Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (9): 997-1003.DOI: 10.15541/jim20160060

Special Issue: 庆祝上海硅酸盐所独立建所60周年虚拟专刊!

• Orginal Article • Previous Articles Next Articles

YANG Xiao-Yan1, 3, WU Jie-Hua2, REN Du-Di2, ZHANG Tian-Song2, CHEN Li-Dong1

Received:2016-01-27

Published:2016-09-20

Online:2016-08-29

About author:YANG Xiao-Yan(1988–), female, candidate of PhD. E-mail: yangxy116@student.sic.ac.cn

Supported by:CLC Number:

YANG Xiao-Yan, WU Jie-Hua, REN Du-Di, ZHANG Tian-Song, CHEN Li-Dong. Microstructure and Thermoelectric Properties of p-type Si80Ge20B0.6-SiC Nanocomposite[J]. Journal of Inorganic Materials, 2016, 31(9): 997-1003.

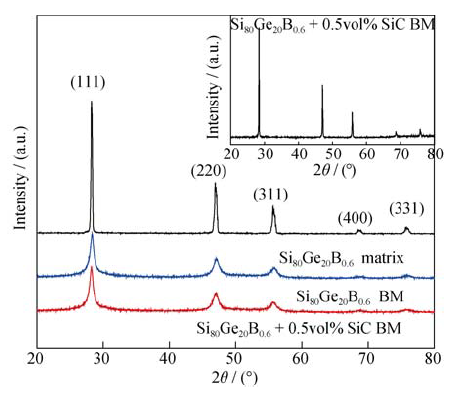

Fig. 1 Powder XRD patterns of Si80Ge20B0.6 matrix, Si80Ge20B0.6 BM and Si80Ge20B0.6 + 0.5vol% SiC BM samples before SPS. The inset in the upper right depicts XRD pattern of Si80Ge20B0.6 + 0.5vol% SiC BM sample sintered by SPS

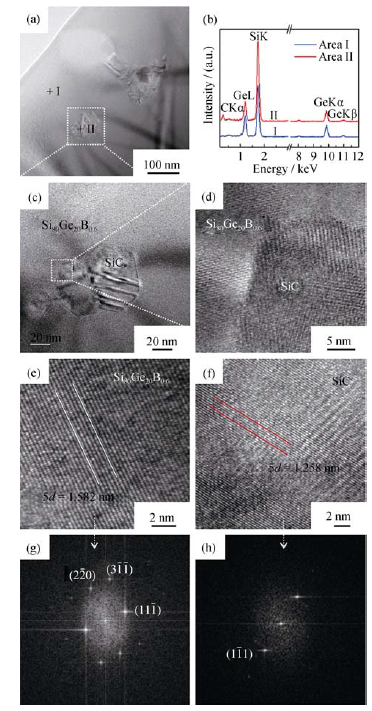

Fig. 4 TEM images and EDS results of Si80Ge20B0.6 + 0.5vol% SiC BM sample(a) TEM image of the composite containing nano-SiC; (b) EDS of the region at areas I and II in (a); (c) High magnification of the sub-region in (a); (d) HRTEM image of the interface between Si80Ge20B0.6 matrix and nano-SiC particle; (e, f) HRTEM images of Si80Ge20B0.6 matrix and nano-SiC particle, respectively; (g, h) Fourier transfer diffraction patterns of (e) and (f), respectively

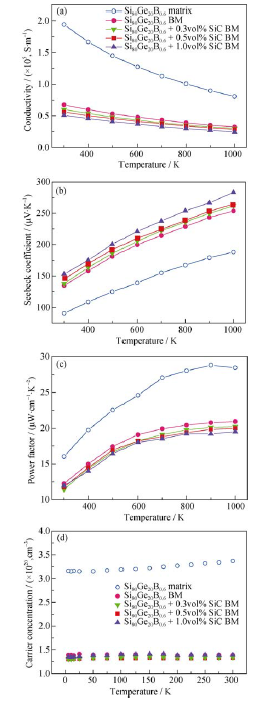

Fig. 5 Temperature dependence of (a) electrical conductivity, (b) Seebeck coefficient, (c) power factor and (d) carrier concentration for Si80Ge20B0.6 matrix, Si80Ge20B0.6 BM and Si80Ge20B0.6 + xvol% SiC BM (x = 0.3, 0.5, 1.0) samples

| Sample | Carrier concentration/ (×1020, cm-3) | Carrier mobility/ (cm2·V-1·s-1) |

|---|---|---|

| Si80Ge20B0.6 matrix | 3.4 | 36 |

| Si80Ge20B0.6 BM | 1.4 | 30 |

| Si80Ge20B0.6 + 0.3vol% SiC BM | 1.3 | 28 |

| Si80Ge20B0.6 + 0.5vol% SiC BM | 1.3 | 26 |

| Si80Ge20B0.6 + 1.0vol% SiC BM | 1.4 | 23 |

Table 1 Room temperature carrier concentration and mobility for Si80Ge20B0.6 matrix, Si80Ge20B0.6 BM and Si80Ge20B0.6 + xvol% SiC BM (x = 0.3, 0.5, 1.0) samples

| Sample | Carrier concentration/ (×1020, cm-3) | Carrier mobility/ (cm2·V-1·s-1) |

|---|---|---|

| Si80Ge20B0.6 matrix | 3.4 | 36 |

| Si80Ge20B0.6 BM | 1.4 | 30 |

| Si80Ge20B0.6 + 0.3vol% SiC BM | 1.3 | 28 |

| Si80Ge20B0.6 + 0.5vol% SiC BM | 1.3 | 26 |

| Si80Ge20B0.6 + 1.0vol% SiC BM | 1.4 | 23 |

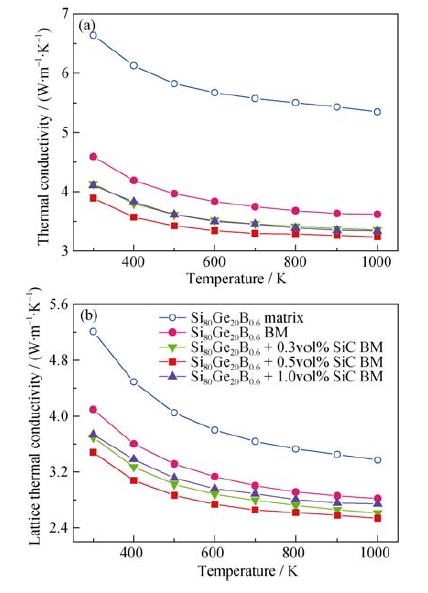

Fig. 6 Temperature dependence of (a) thermal conductivity and (b) lattice thermal conductivity for Si80Ge20B0.6 matrix, Si80Ge20B0.6 BM and Si80Ge20B0.6 + xvol% SiC BM (x = 0.3, 0.5, 1.0) samples

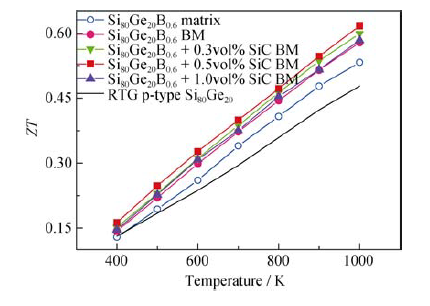

Fig. 7 Temperature dependence of ZT values for RTG p-type Si80Ge20 alloy[3], Si80Ge20B0.6 matrix, Si80Ge20B0.6 BM and Si80Ge20B0.6 + xvol% SiC BM (x = 0.3, 0.5, 1.0) samples

| [1] | SLACK G A, HUSSAIN M A.The maximum possible conversion efficiency of silicon-germanium thermoelectric generators.Journal of Applied Physics, 1991, 70(5): 2694-2718. |

| [2] | STEELE M C, ROSI F D.Thermal conductivity and thermoelectric power of germanium-silicon alloys.Journal of Applied Physics, 1958, 29(11): 1517-1520. |

| [3] | VINING C B.A model for the high-temperature transport-properties of heavily doped n-type silicon-germanium alloys.Journal of Applied Physics, 1991, 69(1): 331-341. |

| [4] | ROWE D M, ed. CRC Handbook of Thermoelectrics. Boca Raton: CRC Press, 1995, chap. 28. |

| [5] | VINING C B, LASKOW W, HANSON J O, et al.Thermoelectric properties of pressure-sintered Si0.8Ge0.2 thermoelectric alloys.Journal of Applied Physics, 1991, 69(8): 4333-4340. |

| [6] | KUNDU A, MINGO N, BROIDO D A, et al. Role of light and heavy embedded nanoparticles on the thermal conductivity of SiGe alloys. Physical Review B, 2011, 84(12): 125426-1-5. |

| [7] | ROWE D M, SHUKLA V S, SAVVIDES N.Phonon scattering at grain boundaries in heavily doped fine-grained silicon-germanium alloys.Nature, 1981, 290: 765-766. |

| [8] | SHI L H, JIANG J J, ZHANG G, et al. High thermoelectric figure of merit in silicon-germanium superlattice structured nanowires. Applied Physics Letters, 2012, 101(23):233114/1-233114/4. |

| [9] | LU J B, GUO R Q, DAI W J, et al.Enhanced in-plane thermoelectric figure of merit in p-type SiGe thin films by nanograin boundaries.Nanoscale, 2015, 7: 7331-7339. |

| [10] | MINNICH A J, DRESSELHAUS M S, REN Z F, et al.Bulk nanostructured thermoelectric materials: current research and future prospects.Energy & Environmental Science, 2009, 2: 466-479. |

| [11] | DRESSELHAUS M S, CHEN G, TANG M Y, et al.New directions for low dimensional thermoelectric materials.Advanced Materials, 2007, 19(8): 1043-1053. |

| [12] | JOSHI G, LEE H, LAN Y C, et al.Enhanced thermoelectric figure-of-merit in nanostructured p-type silicon germanium bulk alloys.Nano Letters, 2008, 8(12): 4670-4674. |

| [13] | WANG X W, LEE H, LN Y C, et al. Enhanced thermoelectric figure of merit in nanostructured n-type silicon germanium bulk alloy. Journal of Applied Physics, 2008, 93(19): 193121-1-3. |

| [14] | BASU R, BHATTACHARYA S, BHATT R, et al.Improved thermoelectric performance of hot pressed nanostructured n-type SiGe bulk alloys.Journal of Materials Chemistry A, 2014, 2(19): 6922-6930. |

| [15] | BATHULA S, JAYASIMHADRI M, GAHTORI B, et al.The role of nanoscale defect features in enhancing the thermoelectric performance of p-type nanostructured SiGe alloys.Nanoscale, 2015, 7(29): 12474-12483. |

| [16] | BATHULA S, JAYASIMHADRI M, SINGH N, et al. Enhanced thermoelectric figure-of-merit in spark plasma sintered nanostructured n-type SiGe alloys. Applied Physics Letters, 2012,101(21):213902/1-213902/5. |

| [17] | POUDEL B, HAO Q, MA Y, LAN Y, et al.High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys.Science, 2008, 320(5876): 634-638. |

| [18] | ZHOU X, WANG G, ZHANG L, et al.Enhanced thermoelectric properties of Ba-filled skutterudites by grain size reduction and Ag nanoparticle inclusion.Journal of Materials Chemistry, 2012, 22: 2958-2964. |

| [19] | ZHAO X Y, SHI X, CHEN L D, et al. Synthesis of YbyCo4Sb12/Yb2O3 composites and their thermoelectric properties. Applied Physics Letters, 2006, 89(9): 092121-1-3. |

| [20] | DING J, LIU R H, GU H, et al.Study on the high temperature stability of YbyCo4Sb12/Yb2O3 composite thermoelectric material. Journal of Inorganic Materials, 2014, 29(2): 209-214. |

| [21] | LI J, TAN Q, LI J, et al.BiSbTe-based nanocomposites with high ZT: the effect of SiC nanodispersion on thermoelectric properties.Advanced Functional Materials, 2013, 23(35): 4317-4323. |

| [22] | MINGO N, HAUSER D, KOBAYASHI NP, et al."Nanoparticle-in-Alloy" approach to efficient thermoelectrics: silicides in SiGe.Nano Letters, 2009, 9(2): 711-715. |

| [23] | FAVIER K, BERNARD-GRANGER G, NAVONE C, et al.Influence of in situ formed MoSi2 inclusions on the thermoelectrical properties of an N-type silicon-germanium alloy.Acta Material, 2014, 64: 429-442. |

| [1] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [2] | CHENG Jun, ZHANG Jiawei, QIU Pengfei, CHEN Lidong, SHI Xun. Preparation and Thermoelectric Transport Properties of P-doped β-FeSi2 [J]. Journal of Inorganic Materials, 2024, 39(8): 895-902. |

| [3] | CHEN Hao, FAN Wenhao, AN Decheng, CHEN Shaoping. Improvement of Thermoelectric Performance of SnTe by Energy Band Optimization and Carrier Regulation [J]. Journal of Inorganic Materials, 2024, 39(3): 306-312. |

| [4] | LI Lei, CHENG Qunfeng. Recent Advances in the High Performance MXenes Nanocomposites [J]. Journal of Inorganic Materials, 2024, 39(2): 153-161. |

| [5] | TIAN Zhen, JIANG Quanwei, LI Jianbo, YU Lifeng, KANG Huijun, WANG Tongmin. Simultaneous Optimization of Electrical and Thermal Transport Properties of BiSbSe1.50Te1.50 Thermoelectrics by Hot Deformation [J]. Journal of Inorganic Materials, 2024, 39(12): 1316-1324. |

| [6] | ZHANG Zhe, SUN Tingting, WANG Lianjun, JIANG Wan. Flexible Thermoelectric Films with Different Ag2Se Dimensions: Performance Optimization and Device Integration [J]. Journal of Inorganic Materials, 2024, 39(11): 1221-1227. |

| [7] | MENG Yuting, WANG Xuemei, ZHANG Shuxian, CHEN Zhiwei, PEI Yanzhong. Single- and Two-band Transport Properties Crossover in Bi2Te3 Based Thermoelectrics [J]. Journal of Inorganic Materials, 2024, 39(11): 1283-1291. |

| [8] | SU Haojian, ZHOU Min, LI Laifeng. Optimization of Thermoelectric Properties of SnTe via Multi-element Doping [J]. Journal of Inorganic Materials, 2024, 39(10): 1159-1166. |

| [9] | XIAO Yani, LYU Jianan, LI Zhenming, LIU Mingyang, LIU Wei, REN Zhigang, LIU Hongjing, YANG Dongwang, YAN Yonggao. Hygrothermal Stability of Bi2Te3-based Thermoelectric Materials [J]. Journal of Inorganic Materials, 2023, 38(7): 800-806. |

| [10] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [11] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [12] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [13] | CHENG Cheng, LI Jianbo, TIAN Zhen, WANG Pengjiang, KANG Huijun, WANG Tongmin. Thermoelectric Property of In2O3/InNbO4 Composites [J]. Journal of Inorganic Materials, 2022, 37(7): 724-730. |

| [14] | LOU Xunuo, DENG Houquan, LI Shuang, ZHANG Qingtang, XIONG Wenjie, TANG Guodong. Thermal and Electrcial Transport Properities of Ge Doped MnTe Thermoelectrics [J]. Journal of Inorganic Materials, 2022, 37(2): 209-214. |

| [15] | JIN Min, BAI Xudong, ZHANG Rulin, ZHOU Lina, LI Rongbin. Metal Sulfide Ag2S: Fabrication via Zone Melting Method and Its Thermoelectric Property [J]. Journal of Inorganic Materials, 2022, 37(1): 101-106. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||