无机材料学报 ›› 2023, Vol. 38 ›› Issue (6): 589-605.DOI: 10.15541/jim20220331 CSTR: 32189.14.10.15541/jim20220331

所属专题: 【能源环境】储能电池(202506); 【能源环境】锂离子电池(202412)

• 综述 • 下一篇

收稿日期:2022-06-14

修回日期:2022-12-28

出版日期:2023-01-11

网络出版日期:2023-01-11

通讯作者:

陈军,教授. E-mail: chenabc@nankai.edu.cn作者简介:杨卓(1993-), 男, 博士研究生. E-mail: yzhuo94@outlook.com.

基金资助:

YANG Zhuo( ), LU Yong, ZHAO Qing, CHEN Jun(

), LU Yong, ZHAO Qing, CHEN Jun( )

)

Received:2022-06-14

Revised:2022-12-28

Published:2023-01-11

Online:2023-01-11

Contact:

CHEN Jun, professor. E-mail: chenabc@nankai.edu.cnAbout author:YANG Zhuo (1993-), male, PhD candidate. E-mail: yzhuo94@outlook.com.

Supported by:摘要:

2022年是X射线衍射(XRD)发现的110周年。XRD Rietveld精修作为材料结构分析的重要手段, 在建立材料“构-效”关系方面发挥着重要的作用。正极材料是锂离子电池的重要组成部分, 深入理解其晶体结构及原子分布规律有助于推动锂离子电池正极材料的发展。本文简要介绍了XRD Rietveld结构精修及其在锂离子电池正极材料中的应用, 围绕几类典型正极材料, 重点讨论了Rietveld结构精修在正极材料的合成、退化衰减及结构改性中的应用和研究进展。XRD Rietveld精修可以得到物相比例、晶胞参数、关键原子占比、原子坐标等结构信息, 对开发高性能锂离子电池正极材料具有重要的指导意义。最后, 本文展望了X射线衍射技术在锂电正极材料结构研究中的机遇与挑战。

中图分类号:

杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605.

YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2023, 38(6): 589-605.

图2 原位X射线衍射装置示意图[20-21]

Fig. 2 Schemes of in situ X-ray diffraction[20-21] (a) Charge-discharge process (© 2020, MDPI) [20]; (b) Heating process (© 2015, Elsevier B.V.)[21]

| Cathode material | Crystal structure | Space group | Cell parameter | Atom site | Theoretical specific capacity/(mAh·g-1) | Working voltage/ V (vs. Li+/Li) | |

|---|---|---|---|---|---|---|---|

| LiFePO4 | Olivine | Pnma | a≠b≠c | Li | 4a | 170 | 3.4 |

| Fe | 4c | ||||||

| O | 4c/8d | ||||||

| LiMn2O4 | Spinel | Fd-3m | a=b=c | Li | 8a | 148 | 4 |

| Mn | 16d | ||||||

| O | 32e | ||||||

| LiCoO2 | Layer | R-3m | a=b≠c | Li | 3a | 274 | 3.9 |

| Co | 3b | ||||||

| O | 6c | ||||||

| LiNixCoy(Mn/Al)1-x-yO2 | Layer | R-3m | a=b≠c | Li | 3a | 273-285 | 3.8 |

| Ni/Co/Mn/Al | 3b | ||||||

| O | 6c | ||||||

| xLi2MnO3·(1-x)LiMO2 (0<x<1, M=Ni, Co, Mn) | Layer | R-3m+ C2/m | a=b≠c | Li | 2b/2c/4h | 273-350 | 3.8 |

| Mn | 4g | ||||||

| O | 4i/4j | ||||||

表1 常见的锂离子电池正极材料的结构及性能[24⇓⇓⇓-28]

Table 1 Structures and properties of common cathode materials for lithium-ion batteries[24⇓⇓⇓-28]

| Cathode material | Crystal structure | Space group | Cell parameter | Atom site | Theoretical specific capacity/(mAh·g-1) | Working voltage/ V (vs. Li+/Li) | |

|---|---|---|---|---|---|---|---|

| LiFePO4 | Olivine | Pnma | a≠b≠c | Li | 4a | 170 | 3.4 |

| Fe | 4c | ||||||

| O | 4c/8d | ||||||

| LiMn2O4 | Spinel | Fd-3m | a=b=c | Li | 8a | 148 | 4 |

| Mn | 16d | ||||||

| O | 32e | ||||||

| LiCoO2 | Layer | R-3m | a=b≠c | Li | 3a | 274 | 3.9 |

| Co | 3b | ||||||

| O | 6c | ||||||

| LiNixCoy(Mn/Al)1-x-yO2 | Layer | R-3m | a=b≠c | Li | 3a | 273-285 | 3.8 |

| Ni/Co/Mn/Al | 3b | ||||||

| O | 6c | ||||||

| xLi2MnO3·(1-x)LiMO2 (0<x<1, M=Ni, Co, Mn) | Layer | R-3m+ C2/m | a=b≠c | Li | 2b/2c/4h | 273-350 | 3.8 |

| Mn | 4g | ||||||

| O | 4i/4j | ||||||

图3 正极材料晶体结构示意图[25⇓⇓-28]

Fig. 3 Schematic diagram of the crystal structures of cathode materials[25⇓⇓-28] (a) LiMPO4 (M=Fe, Mn)(© 2021, IOP Publishing)[25]; (b) LiMn2O4 (© 2022, MDPI)[26]; (c) LiMO2 (M=Ni, Co, Mn, Al) (© 2021, Elsevier Ltd.)[27]; (d) xLi2MnO3·(1-x)LiMO2 (M=Ni, Co, Mn) (© 2022, Springer Nature)[28] Colorful figures are available on website

图5 LiNi0.8Co0.2O2合成过程中的结构演化[41]

Fig. 5 Structural evolution during high temperature synthesis of LiNi0.8Co0.2O2 (© 2017, Wiley-VCH)[41] (a) Concentration of the phases Ni(Co)O, Li2CO3, and LiNi0.8Co0.2O2 at different temperatures; (b) Ratio unit cell parameters (c/a), (c) content of Li+ occupying the 3a sites (Li sites), and (d) Ni-O and Li-O bond lengths as a function of temperature; (e) Schematic diagram of the structural evolution and variation of the interlayer distances of the Li and Ni(Co) slabs during the synthesis of LiNi0.8Co0.2O2. 1 Å=0.1 nm. Colorful figures are available on website

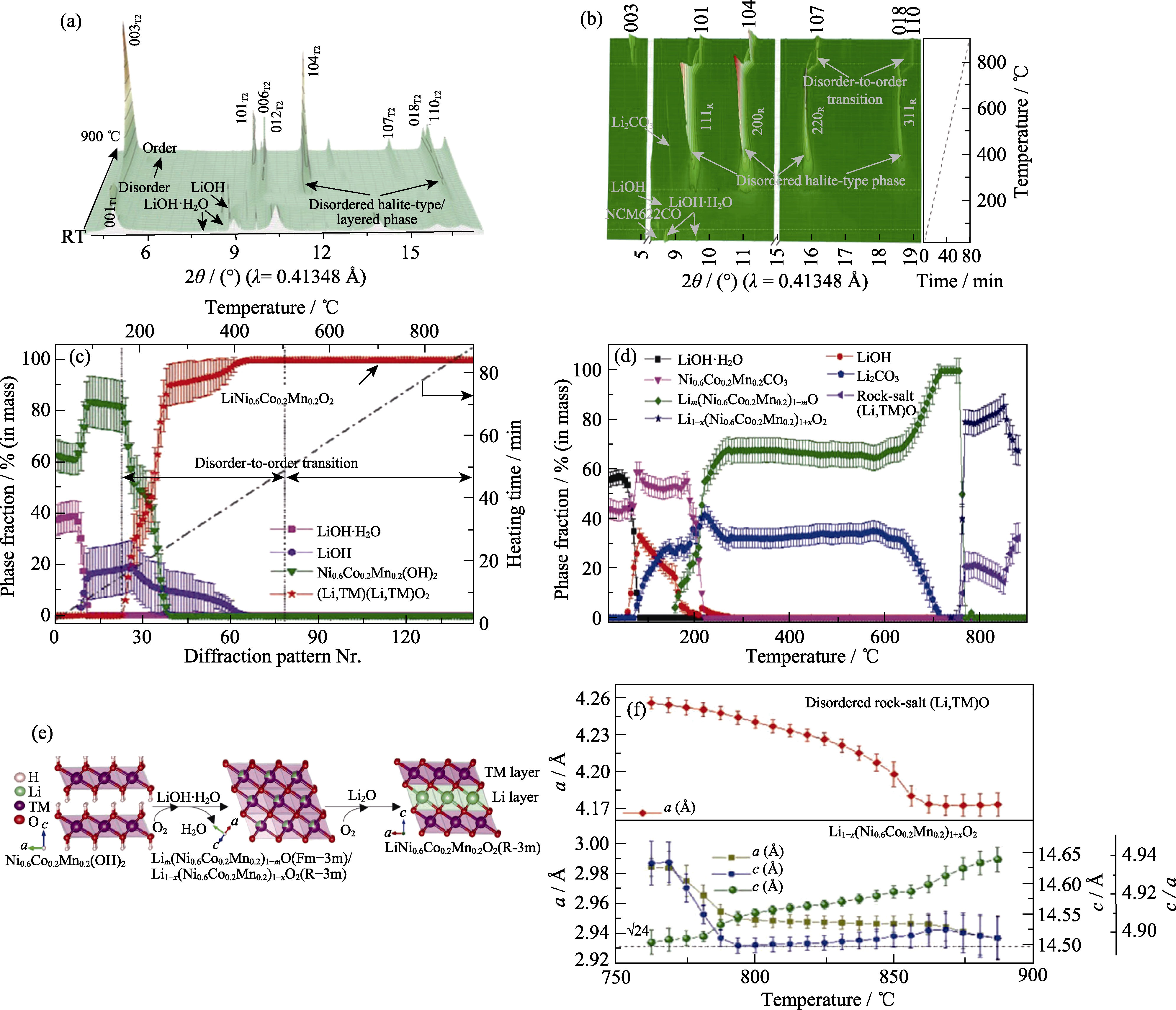

图6 正极材料LiNi0.6Co0.2Mn0.2O2的合成过程温度分辨XRD表征结果[43]

Fig. 6 Temperature-resolved XRD characterization of synthesis process of cathode material LiNi0.6Co0.2Mn0.2O2 (© 2021, Wiley-VCH)[43] (a) In situ XRD patterns of the mixture of Ni0.6Co0.2Mn0.2(OH)2 and LiOH·H2O during heating and (c) corresponding weight fractions of different phases as a function of temperature; (b) 3D profiles of in situ XRD patterns, corresponding (d) evolution of phase fraction and (f) lattice parameters of the samples as a function of heating temperature starting from mixture of the Ni0.6Co0.2Mn0.2CO3 and LiOH·H2O; (e) Schematic illustration of structural evolution during synthesis of LiNi0.6Co0.2Mn0.2O2; In (a, b), the subscripts T1, T2 and R represent Ni0.6Co0.2Mn0.2(OH)2 (P-3m1, T1 phase), LiNi0.6Co0.2Mn0.2O2 (R-3m, T2 phase) and the rock-salt-type, respectively. 1 Å=0.1 nm Colorful figures are available on website

图7 LiNi1/3Mn1/3Co1/3O2(NCM111)的微波水热合成原位XRD表征结果[44]

Fig. 7 In-situ XRD characterization of microwave (MW) hydrothermal synthesis of NCM111(© 2020, AAAS) [44] (a) Schematic illustration of the experimental setup specialized for fast synchrotron X-ray probing of the microwave hydrothermal synthesis; (b) Time resolved synchrotron XRD patterns during MW hydrothermal synthesis of NCM111; (c) Lattice parameter c of the Ni1/3Co1/3Mn1/3(OH)2 precursor (green) as a function of temperature during solid-state synthesis (black), hydrothermal synthesis (blue), and MW hydrothermal synthesis (red). 1 Å=0.1 nm. Colorful figures are available on website

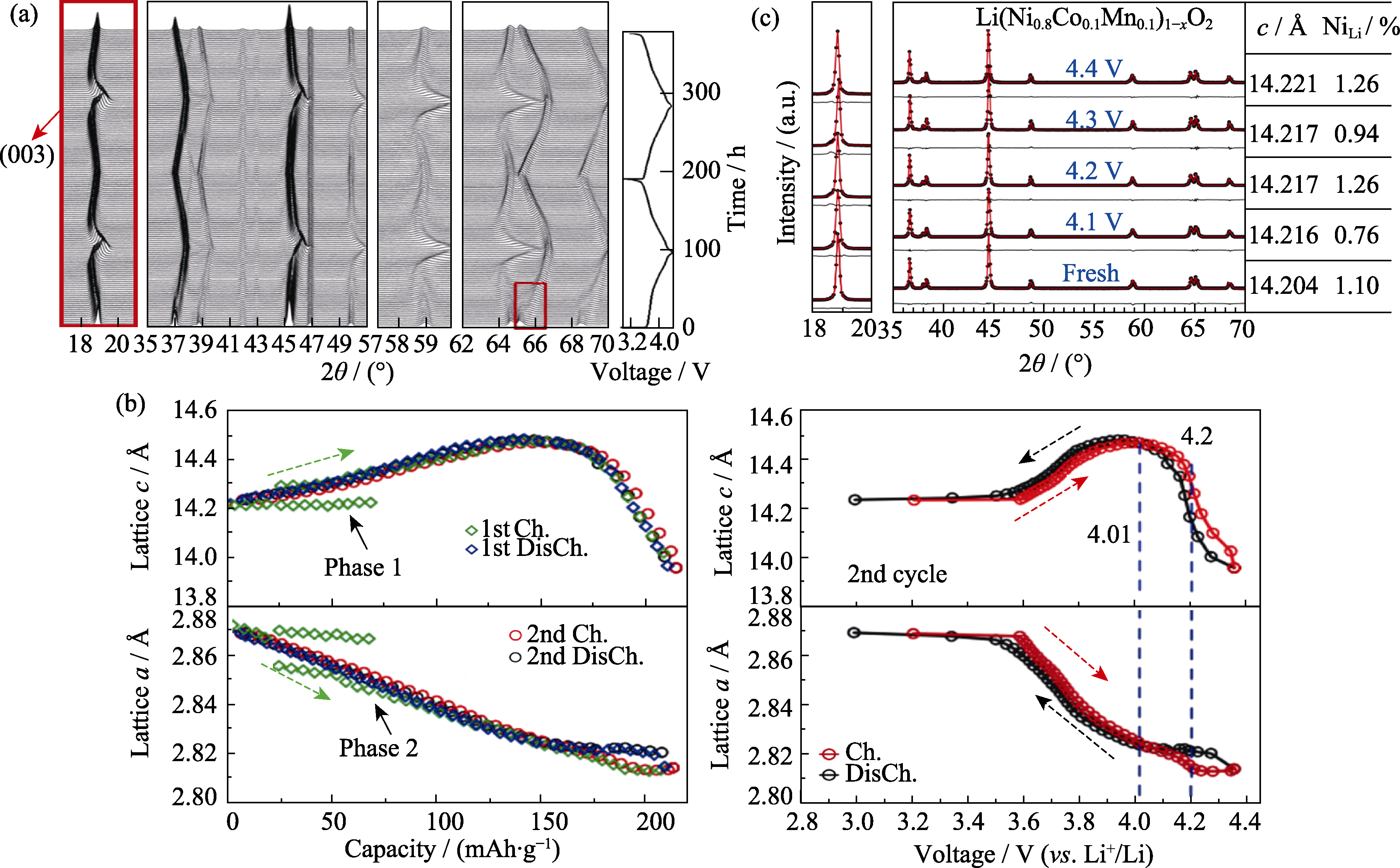

图8 高镍正极LiNi0.8Co0.1Mn0.1O2的充放电原位XRD表征结果[49]

Fig. 8 In situ XRD characterization of Ni-rich cathode LiNi0.8Co0.1Mn0.1O2(NCM811) during charge-discharge (© 2015, ECS)[49] (a) In-situ XRD patterns of NCM811 cycled between 3.0-4.4 V at a rate of C/100 for two cycles; (b) Cell parameters c and a as functions of specific capacity and cell potential; (c) XRD refinement patterns, corresponding cell parameters and Li/Ni occupation information of fresh NCM811 electrode and the recovered electrodes that cycled 200 times to 4.1, 4.2, 4.3 and 4.4 V, respectively. 1 Å=0.1 nm; Ch: Charged; DisCh: Discharged. Colorful figures are available on website

图9 Li1.2Ni0.13Co0.13Mn0.54O2的充放电原位同步辐射XRD表征结果[54]

Fig. 9 In-situ XRD characterization of Li1.2Ni0.13Co0.13Mn0.54O2 during charge-discharge process (© 2021, Springer Nature)[54] (a) Charge-discharge curve and corresponding contour plot of XRD pattern during the 201st cycle with the colour red to blue representing the decreasing peak intensity; (b, c) Lattice parameters (c and V) as functions of potential during the 1st and 201st cycles after the electrode activated at a rate of 0.1C. 1 Å=0.1 nm. Colorful figures are available on website

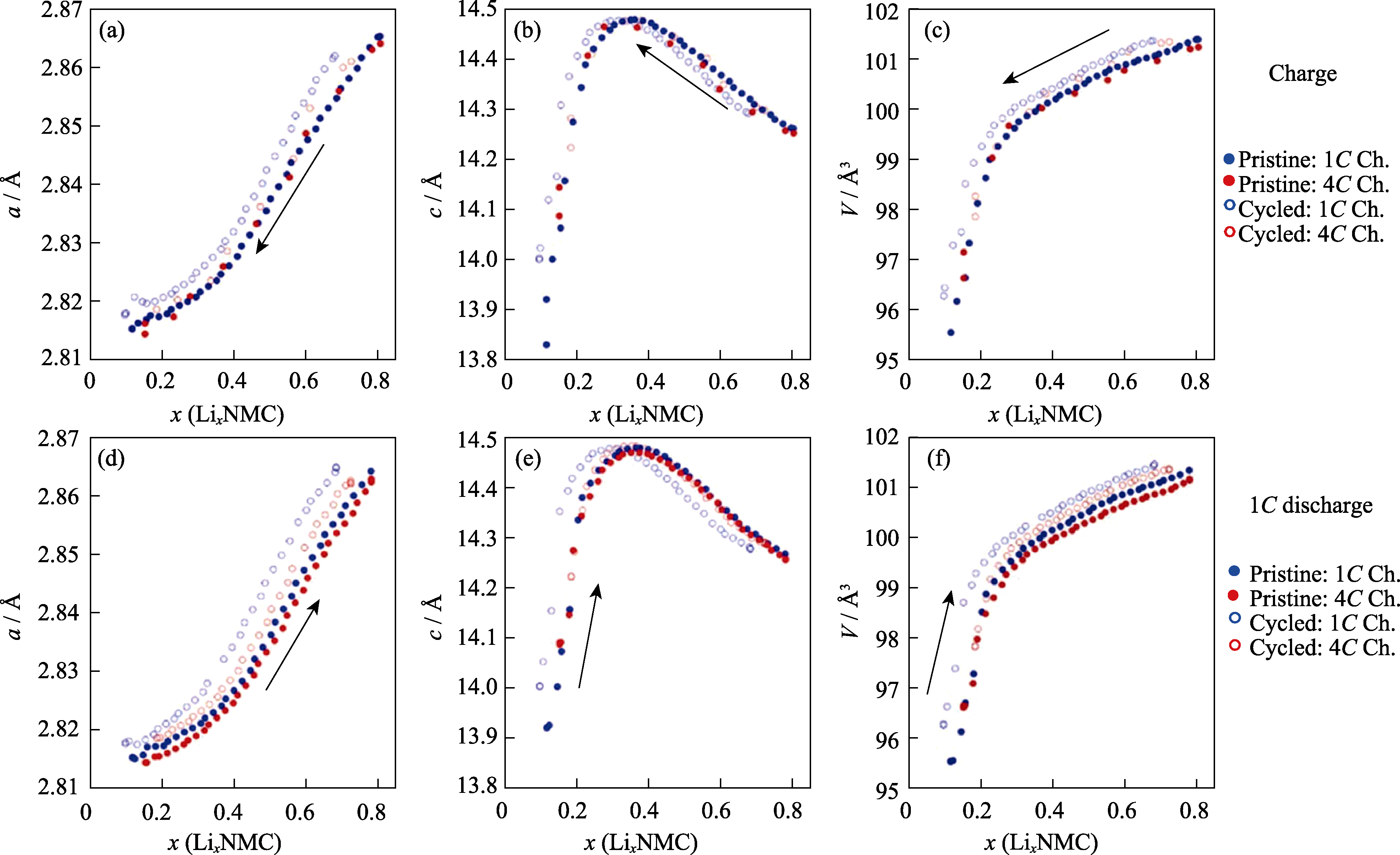

图10 LiNi0.8Co0.1Mn0.1O2正极材料的充放电原位XRD Rietveld精修结果[57]

Fig. 10 In-situ XRD Rietveld refinement results of LiNi0.8Co0.1Mn0.1O2 cathode materials during charge and discharge process (© 2022, ECS)[57] (a, d) Lattice parameters a; (b, e) Lattice parameters c; (c, f) Unit cell volumes. 1 Å=0.1 nm. Colorful figures are available on website

| Sample | Doped atomic radius/nm | Displace ion radius/nm | Lattice constant/nm | Lattice volume/nm3 | Interatomic distance/nm | Reliability factor |

|---|---|---|---|---|---|---|

| LFP | rFe = 0.172 | rFe2+ = 0.074 | a=1.031634 b=0.600129 c=0.469139 | 0.29045 | Li-O1:0.21664 Li-O2:0.20901 Li-O3:0.21651 Li-O:0.214050 | Rwp = 7.72% Rp =5.63% χ2 = 2.794 |

| LFMgP | rMg = 0.172 | rMg2+ = 0.065 | a=1.031583 b=0.600035 c=0.469090 | 0.29036 | Li-O1:0.21712 Li-O2:0.21041 Li-O3:0.21665 Li-O:0.214720 | Rwp = 9.32% Rp = 6.79% χ2 = 2.878 |

| LFAlP | rAl = 0.182 | rAl3+ = 0.050 | a=1.032204 b=0.600358 c=0.469072 | 0.29068 | Li-O1:0.21670 Li-O2:0.21001 Li-O3:0.21747 Li-O:0.214730 | Rwp = 9.14% Rp = 6.60% χ2 = 2.989 |

| LFNiP | rNi = 0.162 | rNi2+ = 0.072 | a=1.031083 b=0.599820 c=0.468923 | 0.29001 | Li-O1:0.21734 Li-O2:0.20863 Li-O3:0.21586 Li-O:0.213950 | Rwp = 8.26% Rp = 6.12% χ2= 2.929 |

| LFVP | rV = 0.192 | rV3+ = 0.074 | a=1.032223 b=0.600494 c=0.469485 | 0.291 | Li-O1:0.21864 Li-O2:0.21074 Li-O3:0.21794 Li-O:0.215770 | Rwp = 9.86% Rp = 7.15% χ2= 2.426 |

表2 LiFePO4和LiFe0.95M0.05PO4的结构精修结果[62]

Table 2 Structure refinement result of LiFePO4 and LiFe0.95M0.05PO4 (M=Mg2+, Ni2+, Al3+, V3+) (© 2010, EC)[62]

| Sample | Doped atomic radius/nm | Displace ion radius/nm | Lattice constant/nm | Lattice volume/nm3 | Interatomic distance/nm | Reliability factor |

|---|---|---|---|---|---|---|

| LFP | rFe = 0.172 | rFe2+ = 0.074 | a=1.031634 b=0.600129 c=0.469139 | 0.29045 | Li-O1:0.21664 Li-O2:0.20901 Li-O3:0.21651 Li-O:0.214050 | Rwp = 7.72% Rp =5.63% χ2 = 2.794 |

| LFMgP | rMg = 0.172 | rMg2+ = 0.065 | a=1.031583 b=0.600035 c=0.469090 | 0.29036 | Li-O1:0.21712 Li-O2:0.21041 Li-O3:0.21665 Li-O:0.214720 | Rwp = 9.32% Rp = 6.79% χ2 = 2.878 |

| LFAlP | rAl = 0.182 | rAl3+ = 0.050 | a=1.032204 b=0.600358 c=0.469072 | 0.29068 | Li-O1:0.21670 Li-O2:0.21001 Li-O3:0.21747 Li-O:0.214730 | Rwp = 9.14% Rp = 6.60% χ2 = 2.989 |

| LFNiP | rNi = 0.162 | rNi2+ = 0.072 | a=1.031083 b=0.599820 c=0.468923 | 0.29001 | Li-O1:0.21734 Li-O2:0.20863 Li-O3:0.21586 Li-O:0.213950 | Rwp = 8.26% Rp = 6.12% χ2= 2.929 |

| LFVP | rV = 0.192 | rV3+ = 0.074 | a=1.032223 b=0.600494 c=0.469485 | 0.291 | Li-O1:0.21864 Li-O2:0.21074 Li-O3:0.21794 Li-O:0.215770 | Rwp = 9.86% Rp = 7.15% χ2= 2.426 |

图11 LiFePO4改性前后XRD精修结果[63]

Fig. 11 XRD Rietveld refinement results of LiFePO4 before and after modification (© 2021, RSC)[63] (a, b) XRD Rietveld refinement patterns of (a) LFP/C and (b) LFP/C-YF-2; (c, d) Schematic diagrams of change in Li-O bond length of (c) LFP/C and (d) LFP/C-YF-2. 1 Å=0.1 nm. Colorful figures are available on website

| Sample | a/nm | b/nm | c/nm | V/nm3 |

|---|---|---|---|---|

| LFP/C | 1.03229 | 0.60061 | 0.46941 | 0.29104 |

| LFP/C-YF-1 | 1.03054 | 0.59985 | 0.46903 | 0.28994 |

| LFP/C-YF-2 | 1.03082 | 0.59977 | 0.46874 | 0.28980 |

| LFP/C-YF-3 | 1.03069 | 0.59989 | 0.46892 | 0.28994 |

表3 XRD精修得到LiFePO4改性前后的晶胞参数[63]

Table 3 Cell parameters of LiFePO4 before and after modification by XRD refinement (© 2021, RSC)[63]

| Sample | a/nm | b/nm | c/nm | V/nm3 |

|---|---|---|---|---|

| LFP/C | 1.03229 | 0.60061 | 0.46941 | 0.29104 |

| LFP/C-YF-1 | 1.03054 | 0.59985 | 0.46903 | 0.28994 |

| LFP/C-YF-2 | 1.03082 | 0.59977 | 0.46874 | 0.28980 |

| LFP/C-YF-3 | 1.03069 | 0.59989 | 0.46892 | 0.28994 |

| Atom | Site | x | y | z | Occupancy | Uiso |

|---|---|---|---|---|---|---|

| Lia | 3a | 0 | 0 | 0 | 1.000 | 0.014(6) |

| Coa | 3b | 0 | 0 | 0.50000 | 1.000 | 0.023(8) |

| Oa | 6c | 0 | 0 | 0.2300(6) | 1.000 | 0.049(1) |

| Lib | 3a | 0 | 0 | 0 | 0.98(1) | 0.020(1) |

| Mgb | 3a | 0 | 0 | 0 | 0.01(9) | 0.020(1) |

| Cob | 3b | 0 | 0 | 0.50000 | 0.99(7) | 0.001(2) |

| Alb | 3b | 0 | 0 | 0.50000 | 0.002(0) | 0.001(2) |

| Tib | 3b | 0 | 0 | 0.50000 | 0.001(0) | 0.001(2) |

| Ob | 6c | 0 | 0 | 0.2476(3) | 1.000 | 0.068(5) |

表4 Al、Ti、Mg共掺杂LiCoO2及纯LiCoO2的XRD结构精修结果[64]

Table 4 XRD refinement result of Al, Ti, Mg co-doped LiCoO2 and bare LiCoO2 (© 2019, Wiley-VCH)[64]

| Atom | Site | x | y | z | Occupancy | Uiso |

|---|---|---|---|---|---|---|

| Lia | 3a | 0 | 0 | 0 | 1.000 | 0.014(6) |

| Coa | 3b | 0 | 0 | 0.50000 | 1.000 | 0.023(8) |

| Oa | 6c | 0 | 0 | 0.2300(6) | 1.000 | 0.049(1) |

| Lib | 3a | 0 | 0 | 0 | 0.98(1) | 0.020(1) |

| Mgb | 3a | 0 | 0 | 0 | 0.01(9) | 0.020(1) |

| Cob | 3b | 0 | 0 | 0.50000 | 0.99(7) | 0.001(2) |

| Alb | 3b | 0 | 0 | 0.50000 | 0.002(0) | 0.001(2) |

| Tib | 3b | 0 | 0 | 0.50000 | 0.001(0) | 0.001(2) |

| Ob | 6c | 0 | 0 | 0.2476(3) | 1.000 | 0.068(5) |

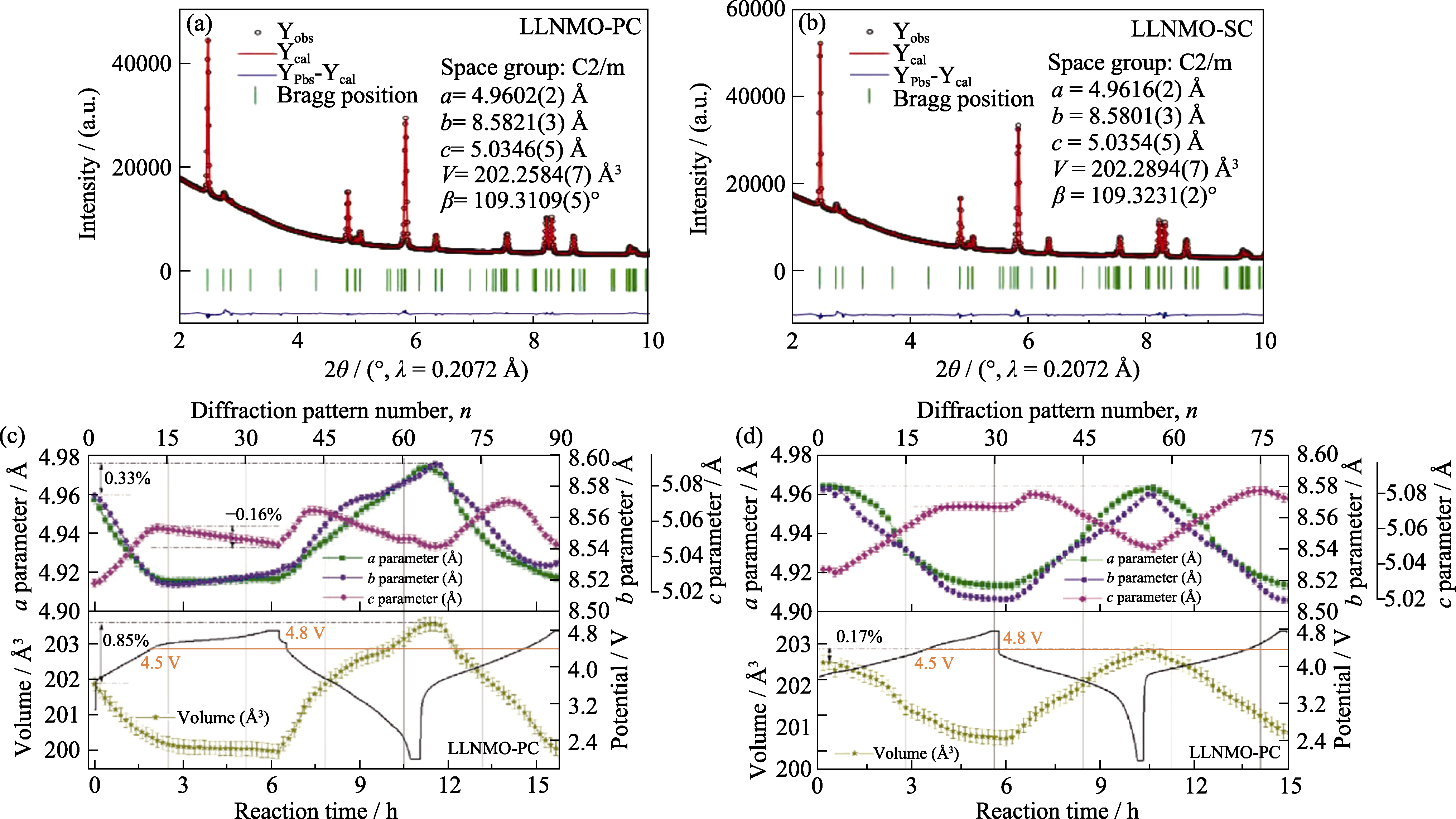

图12 Li(Li0.2Ni0.2Mn0.6)O2正极材料的XRD结构精修结果[66]

Fig. 12 XRD Rietveld refinement results of Li(Li0.2Ni0.2Mn0.6)O2 cathode materials (© 2022, Wiley-VCH)[66] (a, b) Experimental XRD patterns and Rietveld refinement results of (a) LLNMO-PC and (b) LLNMO-SC; (c, d) Changes of lattice parameters (a, b, c, and V) for (c) LLNMO-PC and (d) LLNMO-SC electrodes during charge and discharge 1 Å=0.1 nm. Colorful figures are available on website

| Formula | Calculated | Experimental | ||||

|---|---|---|---|---|---|---|

| a/nm | b/nm | c/nm | V/nm3 | a/nm | V/nm3 | |

| Li8Mn16O32 | 0.886205 | 0.886205 | 0.886205 | 0.695990 | - | - |

| Li8Mn15AlO32 | 0.826725 | 0.826725 | 0.826725 | 0.567617 | 0.82507 | 0.561658 |

| Li8Mn14Al2O32 | 0.831493 | 0.831493 | 0.799071 | 0.552416 | 0.82466 | 0.560821 |

| Li8Mn13Al3O32 | 0.814375 | 0.826337 | 0.820583 | 0.551780 | 0.82110 | 0.553590 |

表5 Al掺杂LiMn2O4的XRD结构精修结果[69]

Table 5 XRD structure refinement result of Al doped LiMn2O4 (© 2019, Elsevier Ltd.)[69]

| Formula | Calculated | Experimental | ||||

|---|---|---|---|---|---|---|

| a/nm | b/nm | c/nm | V/nm3 | a/nm | V/nm3 | |

| Li8Mn16O32 | 0.886205 | 0.886205 | 0.886205 | 0.695990 | - | - |

| Li8Mn15AlO32 | 0.826725 | 0.826725 | 0.826725 | 0.567617 | 0.82507 | 0.561658 |

| Li8Mn14Al2O32 | 0.831493 | 0.831493 | 0.799071 | 0.552416 | 0.82466 | 0.560821 |

| Li8Mn13Al3O32 | 0.814375 | 0.826337 | 0.820583 | 0.551780 | 0.82110 | 0.553590 |

图13 复相正极材料的XRD精修图谱

Fig. 13 Refined XRD patterns of multiphase materials (a) Li1.25Co0.25Mn0.50O2 (© 2018, Wiley-VCH)[70]; (b) LiMnPO4·Li3V2(PO4)3/C (© 2016, American Chemical Society)[71]

| [1] | 郑琼, 江丽霞, 徐玉杰, 等. 碳达峰、碳中和背景下储能技术研究进展与发展建议. 中国科学院院刊, 2022, 37(4):529. |

| [2] |

TARASCON J, ARMAND M. Issues and challenges facing rechargeable lithium batteries. Nature, 2001, 414(6861):359.

DOI URL |

| [3] |

ZENG H, HANG F. Energy materials in new era. Journal of Inorganic Materials, 2022, 37(2):113.

DOI |

| [4] |

ARMAND M, TARASCON J M. Building better batteries. Nature, 2008, 451(7179):652.

DOI |

| [5] |

XIANG J, WEI Y, ZHONG Y, et al. Building practical high-voltage cathode materials for lithium-ion batteries. Advanced Materials, 2022, 34(52): 2200912.

DOI URL |

| [6] |

WANG L, QIU J, WANG X, et al. Insights for understanding multiscale degradation of LiFePO4 cathodes. eScience, 2022, 2(2):125.

DOI URL |

| [7] |

ASSAT G, TARASCON J M. Fundamental understanding and practical challenges of anionic redox activity in Li-ion batteries. Nature Energy, 2018, 3(5):373.

DOI |

| [8] |

CHEN Z, ZHANG W, YANG Z. A review on cathode materials for advanced lithium ion batteries: microstructure designs and performance regulations. Nanotechnology, 2020, 31(1):012001.

DOI URL |

| [9] |

SINGH J P, PAIDI A K, CHAE K H, et al. Synchrotron radiation based X-ray techniques for analysis of cathodes in Li rechargeable batteries. RSC Advance, 2022, 12(31):20360.

DOI URL |

| [10] |

RIETVELD H. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallographica, 1967, 22(1):151.

DOI URL |

| [11] | BRAGG W L. The structure of some crystals as indicated by their diffraction of X-rays. Proceedings of the Royal Society of London A, 1913, 89(610):248. |

| [12] | CULLITY B D. Elements of X-ray diffraction. Boston: Addison- Wesley Publishing Company, 1978:102. |

| [13] | HULBERT S L, WILLIAMS G P. 1. Synchrotron Radiation Sources. In: SAMSON J A R, EDERER D L. Experimental Methods in the Physical Sciences. Salt Lake City: Academic Press, 1998:1-25. |

| [14] |

MORCRETTE M, CHABRE Y, VAUGHAN G, et al. In situ X-ray diffraction techniques as a powerful tool to study battery electrode materials. Electrochemica Acta, 2002, 47(19):3137.

DOI URL |

| [15] |

HUANG N, DENG H, LIU B, et al. Features and futures of X-ray free-electron lasers. The Innovation, 2021, 2(2):100097.

DOI URL |

| [16] | ISHIKAWA T. Accelerator-based X-ray sources: synchrotron radiation, X-ray free electron lasers and beyond. Philosophical Transactions of the Royal Society A, 2019, 377(2147):20180231. |

| [17] | WELZEL U, MITTEMEIJER E J. Laboratory Instrumentation for X-Ray Powder Diffraction:Developments and Examples// MITTEMEIJER E J, WELZEL U. Modern Diffraction Methods. San Francisco: John Wiley and Sons, 2012:359-398. |

| [18] |

DAHN J R, HAERING R R. Anomalous Bragg peak widths in LixTiS2. Solid State Communications, 1981, 40(3):245.

DOI URL |

| [19] |

XIA M, LIU T, PENG N, et al. Lab-scale in situ X-ray diffraction technique for different battery systems: designs, applications, and perspectives. Small Methods, 2019, 3(7):1900119.

DOI URL |

| [20] |

LLEWELLYN A V, MATRUGLIO A, BRETT D J L, et al. Using in-situ laboratory and synchrotron-based X-ray diffraction for lithium-ion batteries characterization: a review on recent developments. Condensed Matter, 2020, 5(4):75.

DOI URL |

| [21] |

MUHAMMAD S, LEE S, KIM H, et al. Deciphering the thermal behavior of lithium rich cathode material by in situ X-ray diffraction technique. Journal of Power Sources, 2015, 285:156.

DOI URL |

| [22] |

MCCUSKER L B, VON DREELE R B, COX D E, et al. Rietveld refinement guidelines. Journal of Applied Crystallography, 1999, 32(1):36.

DOI URL |

| [23] | YOUNG R A. The Rietveld method. New York: Oxford University Press, 1993: 1. |

| [24] |

THOMAS M G S R, BRUCE P G, GOODENOUGH J B. AC impedance analysis of polycrystalline insertion electrodes: application to Li1-xCoO2. Journal of The Electrochemical Society, 1985, 132(7):1521.

DOI |

| [25] | ASTUTI F, MAGHFIROHTUZZOIMAH V L, INTIFADHAH S H, et al. Local structure and electronic structure of LiFePO4 as a cathode for lithium-ion batteries. Journal of Physics: Conference Series, 2021, 1951(1): 012007. |

| [26] |

YU F, WANG Y, GUO C, et al. Spinel LiMn2O4 cathode materials in wide voltage window: single-crystalline versus polycrystalline. Crystals, 2022, 12(3):317.

DOI URL |

| [27] |

LÜ Y, HUANG S, ZHAO Y, et al. A review of nickel-rich layered oxide cathodes: synthetic strategies, structural characteristics, failure mechanism, improvement approaches and prospects. Applied Energy, 2022, 305:117849.

DOI URL |

| [28] |

NIE L, CHEN S, LIU W. Challenges and strategies of lithium-rich layered oxides for Li-ion batteries. Nano Research, 2023, 16:391.

DOI |

| [29] |

PADHI A K, NANJUNDASWAMY K S, GOODENOUGH J B. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries. Journal of The Electrochemical Society, 1997, 144(4):1188.

DOI |

| [30] | RADZI Z I, ARIFIN K H, KUFIAN M Z, et al. Review of spinel LiMn2O4 cathode materials under high cut-off voltage in lithium-ion batteries: challenges and strategies. Journal of Electroanalytical Chemistry, 2022, 920: 116623. |

| [31] |

THACKERAY M M.Exploiting the spinel structure for Li-ion battery applications: a tribute to John B. Goodenough. Advanced Energy Materials, 2021, 11(2):2001117.

DOI URL |

| [32] |

GRENIER A, REEVES P J, LIU H, et al. Intrinsic kinetic limitations in substituted lithium-layered transition-metal oxide electrodes. Journal of the American Chemical Society, 2020, 142(15):7001.

DOI PMID |

| [33] |

LIU J, WANG J, NI Y, et al. Recent breakthroughs and perspectives of high-energy layered oxide cathode materials for lithium ion batteries. Materials Today, 2021, 43:132.

DOI URL |

| [34] |

YOON C S, PARK K J, KIM U H, et al. High-energy Ni-rich Li[NixCoyMn1-x-y]O2 cathodes via compositional partitioning for next-generation electric vehicles. Chemistry of Materials, 2017, 29(24):10436.

DOI URL |

| [35] | 朱先军, 詹晖, 周运鸿. LiNi0.85Co0.15O2合成和结构与电化学性能关系. 化学学报, 2002, 10(60):1742. |

| [36] |

NI L, GUO R, FANG S, et al. Crack-free single-crystalline Co-free Ni-rich LiNi0.95Mn0.05O2 layered cathode. eScience, 2022, 2(1):116.

DOI URL |

| [37] |

HUA W, YANG X, CASATI N P M, et al. Probing thermally- induced structural evolution during the synthesis of layered Li-, Na-, or K-containing 3D transition-metal oxides. eScience, 2022, 2(2):183.

DOI URL |

| [38] |

ZHAO S, YAN K, ZHANG J, et al. Reaction mechanisms of layered lithium-rich cathode materials for high-energy lithium-ion batteries. Angewandte Chemie International Edition, 2021, 60(5): 2208.

DOI URL |

| [39] | YE Z, QIU L, YANG W, et al. Nickel-rich layered cathode materials for lithium-ion batteries. Chemistry, 2021, 27(13):4249. |

| [40] |

ZHENG J, YE Y, LIU T, et al. Ni/Li disordering in layered transition metal oxide: electrochemical impact, origin, and control. Accounts of Chemical Research, 2019, 52(8): 2201.

DOI PMID |

| [41] |

ZHAO J, ZHANG W, HUQ A, et al. In situ probing and synthetic control of cationic ordering in Ni-rich layered oxide cathodes. Advanced Energy Materials, 2017, 7(3):1601266.

DOI URL |

| [42] |

WEBER R, LI H, CHEN W, et al. In situ XRD studies during synthesis of single-crystal LiNiO2, LiNi0.975Mg0.025O2, and LiNi0.95Al0.05O2 cathode materials. Journal of the Electrochemical Society, 2020, 167(10):100501.

DOI |

| [43] |

WANG S, HUA W, MISSYUL A, et al. Kinetic control of long- range cationic ordering in the synthesis of layered Ni-rich oxides. Advanced Functional Materials, 2021, 31(19):2009949.

DOI URL |

| [44] |

ZHANG M J, DUAN Y, YIN C, et al. Ultrafast solid-liquid intercalation enabled by targeted microwave energy delivery. Science Advances, 2020, 6(51):eabd9472.

DOI URL |

| [45] |

LEE E J, CHEN Z, NOH H J, et al. Development of microstrain in aged lithium transition metal oxides. Nano Letters, 2014, 14(8):4873.

DOI URL |

| [46] |

XU C, MARKER K, LEE J, et al. Bulk fatigue induced by surface reconstruction in layered Ni-rich cathodes for Li-ion batteries. Nature Materials, 2021, 20(1):84.

DOI |

| [47] |

PUSHNITSA K A, KIM A E, POPOVICH A A, et al. Structural transformation of LiNi0.8Co0.1Mn0.1O2 cathode material during cycling with overcharge investigated by in situ X-ray diffraction. Journal of Electronic Materials, 2019, 48(10):6694.

DOI |

| [48] |

DE BIASI L, SCHIELE A, ROCA-AYATS M, et al. Phase transformation behavior and stability of LiNiO2 cathode material for Li-ion batteries obtained from in situ gas analysis and operando X-ray diffraction. ChemSusChem, 2019, 12(10):2240.

DOI URL |

| [49] |

LI J, DOWNIE L E, MA L, et al. Study of the failure mechanisms of LiNi0.8Mn0.1Co0.1O2 cathode material for lithium ion batteries. Journal of the Electrochemical Society, 2015, 162(7):A1401.

DOI URL |

| [50] |

LIU J, WU Z, YU M, et al. Building homogenous Li2TiO3 coating layer on primary particles to stabilize Li-rich Mn-based cathode materials. Small, 2022, 18(10):2106337.

DOI URL |

| [51] |

LIU T, LIU J, LI L, et al. Origin of structural degradation in Li-rich layered oxide cathode. Nature, 2022, 606(7913):305.

DOI |

| [52] |

ZHANG S, CHEN J, TANG T, et al. A novel strategy to significantly enhance the initial voltage and suppress voltage fading of a Li-and Mn-rich layered oxide cathode material for lithium-ion batteries. Journal of Materials Chemistry A, 2018, 6(8):3610.

DOI URL |

| [53] |

CHERNYAVSKY V, KIM A, KOSHTYAL Y, et al. Structural features of complete and partial activation of Li-rich cathodes studied by in-situ XRD. Electrochemica Acta, 2022, 414:140237.

DOI URL |

| [54] |

WANG L, LIU T, DAI A, et al. Reaction inhomogeneity coupling with metal rearrangement triggers electrochemical degradation in lithium-rich layered cathode. Nature Communications, 2021, 12(1):5370.

DOI PMID |

| [55] |

YANG Z, CHARALAMBOUS H, LIN Y, et al. Extreme fast charge aging: correlation between electrode scale and heterogeneous degradation in Ni-rich layered cathodes. Journal of Power Sources, 2022, 521:230961.

DOI URL |

| [56] | SU Y, CHEN G, CHEN L, et al. High-rate structure-gradient Ni- rich cathode material for lithium-ion batteries. ACS Applied Materials & Interfaces, 2019, 11(40):36697. |

| [57] |

QUILTY C D, WEST P J, WHEELER G P, et al. Elucidating cathode degradation mechanisms in LiNi0.8Mn0.1Co0.1O2 (NMC811)/ graphite cells under fast charge rates using operando synchrotron characterization. Journal of the Electrochemical Society, 2022, 169(2):020545.

DOI |

| [58] |

LÜ C, LI Z, REN X, et al. Revealing the degradation mechanism of Ni-rich cathode materials after ambient storage and related regeneration method. Journal of Materials Chemistry A, 2021, 9(7):3995.

DOI URL |

| [59] |

BLYR A, PASQUIER A D, AMATUCCI G, et al. Origin of self- discharge mechanism in LiMn2O4-based Li-ion cells: a chemical and electrochemical approach. Ionics, 1997, 3:321.

DOI URL |

| [60] | ZHANG C, SU J, WANG T, et al. Significant improvement on electrochemical performance of LiMn2O4 at elevated temperature by atomic layer deposition of TiO2 nanocoating. ACS Sustainable Chemistry & Engineering, 2018, 6(6):7890. |

| [61] |

TANG X, ZHOU J, BAI M, et al. Investigation of the self- discharge behaviors of the LiMn2O4 cathode at elevated temperatures: in situ X-ray diffraction analysis and a co-doping mitigation strategy. Journal of Materials Chemistry A, 2019, 7(21):13364.

DOI URL |

| [62] |

YANG M R, KE W H. The doping effect on the electrochemical properties of LiFe0.95M0.05PO4 (M=Mg2+, Ni2+, Al3+, or V3+ ) as cathode materials for lithium-ion cells. Journal of the Electrochemical Society, 2008, 155(10):A729.

DOI URL |

| [63] |

WANG H, LAI A, HUANG D, et al. Y-F co-doping behavior of LiFePO4/C nanocomposites for high-rate lithium-ion batteries. New Journal of Chemistry, 2021, 45(12):5695.

DOI URL |

| [64] |

WANG L, MA J, WANG C, et al. A novel bifunctional self- stabilized strategy enabling 4.6 V LiCoO2 with excellent long-term cyclability and high-rate capability. Advanced Science, 2019, 6(12): 1900355.

DOI URL |

| [65] |

GE M, WI S, LIU X, et al. Kinetic limitations in single-crystal high-nickel cathodes. Angewandte Chemie International Edition, 2021, 60(32):17350.

DOI URL |

| [66] |

YANG X, WANG S, HAN D, et al. Structural origin of suppressed voltage decay in single-crystalline Li-rich layered Li[Li0.2Ni0.2Mn0.6]O2 Cathodes. Small, 2022, 18(25):2201522.

DOI URL |

| [67] | TAN Z, LI Y, XI X, et al. Lattice engineering to refine particles and strengthen bonds of the LiNi0.9Co0.05Mn0.05O2 cathode toward efficient lithium ion storage. ACS Sustainable Chemistry & Engineering, 2022, 10(11):3532. |

| [68] |

ZHANG Y, LIU J, XU W, et al. Gradient doping Mg and Al to stabilize Ni-rich cathode materials for rechargeable lithium-ion batteries. Journal of Power Sources, 2022, 535:231445.

DOI URL |

| [69] |

CAI Z, MA Y, HUANG X, et al. High electrochemical stability Al-doped spinel LiMn2O4 cathode material for Li-ion batteries. Journal of Energy Storage, 2020, 27:101036.

DOI URL |

| [70] |

ZUO Y, LI B, JIANG N, et al. A high-capacity O2-type Li-rich cathode material with a single-layer Li2MnO3 superstructure. Advanced Materials, 2018, 30(16):1707255.

DOI URL |

| [71] | CAO X, PAN A, ZHANG Y, et al. Nanorod-nanoflake interconnected LiMnPO4·Li3V2(PO4)3/C composite for high-rate and long-life lithium-ion batteries. ACS Applied Materials & Interfaces, 2016, 8(41):27632. |

| [72] |

LU J, CAO B, HU B, et al. Heavy fluorination via ion exchange achieves high-performance Li-Mn-O-F layered cathode for Li-ion batteries. Small, 2022, 18(6):2103499.

DOI URL |

| [73] | HATSUI T, GRAAFSMA H. X-ray imaging detectors for synchrotron and XFEL sources. IUCrJ, 2015, 2(3):37 |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [5] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [6] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [7] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [8] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [9] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [10] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [11] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [12] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 朱志杰, 申明远, 吴涛, 李文翠. Cu和Mg协同取代抑制钠离子电池正极材料P2-Na2/3Ni1/3Mn2/3O2的P2-O2相变[J]. 无机材料学报, 2025, 40(2): 184-195. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||