无机材料学报 ›› 2019, Vol. 34 ›› Issue (3): 279-293.DOI: 10.15541/jim20180465 CSTR: 32189.14.10.15541/jim20180465

所属专题: 庆祝上海硅酸盐所独立建所60周年虚拟专刊!; 热电材料与器件; 优秀作者论文集锦; 优秀作者作品欣赏:能源材料

张骐昊, 柏胜强, 陈立东

收稿日期:2018-10-08

修回日期:2018-10-29

出版日期:2019-03-20

网络出版日期:2018-11-01

作者简介:张骐昊(1988-), 男, 博士, 助理研究员. E-mail: zhangqh@mail.sic.ac.cn

基金资助:ZHANG Qi-Hao, BAI Sheng-Qiang, CHEN Li-Dong

Received:2018-10-08

Revised:2018-10-29

Published:2019-03-20

Online:2018-11-01

Supported by:摘要:

热电发电技术在特种电源、绿色能源、环境能量收集与工业余热发电等领域具有重要的应用价值。近年来, 热电材料zT值的纪录不断被刷新, 为热电器件应用技术的发展奠定了坚实的基础。然而, 目前热电应用技术远滞后于热电材料科学的发展, 特别是热电发电技术的大规模应用仍面临着技术瓶颈和挑战。本文介绍了热电器件设计与集成的基本原理及其关键科学与技术问题, 着重总结了器件集成中的界面结构设计与优化、电极连接与器件一体化制备技术、器件服役性能与寿命评价等方面的最新研究进展。同时, 分析和展望了热电发电技术规模化应用面临的挑战与发展策略。

中图分类号:

张骐昊, 柏胜强, 陈立东. 热电发电器件与应用技术: 现状、挑战与展望[J]. 无机材料学报, 2019, 34(3): 279-293.

ZHANG Qi-Hao, BAI Sheng-Qiang, CHEN Li-Dong. Technologies and Applications of Thermoelectric Devices: Current Status, Challenges and Prospects[J]. Journal of Inorganic Materials, 2019, 34(3): 279-293.

图1 热电材料与器件发展态势(a)热电材料zT值[6,7], (b)热电发电器件转换效率[10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40]

Fig. 1 Timelines underscoring the improvement in (a) zT value of typical thermoelectric materials[6,7] and (b) conversion efficiency of typical thermoelectric power generation devices[10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40]

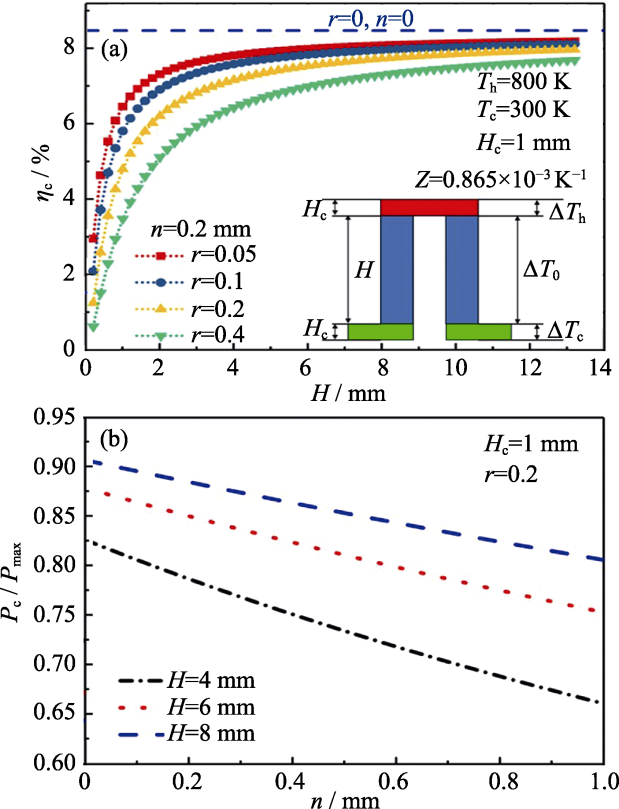

图5 (a)具有不同接触热阻的热电单偶转换效率随热电偶臂高度H的变化关系和(b)具有不同热电偶臂高度的热电单偶相对输出功率随接触电阻参数n的变化关系[46]

Fig. 5 (a) Conversion efficiency as a function of thermoelectricelement height for different thermal contact parameter,r,and (b) power output ratio Pc/Pmax as a function of the electrical contact parameter,n, for different thermoelectric element height[46]

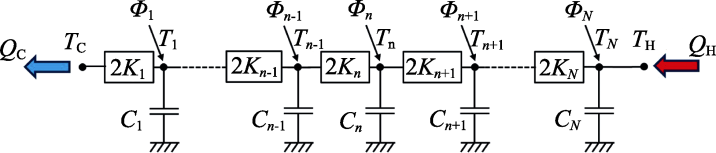

图7 热电效应的等效示意图(热容 $C_{n}=\rho ·n·C_{p_{n}}·\frac{H}{N}·A$ , 热导${{K}_{n}}=\frac{{{k}_{n}}\cdot A}{H\text{/}N}$) [55]

Fig. 7 Analogical scheme of the thermoelectric phenomena with the thermal capacitances $C_{n}=\rho ·n·C_{p_{n}}·\frac{H}{N}·A$ and thermal conductances $K_{n}=\frac{k_{n}·A}{H/N}$ [55]

| Thermoelectric material | (Th/Tc)/℃ | Electrode | Interface layer | Joining method | Ref. |

|---|---|---|---|---|---|

| Bismuth telluride | 240/22 | Cu | Ni | Soldering | [59-60] |

| Bismuth telluride | - | - | Ni | One-step hot press sintering | [61] |

| Bismuth telluride | 200/- | Cu | Ni | Solid-liquid diffusion welding | [62] |

| Bismuth telluride | 250/50 | Al | Mo | Plasma spraying | [63] |

| Bismuth telluride | 240/20 | Cu | Mo | Arc spraying | [64] |

| MgAg0.965Ni0.005Sb0.99 | 245/20 | Ag | - | Diffusion welding | [65] |

| Poly[Ax(M-ett)] | 147/67 | Hot side: Al | Au | [66] | |

| Cold side: Ag | |||||

| n-type PbTe + p-type TAGS 85 | 500/100 | Ag | Ag/Fe/Ag + Fe | Diffusion welding | [25] |

| Skutterudite | 500/40 | Al | Mo | Brazing | [67] |

| Skutterudite | 550/70 | n-type: CoSi2 | [31] | ||

| p-type: Co2Si | |||||

| Skutterudite | 600/35 | Hot side: Mo-Cu Cold side: Cu | Ti-Al | Brazing | [17] |

| n-type Bi2Te3/PbTe + p-type Sb2Te3/PbTe | 600/10 | Cu | Hot side: Co0.8Fe0.2 | Liquid InGa eutectic alloy | [35] |

| Cold side: Ni | |||||

| Bismuth telluride/ Skutterudite | 600/35 | Hot side: Mo-Cu | Hot side: Ti-Al | Welding | [40] |

| Cold side: Cu | Cold side: Ni | ||||

| Half-Heusler | 718/63 | Hot side: Mo-Cu | Brazing | [18] | |

| Cold side: Cu | |||||

| n-type Fe0.93Co0.07Si1.99Al0.01 + p-type MnSi1.73 | 700/100 | TiSi2 | Welding | [19] | |

| SiGealloy | 870/31 | Mo | Pressure contact | Cold side In welding | [68] |

| SiGe alloy | 553/44 | Mo | C | Brazing | [69] |

| SiGe alloy | 1000/300 | With Ti layer | Diffusion welding | [70] | |

| n-type Ca0.92La0.08MnO3 + p-type Ca2.75Gd0.25Co4O9 | 773 /383 | Silver electrode | Silver paste | [71] | |

| p-type Mg2Si0.53Sn0.4Ge0.05Bi0.02 + n-type MnSi1.75Ge0.01 | 735/50 | Hot side: Mo | p-type: Ni/Pb/Ni | Spring contact | [37] |

| Cold side: Cu | n-type: Cu |

表1 典型热电发电元件的电极材料、过渡层材料及其连接方式

Table 1 Electrode, interface layer and joining method of typical thermoelectric devices

| Thermoelectric material | (Th/Tc)/℃ | Electrode | Interface layer | Joining method | Ref. |

|---|---|---|---|---|---|

| Bismuth telluride | 240/22 | Cu | Ni | Soldering | [59-60] |

| Bismuth telluride | - | - | Ni | One-step hot press sintering | [61] |

| Bismuth telluride | 200/- | Cu | Ni | Solid-liquid diffusion welding | [62] |

| Bismuth telluride | 250/50 | Al | Mo | Plasma spraying | [63] |

| Bismuth telluride | 240/20 | Cu | Mo | Arc spraying | [64] |

| MgAg0.965Ni0.005Sb0.99 | 245/20 | Ag | - | Diffusion welding | [65] |

| Poly[Ax(M-ett)] | 147/67 | Hot side: Al | Au | [66] | |

| Cold side: Ag | |||||

| n-type PbTe + p-type TAGS 85 | 500/100 | Ag | Ag/Fe/Ag + Fe | Diffusion welding | [25] |

| Skutterudite | 500/40 | Al | Mo | Brazing | [67] |

| Skutterudite | 550/70 | n-type: CoSi2 | [31] | ||

| p-type: Co2Si | |||||

| Skutterudite | 600/35 | Hot side: Mo-Cu Cold side: Cu | Ti-Al | Brazing | [17] |

| n-type Bi2Te3/PbTe + p-type Sb2Te3/PbTe | 600/10 | Cu | Hot side: Co0.8Fe0.2 | Liquid InGa eutectic alloy | [35] |

| Cold side: Ni | |||||

| Bismuth telluride/ Skutterudite | 600/35 | Hot side: Mo-Cu | Hot side: Ti-Al | Welding | [40] |

| Cold side: Cu | Cold side: Ni | ||||

| Half-Heusler | 718/63 | Hot side: Mo-Cu | Brazing | [18] | |

| Cold side: Cu | |||||

| n-type Fe0.93Co0.07Si1.99Al0.01 + p-type MnSi1.73 | 700/100 | TiSi2 | Welding | [19] | |

| SiGealloy | 870/31 | Mo | Pressure contact | Cold side In welding | [68] |

| SiGe alloy | 553/44 | Mo | C | Brazing | [69] |

| SiGe alloy | 1000/300 | With Ti layer | Diffusion welding | [70] | |

| n-type Ca0.92La0.08MnO3 + p-type Ca2.75Gd0.25Co4O9 | 773 /383 | Silver electrode | Silver paste | [71] | |

| p-type Mg2Si0.53Sn0.4Ge0.05Bi0.02 + n-type MnSi1.75Ge0.01 | 735/50 | Hot side: Mo | p-type: Ni/Pb/Ni | Spring contact | [37] |

| Cold side: Cu | n-type: Cu |

图10 在550 ℃不同老化时间下的CoSb3/Ti/Mo-Cu界面扫描电镜照片[115]

Fig. 10 Scanning electron microscope images of CoSb3/Ti/Mo-Cu interface after thermal aging at 550 ℃ for different periods[115](a) 0; (b) 8 d; (c) 20 d; (d) 30 d

图11 (a)Ti(100-x)Alx-Yb0.6Co4Sb12界面结构形成示意图; (b)600 ℃、真空条件下Ti(100-x)Alx-Yb0.6Co4Sb12元件界面扩散层厚度随热持久时间的演化; (c)600 ℃、真空条件下Ti(100-x)Alx-Yb0.6Co4Sb12元件接触电阻率随热持久时间的演化[79]

Fig. 11 (a) Schematic diagram of the formation of Ti(100-x)Alx-Yb0.6Co4Sb12 interface, (b) the diffusion layer thickness and (c) specificcontact resistivity of the Ti(100-x)Alx-Yb0.6Co4Sb12 interface as a function of the thermal aging time under 600 ℃ and vacuum condition[79]

| [1] | ROWE D M. Modules, Systems,Applications in Thermoelectrics. Boca Raton: CRC Press, 2012. |

| [2] | KRAEMER D, JIE Q, MCENANEY K, et al.Concentrating solar thermoelectric generators with a peak efficiency of 7.4%. Nat. Energy, 2016, 1(11): 16153. |

| [3] | SUAREZ F, NOZARIASBMARZ A, VASHAEE D, et al.Designing thermoelectric generators for self-powered wearable electronics. Energy Environ. Sci., 2016, 9(6): 2099-2113. |

| [4] | CHAMPIER D.Thermoelectric generators: a review of applications. Energy Convers. Manage., 2017, 140: 167-181. |

| [5] | ROWE D M.CRC Handbook of Thermoelectrics. CRC Press, 1995. |

| [6] | SHI X, CHEN L, UHER C.Recent advances in high-performance bulk thermoelectric materials. Int. Mater. Rev., 2016, 61(6): 1-37. |

| [7] | QIN Y T, ZHANG Q H, QIU P F, et al.High-performance bulk thermoelectric materials and devices. Science Foundation in China, 2016, 24(4): 67-80. |

| [8] | AN H C, SEON J H.Thermoelectric generator for vehicle. US8839614. 2014. |

| [9] | KIM T Y, NEGASH A A, CHO G.Waste heat recovery of a diesel engine using a thermoelectric generator equipped with customized thermoelectric modules. Energy Convers. Manage., 2016, 124: 280-286. |

| [10] | KUROKI T, KABEYA K, MAKINO K, et al.Thermoelectric generation using waste heat in steel works. [J]. Electron. Mater., 2014, 43(6): 2405-2410. |

| [11] | BENNETT G L.Space Applications. in CRC Handbook of Thermoelectrics. ed Rowe D M, CRC Press, 1995, 515-537. |

| [12] | ZHANG J Z. Thermoelectric Technology.Tianjin: Tianjin Science and Technology Press, 2013. |

| [13] | HAO F, QIU P, TANG Y, et al.High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 ℃. Energy Environ. Sci., 2016, 9(10): 3120-3127. |

| [14] | GUO J Q, GENG H Y, OCHI T, et al.Development of skutterudite thermoelectric materials and modules. [J]. Electron. Mater., 2012, 41(6): 1036-1042. |

| [15] | GENG H, OCHI T, SUZUKI S, et al.Thermoelectric properties of multifilled skutterudites with La as the main filler. [J]. Electron. Mater., 2013, 42(7): 1999-2005. |

| [16] | BARTHOLOMÉ K, BALKE B, ZUCKERMANN D, et al.Thermoelectric modules based on half-Heusler materials produced in large quantities. [J]. Electron. Mater., 2014, 43(6): 1775-1781. |

| [17] | ZHANG Q, ZHOU Z, DYLLA M, et al.Realizing high-performance thermoelectric power generation through grain boundary engineering of skutterudite-based nanocomposites. Nano Energy, 2017, 41: 501-510. |

| [18] | FU C G, BAI S Q, LIU Y, et al. Realizing high figure of merit in heavy-band p-type half-Heusler thermoelectric materials. Nat. Commun., 2015, 6: 8144-1-7. |

| [19] | GROB E, RIFFEL M, STÖHRER U. Thermoelectric generators made of FeSi2 and HMS: fabrication and measurement. [J]. Mater. Res., 1995, 10: 34-40. |

| [20] | CAILLAT T, FLEURIAL J P, SNYDER G N, et al.Development of High Efficiency Segmented Thermoelectric Unicouples. 20th International Conference on Thermoelectrics, Beijing, China, 2001: 282-285. |

| [21] | AOYAMA I, KAIBE H, RAUSCHER L, et al.Doping effects on thermoelectric properties of higher manganese silicides (HMSs, MnSi1.74) and characterization of thermoelectric generating module using, p-type (Al, Ge and Mo)-doped HMSs and n-type Mg2Si0.4Sn0.6 legs. Jpn. J. Appl. Phys., 2005, 44(6A): 4275-4281. |

| [22] | EL-GENK M S, SABER H H, CAILLAT T, et al. Tests results and performance comparisons of coated and uncoated skutterudite based segmented unicouples. Energy Convers. Manage., 2006, 47(2): 174-200. |

| [23] | HORI Y, ITO T.Fabrication of 500 ℃ Class Thermoelectric Module and Evaluation of its High Temperature Stability. 25th International Conference on Thermoelectrics, Vienna, Austria, 2006: 642-645. |

| [24] | SABER H H, EL-GENK M S, CAILLAT T. Tests results of skutterudite based thermoelectric unicouples. Energy Convers. Manage., 2007, 48(2): 555-567. |

| [25] | SINGH A, BHATTACHARYA S, THINAHARAN C, et al. Development of low resistance electrical contacts for thermoelectric devices based on n-type PbTe and p-type TAGS-85 ((AgSbTe2)0.15(GeTe)0.85). J. Phys. D Appl. Phys., 2009, 42(1): 015502-1-5. |

| [26] | VIKHOR L N, ANATYCHUK L I.Generator modules of segmented thermoelements. Energy Convers. Manage., 2009, 50(9): 2366-2372. |

| [27] | ZHAO D, TIAN C, TANG S, et al.Fabrication of a CoSb3-based thermoelectric module. Mater. Sci. Semicon. Proc., 2010, 13(3): 221-224. |

| [28] | POON S J, WU D, ZHU S, et al.Half-Heusler phases and nanocomposites as emerging high-ZT thermoelectric materials. [J]. Mater. Res., 2011, 26(22): 2795-2802. |

| [29] | ANATYCHUK L I, VIKHOR L N, STRUTYNSKA L T, et al.Segmented generator modules using Bi2Te3-based materials. [J]. Electron. Mater., 2011, 40(5): 957-961. |

| [30] | SEETAWAN T. Designing and fabricating of low cost thermoelectric power generators. Appl. Mechan. Mater., 2011, 110-116: 4101-4105. |

| [31] | MUTO A, YANG J, POUDEL B, et al.Skutterudite unicouple characterization for energy harvesting applications. Adv. Energy Mater., 2013, 3(2): 245-251. |

| [32] | TAKABATAKE T.Nano-cage Structured Materials: Clathrates. in Thermoelectric Nanomaterials: Materials Design and Application[M]//KOUMOTO K, MORI T. Springer, Heidelberg, 2013, 33-49. |

| [33] | KRAEMER D, SUI J, MCENANEY K, et al.High thermoelectric conversion efficiency of MgAgSb-based material with hot-pressed contacts. Energy Environ. Sci., 2015, 8(4): 1299-1308. |

| [34] | LE T H, NONG N V, SNYDER G J, et al.High performance p-type segmented leg of misfit-layered cobaltite and half-Heusler alloy. Energy Convers. Manage., 2015, 99: 20-27. |

| [35] | HU X, YAMAMOTO A, NAGASE K.Characterization of half-Heusler unicouple for thermoelectric conversion. [J]. Appl. Phys., 2015, 117(22): 1457-1461. |

| [36] | BALAYA P.High-efficiency energy harvesting using TAGS-85/half-Heusler thermoelectric devices. Energy Harvesting and Storage: Materials, Devices, and Applications V, 2014, 9115: 911507. |

| [37] | SKOMEDAL G, HOLMGREN L, MIDDLETON H, et al.Design, assembly and characterization of silicide-based thermoelectric modules. Energy Convers. Manage., 2016, 110: 13-21. |

| [38] | ZONG P A, HANUS R, DYLLA M, et al.Skutterudite with graphene-modified grain-boundary complexion enhances zT enabling high-efficiency thermoelectric device. Energy Environ. Sci., 2017, 10(1): 183-191. |

| [39] | HU X, JOOD P, OHTA M, et al.Power generation from nanostructured PbTe-based thermoelectrics: comprehensive development from materials to modules. Energy Environ. Sci., 2016, 9(2): 517-529. |

| [40] | ZHANG Q, LIAO J, TANG Y, et al.Realizing thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy-loss minimized integration. Energy Environ. Sci., 2017, 10(4):956-963. |

| [41] | WHALEN S A, APBLETT C A, ASELAGE T L.Improving power density and efficiency of miniature radioisotopic thermoelectric generators. [J]. Power Sources, 2008, 180(1): 657-663. |

| [42] | HAMMEL T, BENNETT R, OTTING W, et al. Multi-mission Radioisotope Thermoelectric Generator (MMRTG) and Performance Prediction Model. Int. Energy Convers. Engineer. Conf., 2013: 551-555. |

| [43] | SONG J Q, SHI X, ZHANG W Q, et al.Heat conduction in thermoelectric materials and micro-devices. Physics, 2013, 42(2): 112-123. |

| [44] | ZHANG F, ZANG Y, HUANG D, et al. Flexible and self-powered temperature-pressure dual-parameter sensors using microstructure-frame-supported organic thermoelectric materials. Nat. Commun., 2015, 6: 8356-1-10. |

| [45] | CHEN L D, LIU R H, SHI X.Thermoelectric Materials and Devices. Beijing: Science Press, 2017. |

| [46] | ZHANG Q H, HUANG X Y, BAI S Q, et al.Thermoelectric devices for power generation: recent progress and future challenges. Adv. Eng. Mater., 2016, 18(2): 194-213. |

| [47] | CHEN J, YAN Z, WU L.The influence of Thomson effect on the maximum power output and maximum efficiency of a thermoelectric generator. [J]. Appl. Phys., 1996, 79(11): 8823-8828. |

| [48] | FRAISSE G, RAMOUSSE J, SGORLON D, et al.Comparison of different modeling approaches for thermoelectric elements. Energy Convers. Manage., 2013, 65(1): 351-356. |

| [49] | CHEN L, GONG J, SUN F, et al.Effect of heat transfer on the performance of thermoelectric generators. Int. [J]. Therm. Sci., 2002, 41(1): 95-99. |

| [50] | LEE H S.Optimal design of thermoelectric devices with dimensional analysis. Appl. Energy, 2013, 106(11): 79-88. |

| [51] | MONTECUCCO A, BUCKLE J R, KNOX A R.Solution to the 1-D unsteady heat conduction equation with internal Joule heat generation for thermoelectric devices. Appl. Therm. Engineer., 2012, 35(3): 177-184. |

| [52] | CHEN M, ROSENDAHL L A, CONDRA T.A three-dimensional numerical model of thermoelectric generators in fluid power systems. Int. [J]. Heat Mass Trans., 2011, 54(1/2/3): 345-355. |

| [53] | CHENG C H, HUANG S Y, CHENG T C.A three-dimensional theoretical model for predicting transient thermal behavior of thermoelectric coolers. Int. [J]. Heat Mass Trans., 2010, 53(9): 2001-2011. |

| [54] | CHEN W H, LIAO C Y, HUNG C I.A numerical study on the performance of miniature thermoelectric cooler affected by Thomson effect. Appl. Energy, 2012, 89(1): 464-473. |

| [55] | FRAISSE G, LAZARD M, GOUPIL C, et al.Study of a thermoelement’s behaviour through a modelling based on electrical analogy. Int. [J]. Heat Mass Trans., 2010, 53(17/18): 3503-3512. |

| [56] | ANTONOVA E E, LOOMAN D C.Finite Elements for Thermoelectric Device Analysis in ANSYS. International Conference on Thermoelectrics. IEEE Xplore, 2005: 215-218. |

| [57] | XU J F. ANSYS Workbench 15. 0. Publishing House of Electronics Industry, Beijing, China, 2014. |

| [58] | JIA X D.Studies on the Properties of Thermoelectric Materials and Coupled Thermal-El-Mechanical Behaviors of Thermoelectric Devices. Lanzhou: Lanzhou University dissertation, PhD, 2015. |

| [59] | BUIST R J, ROMAN S J.Development of a Burst Voltage Measurement System for High-Resolution Contact Resistance Tests of Thermoelectric Heterojunctions. Eighteenth International Conference on Thermoelectrics. IEEE, 1999: 249-251. |

| [60] | LIAO C N, LEE C H, CHEN W J.Effect of interfacial compound formation on contact resistivity of soldered junctions between bismuth telluride-based thermoelements and copper. Electrochem. Solid-State Lett., 2007, 10(9): P23-P25. |

| [61] | FENG S P, CHANG Y H, YANG J, et al.Reliable contact fabrication on nanostructured Bi2Te3-based thermoelectric materials. Phys, Chem. Chem. Phys., 2013, 15(18): 6757-6762. |

| [62] | LIN Y C, YANG C L, HUANG J Y,et al.Low-temperature bonding of Bi0.5Sb1.5Te3 thermoelectric material with Cu electrodes using a thin-film In interlayer. Metall. Mater. Trans. A, 2016, 47(9): 4767-4776. |

| [63] | LEAVITT F A, BASS J C, ELSNER N B.Thermoelectric Module with Gapless Eggcrate. US5875098A, 1999. |

| [64] | 陈立东,李菲,黄向阳, 等. 一种碲化铋基热电发电器件及其制造方法. CN102412366A, 2011. |

| [65] | KRAEMER D, SUI J, MCENANEY K, et al.High thermoelectric conversion efficiency of MgAgSb-based material with hot-pressed contacts. Energy Environ. Sci., 2015, 8(4): 1299-1308. |

| [66] | SUN Y, SHENG P, DI C, et al.Organic thermoelectric materials and devices based on p- and n-type poly (metal 1, 1, 2, 2-ethenetetrathiolate)s. Adv. Mater., 2012, 24(7): 932-937. |

| [67] | SALVADOR J R, CHO J Y, YE Z, et al.Conversion efficiency of skutterudite-based thermoelectric modules. Phys. Chem. Chem. Phys., 2014, 16(24): 12510-12520. |

| [68] | ABELES B, COHEN R W.Ge-Si thermoelectric power generator. [J]. Appl. Phys., 1964, 35(1): 247-248. |

| [69] | TAGUCHI K, TERAKADO K, OGUSU M, et al.Linear-shaped Si-Ge thermoelectric module.Semiconductors, 2000: 53-57. |

| [70] | NAKAHARA JF, FRANKLIN B, DEFILLIPO LE.Development of an improved performance SiGe unicouple. AIP Conf. Proc., 1995, 324: 809-814. |

| [71] | MATSUBARA I, FUNAHASHI R, TAKEUCHI T, et al.Fabrication of an all-oxide thermoelectric power generator. Appl. Phys. Lett., 2001, 78(23): 3627-3629. |

| [72] | FAN J, CHEN L, BAI S, et al.Joining of Mo to CoSb3 by spark plasma sintering by inserting a Ti interlayer. Mater. Lett., 2004, 58(30): 3876-3878. |

| [73] | WOJCIECHOWSKI K T, ZYBALA R, MANIA R.High temperature CoSb3-Cu junctions. Microelectron. Reliab., 2011, 51(7): 1198-1202. |

| [74] | ZHAO D G, LI X Y, JIANG W, et al.Fabrication of CoSb3/MoCu thermoelectric joint by one-step SPS and evaluation. [J]. Inorg. Mater., 2009, 24(3): 545-548. |

| [75] | ZHAO D G, WANG L, CAI Y H, et al.One-step sintering of CoSb3 thermoelectric material and Cu-W alloy by spark plasma sintering. Mater. Sci. Forum., 2009: 389-393. |

| [76] | TANG Y S, BAI S Q, REN D D, et al.Interface structure and electrical property of Yb0.3Co4Sb12/Mo-Cu element prepared by welding using Ag-Cu-Zn Solder. [J]. Inorg. Mater., 2015, 30(3): 256-260. |

| [77] | REN Z F, LAN Y C, ZHANG Q Y.Advanced Thermoelectrics: Materials, Contacts, Devices, and System. CRC Press, 2018. |

| [78] | ZHAO D, LI X, HE L, et al.High temperature reliability evaluation of CoSb3/electrode thermoelectric joints. Intermetallics, 2009, 17(3): 136-141. |

| [79] | GU M, XIA X, LI X, et al.Microstructural evolution of the interfacial layer in the Ti-Al/Yb0. 6Co4Sb12 thermoelectric joints at high temperature. [J]. Alloys Compd., 2014, 610:665-670. |

| [80] | FLEURIAL J P, CAILLAT T, CHI S C.Electrical Contacts for Skutterudite Thermoelectric Materials. US20120006376 A1, 2012. |

| [81] | HASEZAKI K, TSUKUDA H, YAMADA A, et al.Thermoelectric Semiconductor and Electrode-fabrication and Evaluation of SiGe/electrode. XVI International Conference on Thermoelectrics. IEEE, 1997: 599-602. |

| [82] | BENNETT G L.Space Applications. in: ROWE D. M. CRC Handbook of Thermoelectrics. BocaRaton: CRC press, 1995. |

| [83] | MONDT J F.SP-100 Space Subsysterns. in: ROWE D. M. CRC Handbook of Thermoelectrics. Boca Raton: CRC press, 1995. |

| [84] | COCKFIELD R D.Engineering Development Testing of the GPHS-RTG Converter. Intersociety Energy Conversion Engineering Conference, 1981: 321-325. |

| [85] | LIN J S, TANIHATA K, MIYAMOTO Y, et al.Microstructure and property of (Si-MoSi2)/SiGe thermoelectric convertor unit. Functionally Graded Materials, 1996, 1997: 599-604. |

| [86] | LIN J S, MIYAMOTO Y.One-step sintering of SiGe thermoelectric conversion unit and its electrodes. [J]. Mater. Res., 2000, 15(3): 647-652. |

| [87] | YANG X Y, WU J H, GU M, et al.Fabrication and contact resistivity of W-Si3N4/TiB2-Si3N4/p-SiGe thermoelectric joints. Ceram. Int., 2016, 42(7): 8044-8050. |

| [88] | ELGENK M S, SABER H H.Radioisotope power systems with skutterudite-based thermoelectric converters. American Institute of Physics, 2005: 485-494. |

| [89] | WHALEN S A, APBLETT C A, ASELAGE T L.Improving power density and efficiency of miniature radioisotopic thermoelectric generators. [J]. Power Sources, 2008, 180(1): 657-663. |

| [90] | EL-GENK M S, SABER H H, SAKAMOTO J, et al. Life Tests of a Skutterudites Thermoelectric Unicouple (MAR-03). 22nd International Conference on Thermoelectrics, 2003: 417-420. |

| [91] | XIA X, HUANG X, LI X, et al.Preparation and structural evolution of Mo/SiOx protective coating on CoSb3-based filled skutterudite thermoelectric material. [J]. Alloys Compd., 2014, 604: 94-99. |

| [92] | DONG H, LI X, HUANG X, et al.Improved oxidation resistance of thermoelectric skutterudites coated with composite glass. Ceram. Int., 2013, 39(4): 4551-4557. |

| [93] | DONG H, LI X, TANG Y, et al.Fabrication and thermal aging behavior of skutterudites with silica-based composite protective coatings. [J]. Alloys Compd., 2012, 527: 247-251. |

| [94] | CAILLAT T, CHI I, FIRDOSY S, et al.Skutterudite-based Advanced Thermoelectric Technology for Potential Integration into an Enhanced MMRTG (eMMRTG). XVI International Forum on Thermoelectricity, 2015. |

| [95] | CLIN T, TURENNE S, VASILEVSKIY D, et al.Numerical simulation of the thermomechanical behavior of extruded bismuth telluride alloy module. [J]. Electron. Mater., 2009, 38(7): 994-1001. |

| [96] | LI S L, LIU C K, HSU C Y, et al.Thermo-mechanical Analysis of Thermoelectric Modules. Microsystems Packaging Assembly and Circuits Technology Conference, 2010: 1-4. |

| [97] | QUNGUI DU, JIANG X, ZHANG X, et al.Influence of structure parameters on performance of the thermoelectric module. J. Wuhan Uni. Tech. (Mater. Sci. Edition), 2011, 26(3): 464-468. |

| [98] | SEETAWAN T, SEETAWAN U, RATCHASIN A, et al.Analysis of thermoelectric generator by finite element method. Procedia Eng., 2012, 32: 1006-1011. |

| [99] | AL-MERBATI A S, YILBAS B S, SAHIN A Z. Thermodynamics and thermal stress analysis of thermoelectric power generator: influence of pin geometry on device performance. Appl. Therm. Eng., 2013, 50(1): 683-692. |

| [100] | WU G, YU X.A holistic 3D finite element simulation model for thermoelectric power generator element. Energy Convers. Manage., 2014, 86(10): 99-110. |

| [101] | YU H, ZHANG Z, QIU Q, et al.Performance of thermoelectric generator with ANSYS. Trans. China Electrotech. Soc., 2014, 29(7): 253-260. |

| [102] | TURENNE S, CLIN T, VASILEVSKIY D, et al.Finite element thermomechanical modeling of large area thermoelectric generators based on bismuth telluride alloys. [J]. Electron. Mater., 2010, 39(9): 1926-1933. |

| [103] | GAO J L, DU Q G, ZHANG X D, et al.Thermal stress analysis and structure parameter selection for a Bi2Te3-based thermoelectric module. [J]. Electron. Mater., 2011, 40(5): 884-888. |

| [104] | CHEN G, MU Y, ZHAI P, et al.An investigation on the coupled thermal-mechanical-electrical response of automobile thermoelectric materials and devices. [J]. Electron. Mater., 2013, 42(7): 1762-1770. |

| [105] | ERTURUNA U, ERERMISB K. MOSSIA K.Effect of various leg geometries on thermo-mechanical and power generation performance of thermoelectric devices.Appl. Therm. Eng., 2014, 73(1): 128-141. |

| [106] | ANATYCHUK L I, LUSTE O J.On the Reliability of Thermoelectric Cooling and Generator Modules. 17th International Conference on Thermoelectrics, 1998: 101-104. |

| [107] | SETTY K, SUBBARAYAN G, NGUYEN L.Power cycling reliability, failure analysis and acceleration factors of Pb-free solder joints. Proceedings Electronic Components and Technology, 2005, 1: 907-915. |

| [108] | CHOI H S, SEO W S, CHOI D K.Prediction of reliability on thermoelectric module through accelerated life test and physics-of-failure. Electron. Mater. Lett., 2011, 7(3): 271-275. |

| [109] | PARK W, BARAKO M T, MARCONNET A M, et al.Effect of Thermal Cycling on Commercial Thermoelectric Modules. Thermal and Thermomechanical Phenomena in Electronic Systems. IEEE, 2012: 107-112. |

| [110] | BARAKO M T, PARK W, MARCONNET A M, et al.A Reliability Study with Infrared Imaging of Thermoelectric Modules Under Thermal Cycling. Thermal and Thermomechanical Phenomena in Electronic Systems, IEEE, 2012: 86-92. |

| [111] | BARAKO M T, MARCONNET A M, ASHEGHI M, et al.Thermal cycling, mechanical degradation, and the effective figure of merit of a thermoelectric module. [J]. Electron. Mater., 2013, 42(3): 372-381. |

| [112] | DING L C, AKBARZADEH A, DATE A.Performance and reliability of commercially available thermoelectric cells for power generation. Appl. Therm. Eng., 2016, 102: 548-556. |

| [113] | KARRI N K, MO C.Reliable thermoelectric module design under opposing requirements from structural and thermoelectric considerations. [J]. Electron. Mater., 2018, 47(6): 3127-3135. |

| [114] | TENORIO H C R L, VIEIRA D A, SOUZA C P D. Measurement of parameters and degradation of thermoelectric modules. IEEE Instru. Meas. Mag., 2017, 20(2): 13-19. |

| [115] | ZHAO D, LI X, HE L, et al.Interfacial evolution behavior and reliability evaluation of CoSb3/Ti/Mo-Cu thermoelectric joints during accelerated thermal aging. [J]. Alloys Compd., 2009, 477(1/2): 425-431. |

| [116] | GU M, BAI S, XIA X, et al. Study on the high temperature interfacial stability of Ti/Mo/Yb0.3Co4Sb12 thermoelectric joints. Appl. Sci., 2017, 7(9): 952-1-10. |

| [1] | 魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978. |

| [2] | 杨鑫, 韩春秋, 曹玥晗, 贺桢, 周莹. 金属氧化物电催化硝酸盐还原合成氨研究进展[J]. 无机材料学报, 2024, 39(9): 979-991. |

| [3] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [4] | 黄洁, 汪刘应, 王滨, 刘顾, 王伟超, 葛超群. 基于微纳结构设计的电磁性能调控研究进展[J]. 无机材料学报, 2024, 39(8): 853-870. |

| [5] | 陈乾, 苏海军, 姜浩, 申仲琳, 余明辉, 张卓. 超高温氧化物陶瓷激光增材制造及组织性能调控研究进展[J]. 无机材料学报, 2024, 39(7): 741-753. |

| [6] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [7] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [8] | 吴晓晨, 郑瑞晓, 李露, 马浩林, 赵培航, 马朝利. SiCf/SiC陶瓷基复合材料高温环境损伤原位监测研究进展[J]. 无机材料学报, 2024, 39(6): 609-622. |

| [9] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [10] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [11] | 张幸红, 王义铭, 程源, 董顺, 胡平. 超高温陶瓷复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 571-590. |

| [12] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [13] | 李宗晓, 胡令祥, 王敬蕊, 诸葛飞. 氧化物神经元器件及其神经网络应用[J]. 无机材料学报, 2024, 39(4): 345-358. |

| [14] | 鲍可, 李西军. 化学气相沉积法制备智能窗用热致变色VO2薄膜的研究进展[J]. 无机材料学报, 2024, 39(3): 233-258. |

| [15] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||