无机材料学报 ›› 2019, Vol. 34 ›› Issue (10): 1128-1133.DOI: 10.15541/jim20190005 CSTR: 32189.14.10.15541/jim20190005

• 研究快报 • 上一篇

收稿日期:2019-01-03

出版日期:2019-09-23

网络出版日期:2019-05-29

CHENG Guo-Feng( ),RUAN Yin-Jie,SUN Yue,YIN Han-Di

),RUAN Yin-Jie,SUN Yue,YIN Han-Di

Received:2019-01-03

Published:2019-09-23

Online:2019-05-29

Supported by:摘要:

本研究利用原位高温衍射和高温拉曼技术对纯相BiFeO3粉体的热稳性和热膨胀性质进行了系统的解析。在升温阶段BiFeO3始终保持斜方的R3c结构, 但是在降温阶段少量BiFeO3会分解成为Bi2Fe4O9和Bi25FeO39, 这种分解可能是由氧八面体的倾斜畸变引起的。此外, 还研究了BiFeO3热力学膨胀系数, 发现它具有各向同性正膨胀性。以上结果也被拉曼光谱所证实。本研究的结果可为制备纯相BiFeO3材料提供实验指导。

中图分类号:

程国峰, 阮音捷, 孙玥, 尹晗迪. 纯相BiFeO3的热稳定和热膨胀性质研究[J]. 无机材料学报, 2019, 34(10): 1128-1133.

CHENG Guo-Feng, RUAN Yin-Jie, SUN Yue, YIN Han-Di. Thermodynamic Stability and Thermal Expansion of Pure-phase BiFeO3[J]. Journal of Inorganic Materials, 2019, 34(10): 1128-1133.

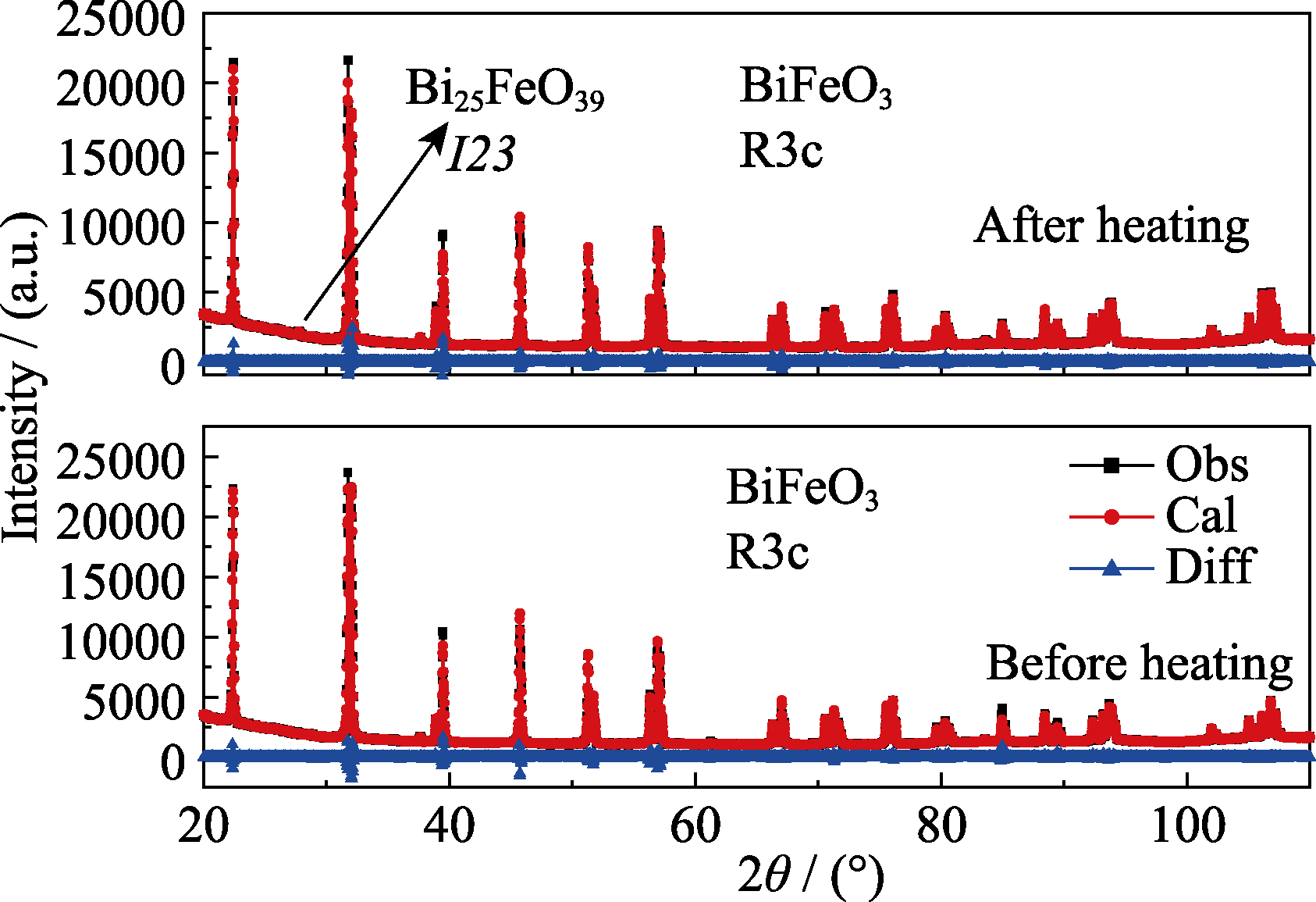

Fig. 3 Observed (black solid lines), calculated (red solid lines) and difference (blue solid lines) XRD patterns of BFO powder before and after heating process

| T/℃ | Lattice parameter | ||

|---|---|---|---|

| a/nm | c/nm | V/nm3 | |

| 25 | 0.5579253(74) | 1.387086(20) | 0.373926(11) |

| 100 | 0.5582803(68) | 1.388433(20) | 0.374766(11) |

| 200 | 0.5588673(71) | 1.390434(20) | 0.376096(11) |

| 300 | 0.5594514(79) | 1.392472(23) | 0.377435(12) |

| 400 | 0.5601610(83) | 1.394704(24) | 0.378999(13) |

| 500 | 0.5608080(19) | 1.396426(49) | 0.380344(29) |

| 600 | 0.5614370(21) | 1.397813(54) | 0.381577(32) |

| 700 | 0.5621000(24) | 1.398977(61) | 0.382797(36) |

| 800 | 0.5628300(22) | 1.399778(58) | 0.384011(34) |

Table 1 Refined lattice parameters of BFO powder in the heating process

| T/℃ | Lattice parameter | ||

|---|---|---|---|

| a/nm | c/nm | V/nm3 | |

| 25 | 0.5579253(74) | 1.387086(20) | 0.373926(11) |

| 100 | 0.5582803(68) | 1.388433(20) | 0.374766(11) |

| 200 | 0.5588673(71) | 1.390434(20) | 0.376096(11) |

| 300 | 0.5594514(79) | 1.392472(23) | 0.377435(12) |

| 400 | 0.5601610(83) | 1.394704(24) | 0.378999(13) |

| 500 | 0.5608080(19) | 1.396426(49) | 0.380344(29) |

| 600 | 0.5614370(21) | 1.397813(54) | 0.381577(32) |

| 700 | 0.5621000(24) | 1.398977(61) | 0.382797(36) |

| 800 | 0.5628300(22) | 1.399778(58) | 0.384011(34) |

| T/℃ | Atom position | Rwp/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bi | Fe | O | ||||||||

| x | y | z | x | y | z | x | y | z | ||

| 25 | 0 | 0 | 0 | 0 | 0 | 0.22124(27) | 0.46400(22) | 0.01990(16) | 0.95452(57) | 5.87 |

| 100 | 0 | 0 | 0 | 0 | 0 | 0.22129(30) | 0.46160(21) | 0.02330(17) | 0.95583(57) | 5.98 |

| 200 | 0 | 0 | 0 | 0 | 0 | 0.22227(29) | 0.44790(19) | 0.02350(18) | 0.95600(65) | 6.05 |

| 300 | 0 | 0 | 0 | 0 | 0 | 0.22039(28) | 0.45230(18) | 0.03560(17) | 0.95718(64) | 5.96 |

| 400 | 0 | 0 | 0 | 0 | 0 | 0.22192(29) | 0.43660(18) | 0.02550(18) | 0.95829(68) | 5.82 |

| 500 | 0 | 0 | 0 | 0 | 0 | 0.22325(32) | 0.42590(23) | 0.01370(23) | 0.95869(84) | 5.88 |

| 600 | 0 | 0 | 0 | 0 | 0 | 0.22484(36) | 0.41590(23) | 0.01790(24) | 0.96229(85) | 6.07 |

| 700 | 0 | 0 | 0 | 0 | 0 | 0.22400(38) | 0.43700(19) | 0.00720(18) | 0.95701(67) | 5.6 |

| 800 | 0 | 0 | 0 | 0 | 0 | 0.22376(49) | 0.43290(20) | 0.01880(21) | 0.95832(77) | 6.02 |

Table 2 Refined structural parameters of BFO powder in the heating process

| T/℃ | Atom position | Rwp/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bi | Fe | O | ||||||||

| x | y | z | x | y | z | x | y | z | ||

| 25 | 0 | 0 | 0 | 0 | 0 | 0.22124(27) | 0.46400(22) | 0.01990(16) | 0.95452(57) | 5.87 |

| 100 | 0 | 0 | 0 | 0 | 0 | 0.22129(30) | 0.46160(21) | 0.02330(17) | 0.95583(57) | 5.98 |

| 200 | 0 | 0 | 0 | 0 | 0 | 0.22227(29) | 0.44790(19) | 0.02350(18) | 0.95600(65) | 6.05 |

| 300 | 0 | 0 | 0 | 0 | 0 | 0.22039(28) | 0.45230(18) | 0.03560(17) | 0.95718(64) | 5.96 |

| 400 | 0 | 0 | 0 | 0 | 0 | 0.22192(29) | 0.43660(18) | 0.02550(18) | 0.95829(68) | 5.82 |

| 500 | 0 | 0 | 0 | 0 | 0 | 0.22325(32) | 0.42590(23) | 0.01370(23) | 0.95869(84) | 5.88 |

| 600 | 0 | 0 | 0 | 0 | 0 | 0.22484(36) | 0.41590(23) | 0.01790(24) | 0.96229(85) | 6.07 |

| 700 | 0 | 0 | 0 | 0 | 0 | 0.22400(38) | 0.43700(19) | 0.00720(18) | 0.95701(67) | 5.6 |

| 800 | 0 | 0 | 0 | 0 | 0 | 0.22376(49) | 0.43290(20) | 0.01880(21) | 0.95832(77) | 6.02 |

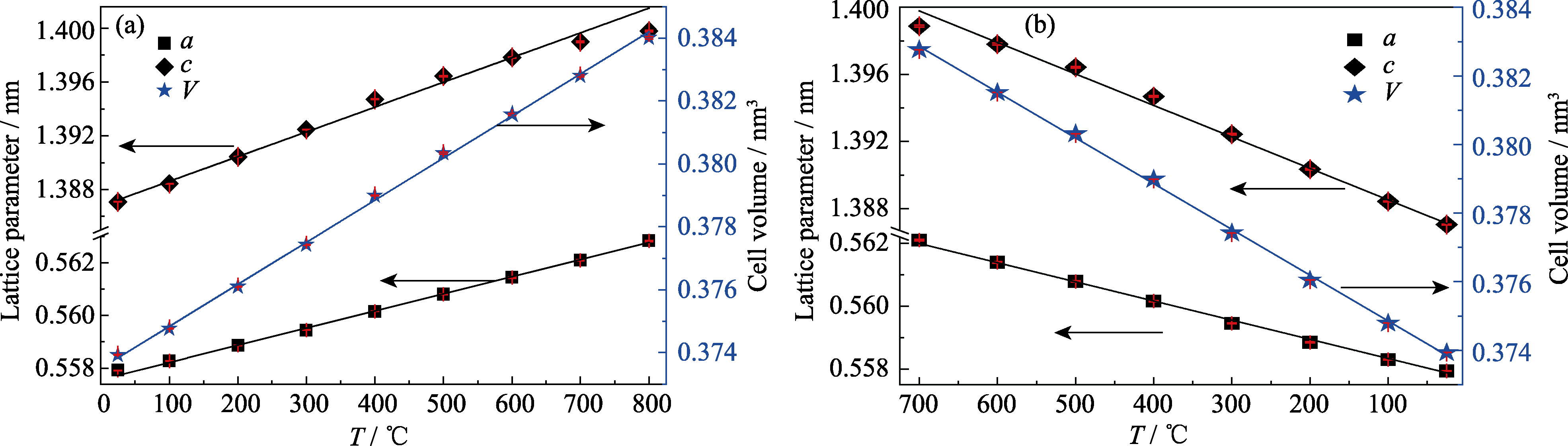

Fig. 4 Lattice parameters and cell volume of BFO in the heating process (temperature regime 25-800 ℃, (a)) and cooling process (temperature regime 700-25 ℃, (b))

| Sample | Temperature/ ℃ | αTa/ (×10-6,℃-1) | αTc/ (×10-6,℃-1) | αTV/ (×10-6,℃-1) |

|---|---|---|---|---|

| BiFeO3 | 25-800 | 11.34 | 11.81 | 34.80 |

Table 3 The thermal linear and volumetric expansion coefficients of pure BFO

| Sample | Temperature/ ℃ | αTa/ (×10-6,℃-1) | αTc/ (×10-6,℃-1) | αTV/ (×10-6,℃-1) |

|---|---|---|---|---|

| BiFeO3 | 25-800 | 11.34 | 11.81 | 34.80 |

| [1] | CARVALHO T T, TAVARES P B . Synthesis and thermodynamic stability of multiferroic BiFeO3. Mater. Lett., 2008,62(24):3984-3986. |

| [2] | BERNARDO M S, JARDIEL T, PEITEADO M , et al. Reaction pathways in the solid state synjournal of multiferroic BiFeO3.[J]. Eur. Ceram. Soc., 2011,31(16):3047-3053. |

| [3] | RANGI M, SANGHI S, JANGRA S , et al. Crystal structure transformation and improved dielectric and magnetic properties of La-substituted BiFeO3 multiferroics. Ceram. Int., 2017,43(15):12095-12101. |

| [4] | MICHEL C, MOREAU J M, ACHENBACH G D , et al. The atomic structure of BiFeO3. Solid State Com., 1969,7(9):701-704. |

| [5] | CHATURVEDI S, BAG R, SATHE V , et al. Holmium induced enhanced functionality at room temperature and structural phase transition at high temperature in bismuth ferrite nanoparticles. J. Mater. Chem. C, 2016,4(4):780-792. |

| [6] | WEI J, HAUMONT R, JARRIER R , et al. Nonmagnetic Fe-site doping of BiFeO3 multiferroic ceramics. Appl. Phys. Lett., 2010,96(10):102509. |

| [7] | GAUTAM A, RANGRA V S . Effect of Ba ions substitution on multiferroic properties of BiFeO3 perovskite. Cryst. Res. Technol., 2010,45(9):953-956. |

| [8] | NALWA K S, GARG A, UPADHYAYA A . Effect of samarium doping on the properties of solid-state synthesized multiferroic bismuth ferrite. Mater. Lett., 2008,62(6/7):878-881. |

| [9] | WANG Y P, ZHOU L, ZHANG M F , et al. Room-temperature saturated ferroelectric polarization in BiFeO3 ceramics synthesized by rapid liquid phase sintering. Appl. Phys. Lett., 2004,84(10):1731-1733. |

| [10] | ZHANG S T, LU M H, WU D , et al. Larger polarization and weak ferromagnetism in quenched BiFeO3 ceramics with a distorted rhombohedral crystal structure. App. Phy. Lett., 2005,87(26):262907. |

| [11] | SELBACH S M, TYBELL T, EINARSRUD M A , et al. Size-dependent properties of multiferroic BiFeO3 nanoparticles. Chem. Mater., 2007,19:6478-6484. |

| [12] | ZHANG L, CAO X F, MA Y L , et al. Polymer-directed synjournal and magnetic property of nanoparticles-assembled BiFeO3 microrods.[J]. Solid. State. Chem., 2010,183(8):1761-1766. |

| [13] | KUMAR M M, PALKAR V R, SRINIVAS K , et al. Ferroelectricity in a pure BiFeO3 ceramic. Appl. Phys. Lett., 2000,76(19):2764-2766. |

| [14] | SELBACH S M, EINARSRUD M A, GRANDE T . On the thermodynamic stability of BiFeO3. Chem. Mater., 2009,21(1):169-173. |

| [15] | CHENG G F, RUAN Y J, LIU W , et al. Effect of temperature variation on the phase transformation in the reaction sintering of BiFeO3 ceramics. Mater. Lett., 2015,143:330-332. |

| [16] | CHEN J, FAN L, REN Y , et al, Unusual transformation from strong negative to positive thermal expansion in PbTiO3-BiFeO3 perovskite. Phys. Rev. Lett., 2013,110:115901. |

| [17] | BHATTACHARJEE S, TAJI K, MORIYOSHI C , et al. Temperature- induced isostructural phase transition, associated large negative volume expansion, and the existence of a critical point in the phase diagram of the multiferroic (1-x)BiFeO3-xPbTiO3 solid solution system. Phys. Rev. B, 2011,84(10):104116. |

| [18] | KLYNDYUK A I, CHIZHOVA E A . Structure, thermal expansion, and electrical properties of BiFeO3-NdMnO3, solid solutions. Inorg. Mater., 2015,51(3):272-277. |

| [19] | CHEN J, XING X R, LIU G R . Structure and negative thermal expansion in the PbTiO3-BiFeO3 system. Appl. Phys. Lett., 2006,89:101914. |

| [20] | PALAI R, KATIYAR R S, SCHMID H , et al. β, phase and γ-β, metal-insulator transition in multiferroic BiFeO3. Phys. Rev. B, 2008,77(1):014110. |

| [21] | GUSEV A I, SADOVNIKOV S I, CHUKIN A V , et al. Thermal expansion of nanocrystalline and coarse-crystalline silver sulfide Ag2S. Phys. Solid State, 2016,58(2):251-257. |

| [22] | KESKAR M, KRISHNAN K, DAHALE N D . Thermal expansion studies on Th(MoO4)2, Na2Th(MoO4)3, and Na4Th(MoO4)4.[J]. Alloys Compounds, 2008,458(1):104-108. |

| [23] | HALVARSSON M, LANGER V ,VUORINEN S. Determination of the thermal expansion of κ-Al2O3, by high temperature XRD. Surf. Coat. Tech., 1995, 76- 77(5):358-362. |

| [24] | KUBEL F, SCHMID H . Structure of a ferroelectric and ferroelastic monodomain crystal of the perovskite BiFeO3. Acta Cryst., 1990,B46:698-702. |

| [25] | FIZA M, HASSNAIN J G, ISMAT S S . Peculiar magnetism in Eu substituted BiFeO3 and its correlation with local structure. J. Phys.:Condens. Matter, 2018,30:435802. |

| [26] | PANDEY R, PANDA C, KUMAR P , et al. Phase diagram of Sm and Mn co-doped bismuth ferrite based on crystal structure and magnetic properties.[J]. Sol-Gel Sci. Technol., 2018,85:166-177. |

| [1] | 戴乐, 刘洋, 高轩, 王书豪, 宋雅婷, 唐明猛, 刘丽莎, 汪尧进. 浓度梯度掺杂实现BiFeO3薄膜自极化[J]. 无机材料学报, 2024, 39(1): 99-106. |

| [2] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [3] | 李汪国, 刘佃光, 王珂玮, 马百胜, 刘金铃. 闪烧合成高熵氧化物陶瓷(MgCoNiCuZn)O的性能[J]. 无机材料学报, 2022, 37(12): 1289-1294. |

| [4] | 李铁, 李玥, 王颖异, 张珽. 石墨烯-铁酸铋纳米晶复合材料的制备及其催化性能研究[J]. 无机材料学报, 2021, 36(7): 725-732. |

| [5] | 桑玮玮, 张红松, 陈华辉, 温斌, 李新春. (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7高熵陶瓷的制备及热物理性能[J]. 无机材料学报, 2021, 36(4): 405-410. |

| [6] | 樊文琪, 宋雪梅, 黄怡玲, 常程康. CMAS对YSZ涂层腐蚀引起的结构变化及其相变分布[J]. 无机材料学报, 2021, 36(10): 1059-1066. |

| [7] | 喻瑛, 杜红亮, 杨泽田, 靳立, 屈绍波. 无铅块体陶瓷的电卡效应: 现状与挑战[J]. 无机材料学报, 2020, 35(6): 633-646. |

| [8] | 刘小根,包亦望,万德田,孙与康. 硫化镍引发钢化玻璃自爆的临界尺寸及影响[J]. 无机材料学报, 2020, 35(2): 211-216. |

| [9] | 徐东, 朱钰方, 郑元义, 罗宇, 陈航榕. 可注射磁性液固相变材料用于骨肉瘤的磁共振成像与低温磁热治疗研究[J]. 无机材料学报, 2020, 35(11): 1277-1282. |

| [10] | 韩刘洋, 郭少波, 闫世光, RÉMIENSDenis, 王根水, 董显林. Pb0.3CaxSr0.7-xTiO3陶瓷的室温电卡效应[J]. 无机材料学报, 2019, 34(9): 1011-1014. |

| [11] | 张晓晨, 王雪梅, 王春雷. 烧结方式对(K,Na,Li)(Nb,Sb,Ta)O3压电陶瓷的微观结构和物理性能的影响[J]. 无机材料学报, 2019, 34(7): 721-726. |

| [12] | 欧阳婷, 陈云博, 蒋朝, 费又庆. 以中间相沥青为粘结剂的低密度高导热炭纤维网络体的研究[J]. 无机材料学报, 2019, 34(10): 1030-1034. |

| [13] | 陈弘毅, 史迅, 陈立东, 仇鹏飞. Cu2S相变过程中热扩散系数的精确测量和解析[J]. 无机材料学报, 2019, 34(10): 1041-1046. |

| [14] | 程国峰, 阮音捷, 孙玥, 尹晗迪, 解其云. 元素配比对BiFeO3反应烧结相变影响的高温X射线衍射研究[J]. 无机材料学报, 2019, 34(10): 1035-1040. |

| [15] | 宋建民, 代秀红, 梁杰通, 赵磊, 周阳, 葛大勇, 孟旭东, 刘保亭. 偏轴磁控溅射法外延BiFeO3薄膜的介电性能与阻变效应[J]. 无机材料学报, 2018, 33(9): 1017-1021. |

| 阅读次数 | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

全文 850

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

摘要 651

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||