Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (7): 777-784.DOI: 10.15541/jim20160532

• Orginal Article • Previous Articles

WU Ying-Ying

Received:2016-09-20

Published:2017-07-20

Online:2017-06-23

About author:WU Ying-Ying (1992–), female, candidate of master degree. E-mail: tjclwyy2014@163.com

Supported by:CLC Number:

WU Ying-Ying, YE Song,YAO Ai-Hua, LI Hai-Bin, JIA Wei-Tao, HUANG Wen-Hai, WANG De-Ping. Effect of Gas-foaming Porogen-NaHCO3 and Citric Acid on the Properties of Injectable Macroporous Borate Bioactive Glass Cement[J]. Journal of Inorganic Materials, 2017, 32(7): 777-784.

| Samples | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|

| BBG /g | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| (NaHCO3/ BBG) / % | 0 | 5 | 8 | 10 | 12 | 15 |

| Gelatin solution / mL | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Citric acid / mL | 0 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

Table 1 Composition of the samples

| Samples | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|

| BBG /g | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| (NaHCO3/ BBG) / % | 0 | 5 | 8 | 10 | 12 | 15 |

| Gelatin solution / mL | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Citric acid / mL | 0 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

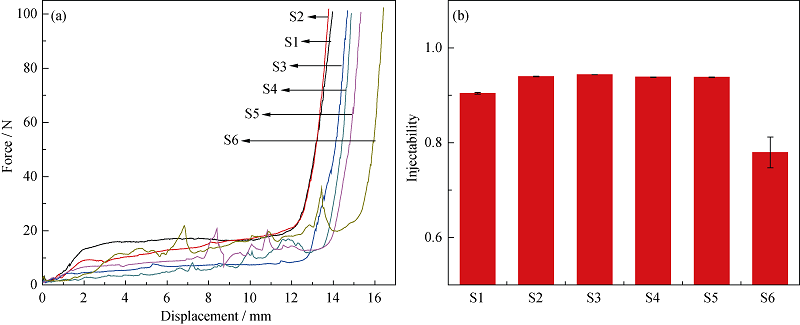

Fig. 1 Injectability study of the cements(a) Representative injectability curves of BBGC with different porogen contents obtained from a syringe with a 1.7 mm diameter at a compression rate of 15 mm/min and maximum applied injection force of 100 N; (b) Injectability percentage measured for BBGC

| No. | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|

| Setting time / min | 110 ± 10 | 175 ± 15 | 82 ± 5 | 55 ± 5 | 25 ± 3 | 20 ± 2 |

| Density / (g•cm-3) | 1.10 ± 0.04 | 1.02 ± 0.02 | 1.04 ± 0.04 | 1.05 ± 0.04 | 0.98 ± 0.01 | 1.07 ± 0.04 |

| Total porosity / % | 47.07 ± 2.01 | 50.71 ± 0.85 | 49.38 ± 1.74 | 48.96 ± 2.13 | 52.18 ± 0.68 | 47.46 ± 1.89 |

Table 2 Physical results of the BBGC

| No. | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|

| Setting time / min | 110 ± 10 | 175 ± 15 | 82 ± 5 | 55 ± 5 | 25 ± 3 | 20 ± 2 |

| Density / (g•cm-3) | 1.10 ± 0.04 | 1.02 ± 0.02 | 1.04 ± 0.04 | 1.05 ± 0.04 | 0.98 ± 0.01 | 1.07 ± 0.04 |

| Total porosity / % | 47.07 ± 2.01 | 50.71 ± 0.85 | 49.38 ± 1.74 | 48.96 ± 2.13 | 52.18 ± 0.68 | 47.46 ± 1.89 |

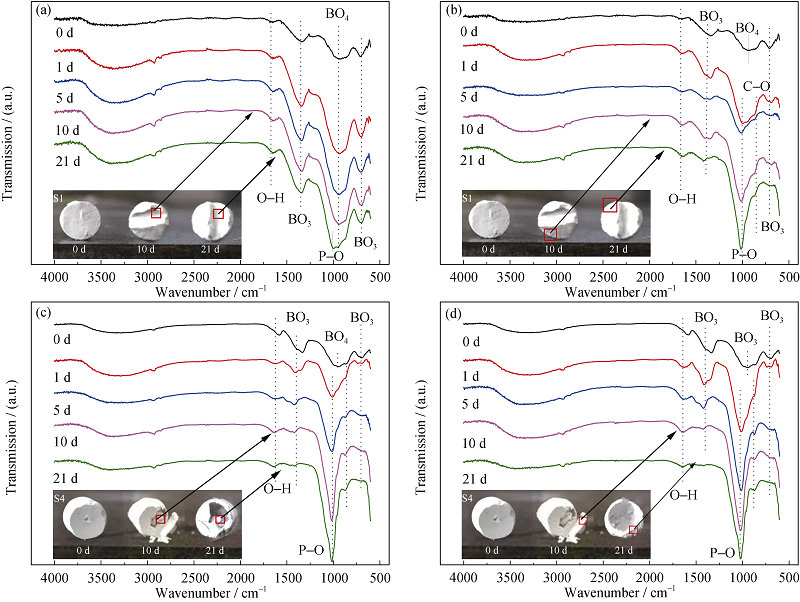

Fig. 7 ATR spectra of S1 and S4 as a function of soaking time (a), (c) materials 2 mm from the surface of S1 and S4 cylinder, respectively; (b) (d) surface materials of S1 cylinder and S4 cylinder, respectively

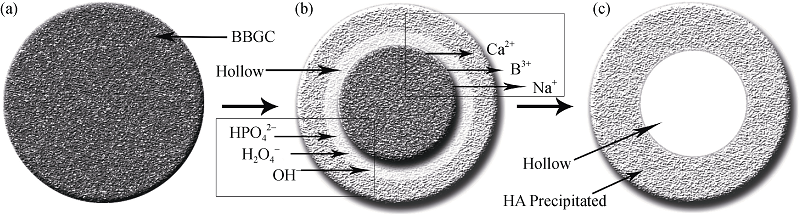

Fig. 8 Schematic illustration showing the degradation mechanism of BBGC in PBS solution as a function of times; sectional morphology of BBGC before soaking (a); BBGC soaking for some time (b); end product (c)

| [1] | HUANG W, DAY D E, KITTIRATANAPIBOON K, et al.Kinetics and mechanisms of the conversion of silicate (45S5), borate, and borosilicate glasses to hydroxyapatite in dilute phosphate solutions. J. Mater. Sci-Mater. Med., 2006, 17(7): 583-596. |

| [2] | ZHANG Y, CUI X, ZHAO S, et al.Evaluation of injectable strontium-containing borate bioactive glass cement with enhanced osteogenic capacity in a critical-sized rabbit femoral condyle defect model. ACS Appl. Mater. Inter., 2015, 7(4): 2393-2403. |

| [3] | LIANG W, RAHAMAN M N, DAY D E, et al.Bioactive borate glass scaffold for bone tissue engineering.J. Non-Cryst. Solids, 2008, 354(15): 1690-1696. |

| [4] | LOPES P P, GARCIA M P, FERNANDES M H, et al.Acrylic formulations containing bioactive and biodegradable fillers to be used as bone cements: properties and biocompatibility assessment.Mater. Sci. Eng: C, 2013, 33(3): 1289-1299. |

| [5] | INNOCENTINI M D M, FALEIROS R K, PISANI JR R, et al. Permeability of porous gel cast scaffolds for bone tissue engineering.J. Porous Mat., 2010, 17(5): 615-627. |

| [6] | LANAO R P F, LEEUWENBURGH S C G, WOLKE J G C, et al. Bone response to fast-degrading, injectable calcium phosphate cements containing PLGA microparticles.Biomaterials, 2011, 32(34): 8839-8847. |

| [7] | KLIJN R J, VAN DEN BEUCKEN J J J P, FÉLIX LANAO R P, et al. Three different strategies to obtain porous calcium phosphate cements: comparison of performance in a rat skull bone augmentation model. Tissue Part Eng. A, 2012, 18(11/12): 1171-1182. |

| [8] | FU Q, RAHAMAN M N, FU H, et al.Silicate, borosilicate, and borate bioactive glass scaffolds with controllable degradation rate for bone tissue engineering applications. I. Preparation and in vitro degradation.J. Biomed. Mater. Res. A, 2010, 95(1): 164-171. |

| [9] | CUI X, ZHAO C, GU Y, et al.A novel injectable borate bioactive glass cement for local delivery of vancomycin to cure osteomyelitis and regenerate bone.J. Mater. Sci-Mater. Med., 2014, 25(3): 733-745. |

| [10] | CHEN W, ZHOU H, TANG M, et al.Gas-foaming calcium phophate cement scaffold encapsulating human umbilical cord stem cells.Tissue Eng. Part A, 2011, 18(7/8): 816-827. |

| [11] | THEIN-HAN W W, XU H H K. Prevascularization of a gas- foaming macroporous calcium phosphate cement scaffold via coculture of human umbilical vein endothelial cells and osteoblasts.Tissue Eng. A, 2013, 19(15/16): 1675-1685. |

| [12] | KIM H J, PARK I K, KIM J H, et al.Gas foaming fabrication of porous biphasic calcium phosphate for bone regeneration.Tissue Eng. Regen. Med., 2012, 9(2): 63-68. |

| [13] | WU C, LUO Y, CUNIBERTI G, et al.Three-dimensional printing of hierarchical and tough mesoporous bioactive glass scaffolds with a controllable pore architecture, excellent mechanical strength and mineralization ability.Acta Biomater., 2011, 7(6): 2644-2650. |

| [14] | CHEN C C, WANG C W, HSUEH N S, et al.Improvement of in vitro physicochemical properties and osteogenic activity of calcium sulfate cement for bone repair by dicalcium silicate.J. Alloy Compd., 2014, 585: 25-31. |

| [15] | ZHANG J, LIU W, SCHNITZLER V, et al.Calcium phosphate cements for bone substitution: chemistry, handling and mechanical properties.Acta Biomater., 2014, 10(3): 1035-1049. |

| [16] | YOKOYAMA A, YAMAMOTO S, KAWASAKI T, et al.Development of calcium phosphate cement using chitosan and citric acid for bone substitute materials.Biomaterials, 2002, 23(4): 1091-1101. |

| [17] | YAMAGUCHI I, IIZUKA S, OSAKA A, et al.The effect of citric acid addition on chitosan/hydroxyapatite composites.Colloid. Surface. A, 2003, 214(1): 111-118. |

| [18] | SARDA S, FERNANDEZ E, NILSSON M, et al.Kinetic study of citric acid influence on calcium phosphate bone cements as water-reducing agent. J. Biomed. Mater. Res., 2002, 61(4): 653-659. |

| [19] | DOWEIDAR H, EL-DAMRAWI G, AL-ZAIBANI M.Distribution of species in Na2O-CaO-B2 O3 glasses as probed by FTIR.Vib. Spectrosc., 2013, 68: 91-95. |

| [20] | FATHI M H, HANIFI A, MORTAZAVI V.Preparation and bioactivity evaluation of bone-like hydroxyapatite nanopowder.J. Mater. Process Tech., 2008, 202(1): 536-542. |

| [21] | PERUT F, MONTUFAR E B, CIAPETTI G, et al.Novel soy bean/gelatine-based bioactive and injectable hydroxyapatite foam: material properties and cell response.Acta Biomater., 2011, 7(4): 1780-1787. |

| [22] | YAO A, WANG D, HUANG W, et al.In vitro bioactive characteristics of borate-based glasses with controllable degradation behavior.J. Am. Ceram. Soc., 2007, 90(1): 303-306. |

| [23] | LIU X, RAHAMAN M N, DAY D E.Conversion of melt-derived microfibrous borate (13-93B3) and silicate (45S5) bioactive glass in a simulated body fluid.J. Mater. Sci-Mater. Med., 2013, 24(3): 583-595. |

| [1] | PAN Yuzhou, HE Fajian, XU Lulu, DAI Shixun. Broadband 3 μm Mid-infrared Emission in Dy3+/Yb3+ Co-doped Tellurite Glass under 980 nm LD Excitation [J]. Journal of Inorganic Materials, 2025, 40(5): 521-528. |

| [2] | WAN Jiabao, ZHANG Minghui, SU Huaiyu, CAO Zhijun, LIU Xuechao, XIE Jiansheng, WANG Xiangyuan, SHI Yinghui, WANG Liang, LEI Shuijin. Structural, Thermal, and Optical Properties of GeO2-La2O3-TiO2 Glasses [J]. Journal of Inorganic Materials, 2023, 38(10): 1230-1236. |

| [3] | ZHU Qingong, ZHAO Gaoling, HAN Gaorong. Effect of Recombination Time on the Structure and Properties of P2O5-Al2O3 Heterogeneous Composite Glass [J]. Journal of Inorganic Materials, 2023, 38(2): 170-176. |

| [4] | WU Rui, ZHANG Minhui, JIN Chenyun, LIN Jian, WANG Deping. Photothermal Core-Shell TiN@Borosilicate Bioglass Nanoparticles: Degradation and Mineralization [J]. Journal of Inorganic Materials, 2023, 38(6): 708-716. |

| [5] | ZHU Zimin, ZHANG Minhui, ZHANG Xuanyu, YAO Aihua, LIN Jian, WANG Deping. In Vitro Mineralization Property of Borosilicate Bioactive Glass under DC Electric Field [J]. Journal of Inorganic Materials, 2021, 36(9): 1006-1012. |

| [6] | LIN Ziyang, CHANG Yuchen, WU Zhangfan, BAO Rong, LIN Wenqing, WANG Deping. Different Simulated Body Fluid on Mineralization of Borosilicate Bioactive Glass-based Bone Cement [J]. Journal of Inorganic Materials, 2021, 36(7): 745-752. |

| [7] | MENG Yanran, WANG Xinger, YANG Jian, XU Han, YUE Feng. Research on Machine Learning Based Model for Predicting the Impact Status of Laminated Glass [J]. Journal of Inorganic Materials, 2021, 36(1): 61-68. |

| [8] | CHANG Yuchen, LIN Ziyang, XIE Xin, WU Zhangfan, YAO Aihua, YE Song, LIN Jian, WANG Deping, CUI Xu. An Injectable Composite Bone Cement Based on Mesoporous Borosilicate Bioactive Glass Spheres [J]. Journal of Inorganic Materials, 2020, 35(12): 1398-1406. |

| [9] | ZHAO Changjiang,MA Chao,LIU Juncheng,LIU Zhigang,CHEN Yan. Sputtering Power on the Microstructure and Properties of MgF2 Thin Films Prepared with Magnetron Sputtering [J]. Journal of Inorganic Materials, 2020, 35(9): 1064-1070. |

| [10] | ZHANG Xiao-Yang, PENG Hai-Bo, LIU Feng-Fei, ZHAO Yan, SUN Meng-Li, GUAN Ming, ZHANG Bing-Tao, DU Xin, YUAN Wei, WANG Tie-Shan. Mechanical Properties of Borosilicate Glass with Different Irradiation of Heavy Ions [J]. Journal of Inorganic Materials, 2019, 34(7): 741-747. |

| [11] | FENG Sheng, SHAN Zhi-Tao, PAN Rui-Kun, XU Bo, ZU Cheng-Kui, TAO Hai-Zheng. Thermo-physical Property of YAG Melt Measured by Aerodynamic Levitation Technique [J]. Journal of Inorganic Materials, 2018, 33(12): 1297-1302. |

| [12] | JIAO Zhi-Wei, DUAN Cui-Cui, ZHOU Wei, LIU Feng-Bin, YANG Yue, ZHAO Pan, XIANG Jun-Fan. Preparation and Infrared Luminescence of Transparent Ni2+-doped ZMAS Glass-ceramics [J]. Journal of Inorganic Materials, 2018, 33(6): 673-677. |

| [13] | WEN Jian-Xiang, WANG Wen-Na, GUO Qi, HUANG Yi, DONG Yan-Hua, PANG Fu-Fei, CHEN Zhen-Yi, LIU Yun-Qi, WANG Ting-Yun. Gamma-ray Radiation on Magneto-optical Property of Pb-doped Silica Fiber [J]. Journal of Inorganic Materials, 2018, 33(4): 416-420. |

| [14] | LI Ren-Yi, LI Xiao-Yu, LI Jian-Qiang, ZHAO Jian-Ling, MA Xiao-Guang, HE Gang, LI Jiang-Tao. Large-sized La2O3-TiO2-SiO2 Amorphous Oxide Fabricated by Hot Press Sintering [J]. Journal of Inorganic Materials, 2017, 32(8): 851-856. |

| [15] | WANG Lian-Jun, ZHOU Bei-Ying, GU Shi-Jia, JIANG Wan. Research Progress on Silicon-based Luminescent Glass and Its Preparation Techniques [J]. Journal of Inorganic Materials, 2016, 31(10): 1013-1022. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||