无机材料学报 ›› 2018, Vol. 33 ›› Issue (2): 138-146.DOI: 10.15541/jim20170363 CSTR: 32189.14.10.15541/jim20170363

范宇驰1, 王连军2, 江莞1,2

收稿日期:2017-08-07

修回日期:2017-09-23

出版日期:2018-02-26

网络出版日期:2018-01-26

作者简介:范宇驰(1984),男,研究员.Email:yuchifan@dhu.edu.cn

基金资助:FAN Yu-Chi1, WANG Lian-Jun2, JIANG Wan1,2

Received:2017-08-07

Revised:2017-09-23

Published:2018-02-26

Online:2018-01-26

Supported by:摘要:

现代社会对于氧化物陶瓷材料的性能不断提出更高的要求, 因此对于氧化物陶瓷复合材料的研究显得尤为重要。石墨烯作为一种具有卓越性能的二维碳材料, 非常适合作为增强相用于提高氧化物陶瓷复合材料的力学和电性能。本文系统总结了过去十年来基于石墨烯的氧化物陶瓷复合材料的相关研究和报道, 从石墨烯/氧化物陶瓷复合材料的制备、烧结、微观结构到性能进行了比较全面的介绍, 从中可以看出: (1)石墨烯的引入使得氧化物陶瓷的力学性能在强度、断裂韧性、应变容忍度等方面获得全面的提升; (2)在电性能方面, 石墨烯/氧化物陶瓷复合材料不仅具有低渗流阈值和良好的电导, 而且其载流子类型还可以通过调节氧化物基体中的氧空位浓度来调控。因此, 基于石墨烯的氧化物陶瓷复合材料有望作为一种高性能结构功能一体化陶瓷获得应用。

中图分类号:

范宇驰, 王连军, 江莞. 基于石墨烯的结构功能一体化氧化物陶瓷复合材料: 从制备到性能[J]. 无机材料学报, 2018, 33(2): 138-146.

FAN Yu-Chi, WANG Lian-Jun, JIANG Wan. Graphene Based Oxide Ceramic Composites with High Mechanical and Functional Performance: from Preparation to Property[J]. Journal of Inorganic Materials, 2018, 33(2): 138-146.

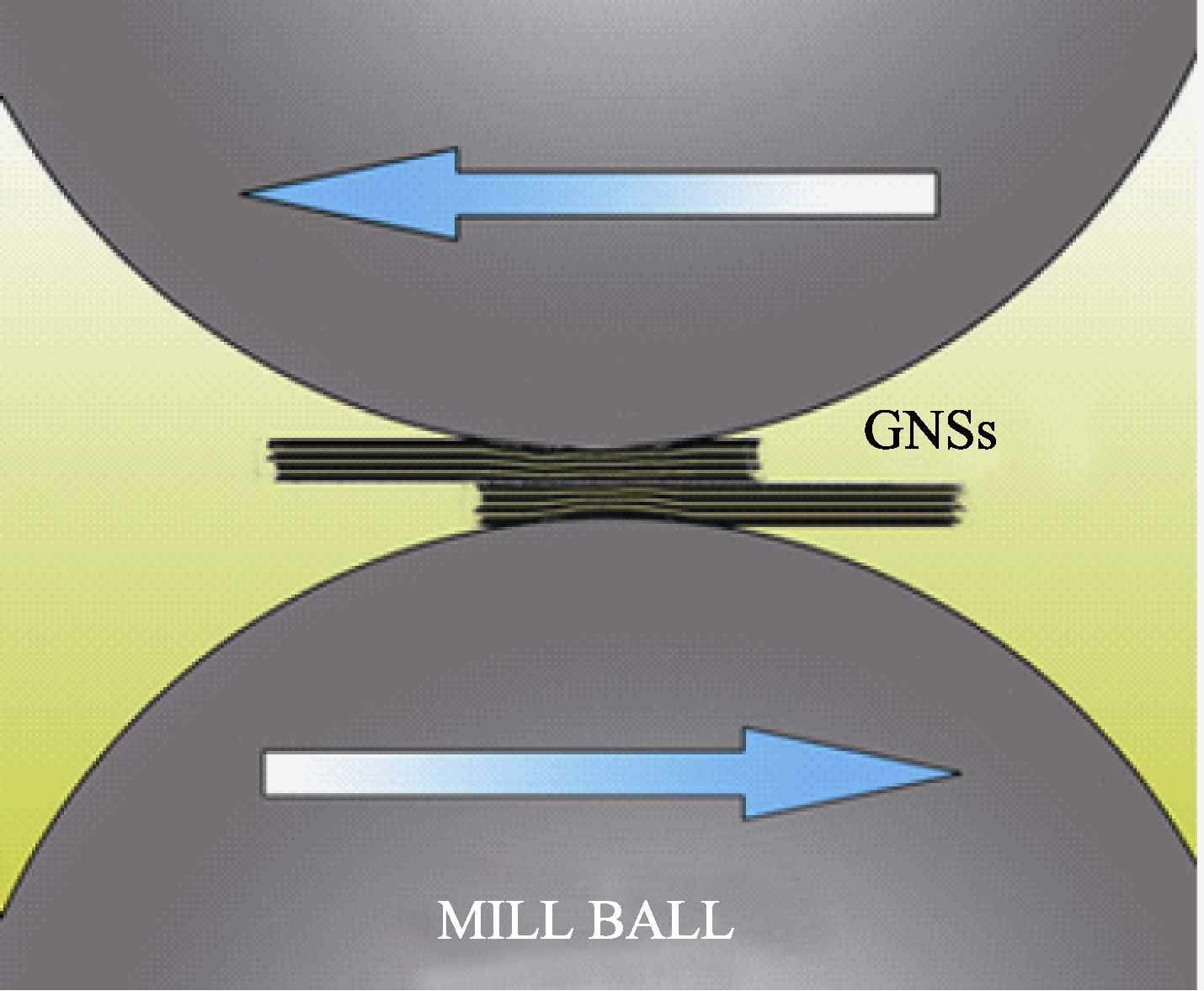

图1 从石墨片层中剥离石墨烯的示意图[8]

Fig. 1 Schematic illustration of exfoliating GNSs from graphite pallets [8] The arrows indicate the shear effect in a ball milling process

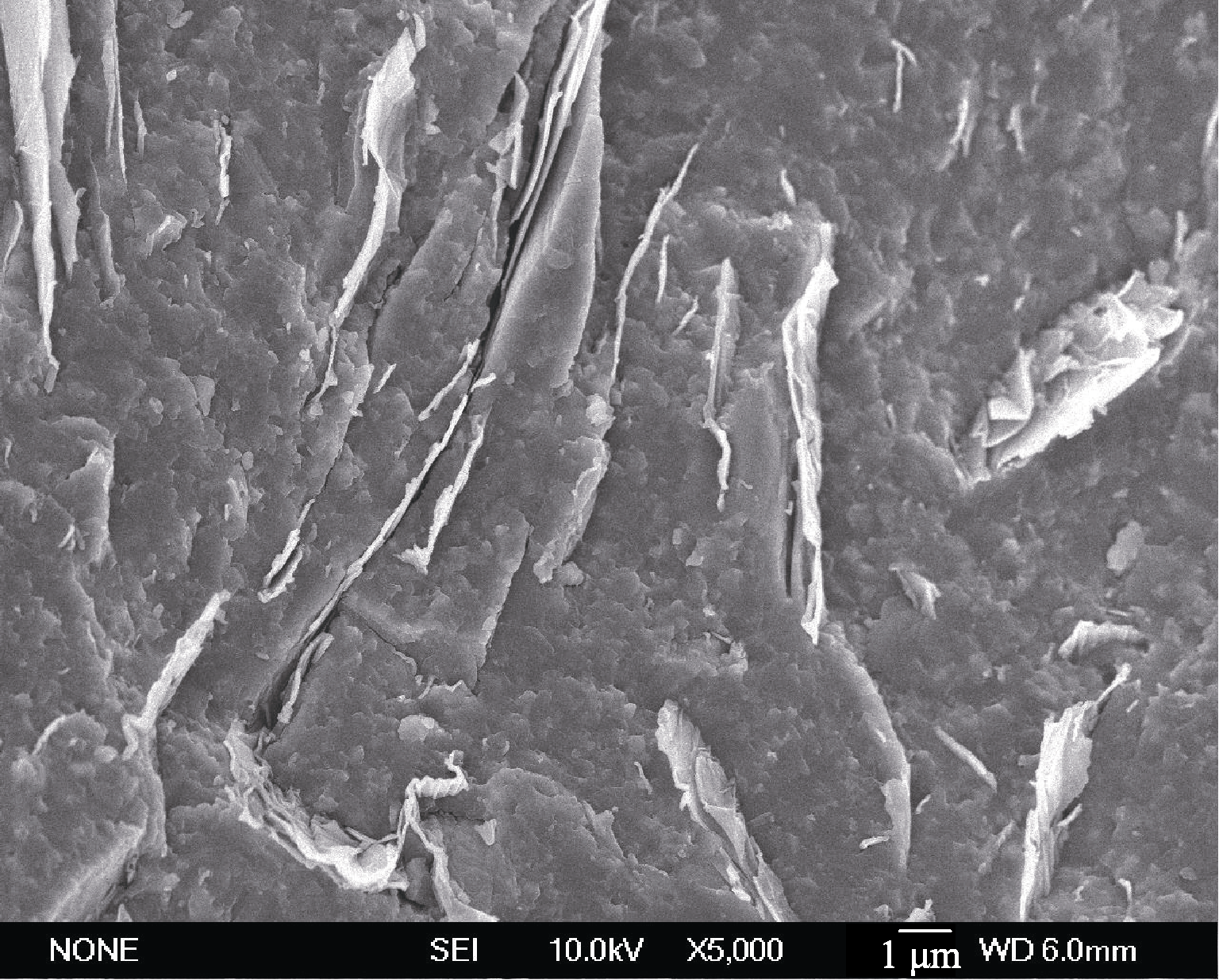

图2 利用机械剥离法制备的石墨烯/氧化铝复合材料断面的SEM照片[8-9]

Fig. 2 SEM image of fracture surface for graphene nanosheet/ Al2O3 composite prepared via mechanical exfoliation[8-9]

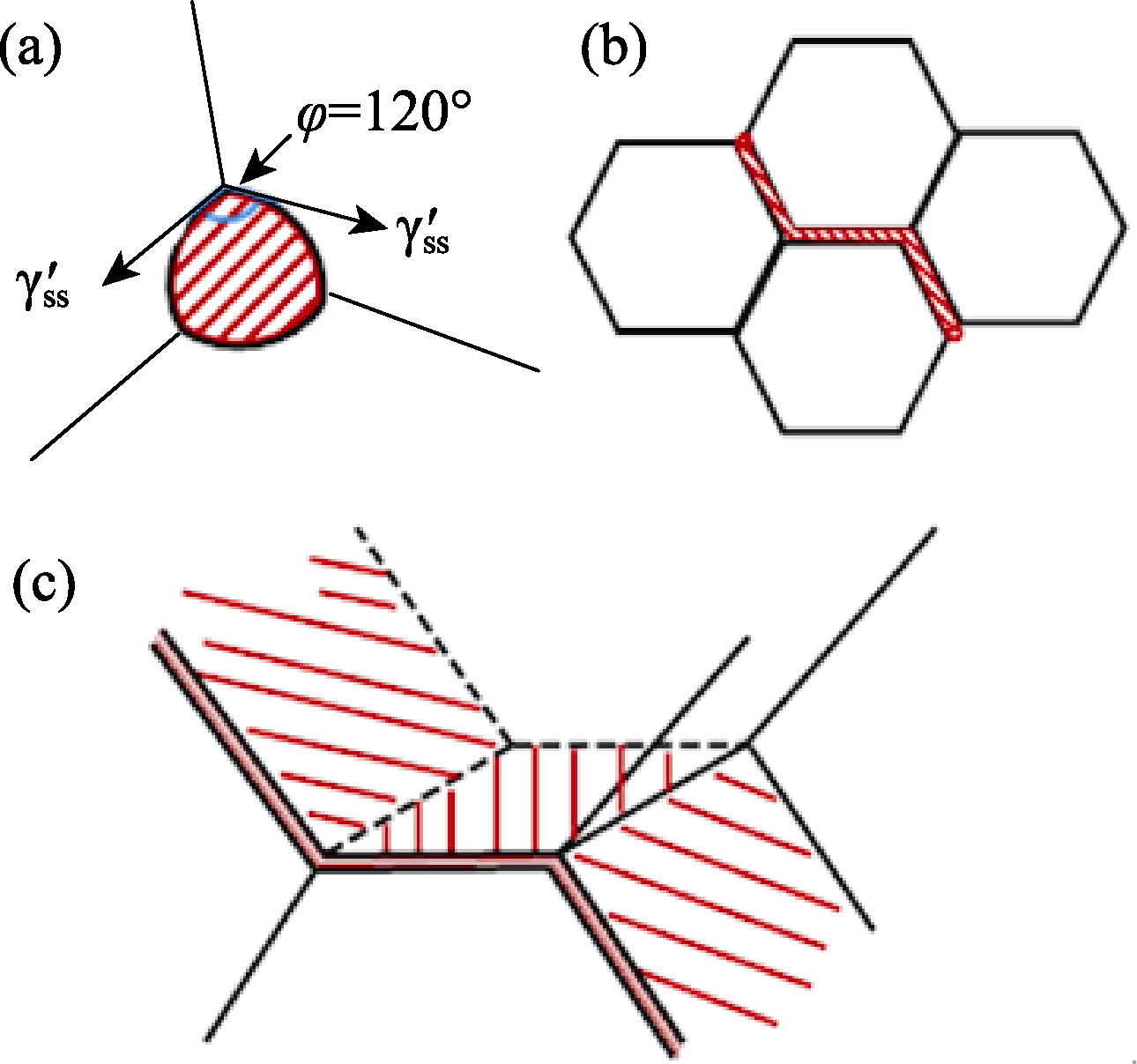

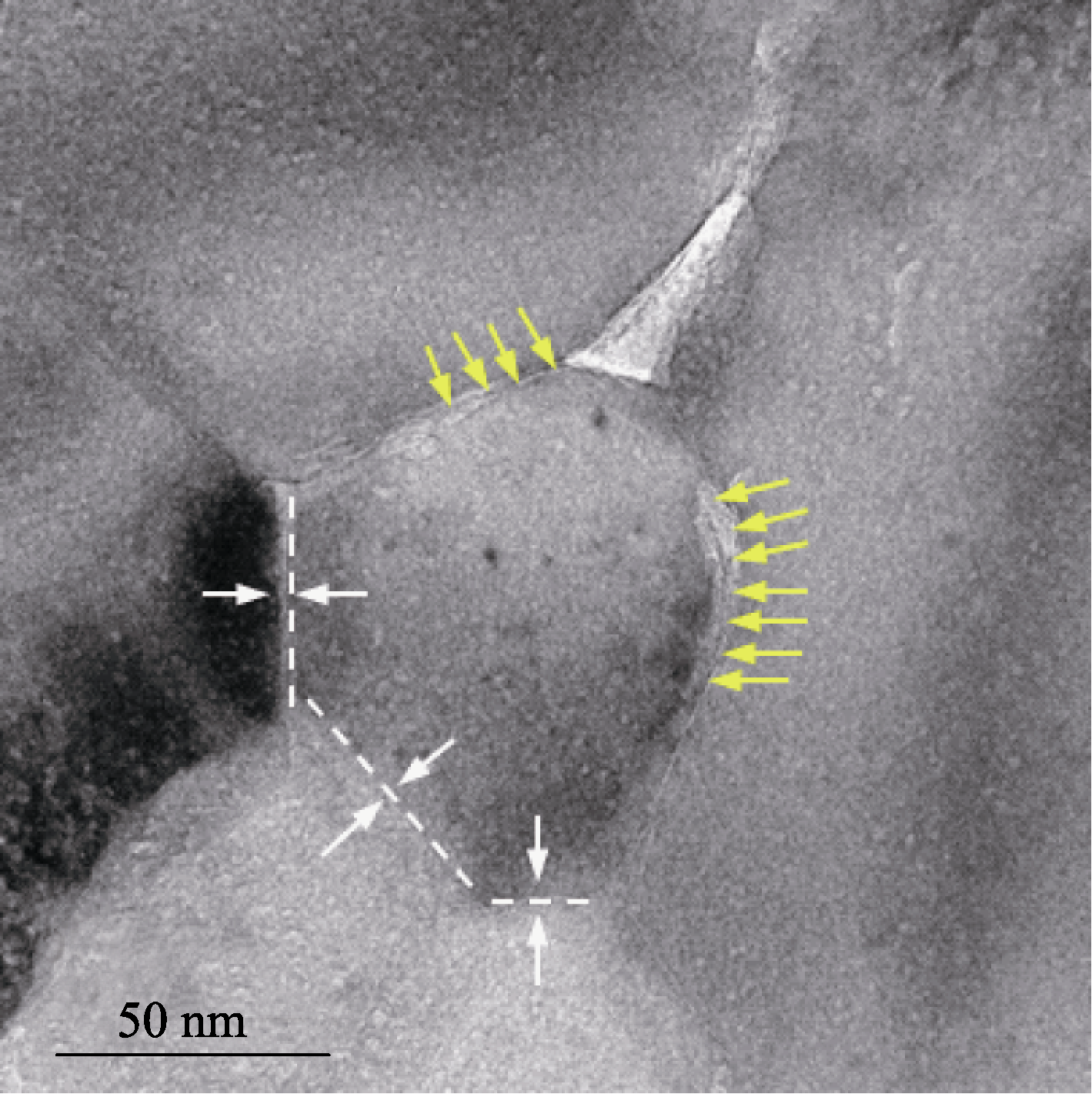

图4 二维材料石墨烯能够更有效的抑制晶粒粗化[21] 除了晶粒大小, 石墨烯对陶瓷基体的影响还体现在晶粒的微观形貌上[21]。以氧化铝为例, 单纯的氧化铝陶瓷烧结之后, 晶粒会呈现不同的楞面, 这是晶界移动达到热力学平衡状态的结果。本课题组发现在石墨烯/氧化铝复合材料中, 很难找到这种含有明显楞面的晶粒, 从复相陶瓷的断面上观察发现大多数晶粒呈现出比较圆滑的表面, 即便进一步提高烧结温度结果仍然如此。研究还发现, 在烧结致密的氧化铝基体中存在一些小于原始粉体粒径的晶粒, 从晶界曲率判断本应该在二次再结晶过程中被周围较大的晶粒吸收, 但由于晶界上存在石墨烯而被完好的保存下来(图5)。这一现象说明由于石墨烯的柔韧性和强大的阻碍晶界移动的能力, 使得在陶瓷复合材料整体达到致密的情况下大量的晶面还未达到热力学平衡的状态。这一独特的结构在其它材料如碳纳米管复合陶瓷材料中并未出现, 这是石墨烯陶瓷复合材料的微观结构特点。

Fig. 4 Schematic illustration showing 2D graphene can retard the coarsening of grain most effectively[21] (a), (b), (c) show the situation for nano-particle, 1D inclusion and 2D inclusion, respectively

图5 石墨烯阻碍晶界移动达到热力学平衡状态[21]

Fig. 5 Graphene prohibits grain boundary reaching dynamic balance[21] The yellow and white arrows indicate grain boundaries with and without graphene, respectively

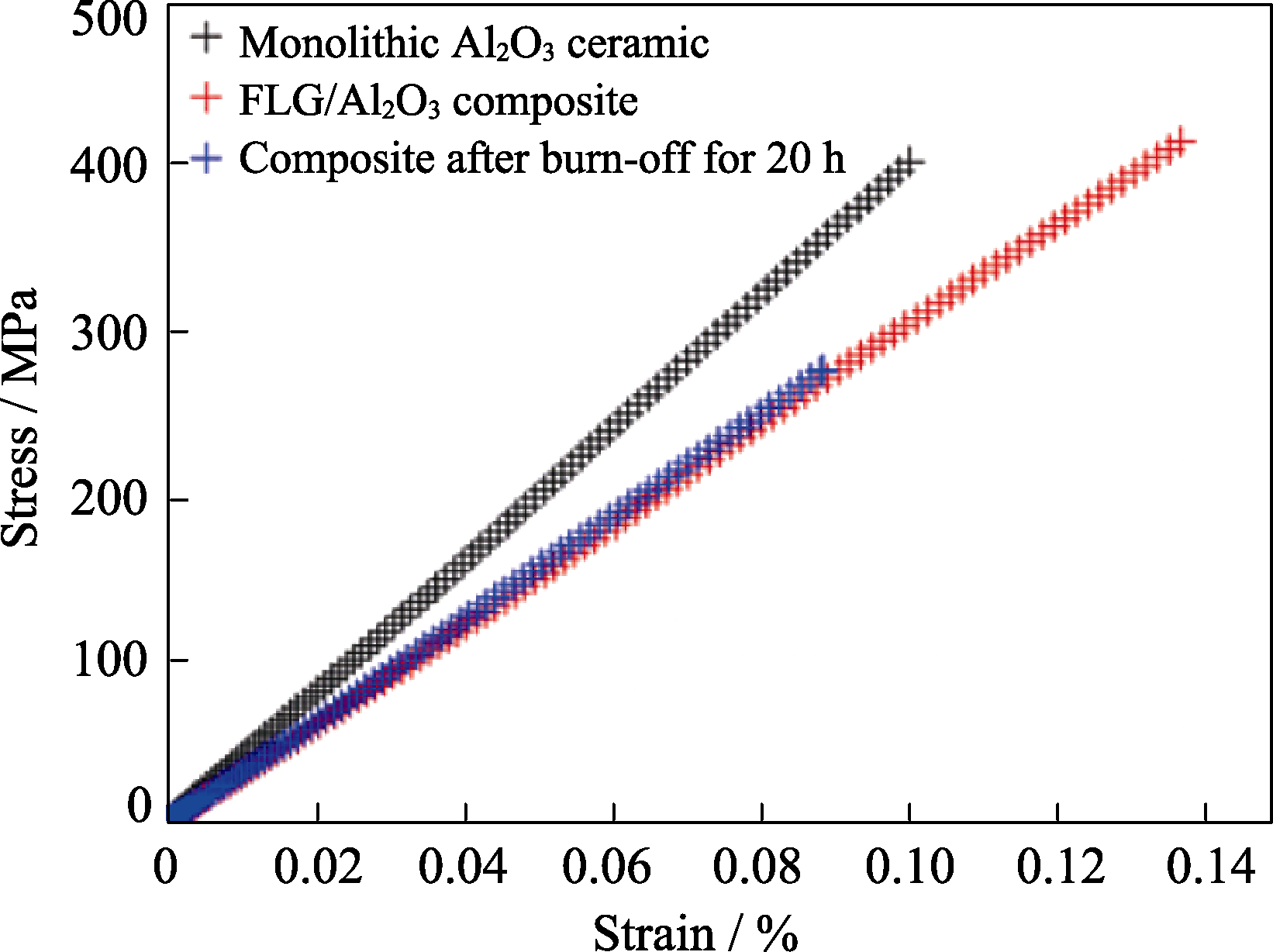

图6 单相氧化铝(黑)、石墨烯/氧化铝复合材料(红)以及烧蚀后氧化铝复合材料(蓝)在四点抗弯试验中的应力-应变曲线[22]

Fig. 6 Stain-stress plots of monolithic Al2O3 ceramic (black), FLG/Al2O3 composite before (red) and after (blue) burn-off for 20 h during four-point bending test, respectively[22]

| Matrix | Raw material of graphene* | Mixing method | Percolation threshold | Maximum electrical conductivity | Reference |

|---|---|---|---|---|---|

| Al2O3 | GO | Heteroaggregation | 0.38vol% | 1038.15 S•m-1 for 2.35vol% | [16] |

| Al2O3 | GO | Heteroaggregation | 0.22wt% | 11.1 S•m-1 for 0.45wt% | [31] |

| Al2O3 | G | Stirring + Ball milling | 7.1vol% | 20.1 S•m-1 for 15vol% | [32] |

| Al2O3 | G | Planetary ball milling | <0.5vol% | 123.3 S•m-1 for 2vol% | [33] |

| Al2O3 | GN | Attrition ball milling | 3vol% | 103 S•m-1 for 15vol% | [34] |

| Al2O3 | EG | Planetary ball milling | 3vol% | 5709 S•m-1 for 15vol% | [8] |

| Al2O3 | EG | Attrition ball milling | 4.7-5.7vol% | 9.6×10-2 S•m-1 for 9.4vol% | [35] |

| YSZ | GO | Sonication | 2.5vol% | 1.2×104 S•m-1 for 4.1vol% | [36] |

| SiO2 | GO | Heteroaggregation | <0.58wt% | 10-2 S•m-1 for 0.98wt% | [37] |

| ZrO2 | GN | Planetary ball milling | <1wt% | 98 S•m-1 for 3wt% | [38] |

表1 一些石墨烯/氧化物陶瓷复合材料的电性能比较

Table 1 Comparison of some reported graphene/oxide ceramic composites

| Matrix | Raw material of graphene* | Mixing method | Percolation threshold | Maximum electrical conductivity | Reference |

|---|---|---|---|---|---|

| Al2O3 | GO | Heteroaggregation | 0.38vol% | 1038.15 S•m-1 for 2.35vol% | [16] |

| Al2O3 | GO | Heteroaggregation | 0.22wt% | 11.1 S•m-1 for 0.45wt% | [31] |

| Al2O3 | G | Stirring + Ball milling | 7.1vol% | 20.1 S•m-1 for 15vol% | [32] |

| Al2O3 | G | Planetary ball milling | <0.5vol% | 123.3 S•m-1 for 2vol% | [33] |

| Al2O3 | GN | Attrition ball milling | 3vol% | 103 S•m-1 for 15vol% | [34] |

| Al2O3 | EG | Planetary ball milling | 3vol% | 5709 S•m-1 for 15vol% | [8] |

| Al2O3 | EG | Attrition ball milling | 4.7-5.7vol% | 9.6×10-2 S•m-1 for 9.4vol% | [35] |

| YSZ | GO | Sonication | 2.5vol% | 1.2×104 S•m-1 for 4.1vol% | [36] |

| SiO2 | GO | Heteroaggregation | <0.58wt% | 10-2 S•m-1 for 0.98wt% | [37] |

| ZrO2 | GN | Planetary ball milling | <1wt% | 98 S•m-1 for 3wt% | [38] |

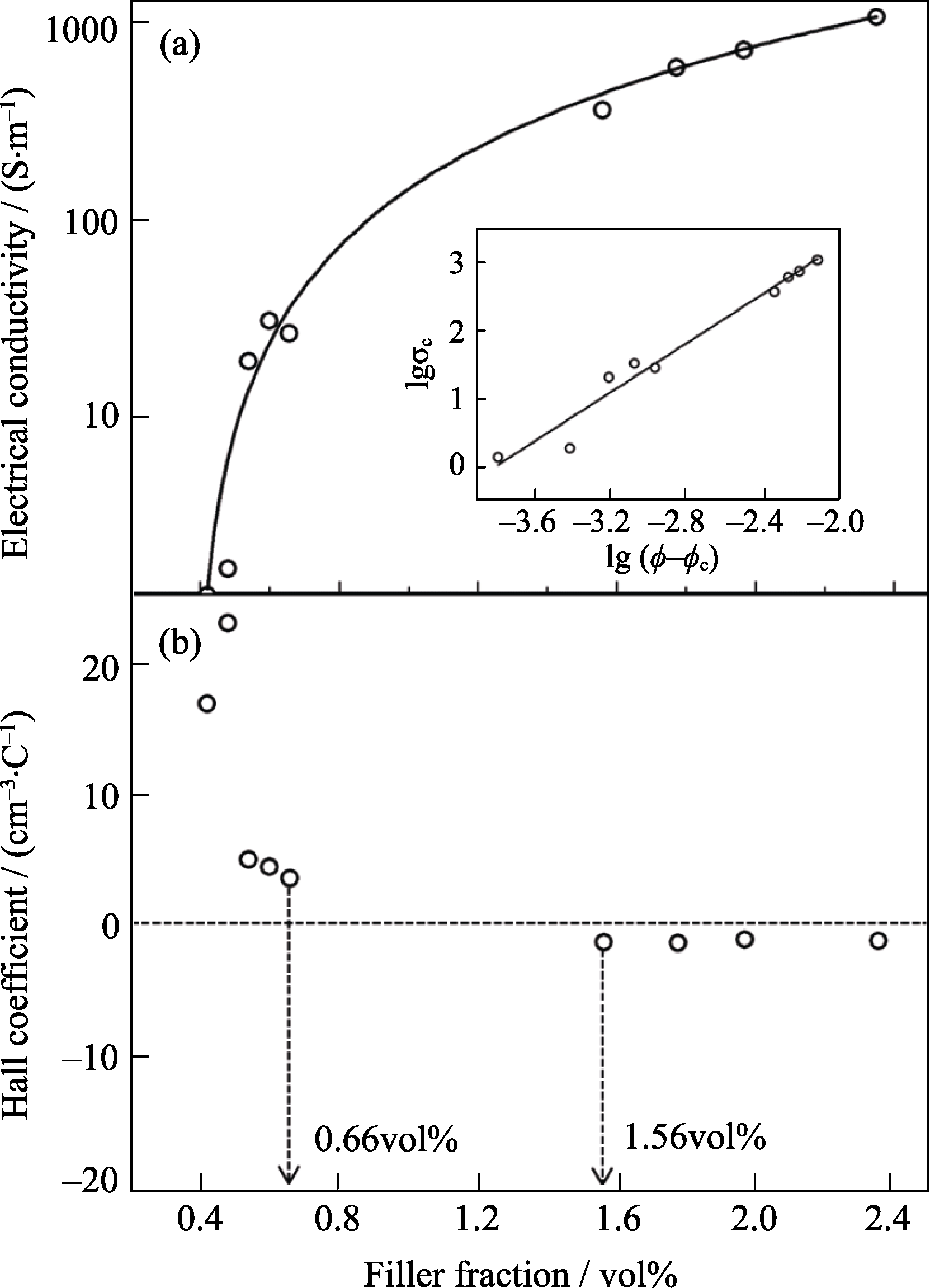

图7 (a)石墨烯/氧化铝复合材料的电导随石墨烯含量的变化关系; (b)霍尔系数随着石墨烯含量的变化关系[16]

Fig. 7 (a) Electrical conductivity of graphene/Al2O3 composites as a function of filler volume fraction; (b) Hall coefficient plotted against filler volume fraction[16]

| [1] | ZAPATA-SOLVAS E, GOMEZ-GARCIA D, DOMINGUEZ- RODRIGUEZ A.Towards physical properties tailoring of carbon nanotubes-reinforced ceramic matrix composites.J. Eur. Ceram. Soc, 2012, 32(12): 3001-3020. |

| [2] | LEE C, WEI X D, KYSAR J W, et al.Measurement of the elastic properties and intrinsic strength of monolayer graphene.Science, 2008, 321(5887): 385-388. |

| [3] | GEIM A K, NOVOSELOV K S.The rise of graphene.Nat. Mater., 2007, 6(3): 183-191. |

| [4] | HUANG X, QI X Y, BOEY F, et al.Graphene-based composites.Chem. Soc. Rev., 2012, 41(2): 666-686. |

| [5] | NOVOSELOV K S, GEIM A K, MOROZOV S V, et al.Electric field effect in atomically thin carbon films.Science, 2004, 306(5696): 666-669. |

| [6] | BURMEISTER C F, KWADE A.Process engineering with planetary ball mills.Chem. Soc. Rev., 2013, 42(18): 7660-7667. |

| [7] | HERNANDEZ Y, NICOLOSI V, LOTYA M, et al.High-yield production of graphene by liquid-phase exfoliation of graphite.Nat. Nanotechnol., 2008, 3(9): 563-568. |

| [8] | FAN Y C, WANG L J, LI J L, et al.Preparation and electrical properties of graphene nanosheet/Al2O3 composites.Carbon, 2010, 48(6): 1743-1749. |

| [9] | LIU X, FAN Y C, LI J L, et al.Preparation and mechanical properties of graphene nanosheet reinforced alumina composites.Adv. Eng. Mater., 2015, 17(1): 28-35. |

| [10] | HUMMERS W S, OFFEMAN R E.Preparation of graphitic oxide.J. Am. Chem. Soc., 1958, 80(6): 1339. |

| [11] | MARCANO D C, KOSYNKIN D V, BERLIN J M, et al.Improved synthesis of graphene oxide.ACS Nano, 2010, 4(8): 4806-4814. |

| [12] | CHEN J, YAO B W, LI C, et al.An improved Hummers method for eco-friendly synthesis of graphene oxide.Carbon, 2013, 64: 225-229. |

| [13] | YU H T, ZHANG B W, BULIN C K, et al.High-efficient synthesis of graphene oxide based on improved hummers method.Sci. Rep.-Uk, 2016, 6: 36143. |

| [14] | YANG D, VELAMAKANNI A, BOZOKLU G, et al.Chemical analysis of graphene oxide films after heat and chemical treatments by X-ray photoelectron and Micro-Raman spectroscopy.Carbon, 2009, 47(1): 145-152. |

| [15] | SUN J, GAO L.Development of a dispersion process for carbon nanotubes in ceramic matrix by heterocoagulation.Carbon, 2003, 41(5): 1063-1068. |

| [16] | FAN Y C, JIANG W, KAWASAKI A.Highly conductive few-layer graphene/Al2O3 nanocomposites with tunable charge carrier type.Adv. Funct. Mater., 2012, 22(18): 3882-3889. |

| [17] | FENG X P, FAN Y C, NOMURA N, et al.Graphene promoted oxygen vacancies in perovskite for enhanced thermoelectric properties.Carbon, 2017, 112: 169-176. |

| [18] | RICE R W, WU C C, BORCHELT F.Hardness grain-size relations in ceramics.J. Am. Ceram. Soc., 1994, 77(10): 2539-2553. |

| [19] | ZHANG S C, FAHRENHOLTZ W G, HILMAS G E, et al.Pressureless sintering of carbon nanotube-Al2O3 composites.J. Eur. Ceram. Soc., 2010, 30(6): 1373-1380. |

| [20] | INAM F, VO T, BHAT B R.Structural stability studies of graphene in sintered ceramic nanocomposites.Ceram. Int., 2014, 40(PB): 16227-16233. |

| [21] | FAN Y C, ESTILI M, IGARASHI G, et al.The effect of homogeneously dispersed few-layer graphene on microstructure and mechanical properties of Al2O3 nanocomposites.J. Eur. Ceram. Soc., 2014, 34(2): 443-451. |

| [22] | LIU X, LI J L, YU X W, et al.Graphene nanosheet/titanium carbide composites of a fine-grained structure and improved mechanical properties.Ceram. Int., 2016, 42(1): 165-172. |

| [23] | FAN Y C, IGARASHI G, JIANG W, et al.Highly strain tolerant and tough ceramic composite by incorporation of graphene.Carbon, 2015, 90: 274-283. |

| [24] | LIU J, YAN H X, JIANG K.Mechanical properties of graphene platelet-reinforced alumina ceramic composites.Ceram. Int., 2013, 39(6): 6215-6221. |

| [25] | KIM H J, LEE S M, OH Y S, et al.Unoxidized graphene/alumina nanocomposite: fracture- and wear-resistance effects of graphene on alumina matrix.Sci. Rep.-Uk., 2014, 4: 5176. |

| [26] | LIU J, YANG Y, HASSANIN H, et al.Graphene-alumina nanocomposites with improved mechanical properties for biomedical applications.ACS Appl. Mater. Inter., 2016, 8(4): 2607-2616. |

| [27] | DEL RIO F, BOADO M G, RAMA A, et al.A comparative study on different aqueous-phase graphite exfoliation methods for few-layer graphene production and its application in alumina matrix composites.J. Eur. Ceram. Soc., 2017, 37(12): 3681-3693. |

| [28] | CHEN C, PAN L M, LI X Y, et al.Mechanical and thermal properties of graphene nanosheets/magnesia composites.Ceram. Int., 2017, 43(13): 10377-10385. |

| [29] | KLEBERT S, BALAZSI C, BALAZSI K, et al.Spark plasma sintering of graphene reinforced hydroxyapatite composites.Ceram. Int., 2015, 41(3): 3647-3652. |

| [30] | RUL S, LEFèVRE-SCHLICK F, CAPRIA E, et al. Percolation of single-walled carbon nanotubes in ceramic matrix nanocomposites.Acta Materialia, 2004, 52(4): 1061-1067. |

| [31] | CENTENO A, ROCHA V G, ALONSO B, et al.Graphene for tough and electroconductive alumina ceramics.J. Eur. Ceram. Soc., 2013, 33(15/16): 3201-3210. |

| [32] | CELIK Y, CELIK A, FLAHAUT E, et al.Anisotropic mechanical and functional properties of graphene-based alumina matrix nanocomposites.J. Eur. Ceram. Soc., 2016, 36(8): 2075-2086. |

| [33] | QING Y C, WEN Q L, LUO F, et al.Temperature dependence of the electromagnetic properties of graphene nanosheet reinforced alumina ceramics in the X-band.J. Mater. Chem. C, 2016, 4(22): 4853-4862. |

| [34] | SUNG J W, KIM K H, KANG M C.Effects of graphene nanoplatelet contents on material and machining properties of GNP-dispersed Al2O3 ceramics for micro-electric discharge machining.Int. J. Pr. Eng. Man.-Gt., 2016, 3(3): 247-252. |

| [35] | LEE E, CHOI K B, LEE S M, et al.A scalable and facile synthesis of alumina/exfoliated graphite composites by attrition milling.RSC Adv., 2015, 5(113): 93267-93273. |

| [36] | SHIN J H, HONG S H.Fabrication and properties of reduced graphene oxide reinforced yttria-stabilized zirconia composite ceramics.J. Eur. Ceram. Soc., 2014, 34(5): 1297-1302. |

| [37] | CHEN B B, LIU X, ZHAO X Q, et al.Preparation and properties of reduced graphene oxide/fused silica composites.Carbon, 2014, 77: 66-75. |

| [38] | KWON S M, LEE S J, SHON I J.Enhanced properties of nanostructured ZrO2-graphene composites rapidly sintered via high- frequency induction heating.Ceram. Int., 2015, 41(1): 835-842. |

| [39] | FAN Y C, KANG L J, ZHOU W W, et al.Control of doping by matrix in few-layer graphene/metal oxide composites with highly enhanced electrical conductivity.Carbon, 2015, 81: 83-90. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [8] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [9] | 杨茗凯, 黄泽皑, 周芸霄, 刘彤, 张魁魁, 谭浩, 刘梦颖, 詹俊杰, 陈国星, 周莹. 基于Cu与金属氧化物-KCl熔融介质的甲烷热解制备少层石墨烯与氢气联产研究[J]. 无机材料学报, 2025, 40(5): 473-480. |

| [10] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [11] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [12] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [13] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [14] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [15] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||