inorganic Materials, 2018, 33(4): 363-372.

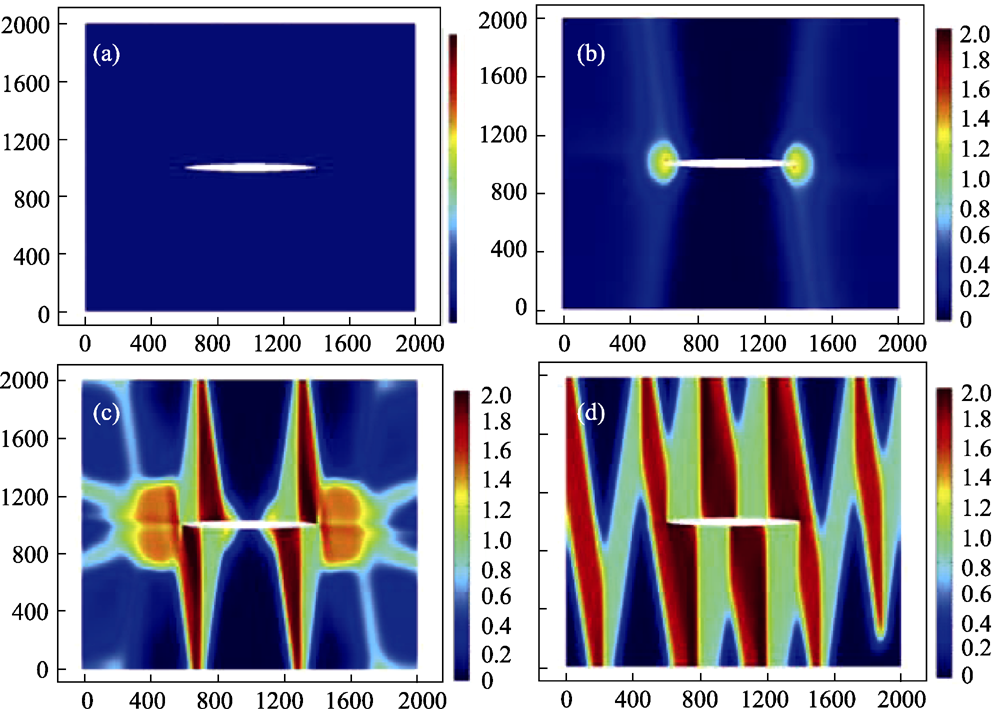

Fig. 1 Nucleation and evolution of monoclinic phase in a cracked tetragonal single crystal under tension stress[6](a)-(d): Correspond to time 0, 1.4 μs, 1.6 μs, 2.5 μs, respectively

| Ref. | Preparation method | Preparation conditions | Grain size/nm |

|---|---|---|---|

| [37] | Co-precipitation | Sintering condition: 1173 K for10 min | 3.3 |

| [38] | Vapor-phase hydrolysis | Precursor solution: ZrCl4: H2O=1:40 | 15.0 |

| [39] | Detonation synthesis | Hot pressure moulding | 24.0 |

Table 1 Grain size of 3Y-TZP prepared by different methods

| Ref. | Preparation method | Preparation conditions | Grain size/nm |

|---|---|---|---|

| [37] | Co-precipitation | Sintering condition: 1173 K for10 min | 3.3 |

| [38] | Vapor-phase hydrolysis | Precursor solution: ZrCl4: H2O=1:40 | 15.0 |

| [39] | Detonation synthesis | Hot pressure moulding | 24.0 |

| Crystal phase | Strength/MPa | Genre |

|---|---|---|

| Al2O3 | 594±52 | In-Ceram Al2O3 |

| Spinel | 378±65 | In-Ceram Spinel |

| 12Ce-TZP-Al2O3 | 630±58 | In-Ceram 12Ce-TZP-Al2O3 |

Table 2 Strength comparison of different genres of In-Ceram ceramics[45]

| Crystal phase | Strength/MPa | Genre |

|---|---|---|

| Al2O3 | 594±52 | In-Ceram Al2O3 |

| Spinel | 378±65 | In-Ceram Spinel |

| 12Ce-TZP-Al2O3 | 630±58 | In-Ceram 12Ce-TZP-Al2O3 |

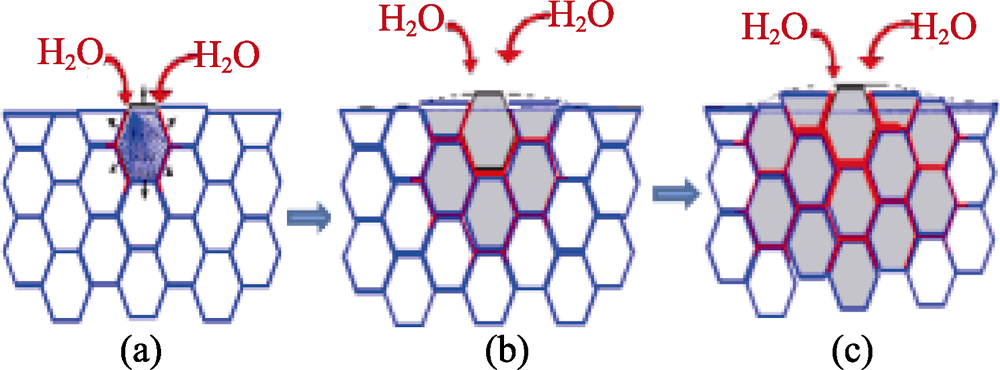

Fig. 10 Scheme of the aging process[55](a) Nucleation on a particular grain at the surface, leading to microcracking and stresses to the neighbors; (b) Growth of the transformed zone, leading to surface roughening; (c) Further development of transformation

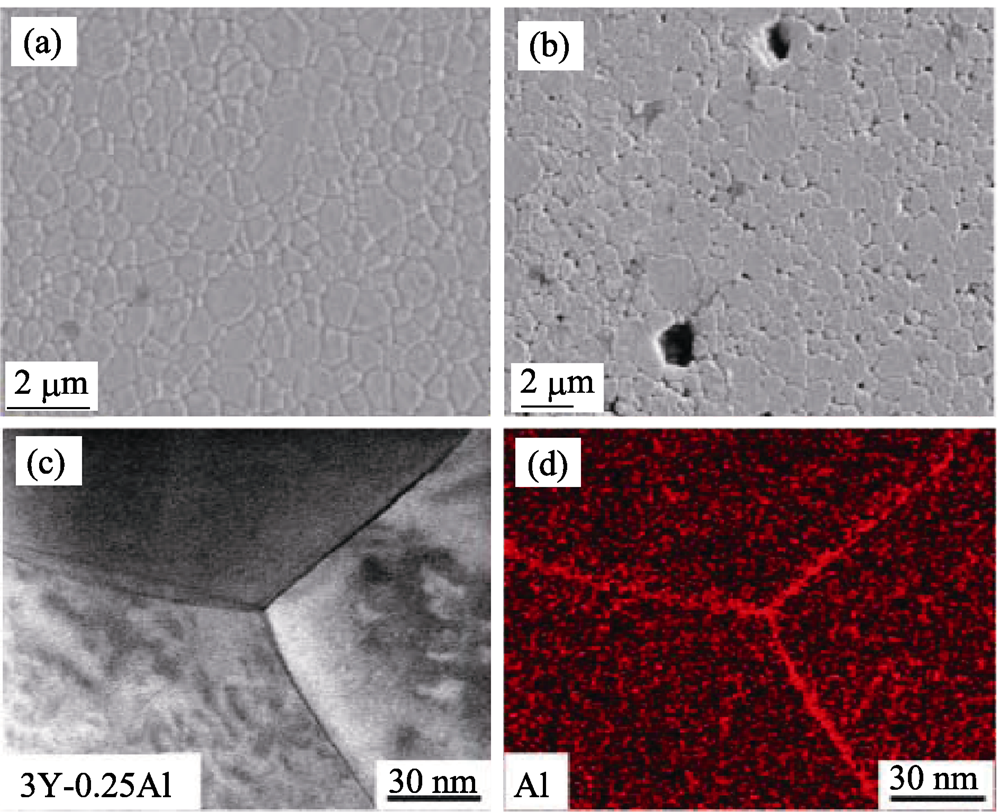

Fig. 11 Topographies of Y-TZP before (a) and after (b) aging[56], STEM images of 3Y-0.25Al grain boundaries (c) and corresponding Al-distribution map (d)[59]

| Ceramics | Hardness/GPa | KIC/(MPa·m1/2) |

|---|---|---|

| ATZ | 21±1.2 | 4.2±0.1 |

| ATZ with LTD | 12±1.5 | 3.7±0.2 |

| 3Y-TZP | 25±0.8 | 5.1±0.2 |

| 3Y-TZP with LTD | 15±1.5 | 4.1±0.3 |

| 8Y-CSZ | 31.3±0.2 | 3.77±0.02 |

| 8Y-CSZ with LTD | 31.2±0.3 | 3.78±0.03 |

Table 3 Mechanical properties of the ceramics samples evaluated by nanoindentation[60]

| Ceramics | Hardness/GPa | KIC/(MPa·m1/2) |

|---|---|---|

| ATZ | 21±1.2 | 4.2±0.1 |

| ATZ with LTD | 12±1.5 | 3.7±0.2 |

| 3Y-TZP | 25±0.8 | 5.1±0.2 |

| 3Y-TZP with LTD | 15±1.5 | 4.1±0.3 |

| 8Y-CSZ | 31.3±0.2 | 3.77±0.02 |

| 8Y-CSZ with LTD | 31.2±0.3 | 3.78±0.03 |

| [1] | SOON G, PINGGUAN-MURPHY B, LAI K W,et al. Review of zirconia-based bioceramic: surface modification and cellular response. Ceramics International, 2016, 42(11): 12543-12555. |

| [2] | FERNANDEZ-GARCIA E, CHEN X, GUTIERREZ-GONZALEZ C F,et al. Peptide-functionalized zirconia and new zirconia/titanium biocermets for dental applications. Journal of Dentistry, 2015, 43(9): 1162-1174. |

| [3] | GARVIE R C, HANNINK R H, PASCOE R T.Ceramic steel?Nature, 1975, 258(5537): 703-704. |

| [4] | DENRY I, KELLY J R.Emerging ceramic-based materials for dentistry.Journal of Dental Research, 2014, 93(12): 1235-1242. |

| [5] | GARVIE R C, NICHOLSON P S.Phase analysis in zirconia systems.Journal of the American Ceramic Society, 2010, 55(6): 303-305. |

| [6] | MAMIVAND M, ZAEEM M A, EL KADIRI H.Phase field modeling of stress-induced tetragonal to monoclinic transformation in zirconia and its effect on transformation toughening.Acta Materialia, 2014, 64: 208-219. |

| [7] | WANG J, STEVENS R.Zirconia toughened alumina (ZTA) ceramics.Journal of Materials Science, 1989, 24(10): 3421-3440. |

| [8] | MANICONE P F, IOMMETTI P R, RAAFFAELLI L.An overview of zirconia ceramics: basic properties and clinical applications.Journal of Dentistry, 2007, 35(11): 819-826. |

| [9] | TORRICELLI P, VERNE E, BROVARONE C V,et al. Biological glass coating on ceramic materials: in vitro evaluation using primary osteoblast cultures from healthy and osteopenic rat bone. Biomaterials, 2001, 22(18): 2535-2543. |

| [10] | TAN JIAN-GUO, ZHOU YONG-SHENG.Dental ceramic materials.Journal of Practical Department of Stomatology, 2009(7): 395-397. |

| [11] | HAN J, ZHAO J, SHEN Z.Zirconia ceramics in metal free implant dentistry.Advances in Applied Ceramics, 2017, 116(3): 138-150. |

| [12] | DAUD M H M, ZENN Y H, ZAMAN J Q,et al. Evaluation of shear bond strength of a novel nano-zirconia and veneering ceramics. Ceramics International, 2017, 43(1): 1272-1277. |

| [13] | MONTAZERIAN M, ZANOTTO E D.Bioactive and inert dental glass-ceramics. Journal of Biomedical Materials Research Part A, 2017, 105(2): 619-639. |

| [14] | DEVILLE S, CHEVALIERR J, GREMILLARD L.Influence of surface finish and residual stresses on the ageing sensitivity of biomedical grade zirconia.Biomaterials, 2006, 27(10): 2186-2192. |

| [15] | LAWSON S.Environmental degradation of zirconia ceramics.Journal of the European Ceramic Society, 1995, 15(6): 485-502. |

| [16] | PALMERO P, FORNABAIO M, MONTANARO L,et al. Towards long lasting zirconia-based composites for dental implants. Part I: Innovative synthesis, microstructural characterization and in vitro stability. Biomaterials, 2015, 50: 38-46. |

| [17] | EVANS A G, HEUER A H.Review-transformation toughening in ceramics: martensitic transformations in crack-tip stress fields.Journal of the American Ceramic Society, 1980, 63(5/6): 241-248. |

| [18] | HANNINK R H J, KELLY P M, MUDDLE B C. Transformation toughening in zirconia-containing ceramics.Journal of the American Ceramic Society, 2000, 83(3): 461-487. |

| [19] | KELLY J R, DENRY I.Stabilized zirconia as a structural ceramic: an overview.Dental Materials Official Publication of the Academy of Dental Materials, 2008, 24(3): 289-298. |

| [20] | MCMEEKING R M, EVANS A G.Mechanics of transformation- toughening in brittle materials.Journal of the American Ceramic Society, 1982, 65(5): 242-246. |

| [21] | AMAZIGO J C, BUDIANSKY B.Steady state crack growth in supercritically transforming materials.International Journal of Solids and Structures, 1988, 24(7): 751-755. |

| [22] | ZHAO T, ZHU J, LUO J.Study of crack propagation behavior insingle crystalline tetragonal zirconia with the phase field method.Engineering Fracture Mechanics, 2016, 159: 155-173. |

| [23] | SMIRNOV A, BELTRAN J I, RODRIGUEZ S T,et al. Unprecedented simultaneous enhancement in damage tolerance and fatigue resistance of zirconia/Ta composites. Scientific Reports, 2017, 7: 44922. |

| [24] | LIU D, GAO Y, LIU J,et al. SiC whisker reinforced ZrO2 composites prepared by flash-sintering. Journal of the European Ceramic Society, 2016, 36(8): 2051-2055. |

| [25] | ROBERTSON T, HUANG X, KEARSEY R.High temperature performance of mullite whisker-reinforced ZTA. Journal of Composite Materials, 2016, 50(26): 3719-3729. |

| [26] | PECHARROMáN C, BELTRAN J I, ESTEBAN-BETEGON F,et al. Zirconia/nickel interface sinmicro-annano composites. Zeitschrift für Metallkunde, 2005, 96(5): 507-514. |

| [27] | ZHANG LI-TONG, CHENG LAI-FEI.Discussion on strategy of sustainable development of ceramic matrix composites reinforced by continuous fiber.Journal of Composite Materials, 2007, 24(2): 1-6. |

| [28] | DUSZA J, BLUGAN G, MORGIEL J,et al. Hot pressed and spark plasma sintered zirconia/carbon nanofiber composites. Journal of the European Ceramic Society, 2009, 29(15): 3177-3184. |

| [29] | 黄红燕. 牙科纳米氧化锆氧化铝(Al2O3/ZrO2)复合陶瓷的基础研究. 北京: 中国医科大学博士学位论文, 2009. |

| [30] | NETTLESHIP I, STEVENS R.Tetragonal zirconia polycrystal (TZP)-a review.International Journal of High Technology Ceramics, 1987, 3(1): 1-32. |

| [31] | PJETURSSON B E, SAILER I, MAKAROV N A,et al. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses(FDPs)? a systematic review of the survival and complication rates. Part II: Multiple-unit FDPs. Dental Material, 2015, 31(6): 624-639. |

| [32] | LE COADOU C, KARST N, EMIEUX F,et al. Assessment of ultrathin yttria-stabilized zirconia foils forbiomedical applications. Journal Material Science, 2015, 50(18): 6197-6207. |

| [33] | BELLI R, GEINZER E, MUSCHWECK A,et al. Mechanical fatigue degradation of ceramics versus resin composites for dental restorations. Dental Material, 2014, 30(4): 424-432. |

| [34] | PICONI C, MACCAURO G.Review: zirconia as a ceramic biomaterial. Biomaterials, 1999, 20(1): 1-25. |

| [35] | ZHANG F, VANMEENSEL K, INOKOSHI M,et al. 3Y-TZP ceramics with improved hydrothermal degradation resistance and fracture toughness. Journal of the European Ceramic Society, 2014, 34(10): 2453-2463. |

| [36] | AMARAL M, VALANDRO L F.Low-temperature degradation of a Y-TZP ceramic after surface treatments.Society for Biomaterial, 2013, 101(8): 1387-1392. |

| [37] | HUANG H J, WANG M C.The phase formation and stability of tetragonal ZrO2 prepared in a silica bath.Ceramics International, 2013, 39(2): 1729-1739. |

| [38] | WANG Q, LI C, GUO M,et al. Controllable synthesis of zirconia nano-powders using vapor-phasehy drolysis and the oretical analysis. Journal of Materials Chemistry A, 2014, 2(5): 1346-1352. |

| [39] | KERN F, LINDNER V, GADOW R J CERAM. Low temperature degradation behaviour and mechanical properties of a 3Y-TZP manufactured from detonation synthesized powder.Journal of Ceramic Science and Technology, 2016, 7(4): 313-321. |

| [40] | CHINTAPALLI R K, MESTRA R A, GARCIA M F,et al. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. Journal of the Mechanical Behavior of Biomedical Materials, 2014, 29: 126-137. |

| [41] | MUñOZ-TABARES J A, ANGLADA M. Hydrothermal degradation of ground 3Y-TZP.Journal of the European Ceramic Society, 2012, 32(2): 325-333. |

| [42] | INOKOSHI M, ZHANG F, VANMEENSEL K,et al. Residual compressive surface stress increases the bending strength of dental zirconia. Dental Materials, 2017. 33(4): 147-154. |

| [43] | AMARAL M, CESAR P F, BOTTINO M A,et al. Fatigue behavior of Y-TZP ceramic after surface treatments. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 57: 149-156. |

| [44] | EL-GHANY O S A, SHERIEF A H. Zirconia based ceramics, some clinical and biological aspects: review.Future Dental Journal, 2016, 2(2): 55-64. |

| [45] | DENRY I, HOLLOWAY J A.Ceramics for dental applications: a review.Materials, 2010, 3(1): 351-368. |

| [46] | CHAAR M S, PASSIA N, KERN M.Ten-year clinical outcome of three-unit posterior FDPs made from a glass-infiltrated zirconia reinforced alumina ceramic (In-Ceram Zirconia).Journal of Dentistry, 2015, 43(5): 512-517. |

| [47] | ROY M E, WHITESIDE L A, KATERBERG B J,et al. Phase transformation, roughness, and microhardness oartificially aged yttria-and magnesia-stabilized zirconia femoral heads. International Science, 2007, 83(4): 1096-1102. |

| [48] | GARVIE R C, URBANI C, KENNEDY D R,et al. Biocompatibility of magnesia-partially stabilized zirconia (Mg-PSZ) ceramics. Journal of Materials Science, 1984, 19(10): 3224-3228. |

| [49] | DURET F, BLOUIN J L, DURET B.CAD-CAM in dentistry.Journal American Dental Association, 1988, 117(6): 715-720. |

| [50] | CARVALHO A O, BRUZI G, GIANNINI M,et al. Fatigue resistance of CAD/CAM complete crowns with a simplified cementation process. The Journal of Prosthetic Dentistry, 2014, 111(4): 310-317. |

| [51] | GUAZZATO M, ALBAKRY M, RINGER S P,et al. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dental Materials, 2004, 20(5): 449-456. |

| [52] | ZHENG K, Li Z, LIAO W,et al. Friction and wear performance on ultrasonic vibration assisted grinding dental zirconia ceramics against natural tooth. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2016, 39(3): 833-843. |

| [53] | ZARONE F, RUSSO S, SORRENTINO R.From porcelain fused to metal to zirconia: clinical and experimental considerations.Dental Material, 2011, 27(1): 83-96. |

| [54] | KOBAYASHI K, KUWAJIMA H, MASAKI T.Phase change and mechanical properties of ZrO2-Y2O3 solid electrolyte after ageing.Solid State Ionics, 1981, 3(4): 489-493. |

| [55] | CHEVALIER J.What future for zirconia as a biomaterial?Biomaterials, 2006, 27(4): 535-543. |

| [56] | HALLMANN L, ULMER P, REUSSER E,et al. Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. Journal of the European Ceramic Society, 2012, 32(16): 4091-4104. |

| [57] | INOKOSHI M, ZHANG F, DE MUNCK J,et al. Influence of sintering conditions on low-temperature degradation of dental zirconia. Dental Materials, 2014, 30(6): 669-678. |

| [58] | COTIC J, JEVNIKAR P, KOCJAN A,et al. Complexity of the relationships between the sintering-temperature-dependent grain size, airborne-particle abrasion, ageing and strength of 3Y-TZP ceramics. Dental Materials, 2016, 32(4): 510-518. |

| [59] | ZHANG F, VANMEENSEL K, INOKOSHI M,et al. Critical influence of alumina content on the low temperature degradation of 2-3mol% yttria-stabilized TZP for dental restorations. Journal of the European Ceramic Society, 2015, 35(2): 741-750. |

| [60] | ARAGON-DUARTE M C, NEVAREZ-RASCóN A, ESPARZA- PONCE H E,et al. Nanomechanical properties of zirconia-yttria and alumina zirconia-yttria biomedical ceramics, subjected to low temperature aging. Ceramics International, 2017, 43(5): 3931-3939. |

| [61] | HUAN C T, XIA J F, JIANG D Y, et al. Aging properties of yttria- stabilized zirconia ceramics.Key Engineering Materials, 2012, 512-515: 435-438. |

| [62] | MOHAMED E, TAHERI M, MEHRJOO M,et al. In vitro biocompatibility and ageing of 3Y-TZP/CNTs composites.Ceramics International, 2015, 41(10): 12773-12781. |

| [63] | KIM J W, COVEL N S, GUESS P C,et al. Concerns of hydrothermal degradation in CAD/CAM zirconia. Journal of Dental Research, 2010, 89(1): 91-95. |

| [64] | HÜBSCH C, DELLINGER P, MAIER H J,et al. Protection of yttria- stabilized zirconia for dental applications by oxidic PVD coating. Acta Biomaterialia, 2015, 11(1): 488-493. |

| [65] | TRUBY R L, LEWIS J A.Printing soft matter in three dimensions.Nature, 2016, 540(7633): 371-378. |

| [66] | ZHU D B, XU A P, QU Y X,et al. Functionalized bio-artifact fabricated via selective slurry extrusion. Part 1: Preparation of slurry containing tourmaline superfine powders. Journal of Nanoscience and Nanotechnology, 2011, 11(12): 10891-10895. |

| [67] | ZHU D B, LIANG J P, QU Y X,et al. Functionalized bio-artifact fabricated via selective slurry extrusion. Part 2: Fabrication of ceramic dental crown. Journal of Nanoscience and Nanotechnology, 2014, 14(5): 3703-3706. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | LIU Huilai, LI Zhihao, KONG Defeng, CHEN Xing. Preparation of FePc/MXene Composite Cathode and Electro-Fenton Degradation of Sulfadimethoxine [J]. Journal of Inorganic Materials, 2025, 40(1): 61-69. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||